Have you considered how the choice of marking technology impacts more than just speed and appearance? While many focus on precision and productivity, there’s a bigger picture often overlooked—sustainability, durability, and long-term value. Laser marking machines bring more than just clean lines and permanent marks; they offer advantages that can improve efficiency, reduce waste, and support environmental responsibility.

In this article, we’ll explore the key advantages and disadvantages of laser marking machines, helping you make a more informed decision for your business or project.

High Precision in Laser Marking Machines

I find laser marking machines offer outstanding precision and accuracy. They mark many materials well. Using a focused laser beam, these machines produce very fine, detailed designs. I think an older marking method cannot achieve this level of detail.

Key Advantages of High Precision Laser Marking

Laser marking offers exceptional accuracy, handling tolerances as tight as ±0.001 inches—essential for industries where precision is critical. It’s also ideal for marking small, complex parts, making it a key tool in high-tech sectors like electronics. With computer-controlled precision, it enhances both product quality and performance.

I believe the high precision of laser marking machines helps manufacturers in many fields. It gives them confidence to meet tough quality standards. This helps them stay ahead in growing markets.

Non-Contact Process: Key Benefits of Non-Touch Laser Marking

I notice that laser marking machines are special because they use a non-contact process. What this means is the laser beam does its work without actually touching the material. This approach offers some really useful advantages:

No Damage to Delicate Parts: Because nothing physically touches the surface, even fragile items stay safe. From my perspective, this is great because it cuts down on waste and helps produce more good parts.

Low Maintenance Needs: With no parts rubbing together, the machine doesn’t wear out quickly. This lowers maintenance costs and means less downtime, which I always recommend aiming for.

Simplified Setup: You don’t need tricky clamps or holders for the parts. I find this makes changing between different jobs or part shapes much simpler.

No Risk of Contamination: The laser process is clean. It won’t transfer oils or dirt onto the part. I think this is essential for fields like medical device manufacturing, where things must be spotless.

Why Industries Prefer Non-Contact Laser Marking

Laser marking is ideal for cleanroom environments due to its non-contaminating nature, making it perfect for industries with strict hygiene standards. Its durable markings ensure lifelong traceability, crucial for compliance and safety. Plus, it offers long-term cost savings by reducing maintenance and supply expenses, especially in large-scale production.

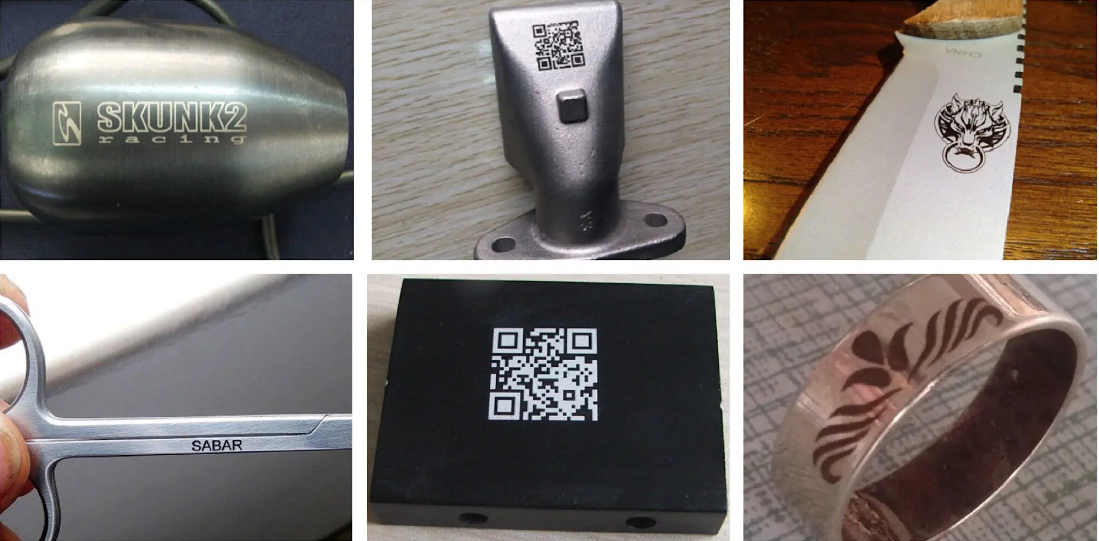

Laser Marking Machines Work on Many Materials

I find that laser marking machines can handle many different materials. This makes them useful for various industries and marking tasks.

Laser Marking on Metals

- Stainless Steel: Manufacturers often use stainless steel. It absorbs fiber laser light well. From my experience, machines like the MaxWave F25CA create sharp, clear marks on stainless steel.

- Aluminum: You’ll find this light metal in cars, planes, and electronics. Fiber lasers mark aluminum effectively, creating high-contrast results. I recommend them for branding, ID marks, and tracking parts.

- Chrome: Chrome resists rust and reflects light. You need to adjust the laser power based on the chrome layer’s thickness. I suggest setting it correctly to mark just the chrome plating, not the material underneath.

- Titanium: I think laser marking works great on titanium, particularly with fiber lasers. This is because of titanium’s physical traits.

- Tungsten and Carbide: These very hard metals work well with the fast marking speeds of fiber lasers. Deep engraving is tough due to their hardness. You’ll need to adjust machine settings for good contrast. Keep in mind tungsten looks lighter, and carbide looks darker after marking.

- Brass and Copper: Fiber lasers mark both brass and copper effectively. They create sharp, lasting images or text.

Laser Marking on Plastics & Composites

- ABS (Acrylonitrile Butadiene Styrene): Many car and electronic parts use ABS. It reacts well to fiber laser marking. I find it produces dependable barcodes, logos, and ID data.

- PVC (Polyvinyl Chloride): People use this plastic often for wires, cables, and pipes. Lasers mark it with product info, safety warnings, and logos. In my experience, it doesn’t harm the material underneath.

- Polyethylene: You see polyethylene in packaging and containers. Fiber lasers mark it effectively for product IDs and shipping labels.

General Plastics: Lasers can mark many different plastics. The marks are clean and last a long time. This suits many industrial and business needs.

High Efficiency: Boost Your Output with Laser Marking Machines

Based on my experience, laser marking machines really stand out for their high efficiency in today’s factories. They offer speed, accuracy, and little downtime. I find this makes them very effective for many industries.

Fast Marking Speeds and Steady Performance

Fiber lasers, which lead the global market with a 45.3% share in 2024, enable fast, non-damaging marking—ideal for industries like automotive, electronics, aerospace, and medical devices. Machines like the MaxWave-Laser Marking Machine, with speeds up to 4000 mm/s², ensure quick, repeatable production for high-volume manufacturing.

Overall, high efficiency is a key benefit of laser marking machines. They achieve faster production speeds. In my opinion, they meet the needs of manufacturers who require dependable, scalable ways to operate.

Permanent Marking with Laser Marking Machines

I find laser marking machines excellent for creating permanent, durable marks on many materials. This lasting identification is a big plus for manufacturers. They often need it for product tracking, safety rules, or meeting standards.

Why Permanent Marking Matters

Laser marking delivers durable, fade-resistant results that withstand wear, heat, and corrosion—ideal for demanding sectors like automotive and aerospace. It supports compliance with standards like ROHS and ensures lifelong traceability with readable IDs and codes, making it essential for quality control and product tracking.

To sum up, I see permanent marking as a key benefit of laser marking machines. It’s essential for industries needing clear, lasting, and standard-compliant identification.

No Consumables: Cost and Environmental Benefits of Laser Marking Machines

Laser marking machines are different. They don’t need extra supplies like ink, ribbons, or labels. Other methods like inkjet or screen printing require these consumables to work. I find this lack of consumables a major advantage.

Key Benefits of a Consumable-Free Marking Solution

Save Money: You stop paying for ink, ribbons, or labels over and over. Based on my experience, manufacturers save thousands of dollars each year. This saving is larger when production levels are high.

Less Waste, Better for Earth: Laser marking cuts waste by up to 95% versus ink methods. It produces no chemical waste, solvent smells, or used labels to throw away. I believe this makes the process a much greener choice.

Easier Operations, Lower Costs: You won’t need to store, manage, or get rid of consumables. This simplifies your work and cuts down on running costs.

Less Downtime: Production doesn’t stop to change supplies. Marking keeps going. I’ve seen this improve factory output noticeably.

Safer Workplace: Getting rid of inks and solvents means workers aren’t exposed to dangerous chemicals or fumes. This creates a safer place to work.

In my opinion, choosing laser marking without consumables leads to cleaner, greener, and cheaper manufacturing. This becomes even clearer as your production grows.

The High Upfront Cost Challenge of Laser Marking Machines

From my experience, a major hurdle for businesses considering laser marking machines is the high upfront cost. I find this is often true for small and medium-sized enterprises (SMEs). This large initial expense frequently causes companies to pause. They might hesitate to pick laser technology over older marking methods.

Price Ranges and Cost Breakdown

The price of a laser marking machine changes quite a bit. It mostly depends on the type and specific setup:

- Fiber laser marking machines: Range from $3,600 to $29,500

- CO2 laser marking machines: Range from $4,600 to $71,000

- UV laser marking machines: The most expensive, from $11,000 to $31,000

If you need a more advanced or custom machine, I’ve seen the total price range from $36,000 to $71,000.

Comparing Alternatives Due to High Upfront Costs

Due to these costs, I notice many companies choose cheaper options. This is common for businesses with limited budgets. They might select inkjet printing or dot peen marking instead. These older methods need less money initially. This makes them look better for quick cost savings.

Market Growth Despite High Cost

Despite these cost issues, I observe the laser marking machine market is growing steadily. For 2024, the market value is $3.22 billion. Experts predict it will reach $3.36 billion by 2025. They expect it to grow to $6.01 billion by 2032. This equals a compound annual growth rate (CAGR) of 7.8%.

In my opinion, the initial price is high. But the long-term benefits could be worth it. These include lower running costs and helping the environment. I think these factors can make the investment sensible for companies planning for the future.

Summary

I’ve looked closely at laser marking technology. I see its real impact reaches much further than the factory floor. Yes, the upfront cost is high. However, I find the benefits for the environment, the high precision, and the long run savings offer genuine value. As we aim for manufacturing methods that are better for the planet, I feel laser marking isn’t just a technology choice. To me, it shows a dedication to our world’s future. It stops the need for inks and solvents and cuts down waste. In my view, these are real steps for cleaner production, one lasting mark after another. For more details about laser welding machine or to get a quote, contact us today!