With so many types of laser marking machines out there, choosing the right one can feel tricky. From speedy fiber lasers to precise UV systems, each has its own strengths. In this guide, I’ll break down the top options so you can find the perfect fit—whether you’re personalizing gifts, branding products, or running an industrial operation.

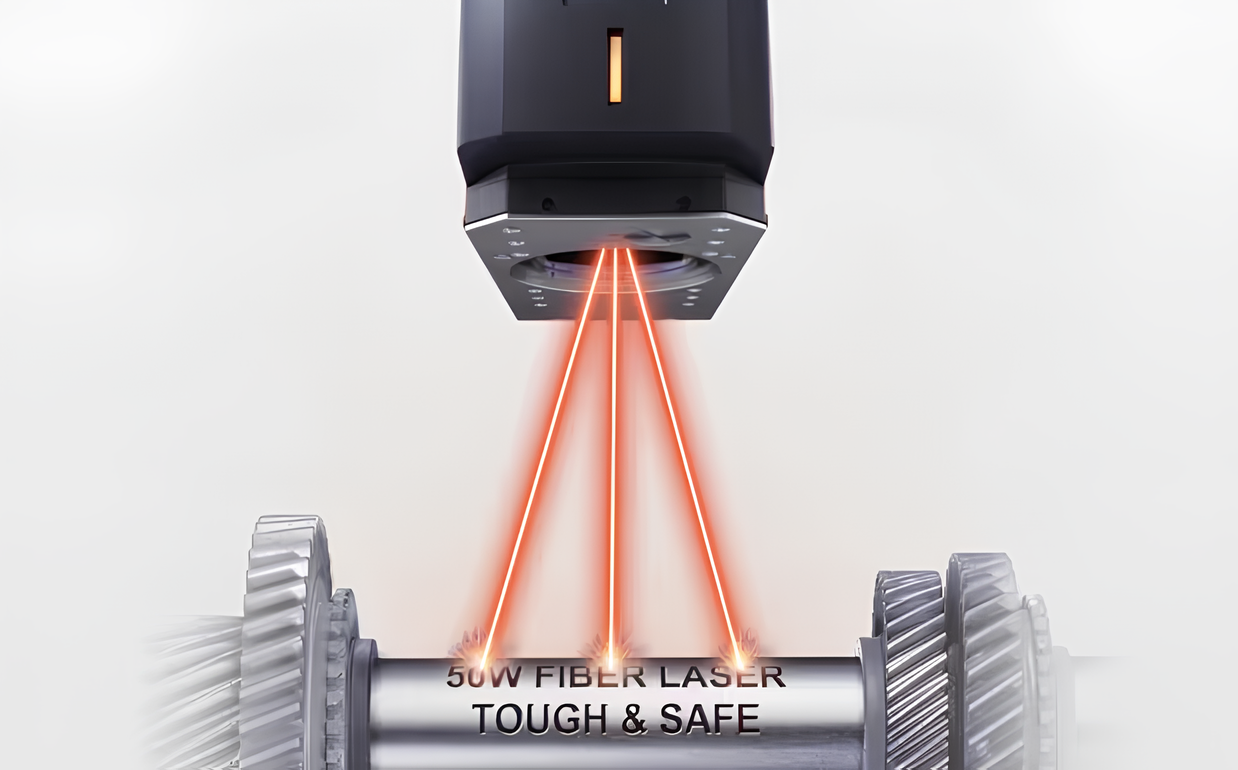

Fiber Laser Marking Machines

Fiber laser markers use a solid laser source. The core of this is a special material, ytterbium-doped fiber, which creates a powerful light beam at a 1064 nm wavelength. From my experience, these machines are powerhouses. They offer output power from 20W to over 120W. This power lets them mark at very high speeds, up to 3,000 mm/sec with a standard 160mm lens.

Key Features & Marking Process

- Marking Speed: You can get detailed marks at very high speeds. I find this perfect for busy production lines.

- Precision: These laser marking machines are incredibly accurate. They can achieve 3.5 μm precision across the whole work area.

- Deep Engraving: They handle both light surface marks and deep engraving, which is great for metals.

- Supported Materials: You can mark many metals like steel, aluminum, copper, gold, and silver. They also work on some plastics.

Advantages of Fiber Laser Marking

These machines offer a long lifespan, often exceeding 100,000 hours, with minimal maintenance since no consumables are needed, lowering operational costs. Their compact design fits into almost any workspace, and they are highly versatile, performing reliably in both factory and cleanroom environments.

Disadvantages

Fiber lasers have material limitations, performing less effectively on certain non-metal materials, and the initial cost is higher than some alternative marking methods, which should be considered in your budget.

Best For

I recommend fiber laser marking machines for certain businesses. They are a great choice if you need fast, precise marks or deep engraving. They work best on metals and some plastics. I suggest them for industries that need very reliable tools with long life and little upkeep. This includes automotive, electronics, medical device, and jewelry making.

CO₂ Laser Marking Machines

CO₂ laser marking machines use a laser beam with a wavelength of 10,600 nm. From my experience, they are great for fast and steady marking. They are built to work on non-metallic materials. This includes plastics, wood, glass, ceramics, paper, rubber, and some metals with a coating.

Key Features & Marking Process

- Wavelength: 10,600 nm. I find this wavelength is perfect for marking organic and non-metal materials.

- Engraving Speed: They can reach speeds up to 3 m/s. This allows for quick work on a production line.

- Marking Area: You can work on areas from 50 × 50 mm up to 601 × 440 mm. This means the machines can handle items of many sizes.

- Precision: The machine can make lines as fine as 0.05 mm. This gives you very detailed and clean marks.

Advantages of CO₂ Laser Marking

CO₂ laser marking machines are highly versatile, excelling at marking many non-metal materials like wood, plastics, and glass. They offer high throughput, making them ideal for busy factories and packaging lines, while providing stable performance even during long runs. Built for longevity, these machines require minimal maintenance, reducing downtime and costly repairs.

Disadvantages

CO₂ laser marking machines have material limitations, performing poorly on most bare metals, and are best suited for non-metal or coated materials. Their application focus is narrower, making them less effective for direct metal engraving or deep marking tasks.

Best For

I recommend a CO₂ laser marking machine if your work involves materials like plastics, wood, glass, ceramics, paper, or rubber. They also perform well on coated metals.

Based on my experience, they are a great fit for specific industries. This includes packaging, electronics, and woodworking. I suggest them for any job that needs fast, precise marking over a large area on non-metals. You’ll also appreciate the low maintenance and steady, long-term operation.

UV Laser Marking Machines

UV laser marking machines use a short 355 nm wavelength laser. This allows for very precise marking. I call this process cold processing because it creates almost no heat. From my experience, this makes UV lasers a great choice for marking sensitive materials. You won’t see any damage or changes to the material’s shape.

Key Features & Marking Process

- Wavelength: 355 nm. This creates very fine and clear marks.

- High Precision: I find it delivers detailed marks. It’s great for micro-text, complex graphics, and small codes.

- Cold Processing: Very little heat is created. This keeps the material’s structure and surface safe.

- Works on Many Materials: I’ve seen it work well on plastics, glass, ceramics, silicon wafers, sensitive metals, films, and composite materials.

Advantages of UV Laser Marking

UV laser marking machines use a cold process, so there is no heat damage, making them ideal for delicate materials. They offer great compatibility, working on almost all sensitive and fragile items, and produce clean, high-contrast marks that are easy to read. With excellent detail, they can mark tiny features at the micrometer level, perfect for electronics and medical applications.

Disadvantages

The main drawback is higher cost, as UV laser machines are more expensive to buy and maintain than fiber or CO₂ systems. They also have slower speed, especially on large, simple jobs, and require specialized maintenance with skilled operators, which adds to the overall cost.

Best For

I recommend UV laser marking machine for industries that need top precision. It’s also for jobs where you cannot damage the material. They are a good fit for electronics manufacturing, medical device production, advanced engineering, and silicon processing. If your work uses delicate plastics, glass, or films, a UV system is a good solution. I also suggest it if you need to make tiny, complex marks.

MOPA Laser Marking Machines

MOPA laser marking machines use a Master Oscillator Power Amplifier (MOPA) design. This setup is different from standard fiber lasers. I think the biggest difference is that you can adjust both the pulse width and frequency. This control lets you create special marking effects on sensitive metals and plastics. I see MOPA systems used a lot in industries like electronics, automotive parts, medical devices, and jewelry.

Key Features & Marking Process

- Adjustable Pulse Width: I like how MOPA laser marking machines give you complete control over the pulse width, from under 10 ns to over 200 ns. This means you can create fine, light marks or deep, bold ones by just changing the settings.

- Variable Frequency: I find it very useful that you can tune the frequency from 1 kHz all the way to 4000 kHz. This helps you get the perfect mark you want on different surfaces.

- Special Effects: With a MOPA laser marking machine, I can mark plastics without any burning or yellowing. I find it’s also perfect for making clean, black marks on anodized aluminum and color marks on stainless steel.

- Fine Detail: The high level of control means you can make micro-text, data matrix codes, and sharp graphics. In my experience, these details stand out, even on very small parts.

Advantages of MOPA Laser Marking

MOPA lasers are highly versatile, working well on metals like aluminum, stainless steel, titanium, and plastics such as ABS, PVC, and PE. They produce unique marking results, including crisp black marks on anodized aluminum and color marks on stainless steel. With fine control over power and duration, they avoid burning or melting delicate materials. Users can achieve both detailed marks and deep engravings, while enjoying fast processing speeds suitable for large production runs.

Disadvantages of MOPA Laser Marking

The main drawbacks are higher cost, often between $8,000 and $15,000, and a steeper learning curve due to more adjustable parameters. While maintenance is generally low, the complex optical design may require more frequent checks, adding to upkeep requirements.

Best For

I recommend MOPA laser marking machines for any business that needs total flexibility and control. They are your best choice if you often mark plastics, anodized aluminum, or stainless steel with special looks, like black or colored marks. In my view, MOPA lasers are a smart investment for electronics, automotive, medical devices, and high-end jewelry branding. If you want unique finishes or must avoid heat damage, I suggest you choose a MOPA system over a standard fiber or CO₂ option.

My Quick Guide to Choosing the Right Laser

To choose the right laser marking machine, I suggest starting with your business needs. What exactly do you need it to do? Here is a simple framework I use to help people make the best choice:

1. Check Your Materials

CO2 Lasers: I find these work best on organic, non-metal materials. Think wood, glass, plastics, paper, and rubber.

Fiber Lasers: I recommend these for marking metals like steel, aluminum, copper, and gold. They also work on some plastics.

UV & Green Lasers: For delicate materials that are sensitive to heat, I use these. They are great for plastics, glass, ceramics, and even silicon wafers.

2. Consider Power, Wavelength, and Precision

Laser Power (Wattage): – For basic jobs, I find that ~30W is usually enough. – For harder metals, I suggest choosing a higher power option, like 50–120W or more.

Wavelength: In my experience, 1064 nm (fiber) is a flexible choice for most industrial work. The 10,600 nm (CO2) wavelength is for non-metals. I use 355 nm (UV) and 532 nm (green) for very fine, detailed marking work.

Spot Size: For high-precision work like micro-text, you’ll want a smaller spot size. A spot down to 10μm will give you very fine codes.

3. Think About the Final Mark

4. Match the Machine to Your Production Speed

For High-Volume Jobs: To improve your efficiency, I suggest a machine with autofocus. A large marking area and 3-axis control also help a lot. You can connect the machine to your current production lines. This automates the work and reduces mistakes.

For Low to Medium Volume / Prototypes: In this case, I think flexibility is more important than speed. You need a machine that allows for quick changes.

5. Check for Durability and Standards

Your laser marks need to meet certain standards. This could be for industry tracking or for medical and aerospace rules. The marks also need to last. They should resist scratches, chemicals, and temperature changes.

6. Look at the Supplier and Support

I recommend you choose a brand with a good reputation. Make sure they offer quick service and a clear warranty. From my experience, unexpected costs from machine problems can hurt your return on investment.

7. Examples from My Experience

- Automotive (10,000 metal parts/day): For a job like this, I would use a fiber laser. It should be at least 50W with a spot size under 10μm. It needs autofocus and should connect to the factory line.

- Packaging/Woodworking: Here, I suggest a CO2 laser around 30W. It should have a large marking area to work well on non-metals.

- Cleanroom/Electronics: For this, I recommend a UV laser. It creates a very accurate mark without adding heat, which is perfect for sensitive parts.

8. My Selection Checklist

Before you decide, I suggest you ask yourself these questions:

– What materials will I be marking?

– Do I need to engrave deeply, or is a surface mark enough?

– How fast and how much do I need to produce?

– Will I connect this to an automated system, or will it be a standalone machine?

– Do my marks need to meet any regulations or resist tough environments?

– What is my budget for the machine and its upkeep?

Has this supplier shown they are reliable and offer good support?

Answering these questions will help you choose wisely. You can make a smart, cost-effective investment. You will get the right laser marking technology for your specific needs.

Summary

The right laser marking machine can transform your workflow, boost quality, and unlock new creative or business opportunities. Whether for industrial precision or custom designs, choosing wisely means getting professional results fast. Step in, pick your machine, and watch your ideas come to life. Ready to learn more? Contact us now for expert advice on laser marking machine.