Want to take your products or creative projects to the next level? Laser engraving machines can leave precise, lasting marks on almost any material—from shiny metals and sturdy stone to flexible leather and high-tech plastics. Whether it’s brand logos, serial numbers, QR codes, or intricate decorative designs, laser engraving delivers professional, high-precision results. In this article, I’ll show you which materials a laser engraving machine can handle and the best ways to use it.

Stainless Steel Laser Engraving

I often use laser engraving machines on stainless steel because it’s tough and versatile. The best laser type is a fiber laser, which delivers high-contrast, precise, and permanent marks. CO₂ lasers generally don’t work on bare metals without coatings.

My Top Laser Recommendation

I recommend a fiber laser engraving machine for industrial stainless steel marking. It produces clear, durable marks suitable for a wide range of applications.

The Results and How It Works

Fiber lasers can create deep engravings, light surface marks, color marks (annealing), or black marks. Being non-contact, the process avoids warping or heat damage. I can mark barcodes, QR codes, logos, and serial numbers with sharp detail.

Examples: Many companies use fiber lasers to mark data plates, medical tools, and kitchenware for identification and tracking.

Things to Think About

Fiber laser marking is fast and cost-effective ($2,500–$10,000+). Polished surfaces give sharper contrast, and the process works well for mass production or custom jobs. It’s widely used in automotive, aerospace, medical, kitchenware, and electronics for part ID, compliance, and anti-counterfeiting.

Carbon Steel Laser Engraving

I often use laser marking machines on carbon steel because it’s strong, affordable, and widely used. With the right laser, I can make sharp, permanent marks for tracking, branding, or part IDs.

My Top Laser Recommendation

I recommend a fiber laser for carbon steel. It’s precise, fast, and low-maintenance, producing clear, deep marks even on hard or thick steel. High-power CO₂ laser engraving machines can work but usually need a marking agent and don’t match the depth or durability of fiber lasers.

The Results and How It Works

Fiber lasers can create deep engravings or light surface marks depending on power and speed. The process is non-contact, so there’s almost no warping or heat damage. I often mark serial numbers, QR codes, and part IDs on tools and structural components. Marks are durable and corrosion-resistant when using coated or treated steel.

Examples: Laser-marked carbon steel appears in shipbuilding, garage tools, pipes, gears, and heavy machinery for tracking, compliance, and anti-counterfeiting.

Things to Think About

Fiber laser marking on carbon steel is fast and efficient. Entry-level systems start around $2,000–$3,000, while high-power automated setups cost $12,000+. Smooth surfaces give the best contrast, and marks remain permanent and readable even in harsh environments.

Aluminum Laser Engraving

I often use laser engraving on aluminum because it’s light, corrosion-resistant, and ideal for permanent tracking or branding.

My Top Laser Recommendation

A fiber laser works best, producing clear, durable marks. CO₂ laser markers work on coated aluminum but lack the same sharpness. Entry-level fiber systems start around $2,500, while advanced models exceed $10,000.

The Results and How It Works

Fiber lasers engraving machine create deep or light marks depending on power and speed. On anodized aluminum, marks appear bright white or dark; on bare aluminum, gray or dark. The non-contact process prevents warping. I mark barcodes, serial numbers, logos, and more.

Examples: Widely used in electronics, aerospace, automotive, and for consumer items, producing durable, professional, wear-resistant marks.

Things to Think About

Marking is fast and cost-effective, especially for medium to high volumes. Surface finish matters—anodized or matte aluminum gives best contrast; polished surfaces may need extra passes. With the right setup, you get permanent, high-contrast marks for many aluminum applications.

Copper Laser Marking

Chrome Laser Engraving

I’ve found that laser engraving machines are a great solution for chrome and chrome-plated surfaces. Many industries, like automotive and plumbing, use chrome because it is shiny, durable, and resists corrosion. In my opinion, marking chrome can be tricky. Its reflective surface and hardness present a unique challenge.

My Top Laser Recommendation

I recommend a fiber laser marking machine for chrome, which produces clear, readable marks on reflective, hard surfaces. A green laser works well on polished or delicate chrome for high-contrast marks with minimal risk of damage. CO₂ lasers are ineffective due to reflection.

The Results and How It Works

Using fiber or green lasers, I can make deep engravings, black marks, and fine details. By adjusting power, pulse, and speed, the plating avoids overheating or cracking. The non-contact process prevents mechanical damage. I often mark barcodes, serial numbers, and logos on automotive parts, tool handles, and fixtures.

Examples: Chrome marking is common on automotive trim, tools, sanitary fittings, bicycles, and branded hardware, providing permanent, wear-resistant marks for tracking, anti-counterfeiting, and decorative branding.

Things to Think About

Marking chrome is slower than other metals due to reflectivity and hardness. Fiber laser engraving machines start around $3,000, while advanced setups with green lasers or automation can exceed $12,000. Satin or matte finishes give better contrast than polished surfaces.

Laser Marking on Titanium

I often work with titanium, common in aerospace, medical devices, and jewelry for its strength, corrosion resistance, and biocompatibility. Laser marking creates sharp, permanent marks without affecting these qualities.

My Top Laser Recommendation

A fiber laser engraving machine is best for titanium, producing clear, high-contrast marks with minimal heat damage. For color marking, a MOPA fiber laser engraving machine allows precise control. CO₂ lasers are not suitable due to less durable marks.

The Results and How It Works

Fiber lasers can make deep engravings, soft colored marks, and fine designs. Adjusting pulse width and frequency produces colors like blue, purple, yellow, and green. The non-contact process prevents warping. Common marks include QR codes, serial numbers, and measurement lines, which remain readable after sterilization or long-term use.

Examples: Titanium is marked for bone screws, prosthetics, dental implants, aerospace brackets, and luxury watches. Marks are permanent, wear- and corrosion-resistant, suitable for compliance, branding, and traceability.

Things to Think About

Fiber laser engraving is fast and precise. Entry-level systems cost $3,000–$4,000, while MOPA lasers for color exceed $8,000. Both polished and matte surfaces work, with smoother finishes giving better contrast. Proper cleaning ensures optimal results.

Gold Laser Engraving

Gold is used in jewelry, coins, and medical devices. Its softness and value require precise, non-damaging marking. Laser marking machine provides lasting, high-quality results without harming the surface.

My Top Laser Recommendation

I recommend a fiber laser for gold to create high-contrast, precise marks. For color effects, a MOPA fiber laser engraving machine allows controlled colored engraving. CO₂ laser engraving machines are not advised, as they may damage the surface and produce less sharp results.

The Results and How It Works

Fiber and MOPA laser engraving machines create fine details, from shallow identification marks to deeper decorative engravings. Adjusting pulse duration and frequency produces color variations. The non-contact process avoids warping or heat damage. Typical marks include serial numbers, hallmarks, logos, and custom designs that remain readable and durable.

Examples: Fiber lasers are used on rings, watches, coins, investment bars, and surgical implants. Marks support tracking, anti-counterfeiting, compliance, and branding while preserving gold’s quality.

Things to Think About

Laser marking on gold is fast and precise. Entry-level fiber lasers cost $3,500, while advanced MOPA systems range from $8,000–$20,000. Both polished and matte surfaces work, with matte giving better contrast. Pre-cleaning ensures optimal results.

Silver Laser Engraving

Silver is used in jewelry, coins, electronics, and decor. Its softness and reflectivity require delicate, precise marking. Fiber laser Engravers are ideal, producing sharp, lasting marks.

My Top Laser Recommendation

I recommend a fiber laser engraving machine for silver to achieve high-contrast, precise marks. MOPA fiber lasers allow controlled color shading for jewelry. CO₂ laser engraving machines are less effective due to silver’s reflectivity.

The Results and How It Works

Fiber and MOPA laser ebgraving machines create fine details, from hallmarks and serial numbers to logos and QR codes. Adjusting pulse settings allows subtle color marks. The non-contact process avoids warping or heat damage, with marks as small as 0.1 mm that remain durable through handling and cleaning.

Examples: Fiber lasers are used on coins, rings, collector bars, awards, and electronic connectors. Marks provide tracking, authenticity, branding, and decorative customization without reducing silver’s value.

Things to Think About

Marking is fast and precise, even on delicate items. Entry-level fiber lasers cost $3,500, while advanced MOPA systems range $8,000–$18,000. Both polished and matte surfaces work well, with matte giving higher contrast. Pre-cleaning ensures consistent, flawless results.

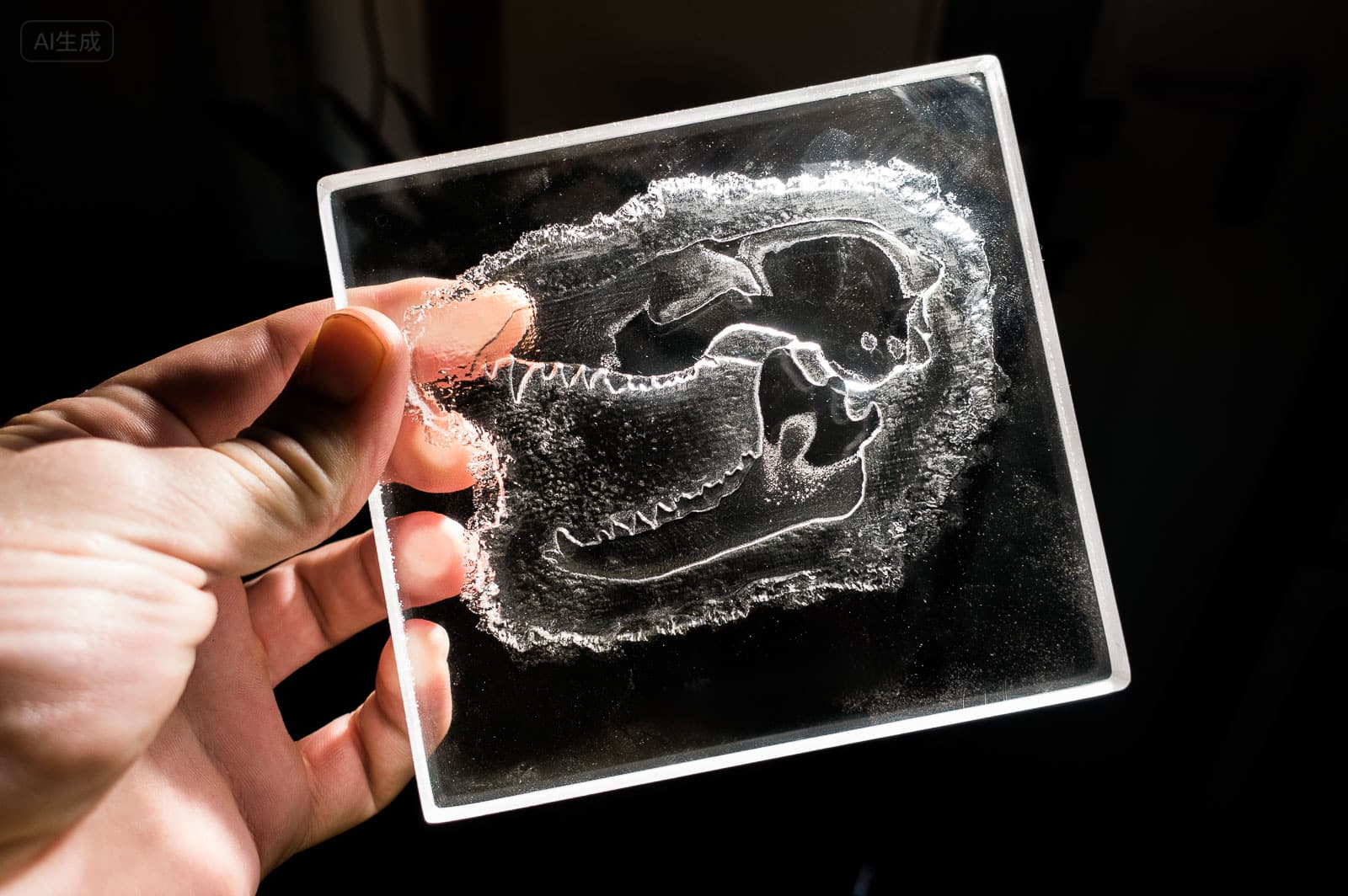

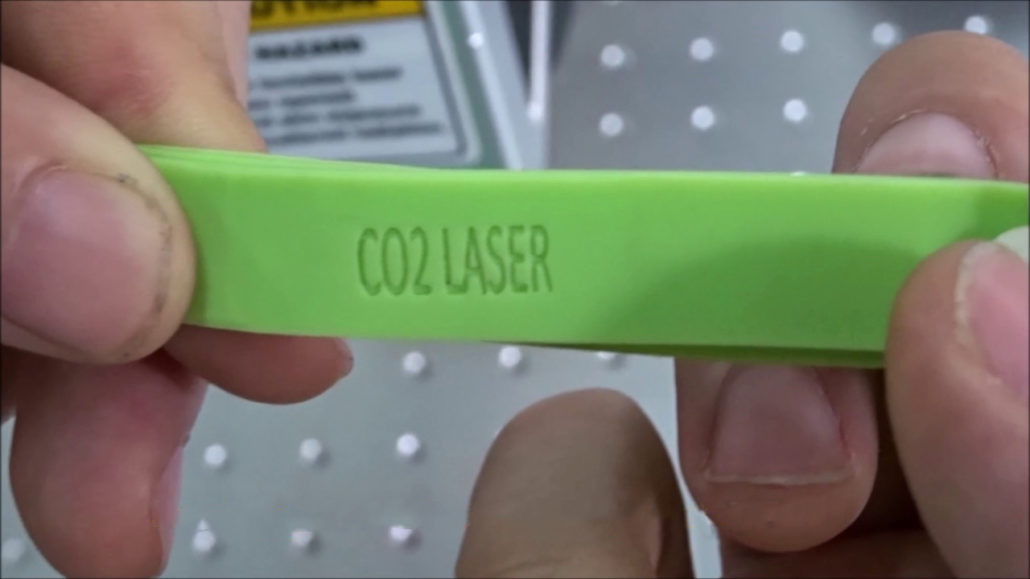

Acrylic (PMMA) Laser Engraving

Acrylic is widely used in displays, signs, awards, and consumer products. It’s valued for being clear, durable, and easy to mark. CO₂ laser marking systems give sharp, frosted marks without damaging the material, while fiber lasers are less effective.

My Top Laser Recommendation

I suggest a CO₂ laser engraving machine for acrylic to create frosted marks, precise text, logos, and QR codes. It also cuts acrylic sheets cleanly with polished edges.

The Results and How It Works

CO₂ lasers produce surface marks or deep engravings. The non-contact process avoids warping or stress. Fine details are possible, and edge-lit signs glow brightly. Marks are permanent and durable under cleaning and light exposure.

Examples: CO₂ lasers are used on award plaques, LED signs, store displays, and instrument panels. Marks remain visible on clear or colored acrylic.

Things to Think About

Marking is fast and efficient. Small items take seconds; automated systems handle high volumes. Entry-level CO₂ laser engraving machines start at $2,000, while industrial units exceed $8,000. Surface finish affects contrast—glossy acrylic shows brighter marks. Pre-cleaning ensures consistent, sharp results.

PVC Laser Marking

PVC is commonly used for electrical cable jackets, plumbing pipes, and industrial components. It requires high-contrast, durable marks for identification and tracking. CO₂ lasers work best, while fiber lasers usually produce faint, unclear results.

My Top Laser Recommendation

I suggest a CO₂ laser for PVC. It creates sharp marks for logos, serial numbers, barcodes, and batch codes without damaging the surface.

The Results and How It Works

CO₂ lasers mark PVC non-contact, preventing warping or damage. Marks can be surface-level or deep, appearing white/gray on dark PVC and dark on light PVC. They remain legible after handling, installation, or sunlight exposure.

Examples: I’ve marked serial numbers, barcodes, and logos on PVC cables and pipes. The marks stayed clear and readable even after outdoor exposure, making them ideal for product tracking and identification.

Things to Think About

PVC marking produces toxic fumes, so proper fume extraction is essential. Smooth, clean surfaces give the best results. CO₂ laser engraving machines are fast and suitable for small or high-volume jobs. Entry-level systems start around $2,000, while industrial setups with automation and extraction cost $8,000–$12,000.

Polycarbonate Laser Engraving

Polycarbonate is widely used in car panels, electronic cases, medical device shells, and safety gear. It’s strong, clear, and versatile. Laser marking machines create clean, permanent marks without damaging the surface.

My Top Laser Recommendation

I recommend a CO₂ laser for polycarbonate. It produces sharp, high-contrast marks without warping. For very fine details, a UV laser engraving machine works well. Fiber lasers are generally unsuitable.

The Results and How It Works

CO₂ laser engraving machines produce legible serial numbers, barcodes, and logos on clear or colored parts. Marks can be deep or surface-level, with frosted smooth finishes on clear polycarbonate. UV lasers offer even finer, precise marks for electronics or medical components. The process is non-contact, so parts stay intact.

Examples

I’ve marked safety shields, electrical boxes, medical shells, and car parts. Marks remain durable, readable, and clear after handling, cleaning, or long-term use.

Things to Think About

Marking polycarbonate produces fumes, so ventilation or fume extraction is essential. Smooth, clean surfaces give the best contrast. Entry-level CO₂ laser engraving machines cost $2,000–$3,000, while UV or advanced CO₂ setups range $8,000–$20,000. Laser marking is fast, reliable, and suitable for both small and large production runs in automotive, electronics, medical, and packaging industries.

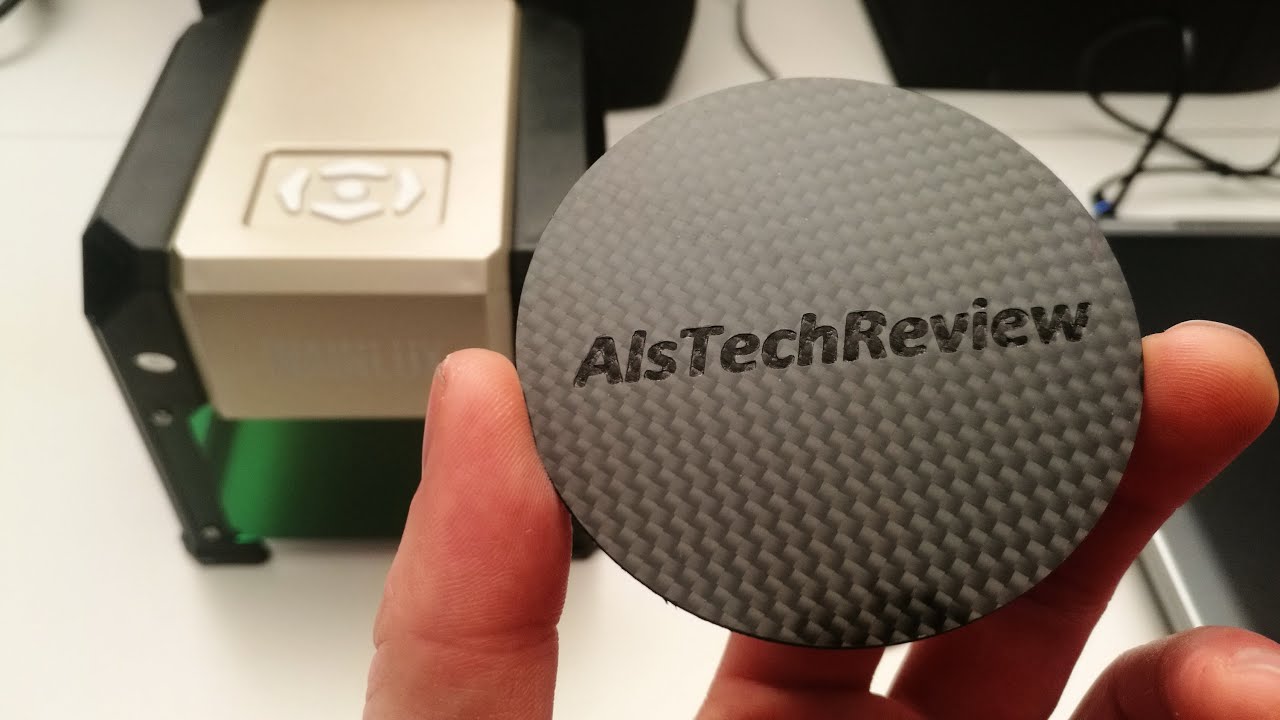

Carbon Fiber Laser Engraving

Carbon fiber is strong, lightweight, and used in aerospace, automotive, sports gear, and industrial applications. Laser marking is the best way to add logos, serial numbers, or IDs without damaging the material.

My Top Laser Recommendation

I recommend a fiber laser for raw carbon fiber and a UV laser engraving machine for coated or delicate surfaces. Fiber lasers create precise, high-contrast marks, while UV lasers reduce heat and prevent burns or peeling. Entry-level fiber systems cost $3,000–$4,000, and UV setups start at $12,000.

The Results and How It Works

With proper settings, I can produce black or gray marks, including text, QR codes, logos, and serial numbers, on matte or glossy carbon fiber. The process is non-contact, vaporizing only the resin layer. UV laser engraving machines give sharper, cleaner marks on coated surfaces.

Examples: I’ve marked racing car parts, aerospace brackets, high-end bike frames, and robotic arms. Marks are permanent, readable, and undamaged, ideal for tracking, warranty, and anti-counterfeiting.

Things to Think About

Carbon fiber is sensitive to heat, so testing on a sample is essential. Adjusting power, speed, and pulse frequency prevents burning or layer separation. Optimized settings produce long-lasting, professional marks, making fiber and UV laser engraving systems reliable for industrial and high-end applications.

Woods Laser Marking

I use laser marking solutions on both hardwoods and softwoods for furniture, décor, signs, and crafts. A CO₂ laser is ideal, producing sharp, dark, permanent marks without damaging the wood. Fiber lasers are not suitable for organic materials.

My Top Laser Recommendation

I recommend a CO₂ laser engraving machine for woods like oak, maple, cherry, walnut, pine, spruce, cedar, and fir. It creates high-contrast text, logos, barcodes, and graphics. Entry-level laser engraving machines start around $2,000, while professional or automated setups range $8,000–$10,000+.

The Results and How It Works

CO₂ laser engraving machines burn the surface to make permanent marks. Adjusting power and speed allows deep engravings or light etching. The process is non-contact, so delicate pieces won’t chip. Marks on light woods appear dark brown to black, and shading on dark woods can be controlled.

Examples: I’ve marked cutting boards, picture frames, instruments, awards, signs, wooden tags, and crates. Marks remain durable and readable even with handling, sunlight, or cleaning.

Things to Think About

Surface prep matters: unfinished or lightly sealed wood absorbs marks best; varnished surfaces may char. Fume extraction is essential due to smoke and dust. Laser marking is fast, efficient, and suitable for both custom and high-volume work. Higher-power machines (80W+) allow 3D relief carving or larger designs.

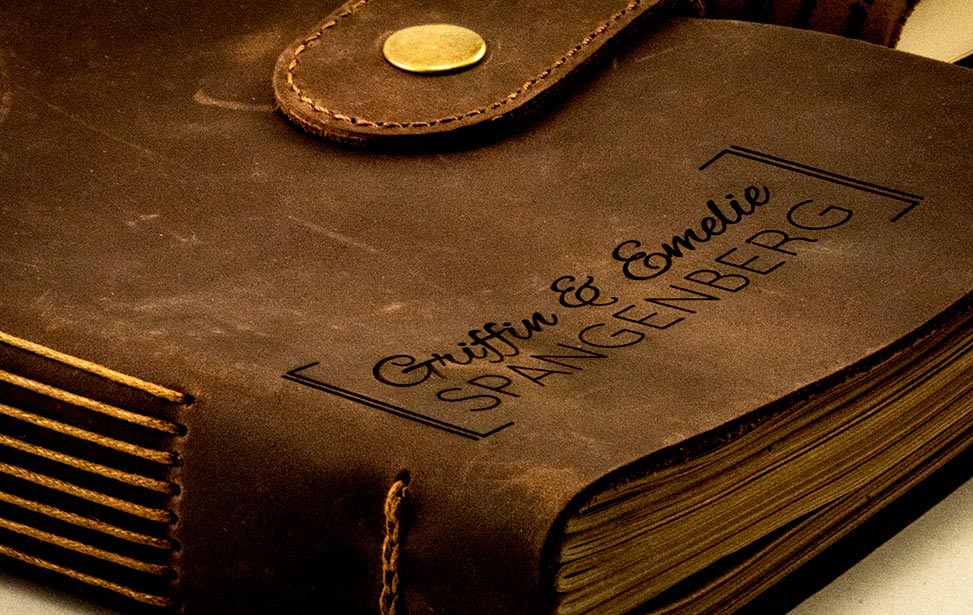

Leather Laser Engraving

I often use laser engraving machines on leather, popular for fashion, accessories, and crafts. A CO₂ laser produces sharp, permanent marks without tearing or discoloring. Fiber lasers are usually unsuitable for leather.

My Top Laser Recommendation

I recommend a CO₂ laser engraving machinefor natural or synthetic leather. It can create logos, patterns, text, and barcodes. Entry-level systems start around $2,000, while higher-power or automated setups range $6,000–$10,000+.

The Results and How It Works

CO₂ lasers vaporize the leather surface without contact, preventing damage. Adjusting power and speed lets you achieve light etching or deeper designs. Marks are durable, high-contrast, and visually appealing.

Examples: I’ve marked wallets, belts, bags, shoes, and furniture. Marks remain precise and long-lasting, even with regular use.

Things to Think About

Clean, dry leather gives the best results. Fume extraction is essential. Smooth leather provides sharper contrast, while textured leather may need slight setting adjustments. CO₂ lasers are fast, reliable, and cost-effective for custom and high-volume work.

Rubber Laser Engraving: Methods, Results, and Key Insights

Glass Laser Marking: Techniques, Machine Choices, and Practical Results

I often use laser marking on glass for drinkware, awards, car parts, and screens. Laser engraving creates lasting, detailed marks without cracking or chipping.

My Top Laser Recommendation

A CO₂ laser works best, producing clean, permanent frosted marks without touching the surface.

The Results and How It Works

CO₂ laser engraving machines vaporize a tiny portion of the glass, leaving frosted logos, serial numbers, barcodes, and graphics. Depth and contrast are adjustable by laser speed and power. The non-contact process prevents cracks or weakening.

Examples: I’ve marked wine glasses, trophies, lab tools, and automotive switches. Marks stay sharp and durable even with washing, sunlight, or handling.

Things to Think About

Start with a clean, smooth surface. Colored, textured, or curved glass may need testing. Marking is fast, and automated systems can handle hundreds per hour. Fume extraction is essential due to fine dust.

Stone Laser Engraving (Marble, Granite)

I use laser engraving on stone like marble and granite for construction, memorials, art, and signs. It creates detailed, permanent, and customizable designs.

My Top Laser Recommendation

A CO₂ laser solution works best, vaporizing a thin layer to leave high-contrast marks. Fiber lasers aren’t effective on stone. Entry-level machines start around $2,500, while industrial laser engraving machines can reach $10,000–$25,000.

The Results and How It Works

Marks can be frosted or bright depending on stone color. The non-contact process avoids chipping or cracking. I can engrave text, logos, photos, and decorative borders on flat or curved surfaces. Marks are durable and weather-resistant.

Examples: I’ve engraved office signs, memorial plaques, architectural panels, and personalized stone gifts.

Things to Think About

Use high-power lasers (60–200W) for deep engraving; lower power for shallow marks. Clean, polished surfaces give the best results. Rough stones may need multiple passes, and fume extraction is essential.

Painted Metal Laser Engraving

Laser marking works well on painted or powder-coated metals in industries like automotive, electronics, and industrial equipment. It creates permanent, precise marks without damaging the underlying metal.

My Top Laser Recommendation

Use a fiber laser to remove paint and reveal the metal. For delicate or heat-sensitive coatings, a UV laser works best. Entry-level fiber systems start around $2,500, while advanced or UV setups can exceed $12,000.

The Results and How It Works

Fiber laser engraving machines produce sharp white, silver, or black marks, while UV lasers give smooth, detailed marks with no charring. The non-contact process protects thin or delicate metals. I’ve marked serial numbers, barcodes, logos, and warning signs on electrical boxes, auto panels, and control equipment. Marks are durable and weather-resistant.

Examples: Common applications include car chassis, shipping containers, branded electronics, and outdoor signage.

Things to Think About

For optimal results, ensure the paint provides good contrast and the surface is clean, dry, and cured. Marking is fast and cost-effective, and fume extraction is essential for safety.

Summary

Whether you’re an entrepreneur, manufacturer, or craft enthusiast, the right laser engraving machine can add real value to your products. With its high precision, non-contact operation, and durable marking capabilities, you can easily create custom branding, anti-counterfeiting marks, and unique gifts. Choose a laser engraving machine today and make your products stand out, professional, and truly unforgettable. Ready to learn more? Contact us now for expert advice on laser marking machine.