| Aspect | MaxWave | Laser Photonics |

|---|---|---|

| Price | More affordable($3,500-$8,000) | Higher priced($4,000-$12,000) |

| Ease of Use | User-friendly | Steeper learning curve |

| Applications | Metals, molds, antiques, coatings, etc. | Mainly industrial use |

| After-Sales Support | 24/7 global service | Mainly regional support |

| Performance | Efficient cleaning with low energy consumption | Stable performance for large-scale projects |

Maxwave vs. Laser Photonics: Laser Cleaner Cost Breakdown

Maxwave Laser Cleaner Pricing

Product Range: From my experience, Maxwave offers a good variety of laser cleaning machines. They seem to work for many different industrial jobs.

300W Pulsed Laser Cleaners: For these models, expect to pay between $8,000 and $12,000. The final price changes based on the machine’s setup and any custom features you choose.

Continuous Wave Handheld Models:

- 1500W systems: Start from $3,500

- 2000W units: Are around $5,500

- 3000W machines: Go up to $8,000

100W–500W Pulsed Handheld Models: These are priced between $3,000 and $8,000.

High-Power Handheld Cleaners: These powerful handheld cleaners cost over $8,000.

Laser Photonics Laser Cleaner Pricing

Industrial Systems: Laser Photonics targets tough jobs with its industrial systems. I find these laser cleaning systems have advanced setups and more power.

- High-End Industrial Models: Their top industrial models will cost between $50,000 and $70,000.

Handheld CT-100 Series: If you need a more affordable option, I suggest looking at their Handheld CT-100 Series. The price for these is $4,000 to $12,000.

Price-to-Feature Value

Maxwave: I recommend Maxwave laser cleaner if you need a good balance of price and performance. It’s a great choice for standard cleaning tasks or for a new business.

Laser Photonics: In my opinion, Laser Photonics is the way to go for heavy-duty industrial work. You will need a larger budget, but you get advanced tools for your projects.

Key Takeaway

Maxwave laser cleaners are more budget-friendly to get started with. I see this most clearly with their mid to high-powered handheld models. Laser Photonics systems are premium-priced. I believe the higher cost is fair because they have better features and a stronger industrial build.

My advice is to consider your initial budget and your specific cleaning needs. This will help you make the right decision.

Maxwave vs. Laser Photonics: Laser Cleaner Specification & Performance Breakdown

From my experience with laser rust removers, a few key differences between Maxwave and Laser Photonics pop up. Both brands are in the industrial laser cleaning space, but I find they each have unique strengths and options.

Maxwave Laser Cleaner Specifications & Performance

- Power Range & Model Highlight: Maxwave offers a power range from 100W to 2000W. I like that their popular MW-LY300 model has 300W of power and weighs just 47kg, which makes it very portable.

- Wavelength: It uses the standard 1064nm wavelength. This gives you deep, even cleaning on many types of materials.

- Cleaning and Scan Area: Cleaning areas are usually 100mm to 300mm. Some handheld models can even reach 260–300mm. I think this is great because it helps you cover large surfaces in fewer passes.

- Cooling System: The portable and handheld systems use air cooling. More powerful models switch to water cooling for better heat control.

- Pulse Width & Scan Control: You can adjust the pulse width (13–500 ns or 0.1–20 ms). I find this gives you the control needed for both gentle restoration work and tough rust stripping.

- Scan Speed: It can scan up to 10 m/s. This helps speed up your cleaning jobs when time is a factor.

- Cleaning Rate: The system cleans up to 20m²/hr, which is excellent for rust removal. For example, a 1000W backpack model can clean large metal beams at this speed on a construction site. I see that as a big productivity boost.

- Fiber Length: The standard fiber is 10m long. You can extend it up to 50m, which I’ve found helpful for reaching high or distant spots.

- User Experience: In my opinion, Maxwave focuses on customization and being eco-friendly. The portable “backpack” design is a great fit for jobs on scaffolding or in small workshops. The wide focal spot option (0.6 to 3mm) lets you do fine-detail and wide-area cleaning with one tool.

Laser Photonics Laser Cleaner Specifications & Performance

- Power Range & Flagship Options: Laser Photonics cleaning systems go from 100W up to 3000W. Their industrial IR-3040 model stands out to me because of its high output.

- Wavelength: It also uses the standard 1064nm, just like Maxwave.

- Mode Versatility: Depending on the model, you can choose between continuous wave and pulsed modes. This supports both handheld and fixed setups for various jobs.

- Cooling System: The cooling system—air or water—depends on the model’s power and how you plan to use it.

- Weight: Their industrial-grade units are heavier. They do offer lighter handheld models for fieldwork.

- Precision & Control: They are known for advanced laser ablation. This gives you more precision, which is great for sensitive restoration or cleaning layered materials.

- Turnkey & Custom Solutions: They serve a wide range of needs. You can get a ready-to-use unit for your shop floor or a fully custom-built solution for a special industrial job.

Key Feature & Performance Comparison Table

| Feature | Maxwave | Laser Photonics |

|---|---|---|

| Power Range | 100W–2000W | 100W–3000W |

| Cleaning/Scan Area | 100–300mm (260–300mm backpack) | Varies by model |

| Cooling Method | Air (≤500W), Water (>500W) | Air/Water (custom by model/power) |

| Weight | 17kg (backpack), 47kg (MW-LY300) | Heavier, varies by model |

| Pulse Width | 13–500ns, 0.1–20ms | Pulsed/Continuous, model-dependent |

| Scan/Operating Speed | Up to 10m/s | Varies; optimized for each machine |

| Precision/Control | Multi-mode scans, wide focal spot | Advanced ablation, selective removal |

| Portability | High (especially backpack and MW-LY300) | Lower—mostly with handheld lines |

| Cleaning Rate | Up to 20m²/hr (rust removal) | Model-dependent |

To sum it up, I think both brands offer great, modern laser cleaning solutions. I recommend you choose the best fit based on your need for mobility, power, and precision for your specific job.

Maxwave vs. Laser Photonics Laser Cleaner: A Look at Their Core Technologies

Maxwave and Laser Photonics both offer unique laser rust removal machines. Each is built for different jobs. Let me show you a direct comparison of their unique technologies and what they can do in the real world.

Maxwave’s Unique Technologies

Customizable Interface & Multilingual Support

With Maxwave, I like that you can customize the interface. You can add your own logo and change software settings. From my experience, this is a big plus for businesses that want their own branding or have global teams. The multi-language support helps users from different countries work together.

Portable & Handheld Innovation

Maxwave designs many of its models to be portable. For instance, the MW-LY300 weighs just 47kg and has a built-in air cooling system. This means you can carry it for on-site jobs. I find this essential for crews who work in new locations each day.

Multiple Cleaning Modes for Versatile Use

Maxwave gives you up to 8 different cleaning modes. You can pick the right mode for the job, whether it’s rust, grease, paint, or grime. I believe this flexibility is great because you can use one tool for many different tasks.

Tough Quality Assurance

I’m impressed by Maxwave’s 48-hour factory test. Each machine is checked thoroughly before it’s shipped to ensure it works well. This gives me peace of mind, which is important for tough industrial jobs.

Laser Photonics’ Advanced Features

Ready-to-Use and Custom Systems

Laser Photonics is great because they offer ready-to-use cleaners and custom systems for specific industries. I suggest them if you need a simple shop floor setup or a special solution for a unique job. This is perfect for industries that need specific performance.

Top-Tier Laser Ablation Technology

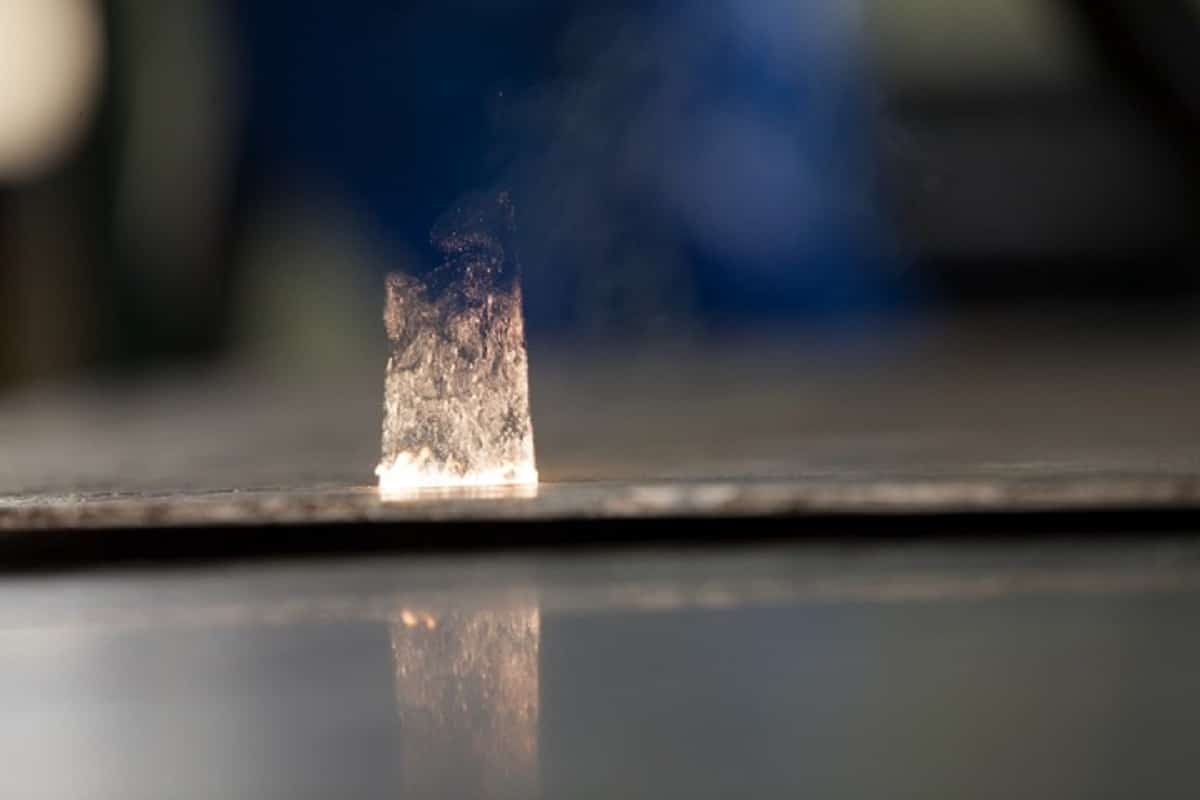

Their unique laser ablation method is impressive. It cleans without contact and is very precise, removing one layer at a time. It even works on delicate or old surfaces. I think this level of precision is critical for aerospace, restoration, and high-value manufacturing.

Universal Application

These systems are very adaptable. You can use them on metals, thermoplastics, composites, and other tough materials. In my book, this makes Laser Photonics a solid choice for companies with varied projects.

Green, Controlled Cleaning

The process is good for the environment. It uses no extra materials and creates very little waste. It’s a safe option compared to older methods like abrasive blasting. I believe these green benefits are becoming more important as industries adopt sustainable methods.

Quick Feature Comparison Table

| Feature | Maxwave | Laser Photonics |

|---|---|---|

| Interface Customization | Add your logo, adjust functions, multi-language | Custom setups for each client |

| Portability | Light models, some down to 47kg | Offers custom and portable models |

| Cleaning Modes | Up to 8 cleaning modes | Modes optimized for each machine |

| Quality Assurance | 48-hour test on every unit | QA specific to the industry/unit |

| Laser Precision | Multiple modes for different materials | High-precision, non-contact cleaning |

| Eco-Friendly | Standard environmental benefits | No extra materials, little waste, very safe |

My view:

Based on my experience, I recommend Maxwave if you need a flexible, portable laser cleaner that you can customize. It’s great if multi-language support and quick setup are important. I would pick Laser Photonics for jobs that require extreme precision, custom systems, and an eco-friendly process, especially for difficult or sensitive tasks.

Maxwave vs. Laser Photonics Laser Cleaners: Who Are They Best For?

Best Suited Users for Maxwave Laser Cleaners

Maxwave laser machines for cleaning are best for users with limited budgets who want lower upfront costs and those who need flexibility in their work. They are especially well-suited for contractors, field workers, and technicians who travel frequently, as well as companies that require cross-country support or multi-language menus. Overall, Maxwave is an excellent option for anyone looking for a versatile tool capable of handling a wide range of cleaning tasks.

Best Suited Users for Laser Photonics Laser Cleaners

Laser Photonics laser cleaners are designed for large enterprises that need durable, high-performance machines. They are a strong choice for companies managing large-scale projects or specialized cleaning needs, and for users who place a premium on power, precision, and reliability. In particular, they appeal to professionals working in highly regulated industries who require the safest and most eco-friendly cleaning solutions available.

Summary

At the end of the day, the best choice depends on your needs: Maxwave is ideal for entrepreneurs and teams seeking a cost-effective, flexible, and easy-to-use laser cleaner, while Laser Photonics is the go-to option for enterprises that require unmatched power, durability, and precision. If you’re ready to get started with a practical solution that balances performance and price, I highly recommend the Maxwave laser cleaner—a trusted tool that helps you clean smarter, faster, and safer. Contact us today to learn more and find the right laser cleaner for your business.