Choosing the right laser cleaner can make a huge difference in efficiency, cost, and results. Handheld units offer mobility and precision, perfect for on-site repairs and delicate restoration, while stationary systems bring automation and consistency, ideal for high-volume industrial cleaning. Knowing which one fits your needs can save time, reduce labor, and protect your valuable equipment.

| Feature | Handheld Laser Cleaner | Stationary Laser Cleaner |

| Flexibility | High, ideal for on-site and mobile work | Low, requires fixed installation |

| Precision | High, good for detailed or complex parts, but depends on operator skill | Consistent and automated, ideal for standardized parts |

| Operation | Manual, requires direct control | Automated, minimal manual intervention |

| Setup | Quick, mostly plug-and-play | Complex, needs permanent location and safety measures |

| Applications | Field service, restoration, automotive maintenance, small-batch production | Industrial production lines, large-scale standardized parts, high-throughput environments |

| Training | Easy to start, but detailed work needs practice | Technical at first, but ensures consistent results |

Choosing Your Laser Cleaner: Mobile or Fixed

If you’re choosing between handheld and stationary laser cleaners, I think mobility is a key factor. It becomes very important if your cleaning jobs are in different places or involve items of different sizes.

Portability and Ease of Use

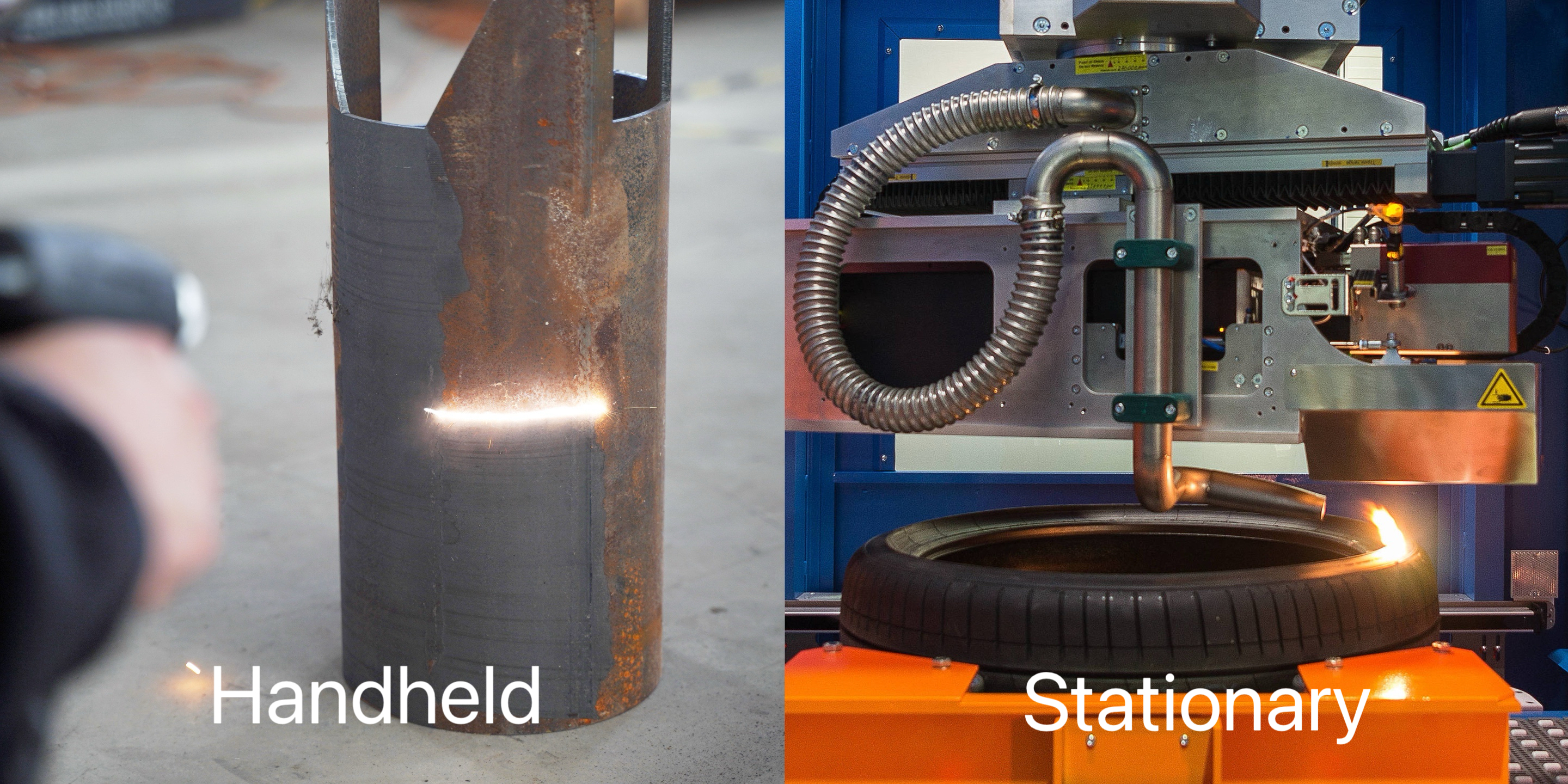

Handheld laser cleaners are lightweight and portable, perfect for on-site work. They make it easy to move around large equipment and reach tight or hard-to-access areas. Ideal for cleaning welds or restoring fixed metal surfaces that cannot be moved.

Stationary laser cleaners are fixed systems, often part of a production line. Though less flexible since items must be brought to them, they work best for factories with steady workflows and consistent parts needing regular, efficient cleaning.

Adaptability to Various Work Environments

- Handheld systems work well in different job sites and settings. Based on my experience, they are very useful on construction sites, in shipyards, and at repair shops because you can use them anywhere.

- Stationary systems are best in controlled setups. I recommend them when doing the same task over and over is more important than moving the cleaner around.

From my perspective, handheld cleaners give you great mobility for a variety of tough jobs. Stationary systems are the clear choice for production environments with steady and predictable tasks.

Laser Cleaner Comparison: Power and Efficiency

Comparing the cleaning power of handheld and stationary laser cleaners shows that both the technology and how you use them make a big difference.

Cleaning Power Range

Handheld Laser Cleaners: From my experience, handheld systems give you a wide power range. Some models start at just 20W, which is perfect for light rust or simple surface dirt. Stronger handheld units can reach 1000W. They can handle tough industrial messes. The final cleaning result, though, depends a lot on the user’s skill and technique.

Stationary Laser Cleaners: Engineers design stationary systems for top power and consistent results. You can set them up with even more output. This makes them a good choice for removing thick coatings, tough buildup, or for non-stop, heavy-duty cleaning. I recommend these setups for large industrial jobs that need deep cleaning.

Efficiency & Duty Cycles

Handheld Systems: I find these are great for quick setups and smaller jobs in specific spots. Using them for a long time can make the operator tired. This can affect how consistent and efficient the cleaning is. This is a big factor when you have large jobs or long work shifts.

Stationary Systems: In contrast, stationary laser cleaners are built for efficiency. They can run at full power for a long time. The user getting tired does not affect performance. This makes them work great for continuous or repeating jobs. I think this is key for production lines where getting the same result every time matters.

Consistency and Operator Influence

Handheld Units: The final result can change based on the user’s experience or care. Operating the machine by hand creates more variation. This can limit how efficient and uniform the results are on long jobs.

Stationary Machines: These machines use automated controls. You can fine-tune them to use the best cleaning settings every time. Based on my experience, this design gives you stable results you can count on.

In summary:

If you need flexibility for different tasks or smaller jobs, I suggest a handheld laser cleaner. It gives you enough power and is fast to set up. For demanding, non-stop cleaning with the best efficiency and power on heavy-duty work, I believe a stationary laser cleaner is the wiser investment.

Precision & Control: Choosing the Right Laser Cleaner

For laser cleaning, I believe precision and control are the most important factors. This is true if you’re working on delicate surfaces or parts with complex shapes. Your choice between a handheld and a stationary laser machine for cleaning determines the control and accuracy you’ll get.

Fine-Tuning Cleaning on Small Parts

Handheld Laser Cleaners: Handheld units offer flexibility for cleaning small, detailed, or oddly shaped surfaces. They can remove just the top layer of rust or paint with high precision, but results depend on the operator’s skill and steadiness. Beginners may find it harder to achieve consistent quality, making them better for custom, detailed work.

Automated Consistency for Large Volumes

Stationary Laser Cleaners: Stationary units deliver consistent, precise results across large volumes. Ideal for automatic setups and identical parts, they ensure uniform quality every time. However, they are less suitable for complex shapes or detailed touch-ups.

Operator Influence and Quality Control

- Handheld: The quality of the work depends on your skill and steady hands. You can move it around easily, but the results might differ each time.

- Stationary: This process is more automatic. It provides the same result every time. I suggest it for big production jobs where every piece must be identical.

To sum it up:

I recommend a handheld laser cleaner for detailed jobs that need careful manual control. If you have a large number of items and need the same result every time, I believe a stationary laser system is the better choice.

Usability & Setup: Choosing the Right Laser Cleaner

If you’re choosing between a handheld and a stationary laser rust cleaning machine, I think the biggest differences are how you use them and set them up. Let’s look at what you can really expect with each one.

Handheld Laser Cleaner: Quick Setup and Flexible Operation

Handheld laser cleaners are mostly plug-and-play and require minimal training, making them ideal for teams with varying experience. Each job site needs a temporary safety zone, and manual operation gives direct control, though long sessions can be tiring. They are best for maintenance teams, repair services, or mobile jobs where fast setup and flexibility are key.

Stationary Laser Cleaner: Advanced Installation and Automated Use

Stationary laser cleaners need a dedicated installation, but their built-in safety enclosure simplifies safety. Once set up, they offer automated operation that reduces labor, handles large or repeated jobs efficiently, and delivers consistent results with minimal operator effort. They are best for production lines and factories performing repeated cleaning tasks without moving the equipment.

Usability Summary

- I recommend a handheld laser cleaner if you need speed and want to move it around. You get direct control, but remember that operators can get tired during long jobs.

- I’d go with a stationary laser cleaner if you have space for a permanent setup. It’s ideal if you want an automated system that handles large amounts of work with little effort.

Laser Cleaner Comparison: Applications and Use Cases

To help you choose between a handheld and a stationary laser cleaner machine, I think it’s best to look at where you’ll use it. This will help you make a smart investment. Each type is suited for different industries and tasks.

Handheld Laser Cleaner Applications: Field Flexibility & Custom Jobs

Handheld laser cleaners are ideal for field service and onsite repairs, including factory maintenance, construction emergencies, and hard-to-reach areas. They excel in restoration work, small-batch manufacturing, and automotive maintenance, offering precise control and flexibility for parts of different shapes and sizes. They are also perfect for immovable or hard-to-transport items, allowing on-site cleaning with minimal downtime.

Stationary Laser Cleaner Applications: Industrial Scale & Consistency

Stationary laser cleaners fit perfectly in industrial production lines for constant surface cleaning. They provide automated cleaning of standardized parts, ensuring consistent results and boosting productivity. Essential for mass manufacturing of cars, electronics, or metal parts, they deliver fast, reliable cleaning without operator fatigue, keeping high-throughput operations on track.

Choosing for Your Needs

- I suggest a handheld laser cleaner if you need to work in different places. It’s also great for careful, detailed work or if your jobs change often. It’s a good fit for restoration work or for repair teams on the move.

- Based on my experience, a stationary laser cleaning system is a good investment for large factories. I’d recommend it if you need to produce a lot of standard parts using automation. It will become a key piece of your production plan.

Laser Cleaner Comparison: Maintenance and Longevity

I’d like to compare handheld and stationary cleaning laser machines on maintenance and durability. Based on my experience, each type has its own strengths and weaknesses you should know about.

Durability in Real-World Conditions

Handheld Laser Cleaners: These cleaners are built for tough, changing environments. Most low-to-mid power models use simple air cooling, which I find is a plus. It means fewer parts can break, lowering your immediate maintenance worries. For high-power handheld units, the needs increase. Moving and operating these machines by hand raises the risk of accidental bumps and drops. Exposure to dust also becomes a bigger problem, which can lead to more wear and repairs over time.

Stationary Laser Cleaners: These are built as industrial workhorses for long-term use. Stationary systems often use advanced water cooling. This keeps the internal parts at a good temperature during long jobs. Since you don’t move these units, there is much less physical stress on delicate components. I believe this results in a lower risk of the accidental damage that can happen with portable machines.

Maintenance Requirements & Cost

Handheld Units: If you do many on-site jobs in rough conditions, I suggest you plan for some upkeep. Common tasks include cleaning air filters, checking cooling fans, and inspecting the lens after you move it. Higher power handhelds make more heat, so they may need more frequent maintenance to prevent extra wear.

Stationary Units: Fixed machines require less attention from operators. You still need planned maintenance, like water cooling checks and system diagnostics. The risk of sudden failures from being dropped or handled poorly is far lower. From what I’ve seen, servicing is more predictable. You can schedule it during production downtimes.

Longevity & Risk of Damage

Handheld Machines: Their best feature is flexibility. Moving them between job sites, however, increases the chance of accidental damage. Dropped units, dirty work areas, and poor power sources can all shorten the machine’s life if you are not careful.

Stationary Machines: With a stable, fixed setup, I find there’s less that can go wrong. No movement means a smaller chance of hard impacts or cable damage. These systems give you a longer service life and fewer surprise repairs. I recommend them if your top priority is keeping downtime to a minimum.

In short:

My recommendation is that handheld laser cleaners are tough enough for fieldwork but will need more frequent care. This is particularly true for high-power models that you move often. Stationary systems are top performers in durability and low-maintenance needs. This makes them a strong choice for heavy industrial work where uptime is essential.

Laser Cleaner Comparison: Cost & Investment

Let’s compare the cost of handheld and stationary laser cleaners. I think it’s crucial to see where your money goes. Each type has a different price and offers different value, both now and in the future.

Initial Investment & Pricing

Handheld laser cleaners have a lower starting price than stationary ones. I find them to be a good value if you need to move around and work on smaller projects. The final price changes based on its power and the quality of its parts. For instance, a simple, low-power handheld cleaner will cost less. From my experience, it won’t clean as strongly, though.

Stationary laser cleaning machines cost a lot more to start with. Their price is higher because they need to be installed in one place. They also have more power and automatic functions. I see these machines built for tough, non-stop jobs. The higher price matches their ability to work in an industrial setting.

Long-Term Cost Efficiency

In my opinion, handheld laser cleaning systems are a smart buy if you have many different jobs in different places. Their low initial cost is very appealing. I suggest using them for smaller jobs or repair work. This is where you save the most money per job because they are so flexible.

Stationary laser cleaners are different. I see them built for making lots of items around the clock. For big, repetitive jobs, this means the cost to clean each part goes down a lot over time. If you need to produce a high volume of items with the same quality every time, I believe the higher initial cost makes sense.

Personal Evaluation

Based on my experience, the right choice depends on how big your jobs are and what kind of work you do. I recommend a handheld system if you need to be flexible and control costs for different small or medium tasks. It keeps your initial spending low. For large factories with automated processes, every minute the line is stopped costs money. In that case, I’d say a stationary cleaner is the smarter long-term purchase, even though it costs more at first.

Laser Cleaner Comparison: Training & Operator Skill

When I think about laser cleaning systems, operator training and skill are key. They affect how much work you get done and your quality control. This influences your cleaning results, daily efficiency, and workplace safety.

Training Needs for Handheld vs. Stationary Lasers

Handheld Laser Cleaner Training: From my experience, starting with a handheld laser cleaner is straightforward, and you can learn the basics quickly. Achieving the best results requires practice, a steady hand, and understanding how to handle different surfaces. Results can be inconsistent, as one person may clean faster or more effectively than another, especially on detailed or uneven surfaces. Because success depends on the operator, I recommend hands-on coaching when performance is critical.

Stationary Laser Cleaner Training: Training for stationary laser cleaners is more technical initially, as you need to learn system setup, programming, and maintenance checks. Once installed and programmed, the system runs automatically, and the operator’s skill has less impact on daily results. It delivers consistent outcomes across different shifts or users, and although the initial training takes effort, it pays off with reliable, uniform work without requiring every operator to be an expert.

Operator Skill and Consistent Results

- Handheld Units: The final cleaning quality is in the operator’s hands. I’ve seen small mistakes or unsteady movements appear in the final product, which is a risk on difficult jobs.

- Stationary Systems: These systems are automated to reduce user error. Software controls the process. A new user can get consistent quality just by following the programmed instructions.

In summary:

I recommend a stationary laser cleaner if you want a system where anyone can get high-quality results after setup. If you need flexibility and a fast start—and can handle different results from different users—then handheld systems are a good fit. My advice is that good operator training and practice are essential for handhelds. Stationary machines reward you for learning upfront with simple, repeatable work later.

Summary

Whether you need flexible, on-the-go cleaning or steady, high-throughput performance, the right laser cleaner can transform your workflow. Invest in a system that fits your operations and experience the efficiency, precision, and reliability that modern laser cleaning technology delivers—your next project deserves nothing less. Contact us today to find the perfect laser cleaner for your needs!