Choosing between a 1000W and a 2000W laser cleaning machine isn’t just about power—it’s about finding the right tool for the job. Are you restoring delicate molds or blasting heavy rust off steel beams? The difference in wattage can mean the difference between precision and speed, energy savings and brute force. In this guide, we’ll break down the real-world performance, efficiency, and ideal use cases of each model—so you can make a confident decision that fits your workflow, budget, and business goals.

Power Output and Cleaning Capability of Laser Cleaning Machines

From my experience, when you choose between a 1000W and a 2000W laser cleaner, the power output changes how well and how fast it cleans.

Cleaning Speed and Efficiency

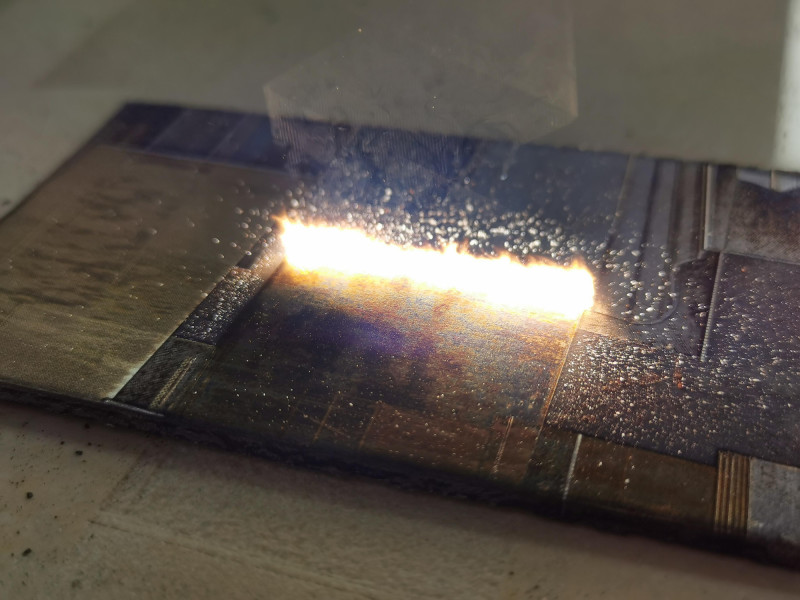

Compared to a 1000W model, a 2000W laser cleaning machine delivers 2–3 times the cleaning speed, significantly reducing project time. For example, a task that typically takes 60 minutes with a 1000W machine can be completed in just 20–30 minutes using a 2000W unit. While the 1000W model may require several passes to remove thick rust or stubborn grime, the 2000W machine often achieves the same result in just one or two passes, making it ideal for urgent tasks and large-scale projects.

Use Cases Based on Cleaning Capability

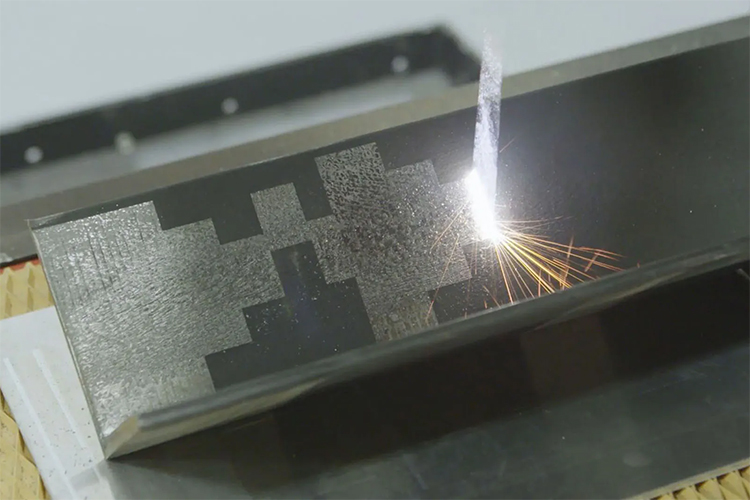

1000W: The 1000W laser cleaning machine is well-suited for detailed and delicate work, such as cleaning molds, precision components, and electronic parts—applications where it’s crucial to avoid surface damage or excessive heat. It’s particularly effective for removing light rust, grease, or contaminants while preserving the integrity of the base material.

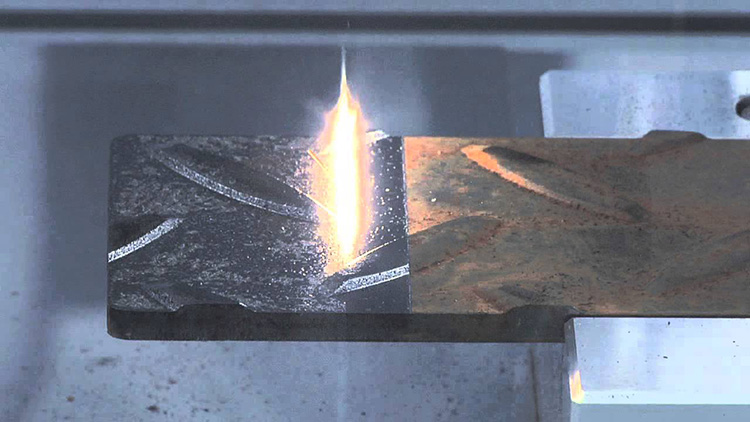

2000W: The 2000W laser cleaning machine is designed for heavy-duty, high-speed cleaning tasks. It’s highly effective at removing thick rust, paint, and stubborn dirt from large surface areas. Common applications include ship hull maintenance, cleaning steel beams, and restoring large equipment frames, where power and efficiency are essential.

Power Level Impact on Application Scenarios

- 1000W: I recommend this when you need gentle cleaning or if the parts are sensitive to heat.

- 2000W: I suggest the 2000W when speed and deep cleaning are your main goals, for tough or very large jobs.

My advice is to match the laser cleaning machine‘s power to your project’s needs. This helps you get both top efficiency and the clean results you want. I recommend the 1000W for fine-detail work and the 2000W for fast cleaning on big areas.

Laser Cleaning Efficiency and Speed

From my experience, the key difference between a 1000W and a 2000W laser rust remover is its power. The machine’s power directly affects its cleaning speed and how well it works for your specific task.

1000W Laser Cleaning Machine: The 1000W laser cleaning machine offers solid cleaning power, making it ideal for precise work and smaller projects like mold maintenance or removing light rust and thin paint. While it works more slowly and may require several passes—especially for tough grime—it’s gentle on delicate surfaces. For example, cleaning heavy rust from a 1m² area takes about 10 minutes. It’s a great choice when preserving the base material is essential.

2000W Laser Cleaning Machine: This 2000W model laser cleaning machine delivers 2 to 3 times the cleaning speed and power of a 1000W machine, making it ideal for large areas in demanding environments like shipbuilding, rail, and steel industries. It removes thick rust, paint, and grime in just one or two sweeps, saving labor time. For example, it can clean heavy rust from a 1m² surface in just 3–5 minutes.

Cleaning Speed: How They Compare in Action

- 1000W cleaning: I use this for light dirt on electronics, molds, and other detailed parts. It’s not built for speed on large industrial surfaces.

- 2000W cleaning: This is my go-to for quick, powerful cleaning on big surfaces like ship hulls or steel frames. You’ll need fewer passes, even with thick rust and paint.

Here’s my final take:

If you need to get high-volume or industrial jobs done fast, I recommend the 2000W laser cleaning machine. It gives you a clear advantage in speed. If your work calls for precision, control, and handling sensitive materials, I believe the 1000W machine is the better option. It’s the right choice when protecting the surface is more important than raw speed.

Keeping Materials Safe with Laser Cleaning Machine

When I compare 1000W and 2000W laser cleaner machines, material safety and precision are my top concerns. Laser cleaning is a no-contact method. This greatly lowers the risk of scratches or damage to delicate items. From my perspective, this makes it much better than using harsh chemicals or abrasive tools.

How Laser Power Affects Material Safety

1000W laser machines give you more control during the cleaning process. I find this lower power is best for delicate or heat-sensitive materials. You want to protect the original surface at all costs.

2000W machines are much faster on tough surfaces. But they also create more heat. This can cause discoloration or even damage if you don’t manage the power well.

Precision Controls and How They Affect Materials

On both 1000W and 2000W models laser cleaning machine, you can adjust settings like pulse duration, frequency, and energy. This is very important. With high-power lasers, these adjustments prevent you from damaging the base material. I also recommend paying close attention to wavelength selection. The right wavelength removes dirt without hurting the material underneath. The wrong one can cause unwanted changes to the surface.

Choosing the Right Power for Your Job

I suggest a 1000W laser a for job where you must protect the underlying material. Think of restoring old artifacts, cleaning electronics, or taking thin coatings off soft metals. 2000W lasers are great for heavy-duty industrial jobs. Use them to strip thick rust or paint from steel. Here, speed is more important than perfect surface preservation.

Real-Life Examples of Material Protection

In one case I saw, a 1000W laser cleaned thin paint from a fragile aluminum aircraft part. It left no marks and was much faster than cleaning by hand. For railway work, a 2000W laser stripped thick rust from steel train wheels in record time. The workers had to make precise adjustments to the controls. This prevented heat damage to the metal’s internal structure.

Based on my experience, picking the right power level and using the machine’s controls is how you get a safe, high-quality result. You protect your materials and your team.

Matching the Laser to Your Industry and Task

From my experience, your choice between a 1000W and a 2000W laser rust removal machine is about your industry and the cleaning jobs you do. Both laser types are great, but for different situations. I believe picking the right tool for the job saves you money and keeps your work safe.

Why I Recommend the 1000W Laser Cleaner for Precision Work

I suggest a 1000W laser cleaning machine for tasks that demand high precision and careful control. This is true if you work with thin or sensitive materials. I’ve seen them used in these common areas:

- Electronics Manufacturing: It removes coatings or oxides from PCBs and delicate electronic parts. I’ve seen it clean surfaces without harming tiny micro-circuits.

- Precision and Semiconductor Manufacturing: It’s great for cleaning wafers and complex parts that need strict quality control. The lower power reduces the risk to fragile surfaces.

- Automotive Manufacturing: I find it’s best for taking off weld residue or mold agents from small, detailed parts. This avoids defects from heat or scratching.

- Art Restoration and Cultural Heritage: It gently removes layers from artworks, statues, and old relics. It does this without hurting the material underneath.

- Tool and Mold Maintenance: It cleans thin films and buildup without risk. I recommend it to help tools and molds last longer by preventing heat or friction damage.

In my opinion, you should choose a 1000W laser cleaning machine for:

– Small parts or detailed work

– Light surface buildup (like oil, thin rust, or light oxidation)

– Jobs where you must protect the material (like soft alloys or painted parts)

Real-world numbers: A 1000W fiber laser cleans about 1–2 m²/hour of light rust or paint. I think this gives a good mix of speed and safety for the surface.

Why I Recommend the 2000W for Heavier Jobs

I recommend the 2000W model laser cleaning machine for big, industrial cleaning jobs. It is the best choice if you need speed and have to remove thick layers of grime.

- Shipbuilding/Yard Maintenance: It is fast at stripping heavy rust and marine coatings from ship decks and hulls. This improves your work rate on large, open areas.

- Metal Processing and Large-Scale Manufacturing: It handles large pipes, sheets with thick oxidation, and steel beams. I’ve found it’s great where the buildup is thick and speed is the priority.

- Power Generation, Oil & Gas, and Chemical Plants: It cleans pipelines, large machines, and reactors that have layers of tough industrial grime. It is perfect for jobs with tight deadlines and difficult buildup.

- Aerospace & Automotive Parts Refurbishment: It strips old paint or deep rust from large, sturdy parts like engines or chassis. On these items, I see minimal risk from the higher power.

I suggest selecting a 2000W cleaning machine for:

– Cleaning large areas or projects that need fast completion

– Thick rust, dense paint, carbon, or scale buildup

– Industrial jobs where the base material is strong and can take extra heat

Real-world output: From what I see in the field, a 2000W laser cleans 4–5 m²/hour of heavy coatings or deep rust. This helps you get the most out of your time on big industrial jobs.

A Few Final Thoughts from My Side

A 2000W laser cleaning machine isn’t suitable for delicate parts due to the risk of heat damage, while a 1000W unit may be too slow for large or heavily soiled surfaces. Both models are available in handheld, semi-automatic, and robotic forms, allowing you to choose the right setup for your workflow. As a rule of thumb: use 1000W for small, sensitive jobs and 2000W for large, tough industrial tasks.

If you match the laser power to your actual jobs, I am confident you will protect your materials and your budget. You’ll get the best value and better results for each project.

Cost and Energy Consumption of Laser Cleaning Machine

When you’re picking between a 1000W and a 2000W laser cleaner, I think you should look at the purchase price and energy use. Your choice affects how much you spend upfront and your running costs over time.

Purchase Cost Comparison

I find that 1000W laser cleaning machines are more budget-friendly. Their prices range from $2,700 to $5,000, based on the brand and its features. 2000W laser cleaning systems cost more. You can expect to pay between $4,500 and $5,500 for basic handheld models. An advanced or automated 2000W unit can cost up to $12,799.

Case examples:

– A 1200W model from MaxWave Laser is priced at $3,600.

– The 2000W version from the same brand is $7,100.

– STYLECNC’s price list starts at $5,500 for 2000W systems in 2025, while their 1500W model is $3,800.

Operational and Energy Costs

A 1000W machine uses about 1 kWh per hour, making it more energy-efficient for small or routine tasks. A 2000W unit consumes 2 kWh per hour but cleans 2 to 3 times faster, often finishing big jobs in a third of the time. So for large-scale work, total energy use per task can be similar—or even lower. Overall, 1000W is better for energy-saving on precision jobs.

Summary

Based on my experience with laser cleaning machine, I have learned an important lesson. Choosing the right power level is not just about the machine itself. You must understand your specific project needs. For example, I suggest the 1000W for detailed work that requires precision. For larger, heavy-duty cleaning tasks, the 2000W is a much better choice. The main goal is to match the laser tool to your project goals.

I recommend you take time to review your projects. Consider your budget. You should also think about long-term cost-effectiveness. Making the correct choice will save you money. It will also produce the quality results your business needs to succeed. For more details about laser cleaning machine or to get a quote, contact us today!