I often think: can changing your cleaning tools help the Earth and your budget? I find portable laser cleaning machines offer strong cleaning. They don’t have the mess, chemicals, or waste of older ways. Based on my experience, people like them for their speed and safety. They are also good for the planet. This sounds pretty good, doesn’t it? But I suggest looking at one big cost most people miss before they buy…

My Guide to Choosing a Portable Laser Cleaning Machine

If you are considering buying a portable laser cleaning machine, I think you should consider some key factors such as the most direct price and power. At the same time, practical details are also important. This will help you make an informed choice and ensure that your machine will work properly.

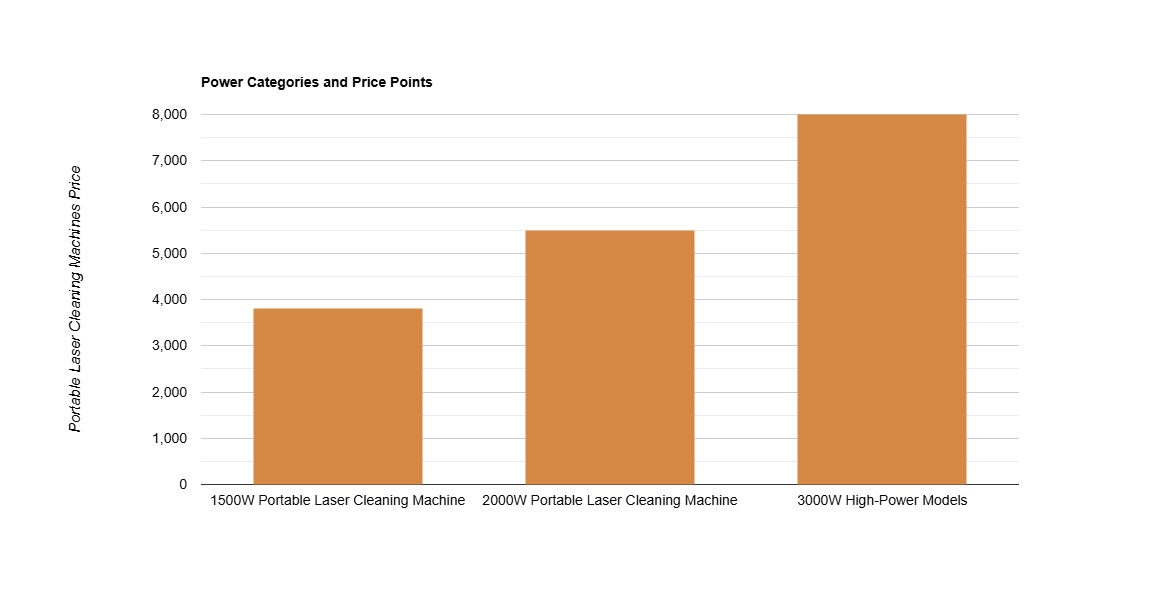

Power Categories and Price Points

My Tip: More power means faster and deeper cleaning. But, I must point out, too much power can damage delicate surfaces. I suggest you think carefully about your usual cleaning tasks before you decide to buy.

Cost Analysis of Portable Laser Cleaning Machines

If you’re thinking about buying a portable laser cleaning machine, I think it’s really important to understand the costs. This helps you make a good choice. The total amount you’ll spend can change a lot. It depends on the machine’s power, what it can do, and what you’ll use it for.

Hourly Operational Costs

When I look at the cost, I don’t just think about the purchase price. I also consider these important ongoing expenses: – Energy consumption: High-pulse machines use more electricity. In my experience, this costs around $0.18 per hour. – Labor costs: Operator wages usually run around $25 per hour. – Maintenance: I’d expect to pay about $1,000 each year for maintenance if you use it for 500 hours. This works out to about $2 per hour. – Depreciation: For a $50,000 machine with a 10,000-hour service life, depreciation is about $5 per hour.

So, the average total cost to run the machine each hour adds up to about $57.18. This includes energy at $0.18, labor at $50, maintenance at $2, and depreciation at $5.

Factors Influencing Machine Price

Several things affect the total cost: – Laser power: Higher wattage machines clean faster. However, they also cost more to buy. – Laser source type: Fiber lasers cost more but, in my opinion, they last longer than CO2 lasers. – Cooling systems: From what I’ve seen, air-cooled units usually cost less than water-cooled ones. – Portability and design: Machines that are easier to move and have comfortable designs can cost more. I think these features are often worth it for ease of use. – Control and automation: If you want advanced features like programmed cleaning cycles, you’ll likely spend more. I find these can really improve efficiency for complex jobs.

Return on Investment (ROI) for Portable Laser Cleaning Machines

If you’re thinking about buying a portable laser cleaning machine, I believe it’s really important to understand its ROI. I want to share what I’ve learned from actual data and my own experience.

Initial Investment and Total Cost

- In 2025, I expect the average handheld laser cleaning machine to cost around $5,000. You can find cheaper 1500W models for about $3,800. Mid-range 2000W options are near $5,500. Powerful 3000W versions can go up to $8,000.

- From my observation, high-end industrial laser cleaning systems cost more. They range from $50,000 up to $500,000. This price depends on their power and any custom features.

- I always recommend budgeting for extra costs. Think about shipping, after-sales support, and any special features you might need for your work.

Operational Savings and Efficiency

- With portable laser cleaning machine, you won’t have ongoing costs for things like consumables such as chemicals or abrasives. From my experience, this saves a lot of money over time.

- I’ve seen that these machines cause very little wear and tear on cleaned surfaces. This means your parts and equipment last longer. You won’t need to replace them as often.

- In situ cleaning means much less downtime. I like that you don’t need to spend hours taking machines apart for deep cleans.

- These machines are easy to use and can

How Laser Cleaners Stack Up Against Old Ways

I find that portable laser cleaning machines have clear benefits over old cleaning ways. These benefits show up in daily use and save money over time.

Precision, Safety, and Surface Care

Portable laser cleaners offer precise cleaning without harming nearby surfaces, making them ideal for delicate work like art restoration or electronics. They’re gentler than sandblasting and don’t use harsh chemicals, making the process safer for both people and materials.

Greener Cleaning and Less Waste

Laser cleaning is environmentally friendly, using only electricity with no chemicals, solvents, or abrasives. This means no chemical spills, no dirty water, and minimal waste. In industries like manufacturing or aerospace, it leads to savings on waste disposal and paperwork for hazardous materials. The process is also dry and clean, eliminating the need for drying time and reducing mess, which helps maintain efficient workspaces and fewer stoppages.

Faster Work and More Done

Laser cleaning is up to 15% faster than chemical methods. Just press a button and the dirt is gone—no soaking, scrubbing, or drying needed. It’s a quick, one-step process that reduces downtime, making it great for car repair shops and factories.

Cost: Upfront vs. Long Run

Although portable laser cleaners cost more upfront, they save money over time. There’s no need for chemicals or waste disposal, and the machines are durable with low maintenance, making each cleaning job more cost-effective in the long run.

Where It’s Used and How Well It Works

Laser cleaning machines are widely used in industries like electronics, aerospace, car repair, and preservation. They clean without damaging surfaces and are eco-friendly. Lasers remove rust, paint, grease, and coatings effectively, though thick dirt may need loosening first for best results.

When Old Ways Might Be Better

I think for some easy jobs, sandpaper, wire brushes, or chemical cleaners can be faster. They also cost less to start with. But, in my opinion, these older ways often need a lot of work. They make a lot of waste. There’s also a higher chance of damaging things by accident or causing safety problems.

In summary, if you need fast, precise, and safe surface cleaning—especially for valuable or delicate items—a portable laser cleaner is a great choice. It’s ideal for most factory, technical, or restoration work. But for tight budgets, very heavy dirt, or one-time jobs, traditional methods may still work.

Ideal Use Cases for Portable Laser Cleaning Machines

From my experience, portable laser cleaning machines truly shine for on-site cleaning tasks. This is especially true when you need flexibility and the ability to move the equipment easily. I find they offer effective solutions for rust removal, paint stripping, and getting rid of coatings, oxide layers, and grease. People also frequently use them for cleaning before and after welding.

Where They Excel

- Small Workshops & Big Factories: I’ve seen both small shops and large factories gain a lot from these machines. They can clean various parts, regardless of shape or size. This works even if you’re dealing with low-volume, high-mix production.

- Hard-to-Reach Areas: Some models are quite light, some as little as 35kg. This means I can take them to spots where fixed machines just can’t go. I think this is a significant advantage for field maintenance, restoration projects, and when you need to do emergency repairs.

Specialized Machine Choices

If you have specific needs or certain surfaces to clean, I recommend looking at these popular models: – MaxWave MW-LY200: I find this model works very well on uneven or complex surfaces. – MW-LCW1500: If you’re looking for good value and have varied needs, the MW-LCW1500 is a solid choice in my opinion.

Why Choose Portable Laser Cleaning?

If I compare laser cleaning machines to traditional cleaning methods (like sandblasting or using chemicals), I notice several clear benefits: – They help lower your operational costs because you don’t need to buy consumables like abrasives or solvents. I find this is a great way to save money in the long run. – They boost workplace safety. You avoid using harsh chemicals, and there’s no dangerous debris created. From my perspective, this greatly improves the work environment. – You can set them up fast. They also adapt well to many different environments or urgent cleaning jobs. I find this operational flexibility very useful.

In my view, these advantages make portable laser cleaning machines a smart investment. I recommend them whenever you need immediate, safe, and thorough surface cleaning.

Summary

As I’ve learned about portable laser cleaning machines, I really like how they are both efficient and good for the environment. I think they are more than just a new way to clean. They help industries become more eco-friendly. With new technology, I expect these machines will be easier to get and useful for more tasks. If you have a small workshop or handle big industrial upkeep, I suggest looking into this technology. It’s useful for your business. Plus, it’s a good choice for our planet. For more details about laser cleaning machine or to get a quote, contact us today!