I’ve seen businesses face a choice: buy a high-end German laser marking machine, or go with a Chinese model that costs less. From my point of view, picking the right machine is about more than just numbers on a page. I suggest you find the best fit for your specific production needs, your budget, and your team’s workflow. I have learned that a few small details can completely change your final decision. In fact, there is one important factor that people often overlook.

Price Range Overview for Laser Marking Machines

In the laser marking machine market, brand and country of origin significantly affect pricing.

-

Chinese-made machines: Offer competitive prices while maintaining essential performance, often 30%–50% cheaper than German models of the same configuration. Ideal for limited budgets or quick ROI.

-

German-made machines: Known for precision, stability, and durability, making them preferred for high-end processing, long-hour operation, and extreme accuracy demands.

Base your choice on budget, production needs, and after-sales service—not just price.

Main Factors Affecting the Price of Laser Marking Machines

1. Laser Type

The type of laser source is one of the biggest price drivers.

-

Fiber laser: Most common for metal marking, offering high precision, long lifespan, and low maintenance. Generally cost-effective for a wide range of industrial applications.

-

CO₂ laser: Ideal for marking non-metallic materials such as wood, leather, acrylic, and glass. Prices can vary depending on power output and beam quality.

-

UV laser: Produces very fine marks with minimal heat impact, making it perfect for plastics, electronic components, and sensitive materials. Usually more expensive due to its advanced technology.

2. Power and Speed

Higher wattage in laser markers generally translates to faster marking speeds and the ability to achieve deeper engraving. Common power levels such as 20W, 30W, and 50W are available, with models featuring higher wattage typically costing more. For businesses handling large production volumes or working with thicker materials, investing in a higher power machine is often necessary, which will naturally increase the overall price.

3. Work Table and Accessories

Extra features can significantly increase the cost of a laser marking machine. For example, autofocus systems automatically adjust the marking head to achieve optimal focus, which saves setup time and ensures consistent results. Rotary axes enable marking on cylindrical objects such as rings, bottles, and pipes, expanding the range of possible applications. Additionally, sliding tables enhance workflow efficiency by allowing multiple workpieces to be processed in sequence, boosting overall productivity.

4. Software and Control System

The quality and capability of the software directly impact both the ease of use and overall productivity of a laser marking machine. Machines that support multiple file formats such as AI, DXF, and PLT offer greater flexibility for different design needs. Additionally, user-friendly interfaces and automation features help reduce training time and minimize operator errors. Some of the latest laser marking machines, like MaxWave’s newest portable laser marking machine—priced at only $1,200—ven support Bluetooth connectivity with smartphones and computers, further enhancing convenience and remote control capabilities.

5. After-Sales Service and Warranty

Support quality plays a crucial role in both the overall cost and long-term value of a laser marking machine. Longer warranty periods offer greater security for your investment, ensuring peace of mind. Additionally, fast and responsive technical support, including remote assistance and on-site service, helps minimize downtime and boosts operational efficiency. For example, MaxWave’s laser marking machines come with a 2-year warranty and lifetime technical support, supported by 24/7 online customer service, providing reliable assistance whenever you need it.

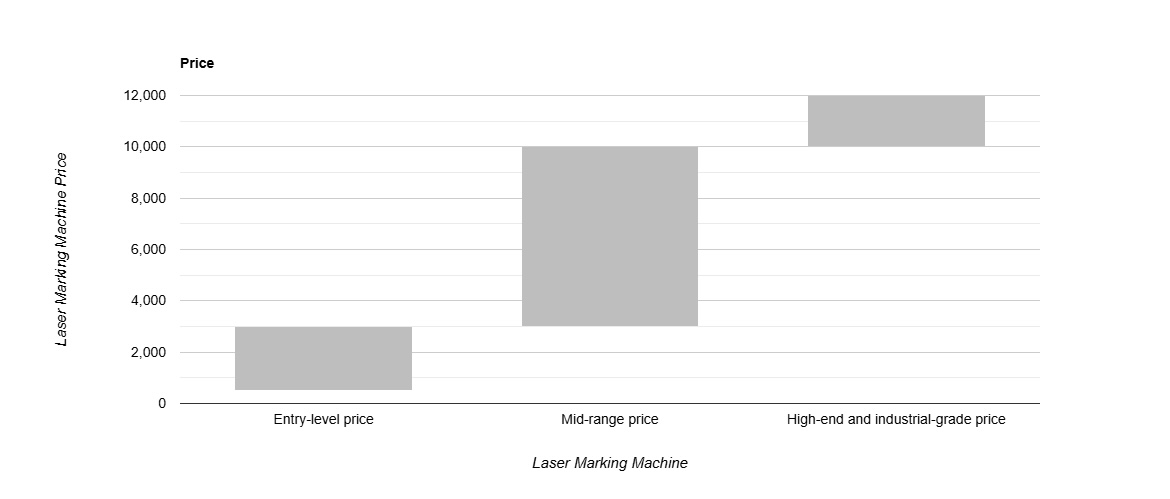

Application Scenarios by Price Range of Laser Marking Machine

Entry-Level

Suitable for personal users, entrepreneurs, and small-batch customization businesses.

– Price: $500-$3,000

– Lower power (around 20W), ideal for marking tasks with minimal speed and depth requirements

– Example applications: personalized gift engraving, small jewelry processing, handicraft carving, small parts numbering

– Advantages: low investment cost, compact size, easy to operate

– Limitations: not suitable for long hours of continuous work or large-scale production

Entry-level laser marking devices are perfect for beginners and small-scale users who need affordable and easy-to-use solutions.

Mid-Range

Designed for small factories, workshops, and businesses requiring stable production.

– Price: $3,000-$10,000

– Medium power (20W–50W), balancing marking speed and depth

– Example applications: medium-batch parts processing, electronic component marking, hardware tool labeling, packaging codes

– Advantages: stable performance, works with a wide range of materials, moderate maintenance cost

– Limitations: may not be efficient enough for ultra-high precision or fully automated large-scale production

Mid-range laser marking machines offer a balance of performance and cost, meeting the needs of many small to medium manufacturing operations.

High-End

Best for large-scale industrial production and industries with extremely high precision requirements.

– Price: $10,000+

– High power (50W and above), supports continuous long-hour operation, often equipped with advanced automation and inspection functions

– Example applications: automotive parts mass marking, aerospace precision components, medical device engraving, integration into large production lines

– Advantages: fast speed, high precision, long lifespan, high level of automation

– Limitations: high upfront investment cost, more suitable for long-term, large-volume, high-value production

High-end laser markingmachines are designed to meet the rigorous demands of large factories and specialized industries requiring maximum precision and reliability.

Summary

Based on my experience with laser marking machines, I’ve learned a key lesson. The cheapest option is not always the right one. I suggest finding the machine that fits your specific needs and budget. This is true if you’re starting with a basic model for personal projects or using high-end industrial equipment. You first need to understand what your work requires. I recommend taking time to evaluate your needs. Think about your current work and your plans for future growth. Good customer support can be a huge factor in your success. Ready to learn more? Contact us now for expert advice on laser marking machines.