From my experience, dealing with stubborn rust on metal parts is annoying. Traditional cleaning methods are messy and time-consuming. I recommend looking into a new method: laser rust removal. This approach is fast, safe, and works without harsh chemicals. I find that most people focus on how efficient and clean it is. But there is another major benefit that often gets overlooked…

Introduction to Laser Rust Removal

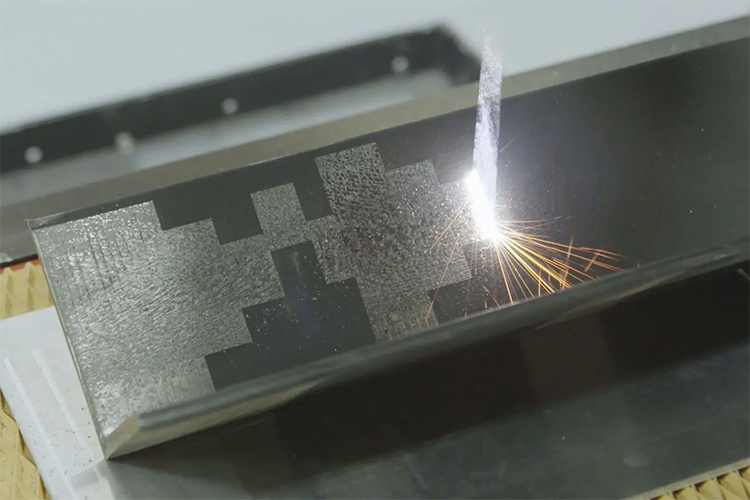

From my experience, laser rust removal is a modern way to clean rust. It uses focused light beams to clean metal surfaces without touching them. The process is simple. I aim strong laser pulses at a rusty spot. The rust soaks up the light and heats up very fast. This intense heat causes the rust to vaporize or flake right off. What I like most is that the metal underneath is left clean and unharmed. I recommend it over older methods like sanding or using chemicals. Laser cleaning is more exact, faster, and much safer for the base material.

How Laser Rust Removal Works

The system works by emitting short bursts of laser light, typically from a fiber or hybrid laser. When the laser hits the surface, contaminants like rust absorb its energy and heat up, generating a small shockwave that blasts the grime away. Thanks to the short laser pulses, the underlying metal doesn’t overheat, helping preserve its strength and integrity.

Technical Performance and Efficiency

From my experience, laser cleaning machine speeds vary with the job — for small, detailed work, you can clean a few square centimeters per minute, while large industrial tasks can reach over one square meter per hour. I recommend pulsed lasers for delicate or intricate surfaces, as they offer better control, while continuous wave lasers are ideal for larger areas or heavy rust removal. With the right energy settings, a laser can strip away multiple layers of rust in a single pass.

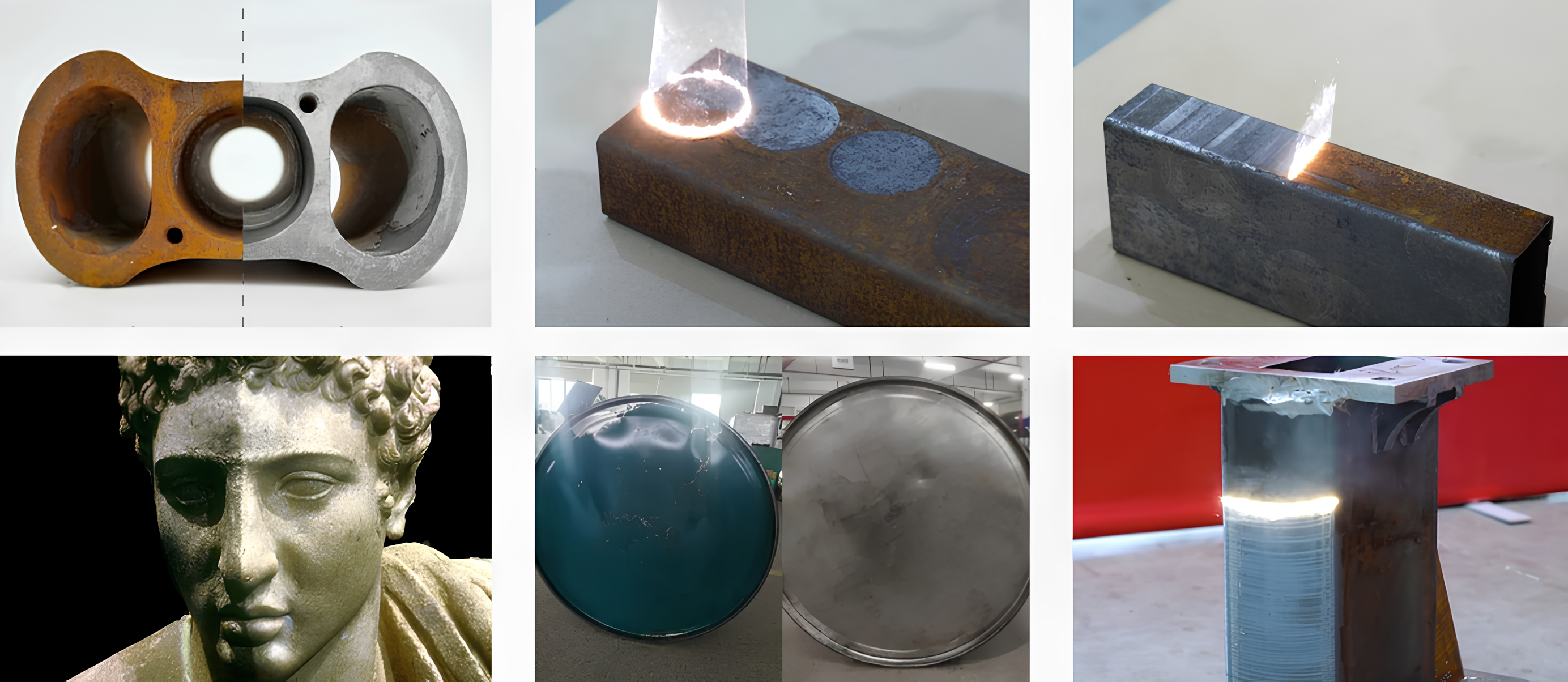

Typical Applications

Automotive: I see it used all the time to remove rust from car bodies, parts, and during restoration jobs.

Industrial Equipment: You can clean large machinery and structures right where they stand.

Welding Processes: I recommend using it to clean surfaces before welding. This gives you a stronger bond. You can also use it after to remove scale for a polished finish.

Precision Industries: This method is common in aerospace, semiconductor, and medical fields. In these jobs, you cannot afford any surface damage or leftover residue.

Advantages Over Traditional Methods

- I like that it doesn’t scrape or touch the surface. This means there is no extra waste like sand, chemicals, or dust.

- It’s a green choice that saves money over time. You don’t have to buy more supplies or pay for waste disposal.

- The system is very flexible. I can change the laser settings to work with different metals and rust levels.

Step-by-Step Process for Laser Rust Removal

- Preparation: First, I clear the workspace and get the metal part ready.

- Setup: Then, I position the laser head over the rusted section.

- Operation: I turn on the laser and move it steadily to cover all the rust.

- Inspection: I check the cleaned surface. If I find any tough spots, I go over them again.

Based on what I’ve seen, laser rust removal is becoming the standard for professionals. It is a fast, precise, and green solution for cleaning rust. I suggest it for anyone who needs a reliable and modern cleaning method.

Step-by-Step Guide to Using a Laser Rust Removal Machine

Based on my experience, the first thing you must do is get your workspace ready. This is a critical step for both safety and for the laser cleaner to work well.

Preparing the Workspace for Laser Rust Removal

1. Remove Hazards and Organize the Area

– I suggest you start by cleaning and organizing the area. Get rid of any clutter. Remove anything that could catch fire, like paper, solvents, or rags.

– A clear workspace helps you avoid tripping and also prevents accidental fires.

2. Set Up Ventilation Systems

– When you use the laser, it creates fumes and tiny particles in the air. You absolutely need good airflow. I recommend using a local exhaust system close to where you are working.

– If you’re in a spot with poor airflow, a portable exhaust fan with a HEPA filter is a great idea. It helps pull harmful stuff out of the air. It gives you extra protection.

– Good ventilation is very effective. Industry data shows it can cut your exposure to airborne particles by more than 90%.

3. Mark and Secure the Laser Work Zone

– Post clear warning signs like “Laser in Use” at all entrances. You should also set up physical barriers around your work area.

– I recommend that you only allow trained people into the work zone. This helps prevent accidents.

– Make sure you have enough light to see everything clearly. This lets you spot dangers and work with better control.

4. Be Ready for Emergencies

– I always check that all emergency stop buttons on the machine work. Make sure you can reach them easily.

– Ensure all staff know where to find emergency equipment and first-aid kits.

– Double-check that emergency exits and walkways are never blocked.

My Pre-Operation Checklist

- Clear all clutter and materials that can catch fire from the area.

- Install local exhaust ventilation at the cleaning site.

- Place warning signs and create physical barriers as needed.

- Keep fire extinguishers close by and confirm they are ready to use.

- Make sure emergency exits and pathways are open and marked.

A Real-Life Example of Setting Up

Before working on a rusted steel panel in a garage with a laser rust remover, here is what an operator did:

– Removed all oils and thinners from the area

– Used a HEPA-filter exhaust fan within 1 meter of the project

– Posted “Laser in Use” warnings at doors

– Put on certified laser safety goggles and gloves

– Tested the emergency stop on the machine to ensure it worked

Key Points I Emphasize

- From my point of view, safety, good airflow, and clear warning signs are the top priorities for any laser rust removal job.

- Using the right protective gear and blocking off the work area lowers the risk of accidents and helps you meet safety rules.

Important Safety Facts:

– Most of these machines use Class 4 lasers. If one of these hits you, it can cause a serious injury.

– Think about this: studies show that over 60% of laser accidents at work happen because the workspace wasn’t set up right or people didn’t use safety gear.

If you follow these steps, you will be set up for a safe and successful rust removal project that meets all the rules.

Safety Precautions for Laser Rust Removal

Laser rust removal machines can be dangerous, so I think safety rules are vital. Without the right protection, you risk serious injury. The Class 4 lasers used for industrial cleaning are powerful, and I’ve seen how important it is to respect them.

Essential Personal Protective Equipment (PPE)

Laser Safety Glasses: I suggest that operators and anyone in the work area wear safety glasses. They must be rated for the laser’s wavelength and optical density (OD). Even a quick, indirect flash of laser light can cause permanent eye damage. From my experience, following standards like EN 60825 (Europe) and ANSI Z136 (United States) is not optional; these rules require proper eyewear.

Protective Gloves: I recommend using flame-resistant gloves. This is critical when you handle high-power lasers. They help prevent burns from accidental contact or reflected beams.

Long-Sleeved Protective Clothing: You should wear flame-retardant clothing that covers your arms and legs. I believe this is the best way to shield your skin from heat and scattered light. Accidental laser exposure or reflections can cause burns.

Face Shields: I suggest using a face shield for extra protection. This is good practice when you work with reflective surfaces or open-beam systems.

Closed-Toe Shoes: In my opinion, you should always wear sturdy, nonflammable shoes.

Mandatory Training and Regulatory Compliance

I believe every operator needs complete laser cleaning system safety training. Your training should teach you to spot hazards, choose the right PPE, and use the emergency shut-off. You also learn to handle the laser cleaning system properly. I want to emphasize that ignoring rules from bodies like OSHA and IEC standards can lead to big fines.

Workplace Controls and Environmental Safety

Laser Hazard Zone: I suggest you mark the work area and keep it restricted. Only trained people should enter. Using the right signs is critical.

Emergency Stop Controls: From my point of view, you must have an easy-to-reach emergency stop button. It needs to be ready anytime the system is on.

Ventilation and Filtration: You need good ventilation or air filtration. This is to remove the dangerous dust and fumes created when the laser vaporizes rust. I’ve seen how quickly the air can get contaminated without it.

Compliance Checklists: I recommend using a PPE checklist before you start working: – Laser safety glasses (rated OD) – Flame-resistant gloves – Long-sleeved protective clothing – Face shields (if required) – Closed-toe, nonflammable shoes

Key Safety Data and Reminders

- Based on my experience, Class 4 lasers can injure you badly, even from a reflected beam. You must treat every beam or reflection as a serious danger.

- You must select PPE that matches your specific laser system. I’ve seen cases where the wrong gear leads to instant and permanent injury.

- It’s my view that you have a constant responsibility to follow EN 60825, ANSI Z136, and other safety standards.

If you follow these safety steps, I believe you can lower the risk of burns. You will also stay compliant with the law and keep everyone safe during laser rust removal.

Summary

Based on my years of experience, I believe laser rust removal is the future for cleaning metal. This technology is a complete game-changer. It works with great efficiency and precision. I feel it’s a responsible choice for our workplaces and the environment. I no longer use harsh chemicals or messy abrasive methods. Now, I know I am helping to make the air cleaner and our work areas safer. I suggest you try laser technology if you are still using older methods for rust removal. The investment pays for itself with great results and gives you peace of mind. Ready to learn more? Contact us now for expert advice on laser cleaning machines.