Imagine a world where every product—from your smartphone to your car engine—carries a permanent, precise digital fingerprint. In 2025, laser markers are no longer just tools for basic engraving; they are transforming industries with innovative applications that boost traceability, ensure safety, and support greener production. In this article, we’ll explore the top 3 groundbreaking uses of laser markers that are reshaping the future of manufacturing and everyday life.

1. My Take on AI Color Laser Marking in Smart Factories

From my perspective, AI color laser marking is a game-changer for smart manufacturing in 2025. These systems offer amazing automation. They use data to control everything. This gives factories more flexibility than ever before.

Better Processes and Saving Energy in Real Time

I find that smart AI programs can watch and adjust color laser markers as they work. This allows factories to produce more items while using less power. The system adjusts the marking settings on the fly based on live feedback. This means the quality stays high, even when making a lot more products.

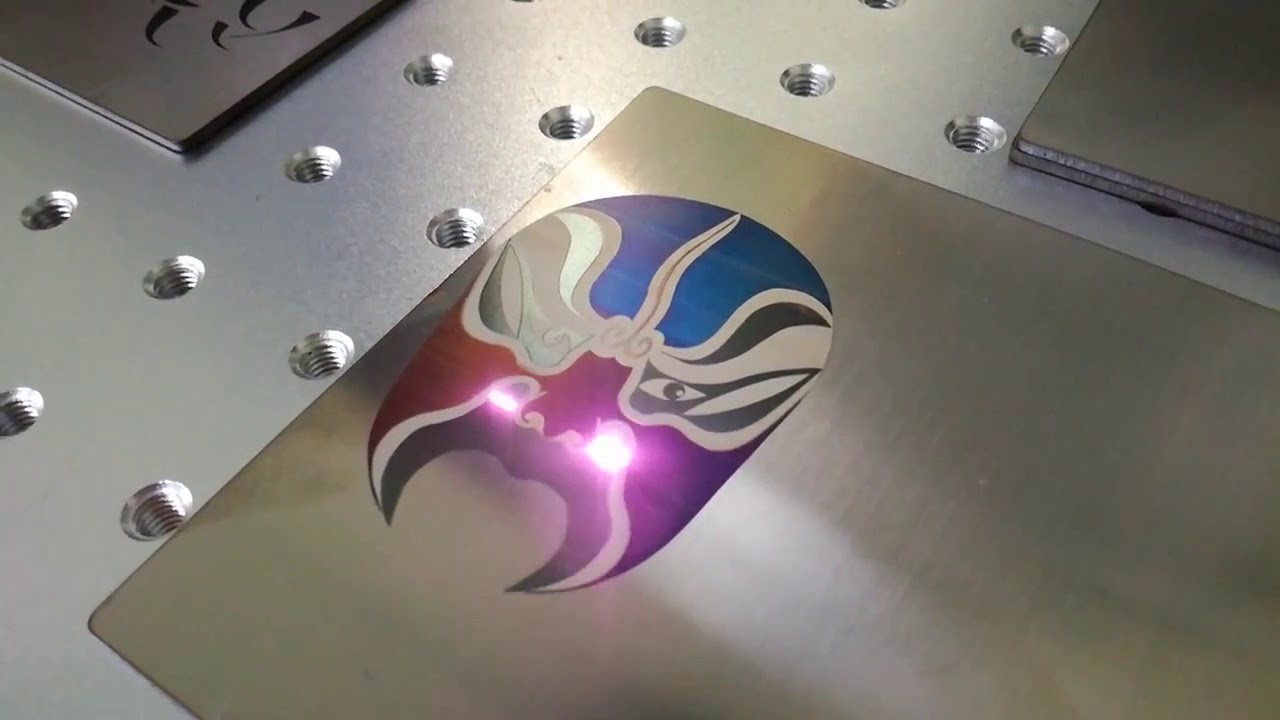

Making Custom Products on a Large Scale

Because these laser marking systems are flexible with color and use AI to make changes, I believe companies can truly personalize products for everyone. For instance, electronics brands now mark millions of devices with bright company logos and required symbols. The system adjusts for small changes in a product’s surface or material. The best part is, it does this without stopping the production line.

Cutting Down on Waste and Costs

The high accuracy from AI means less waste and fewer bad markings. Today’s smart factories using these systems report scrap rates below 0.5%. I think this is a huge step up. Old methods had scrap rates of 2% to 5%. This big difference saves a lot of material and money.

Case Study: Electric Vehicle Battery Pack Labeling

In my experience, I’ve seen EV makers in North America use these AI systems. They label battery packs quickly and without any mistakes. Each battery gets a clear mark with colored serial numbers and QR codes. These markings are readable by both people and machines. They also improve how a product is tracked and prove it’s genuine throughout its life.

Their Place in the Industry 4.0 World

In my opinion, AI color laser markers are a must-have for Industry 4.0. They work with digital models of factories, connect to the Internet of Things (IoT), and use cloud data. They also help track a product from start to finish. I believe these features give companies a real edge, and they are changing what smart, connected factories will look like in 2025.

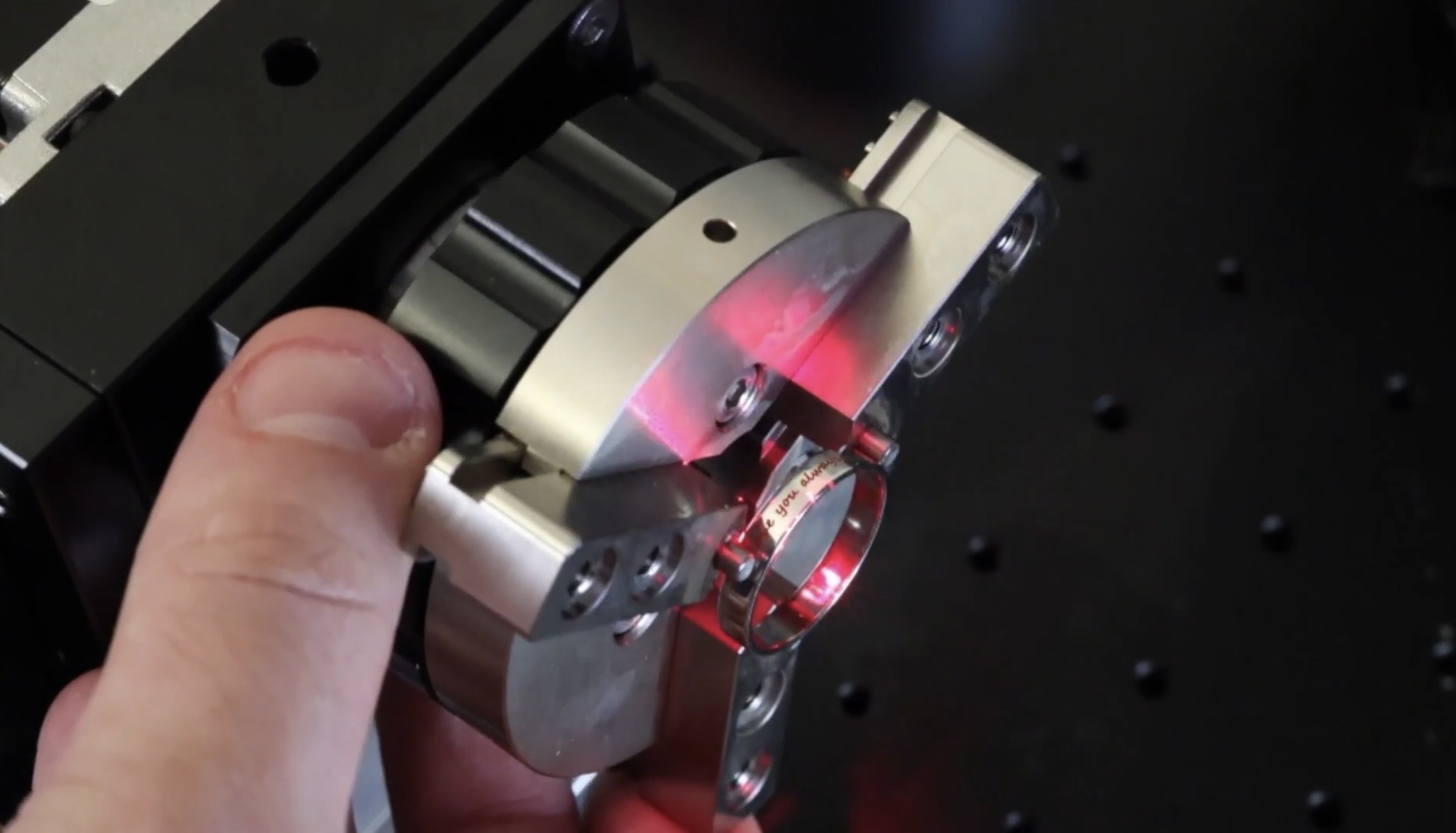

2. 3D and Multi-Axis Laser Marking for Tricky Shapes: Better Marking on Curved Surfaces

In my experience, 3D and multi-axis laser marking is changing how we mark difficult shapes in 2025. These systems change focus and move on several axes. This lets them mark curved, stepped, and uneven surfaces. Standard 2D laser machines can’t do this. I’ve found you get sharp, clear, and lasting marks on even the toughest surfaces.

New Technology: Lenses That Tune Focus in Real-Time

I think the biggest leap forward this year is the focus-tunable lens. These lenses adjust their focal length instantly. This allows the laser to trace 3D shapes with incredible precision. You get a clean, high-quality mark every time, even when the surface depth or angle changes.

Works on Many Different Materials

I’ve found that modern 3D laser marking systems work well on metals, plastics, ceramics, and glass. This flexibility is great for any industry needing a reliable marking tool. It works on almost any material texture or finish.

I Suggest Fiber Lasers for Speed and Efficiency

Based on my experience, fiber lasers are the top choice for 3D jobs in 2025. They use less power and work very fast. I’ve found they are great for marking tricky and reflective metals like copper and brass. Because they can handle difficult shapes and reflective surfaces, more and more advanced manufacturers are using them.

Real Performance Gains

- Faster Production: You don’t have to move parts around. This makes marking quicker, and it’s great for designs that wrap around an object.

- High Precision: You can get micrometer-level detail. This allows for detailed graphics, lots of data, and personal touches on uneven parts.

- Easy Customization: I see brands creating custom marks for every product. This improves part tracking and makes the product look better.

Where I See it Being Used

- Automotive: I recommend this for marking serial numbers and logos on uneven parts like engine blocks or exhaust pipes. The marks stay sharp and easy to read.

- Aerospace & Defense: Parts in tough conditions get strong, detailed marks for identification and tracking. I’ve seen some companies cut assembly time by almost 20%. They did this by marking odd-shaped parts directly, which also helped parts fit better and speed up quality checks.

- Medical Devices: You can create marks on surgical tools and implants that meet regulations. These marks last through sterilization and constant use.

- Electronics: I like how you can make unique, tiny marks on curved cases and circuit boards. The resolution is so fine it meets the industry’s tough standards.

- Jewelry & Watchmaking: Demand is high for detailed engravings and colorful designs on high-end, uneven metal items.

My Take on 2025 Market Trends

I see the demand for 3D and multi-axis marking growing fast. This is because of tougher industry rules and a greater need for custom products. Companies also need better ways to track parts in their global supply chains.

I believe 3D and multi-axis laser engraving system gives companies a real advantage. It helps with clear identification, branding, and quality control on parts where size and shape are a challenge.

3. Sustainable Marking: Using Less Energy and More Materials

From my perspective, sustainability is shaping the future of laser marking technology for 2025. I see the main goals are to use less power and work with different materials. This supports green manufacturing in every industry.

Energy Efficiency & Environmental Impact

New laser marking systems cut energy use by 30–40% compared to old ink or mechanical methods. I find this impressive because it lowers power bills and reduces the carbon footprint for each item. A key benefit I always point out is that there are zero consumables. You don’t need inks, chemicals, or labels. This greatly reduces running costs and trash. Because laser marks are so precise and permanent, I’ve seen many companies lower their product rejection rates by over 20%.

In my experience, laser marking is a great way for companies to meet strict environmental and carbon-reduction rules. Global funding is now focused on green manufacturing. This is why more businesses are choosing these cleaner marking options. As a result, we see a clear drop in harmful volatile organic compound (VOC) emissions.

Multi-Material Adaptability

I believe the ability of laser markers to handle different materials is a major advantage:

– Green lasers mark sensitive items like microelectronics, medical devices, glass, and polymers with high accuracy and no heat damage.

– CO₂ lasers are what I recommend for contact-free marking on wood, acrylic, and even living tissues.

– Fiber lasers create fast, tough marks on metals. They are a top choice in automotive, aerospace, and industrial tools for dependable serial numbers and tracking labels.

This adaptability allows one factory line to mark many different products quickly and dependably.

Durability that Drives Less Waste

Laser marks are made to last. They are permanent, clear, and can handle tough conditions. The marks do not fade from chemicals or wear. This means barcodes and serial numbers can be read for the entire life of the product. Based on what I’ve seen, this reduces the need to rework or re-label parts. This is a huge benefit for medical devices, aerospace parts, and drugs, where clear, trustworthy marks are essential. The outcome is less waste and big savings on materials.

Circular Economy & Product Traceability

Permanent, machine-readable laser marks are essential for circular economy models. I suggest them because they allow for exact product tracking and make recycling and material recovery easier. Top car and airplane makers use laser marking for live inventory control and smoother recycling. This improves sustainability through the whole product life cycle.

Market Trends & Implementation

The laser marking machine market is expected to reach $3.36 billion by 2025, growing at 7.8% annually. Key sectors include automotive, aerospace, medical devices, and electronics. Rising demand for portable and automated solutions gives manufacturers efficient, scalable systems that adapt quickly to production needs. In addition, government regulations and supply chain programs are driving adoption to meet ESG goals and green standards.

Real-World Examples

- AI-driven laser systems adjust energy use and marking settings all the time. This maximizes uptime and cuts energy waste.

- I recommend green lasers for tasks like those at major chipmakers like Intel and TSMC. They make low-damage, sharp marks on delicate electronic and medical components.

- Fiber and CO₂ lasers are key to automatic production lines at machine tool factories, such as Haas Automation and DMG Mori. Here, full traceability in labeling is crucial for their sustainability efforts.

To sum up, I believe efficient laser marking that works on many materials is the new standard for green manufacturing in 2025. It creates durable, high-quality results, lowers energy use and waste, and is now essential for companies that want to meet new global sustainability goals.

Summary

As we move into 2025, these innovative applications prove that investing in a laser marker is more than just upgrading equipment—it’s about staying ahead of the curve. Whether you’re a manufacturer seeking efficiency, a business owner aiming for compliance, or an innovator looking to stand out, the right laser marking machine can unlock new opportunities. Now is the perfect time to explore these technologies and choose a solution that drives precision, sustainability, and growth for your business. Ready to learn more? Contact us now for expert advice on laser marking machines.