Ever wondered how some of the world’s leading manufacturers keep their tools, machines, and surfaces spotless without slowing down production? In this article, we dive into real stories from businesses that faced tough cleaning challenges—and how laser cleaning machines transformed their operations, saving time, cutting costs, and improving quality.

Laser Cleaning in Aerospace Industry: Turbine Blade Maintenance

From my experience, laser cleaning machine has changed how we maintain turbine blades. It provides a precise, no-touch method for cleaning rust, carbon buildup, and other contaminants. I think it is a far better solution than older methods like chemical baths or abrasive blasting. Laser cleaning removes unwanted material without harming the nickel-based turbine blades.

Key Results and Data from Real Aerospace Use

I’ve seen major aerospace companies reduce maintenance time and costs by up to 25% after adopting the MaxWave laser cleaning machine. This eco-friendly process eliminates hazardous chemicals and secondary waste, greatly reducing environmental impact. It also ensures surface integrity and precision, removing layers accurately without heat damage and preserving the strength of heat-resistant alloys. With precise control of ablation thresholds, such as using a Nd:YAG laser at up to 1 J/cm², it can selectively remove compounds like C, Na, Si, Cl, K, Ca, Fe, and oxides—all without melting or harming the base material.

Technological Advances and Implementation

For quick on-site work, MaxWave handheld laser cleaners are ideal, while industrial environments benefit from automated XY tables and galvo-head systems that provide uniform, high-precision cleaning. For large-scale operations, kilowatt-level pulsed fiber lasers handle tough tasks such as stripping paint and corrosion from metal and composite aircraft parts. Most importantly, the process requires no consumables like sand or chemicals, lowering supply costs and reducing hazardous waste.

Benefits for Turbine Blade Performance and Reliability

- Engine efficiency: Clean turbine blades improve the engine’s overall efficiency. This leads to better fuel consumption and performance.

- Enhanced coating adhesion: Based on my observations, laser-cleaned surfaces help protective coatings stick better. These coatings, like aluminides and thermal barriers, are critical for a blade’s long life.

- Consistency and speed: You get fast, repeatable results with controlled laser settings. This practice speeds up maintenance and reduces aircraft downtime.

- Environmental sustainability: Because it eliminates abrasive and chemical runoff, laser cleaning helps aerospace companies meet their sustainability goals. I believe this is a critical benefit.

Industry Evaluation and Evidence

Microscopy analyses (SEM, EDX, stereoscopy) confirm improved surface purity with no heat damage after laser cleaning. Aviation maintenance crews report cleaner blades, shorter turnaround times, and more reliable operation, making laser cleaning a highly effective and trusted solution in the industry.

I recommend laser cleaning machine for aerospace because it cuts down on hazardous waste, speeds up maintenance, and gives precise, repeatable results—helping parts last longer and keeping up with today’s aircraft manufacturing standards.

Automotive Industry: Laser Rust Removal Before Welding

From my experience, laser cleaner machines have truly changed how the car industry handles rust removal before welding. I’ve seen how they make surface preparation faster, cleaner, and more affordable.

Data-Driven Results in Rust Removal and Weld Quality

Car makers report that laser cleaning before welding produces cleaner joints with fewer weak spots, greatly improving weld quality. The results are striking, with some companies cutting waste by up to 90% compared to chemical or abrasive methods. Today’s laser cleaning machines can run 24/7 on automated production lines, ensuring consistent weld prep and keeping production output high.

Fiber Laser Cleaning: Precision, Safety, and Cost Savings

The focused laser beam removes rust and oxides while leaving steel and aluminum untouched, preserving material and providing consistent weld-ready surfaces. A key advantage is that no consumables like chemicals, abrasives, or solvents are needed, cutting costs and eliminating hazardous waste. With precise power control on fiber lasers, only contaminants are removed—an essential feature for thin car-body sheets and complex alloy parts.

Practical Applications in Automotive Manufacturing

- I’ve personally seen the MaxWave laser cleaning machine used on electric vehicle components. It prepares aluminum battery housings and cleans other surfaces for welding, which helps create strong bonds and coatings.

- Both OEMs and Tier 1 suppliers use laser cleaning machine for weld prep. It helps improve rust resistance on everything from big chassis parts to tiny electrical connectors.

- Factories have shown me that by removing surface dirt quickly, their welding speeds increase. This helps them meet tight production deadlines.

Enhanced Safety and Environmental Benefits

Advantages for Automotive Production

- The process is precise and selective, which I think is perfect for protecting sensitive and thin-walled car parts.

- The process adapts well to jobs of all sizes. It works on large chassis assemblies and on small connectors in new electric vehicles.

- I’ve noticed manufacturers get stronger welds and improved corrosion resistance. They also see less rework and waste. All these benefits lead to better efficiency and lower costs.

Based on what I’ve seen, I now suggest laser cleaning machine as the best choice for automotive rust removal before welding. It provides cleaner surfaces, stronger joints, less operational waste, and greater production efficiency.

Marine Industry: Hull Laser Cleaning and Maintenance

I’ve seen how laser machines for cleaning are changing hull cleaning and maintenance. In my opinion, they provide a safer and more efficient choice compared to older abrasive and chemical methods.

Key Outcomes and Business Benefits

From my experience, laser cleaning machine provides comprehensive removal of rust, chloride salts, old marine paint, and biofouling like algae and mussels without damaging the metal hull, making it a precise, surface-protecting method. Companies report up to 15% fuel savings as smoother hulls reduce drag, compared to a 30% increase from heavy buildup. Shipyards also achieve up to 40% faster cleaning, reducing downtime and getting vessels back in service sooner. Additionally, laser hull cleaningis contactless and chemical-free, enhancing worker safety by eliminating risks from abrasives, chemicals, or harmful pollutants.

Environmental and Regulatory Advantages

I appreciate that marine laser cleaning is a green process, producing zero secondary waste and no harmful chemicals, helping operators comply with strict environmental regulations in ports like California and New Zealand. At the same time, it protects the metal structure, preserving the hull’s original strength without causing micro-cracks or thinning, which extends vessel life and reduces repair needs.

Practical Applications and Real-World Success

- Versatile Use Cases: MaxWave handheld laser cleaning machines are suitable for a wide range of tasks. I’ve seen them remove rust, oxides, oil, and wax from hulls, cargo holds, machinery, and underwater structures, including offshore oil platforms and wind turbines.

- Regional Success Stories: Shipyards in the Pacific Northwest have told me they see big reductions in corrosion. Their fleets also have a longer life. In Germany’s Helgoland North Sea trial in 2024, blue diode lasers were tested for removing marine growth. They passed the port’s ecological standards while lowering both fuel and maintenance costs.

Advantages for Shipowners and Marine Operators

- Faster cleaning that requires less labor and costs less.

- Cleaner hulls that lead to better speed and reduced emissions.

- I suggest it because you get consistent regulatory compliance with simple reporting.

- You can wait longer between required maintenance cycles.

- It has great flexibility. I find it works well for small spot repairs and large-area maintenance on different marine structures.

Overall, based on what I’ve seen in the industry and from trial results, I recommend laser cleaning machine for hull cleaning and maintenance. I believe it gives you better efficiency, helps you save money, and meets modern environmental and safety rules.

Manufacturing (Plastics/Rubber): Mold and Tool Laser Cleaning

From my experience, laser cleaner has transformed how we clean molds in the plastics and rubber industry. It offers a non-abrasive, efficient way to clean materials like steel, aluminum, nickel, high-strength steel, and INVAR. I have found that this precise cleaning works on injection molds, press molds, and even composite molding tools for CFRP and GRP. I especially appreciate the minimal risk of damaging the mold’s surface.

Key Technical Data and Performance

- Laser Power Range: I’ve worked with lasers from 12 to 2,000 watts. This range is suitable for fine-maintenance tasks and for deep cleaning clogged molds.

- Cycle Times: Cleaning a tire mold takes about 30 minutes with a 300–1,000 W laser.

- Cleaning Speed: Automated laser cleaning machine systems can clean up to 22 m²/hour. This speed works well for large composite or metal molds.

- Precision Settings: I recommend using pulsed lasers at full power on small areas (like 1” x 1”). This lets you vaporize contaminants without causing thermal damage.

- Unit Longevity: I find modern laser cleaning machine units are quite durable. Some models are rated for hundreds of thousands of cleaning hours.

Real-World Results and Applications

Laser cleaning preserves delicate surfaces, protecting micro-features like vent holes and detailed engravings from damage. It produces very little waste, a major improvement over sandblasting or chemical washing. Plus, it offers excellent automation compatibility, integrating seamlessly into robotic or manual operations for flexible use at any production scale.

Industry Adoption and Broad Benefits

The MaxWave laser cleaning machine is widely used in automotive, aerospace, plastics, and composite industries for cleaning critical molds and tools. It ensures high surface quality, extends mold lifespan, and reduces cycle times and downtime, making tool changes faster and boosting productivity. Its efficiency, precision, and seamless automation make it an essential solution for industrial cleaning.

Advantages At a Glance

- No abrasives or chemicals required

- Minimal risk of tool or mold damage

- A definite reduction in cleaning time and labor costs

- Helps you meet environmental standards

- Supports both manual touch-up and automated cleaning

I believe laser cleaning machine is the top tool for extending mold and tool life. It helps you get exceptional cleanliness and improves operational efficiency in plastics and rubber manufacturing.

Laser Cleaning in Energy Sector: Pipeline Maintenance

I’ve seen more and more energy companies use laser cleaning for pipeline maintenance. I recommend it for removing corrosion, stripping old coatings, and preparing surfaces for inspection or repair. From my experience, laser cleaning systems are safer and more consistent than old methods like sandblasting. They are also better for the environment.

Laser Cleaning for Corrosion and Coating Removal on Pipelines

- Corrosion Removal Efficiency: I’ve found that laser cleaning machine is fast at removing rust, scale, and thick oil from pipelines. It works on carbon steel, stainless steel, and special alloys. The best part is it doesn’t harm the pipe’s metal. I’ve watched pipelines get a clean, metallic finish in just minutes per meter. After that, they are ready for inspection.

- Coating and Insulation Removal: Traditional methods struggle with tough coatings, such as FBE (fusion-bonded epoxy) or rubber cladding. I’ve seen high-power MaxWave laser cleaners easily strip these coatings without leaving any residue, working much faster than grinding or sandblasting—saving up to 80% of the time.

Advantages for Pipeline Operators

Laser cleaning machine provides precise, targeted cleaning, removing only the areas that need attention without damaging surrounding surfaces, including weld seams and high-stress zones. It offers enhanced safety, generating no toxic dust or chemical runoff and reducing the need for heavy PPE. As a green process, it produces no hazardous waste, helping companies meet strict environmental regulations. Additionally, it lowers operating costs by eliminating consumables like sand or solvents—cutting maintenance by up to 30%—and portable handheld systems reduce transport expenses on large projects.

Real-World Results and Business Impacts

I’ve found that laser cleaning machine significantly reduces downtime, with some operators cutting shutdown time by over 40%, keeping pipelines active and minimizing losses. It also provides improved surface preparation, leaving surfaces clean and residue-free, which helps coatings, sealants, and rust-prevention layers adhere better and extends pipeline life. For field work, I recommend modern fiber lasers because they are durable and portable, making them ideal for use on pipelines or offshore rigs compared to older, stationary equipment.

Evidence from Energy Sector Case Studies

From my experience, companies that switched to laser cleaning machine report better results in non-destructive tests (NDT) and experience fewer failed welds on pipelines. Cost benchmarking from projects in the Middle East and the US shows annual maintenance savings of 20–35%, especially on long pipelines. Moreover, laser cleaning ensures environmental compliance, such as meeting the 2024 EU low-waste maintenance rules in the North Sea, helping operators avoid fines and prevent project delays.

From my experience with real projects, I believe laser cleaning machine is a great choice for pipeline operators. It offers a safer, cleaner, and more cost-effective way to remove corrosion and old coatings. It also improves inspection results and helps pipelines last longer.

Automotive Tooling: Large-Format Forming Tool Laser Cleaning

I think cleaning laser machines have transformed how we clean large forming tools in the car industry. This method is now common for cleaning stamping dies and large molds. These parts are essential for making car bodies and frames.

Laser Cleaning for Automotive Tooling: A Data-Backed Shift

From my experience, laser cleaning machine can quickly remove stubborn residues like lubricants, adhesives, and rust from large forming tools. Traditional methods such as scraping or chemical cleaning are slow, inconsistent, and can damage tools. I like MaxWave laser cleaners because they are precise and target only the dirt, making them an excellent solution.

- Better Efficiency: I’ve noticed that factories using laser cleaning machine save up to 60% more time. This is compared to using chemicals or abrasive cleaning.

- No Contact or Damage: The laser turns dirt into vapor. It never touches the tool’s surface. This protects the tool’s shape and makes it last longer. From my perspective, this is very important because forming dies are expensive.

- Less Downtime: I’ve seen factories cut their downtime because they can clean tools right on the machine. There is no need to remove the mold. Cleaning a big stamping die used to take hours. With a powerful laser, I’ve seen it done in under one hour.

Practical Examples and Business Impact

An automotive manufacturer adopted the affordable MaxWave 3000W pulsed fiber laser cleaning machine, priced at just $7,800, to clean their stamping dies. Thanks to its high-efficiency cleaning capabilities, they significantly reduced downtime and labor costs, recouping their investment in less than 3 months. The MaxWave laser cleaning machine can cover large die surfaces in a single pass and reach deep grooves and intricate details that traditional sandblasting or chemical soaking often miss, making mold maintenance faster, more precise, and highly efficient.

Operational and Environmental Benefits

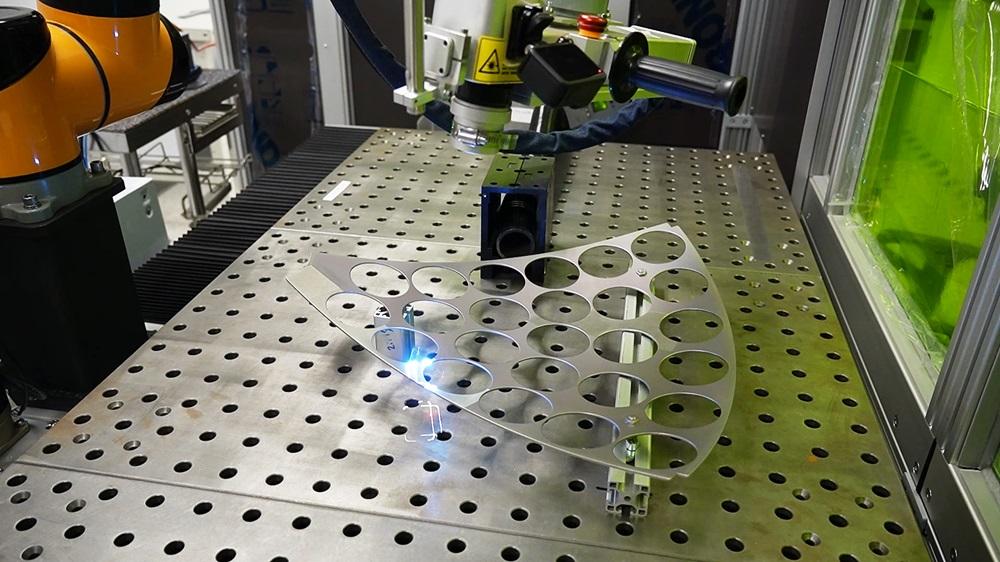

Laser cleaning is a cleaner, safer process, using no harsh chemicals, which protects staff and eliminates hazardous waste. It also keeps surfaces intact, leaving metals free of damage or micro-cracks—essential for press accuracy and high-quality parts. Additionally, it’s easy to automate, as modern laser heads can be mounted on robot arms and integrated with existing systems, delivering consistent results and fitting seamlessly into robotic tool-change cells and die maintenance lines.

Advantages for Automotive Manufacturers

- It greatly reduces labor needs. One person can run several cleaning cycles at once.

- Tools last longer and need less reworking.

- You get the same clean result for every production run. I find this essential for making lots of parts.

- It helps car factories meet ISO 14001 and other environmental standards.

From what I’ve seen in production data, laser cleaning machine is perfect for keeping large automotive tools in top shape. It’s fast, gives a better clean, protects the tools, and cuts operational costs—all crucial for a car company to stay competitive.

Summary

These real-world examples show that laser cleaning machine isn’t just a tech upgrade—it’s a game-changer for efficiency, safety, and cost savings. If you want your business to work smarter, protect valuable equipment, and stay ahead of the competition, now is the time to explore the right laser cleaning machine for your needs. Contact us today and discover how it can solve your toughest cleaning challenges.