When it comes to precision laser welding, two names often spark debate: Trumpf, the German powerhouse known for industrial dominance, and MaxWave, the rising challenger offering cutting-edge performance at a fraction of the cost. But how do they truly compare — in power, precision, and price?

Whether you’re scaling a high-volume production line or launching your first fabrication workshop, this deep dive will reveal which brand offers the better value for your business. If you’ve ever wondered whether premium always means better — or if innovation can come from a leaner, smarter brand — read on. The answers may surprise you.

Technical Specifications of Two Laser Welding Machines

MaxWave 3 in 1 Handheld Laser Welding Machines

The MaxWave MW-HW1500 laser welding machine, priced at $4,300, offers powerful performance and reliable quality at a competitive price point. Based on its configuration and capabilities, it delivers precision fiber laser welding comparable to high-end industrial systems — making it an ideal choice for businesses seeking both affordability and professional-grade results.

- Laser Power Options: 1000W, 1500W, 2000W, 3000W

- Laser Type: Continuous Fiber Laser

- Wavelength: 1064–1080 nm

- Pulse Width: 0.1–20 ms

- Cooling System: Air Cooling

- Dimensions: Approximately 77× 47 × 60cm

- Positioning accuracy: typically between 0.05 mm and 0.1 mm;

Trumpf Laser Welding Machines

I find Trumpf’s top models, like the TruLaser Station 7000 and TruLaser Cell 3000, are really well-engineered. They are designed for accurate 2D and 3D laser welding. The TruLaser Station 7000, in my view, stands out with:

- 5-axis operation for complex 3D welding

- Axis travel: X 650 mm, Y 350 mm, Z 500 mm

- Rotational axes: B axis ±120°, C axis n x 360°

- Axis speed: 6 m/min (individual), 10 m/min (simultaneous)

- Positioning accuracy: 0.08 mm; repeatability: 0.03 mm

- It has a maximum laser power of 2000 W. I like that it supports various lasers like TruDiode, TruDisk, TruFiber, TruMicro, and TruPulse.

Performance & Applications of Two Laser Welding Machines

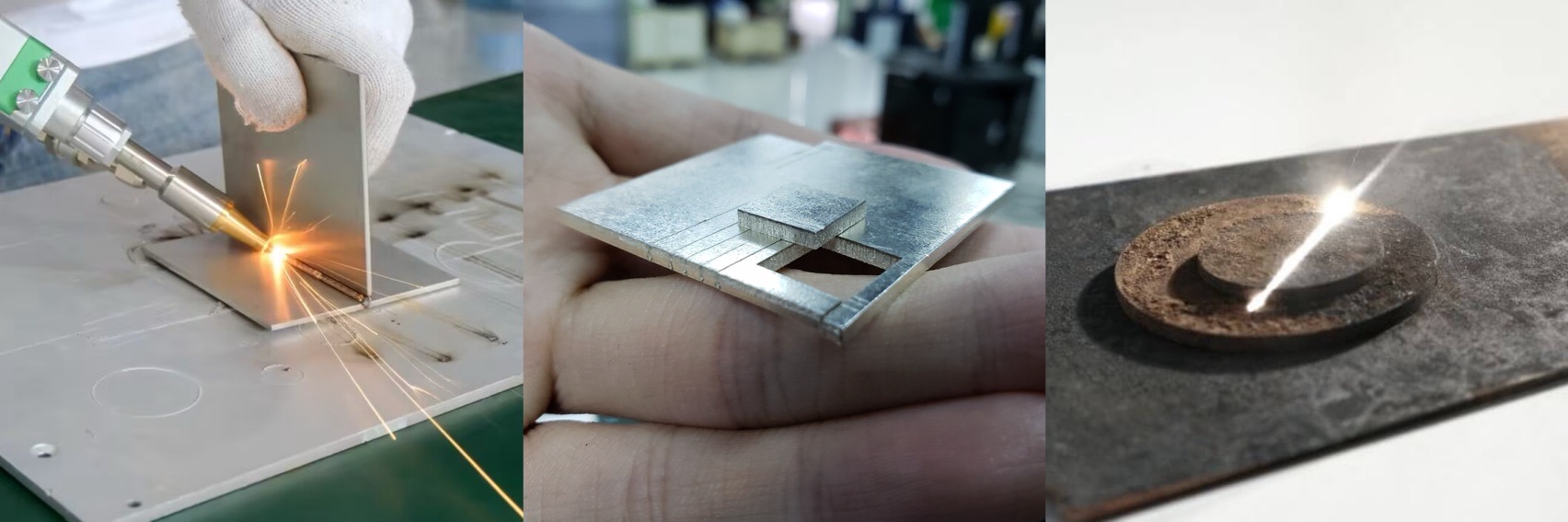

MaxWave MW-HW 3 in 1 handheld laser welding machine, on the other hand, are versatile and accessible in my opinion. The MW-HW series offers 800W to 2000W. These machines can weld steel up to 8mm thick. They use a 1080nm laser source. These models are portable, starting at just 56kg. They use air cooling, which I find makes maintenance easy. A 10m fiber cable extends their working area. You can also get an optional 15m cable. This setup is good for workshops and fieldwork, based on my experience. MaxWave machines do more than just weld. They can also cut and clean surfaces. I think this offers great value for various industrial uses.

I recommend MaxWave for applications such as: – General metal fabrication and putting parts together – Automotive repair shops – Workshops in small to medium manufacturing businesses – On-site repairs and field industrial tasks

TRUMPF laser welding machines offer precision and high productivity. I find they perform well in demanding sectors. Their advanced technology, such as BrightLine Weld, produces clean seams without distortion. This means less rework. The results are high quality. These machines perform well in large-scale production. They also adapt quickly to smaller, flexible batch work and changing manufacturing needs. For instance, the TruLaser Weld 5000 has up to 5000W power. It features robotic welding for complete automation. You often see it used in automotive bodywork. It’s also used for heavy metal fabrication. The price starts from $28,900. I believe this price reflects its top-tier automation and welding power.

I’ve often seen TRUMPF machines used for: – Making automotive parts – Metal processing plants – Creating high-precision industrial parts – Electronics that need strong welds

Performance Comparison

MaxWave:

– Power output between 800W and 2000W (MW-HW series)

– Handheld, portable operation with air cooling

– Welds up to 8mm steel and supports cutting/cleaning functions

– Good for flexible uses, including work on location

– Lightweight, starting from 52kg for greater mobility

TRUMPF:

– Power output up to 5000W (TruLaser Weld 5000)

– Robotic operation with complete automation

– Very precise welds, suitable for high-end manufacturing

– Features like BrightLine Weld create minimal spatter and a clean finish

– Price generally starts above $28,900 for automated systems

Practical Application Examples

The MaxWave MW-HW1500 is a good choice, in my experience. It welds stainless steel furniture, hardware, and kitchenware. It’s also useful for maintenance and repair jobs outside of typical workshops.

I’ve seen TRUMPF lasers used for precise automotive bodywork. They are also chosen for deep welding in metal processing. They help make complex industrial parts that need little finishing work.

Exploring Key Benefits: TRUMPF and MaxWave Laser Welders

MaxWave: Good Value for Your Money

I’ve noticed people often choose MaxWave laser welding machines. They are affordable and easy to use. Information about deep penetration, high speeds, or advanced automation isn’t as common for MaxWave. However, MaxWave is good for specific markets that need easy-to-get solutions.

- MaxWave is a good option if you’re looking for laser welding that’s kind to your wallet or flexible for use in different locations.

- I suggest MaxWave for jobs where top precision isn’t the main goal. It’s better when cost and simple operation are more important.

TRUMPF’s Strengths: Automation, More Output, and Easy Use

I think automation is a key strength of TRUMPF. TRUMPF uses robotic welding cells. These keep weld quality the same and reduce production costs.

Robotic integration: This allows for automatic, consistent welds for large-scale production.

Multi-axis positioners: You can safely and precisely weld complex or big parts.

Programming and fixtures: These make setup and changing between jobs easier. This helps with high output and flexible making.

Integrated image processing: This gives you very reliable and repeatable processes.

In my experience, TRUMPF’s proven precision, depth, speed, and automation make it a top choice in industrial laser welding. This is true when you need high quality and efficient production. In contrast, MaxWave primarily offers good value and simple operation.

Customer Support & Service for Laser Welding Machines

MaxWave Laser Welding Machine Customer Service

MaxWave centers its efforts on providing good customer support. They help users fix problems with handheld laser welding machines fast. Their total service team size and network scale aren’t as publicly known as Trumpf’s. However, based on my experience, MaxWave replies quickly to service requests. They work to address customer concerns as soon as they can.

Quick Issue Resolution: Customers can ask for help and usually receive fast replies.

Information Support: They provide detailed quotes and product information fast when customers ask.

New QR code function: Scanning QR codes sends key data straight to technical support teams. This makes service even faster.

Trumpf Laser Welding Machine Customer Support

Service Network Scale: Trumpf runs a large, international support team.

Problem Escalation: Trumpf uses an official system for quick expert help with tough problems.

Both Trumpf and MaxWave care about customer support, which I appreciate. From my perspective, Trumpf has built a larger, more tech-heavy system for international customers. MaxWave prioritizes quick, direct customer chats. I think this suits buyers looking for simple, easy-to-get service.

Summary

In a world where precision meets productivity, your welding machine isn’t just a tool — it’s the backbone of your business. Trumpf delivers heritage and industrial muscle, no doubt. But if you’re looking for smart performance, affordability, and global-ready reliability, MaxWave offers a compelling edge, especially for entrepreneurs and fast-growing manufacturers.

With prices starting around $4,300, the MaxWave MW-HW1500 proves that innovation doesn’t have to come with a premium price tag. Ready to upgrade your production line with confidence? Choose the laser that works as hard as you do. Choose MaxWave. For more details about laser welding machine or to get a quote, contact us today!