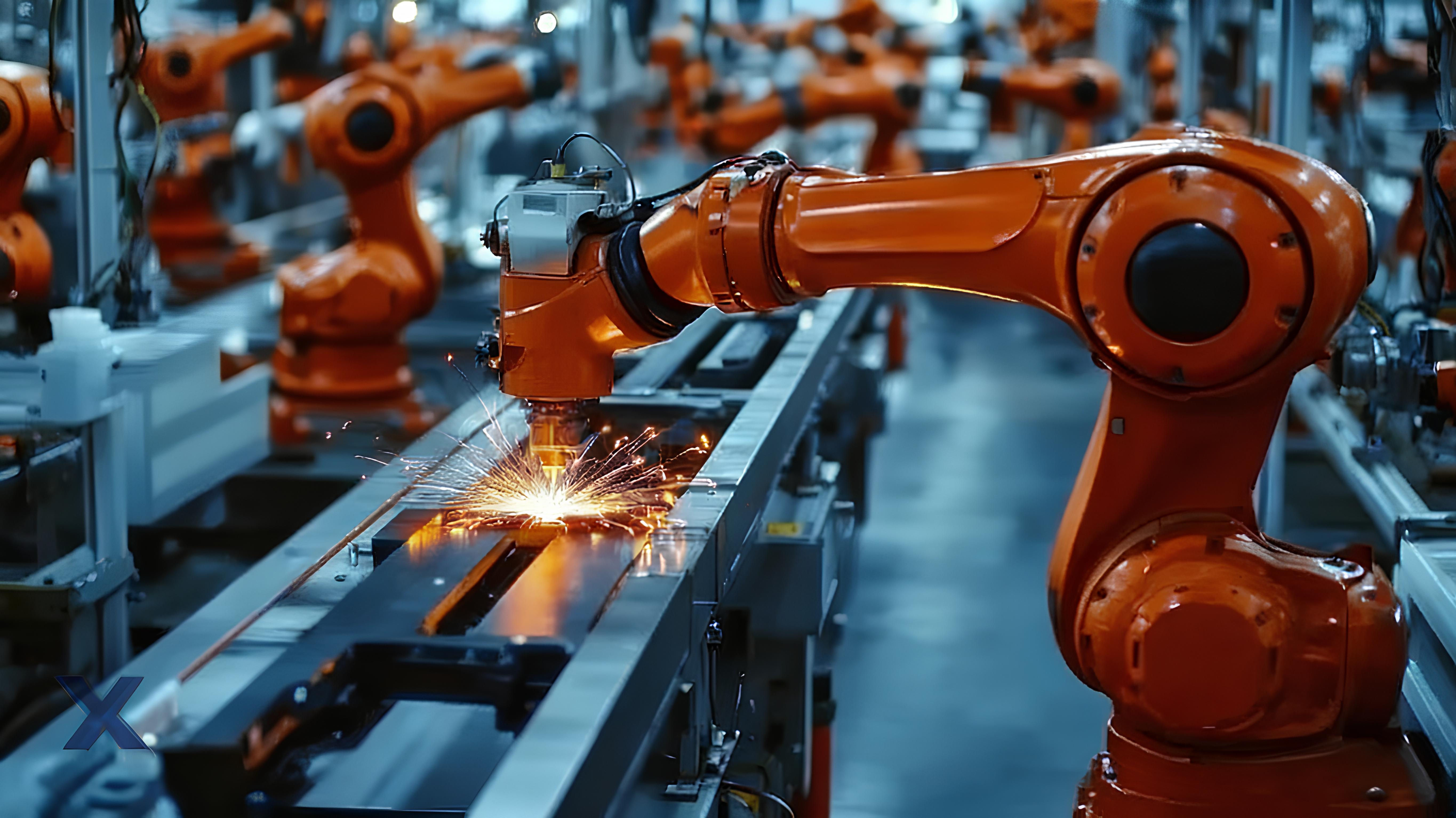

Imagine a robotic arm that stretches, bends, and moves with precision — seamlessly picking parts from a conveyor belt, welding with flawless accuracy, or even performing delicate medical tasks. Designing such an extendable robotic arm isn’t just about mechanics and code; it’s about turning imagination into motion. In this guide, you’ll learn how to bring your own robotic arm to life — from structure and drive systems to control logic and testing — whether you’re an engineer, a maker, or an entrepreneur ready to shape the future of automation.

1. Understanding Extendable Robotic Arms

Telescopic robotic arms have become an essential part of modern automation. Their flexible design and extended reach make them ideal for a wide range of industries — from precision manufacturing to large-scale engineering and even rescue operations. Here are the five most common applications you’ll find today.

-

Industrial robots for automated assembly lines: Commonly used in automotive and electronics manufacturing to perform tasks such as picking, placing, and assembling parts, improving production efficiency and flexibility.

-

Industrial robots for laser cleaning, welding, and cutting: Work alongside laser systems to remove rust, weld, or polish metal surfaces — ideal for industries like shipbuilding, mold manufacturing, and steel structures.

-

Robotic arms for warehouse and logistics handling: Used in warehouses, containers, and logistics centers to load, unload, or sort goods. The telescopic design allows deep reach into tight spaces, enhancing automation efficiency.

-

Engineering robots for bridge, construction, and wind turbine maintenance: Operate in high-altitude or complex environments to perform cleaning, coating, or inspection tasks with greater safety and precision.

-

Service robots for rescue and inspection missions: Deployed in hazardous or confined environments — such as disaster sites, chemical plants, or nuclear facilities — to conduct remote operations, sampling, or emergency rescues.

From manufacturing to maintenance, from logistics to life-saving missions — telescopic robotic arms are redefining how humans interact with machines. Their adaptability, precision, and reliability make them one of the key technologies driving the future of intelligent automation.

2. Key Things to Think About Before You Design Robotic Arm

Before you build an extendable robotic arm, you need to clarify several key factors. These design needs will make your project succeed.

-

How much load can it handle? (What’s the maximum weight it can lift?)

-

What is the required maximum reach?

-

Is it suitable for use in challenging indoor or outdoor conditions?

-

What degree of precision or accuracy does it need to achieve?

3. Mechanical Design of Robotic Arm

I recommend you focus on three main areas when designing an extendable robotic arm. These are structure type, actuation, and core components. They help you achieve the degrees of freedom (DOF), reach, and stability you need.

a. Structural Configuration and Degrees of Freedom

Arm Type: Choose between articulated arms (serial joints), scissor mechanisms, telescopic tubes, or continuum arms depending on your workspace and task requirements.

Degrees of Freedom (DOF): Most practical arms require at least 3–4 DOF to move up, down, forward, and backward. Industrial arms may have 6–7 DOF, mimicking human arm motion and achieving high repeatability (±0.05 mm).

Extension Mechanism:

-

Telescopic Design: Uses nested tubes that slide smoothly for controlled extension.

-

Sliding Rail Design: Uses linear rails and bearings for smooth section extension.

Both require low-friction materials and often rely on gears, belts, or screw-driven actuators.

b. Materials and Weight Management

- Material Selection: Use lightweight yet strong materials such as aluminum, carbon fiber, or composites to reduce stress on the arm; for heavy-duty applications, steel alloys can be used, though they add extra weight.

- Weight Distribution: Keep the end of the arm (gripper or tool) as light as possible to maintain responsiveness and avoid overloading the motors.

- Joint Torque: The elbow joint experiences the highest stress when the arm is fully extended. Heavy end-effectors increase this stress, so materials should be strong but still lightweight.

c. Industry Examples

-

Industrial Welding Arm: Features 6 degrees of freedom, high payload capacity, and a repeatability of ±0.05 mm.

-

Warehouse Picking Arm: Has 4 degrees of freedom and can perform fast operations with cycle times under 2 seconds.

-

Mobile Extendable Robot Arm (MERA): Uses two layers of 2-DOF scissor mechanisms for long reach, easy obstacle navigation, and high power output.

-

Soft Telescopic Continuum Arm: Composed of flexible modular sections, allowing smooth, adjustable motion while supporting telescopic extension.

Based on my experience, these principles ensure your extendable robot arm delivers reliability, reach, and efficiency. They work well for demanding modern applications.

4. Drive System: Choosing the Right Actuators for Extendable Robotic Arms

I believe the drive system is the heart of any extendable robotic arm. It controls how smooth and precise your arm moves. Your actuator choice—electric, pneumatic, or hydraulic—shapes torque, speed, payload, and precision.

Types of Drive Systems and Actuators

-

Electric Drive (Servo, Stepper, DC Motors)

-

Advantages: High control accuracy and smooth motion, capable of fast response and precise repeatability; ideal for medium to light loads and precision tasks.

-

Applications: Production line automation, warehouse picking, light assembly robotic arms, and educational or research robots.

-

-

Hydraulic Drive

- Strengths: Carries the highest load. Strong for heavy-duty arms.

- Use Cases: Industrial lifting. Multi-axis arms for welding. Material handling in tough settings.

-

Pneumatic Drive

- Strengths: Fast extension and retraction. Good for quick cycles. Works well for lighter loads.

- Use Cases: Industrial pick-and-place. Testing. Sorting lines.

I recommend you think beyond just power. Your drive system choice sets your robot arm robot’s accuracy, payload, cycle speed, and future flexibility. Look at your use case. Check your performance needs. Then match them to the right actuator and transmission design. This gives you a strong and modular robotic arm solution.

5. Sensors and Feedback System: Better Precision and Safety in Robotic Arms

-

Position and Angle Sensors: – Encoders: Measure joint angles and rotational positions, widely used for precise motion control. – Potentiometers: Used for basic angle detection or feedback.

-

Force and Torque Sensors – Detect forces on joints or end-effectors to prevent overloads and collisions.

-

Proximity and Distance Sensors – Optical, ultrasonic, or laser sensors for obstacle detection, object positioning, or presence sensing.

-

Vision Systems / Cameras – Enable object recognition, guidance for grasping, and accurate positioning.

-

Tactile and Pressure Sensors – Installed on end-effectors to monitor grip force and detect object contact.

-

Inertial Sensors (IMU: Inertial Measurement Unit) – Measure arm orientation, motion, and acceleration for posture stability and dynamic compensation.

Based on my experience, integrating high-quality sensors and strong feedback control is the most significant upgrade you can make to any robotic arm. It is far more impactful than mechanical improvements alone. It turns an extendable arm from a simple manipulator into a responsive, adaptive, and safe machine. I recommend this for real-world applications and modern industry demands.

6. Control System and Programming: Precision and Safety in Extendable Robotic Arms

A well-designed control system forms the foundation of any extendable robot robotic arm. It ensures precise movement. It provides reliable feedback. It keeps human-robot interaction safe.

The control system functions as the “brain” of the robotic arm, managing motion, precision, and interaction. Key components include microcontrollers, control algorithms, and user interfaces.

a. Microcontrollers and Processors

-

Prototyping boards: Arduino or Raspberry Pi are ideal for simple or experimental setups.

-

Industrial controllers: PLCs (Programmable Logic Controllers) are suited for complex automation and high-reliability applications.

b. Control Algorithms

-

PID Controllers: Ensure smooth, stable motion across joints.

-

Inverse Kinematics: Calculates the necessary joint movements to accurately reach target positions.

-

Machine Learning Integration: Enables adaptive and intelligent motion for advanced robotic tasks.

c. Human-Machine Interface (HMI)

Users can control the robotic arm via:

-

Joysticks for manual guidance

-

Touchscreen panels for intuitive command and monitoring

-

Wireless controllers for remote operation

-

Pre-programmed routines for repetitive or automated tasks

Based on my experience, modular controller designs are key. Feedback loops need to be strong. Safety features must be advanced. These elements create high-performance extendable robotic arms. They adapt well. They operate reliably in real-world industrial settings. They excel in collaborative environments.

7. Power Supply and Management: Ensuring Reliable Operation for Extendable Robotic Arms

A reliable power system is the core of an extendable robotic arm, supplying stable voltage and current to motors, controllers, and sensors for smooth and safe operation. Power type depends on the actuators: electric systems use batteries or AC/DC power, while hydraulic or pneumatic systems need pumps, compressors, and reservoirs. For mobile robots, lithium batteries are preferred for their high energy density.

Common Voltage Standards and Their Usage

- 48 V: I recommend this as the go-to standard for mid- to high-power robotic arms. It transfers energy well, cuts down current draw, and works with most industrial battery systems.

- 24 V: Many people use this for brushless DC and stepper motors in mid-range arms.

- 12 V/5 V: You’ll find these in control electronics, standard servos, and microcontrollers (Arduino, Raspberry Pi, STM32).

- Design Tip: I suggest using separate power rails or regulators for motors and sensitive controllers. This cuts electrical noise.

Battery Solutions for Mobile/Portable Systems

-

Battery Types: Lithium-ion and LiFePO4 battery packs are preferred for their high energy density, long cycle life, and relatively light weight.

-

Battery Management System (BMS): Essential for cell balancing, overcurrent/overdischarge/overtemperature protection, and real-time monitoring—never skip this component.

-

Runtime and Capacity Planning: Calculate battery capacity based on intended runtime (e.g., 8+ hours for exhibitions or field operations) and consider fast charging requirements.

Additional Considerations

-

Power vs. Weight Trade-off: Mobile systems should prioritize energy density and weight; stationary systems can prioritize higher power capacity.

-

Cooling and Protection: Ensure proper heat dissipation and design for environmental protection (dust and moisture resistance).

-

Power Distribution and Wiring: Plan for safe distribution, short-circuit protection, and grounding to minimize voltage drops.

-

Hydraulic/Pneumatic Systems: For non-electric drives, consider pump/compressor power, reservoir or tank size, and the required driving power source or engine.

Following these integrated safety and reliability standards is a legal requirement. Based on my experience, it is also a proven foundation for reducing harm, preventing downtime, and limiting liability in every professional or research robotic arm deployment.

8. Safety and Reliability of Extendable Robotic Arms: Key Strategies and Best Practices

Since robot arms often operate near people or in hazardous environments, safety is critical. Proper safety measures not only protect operators but also ensure reliable operation and prevent equipment damage.

Critical Physical and Electronic Safeguards

-

Physical barriers and safety fencing: Set up fixed fences and interlocked gates around the robot’s workspace. This stops accidental or unauthorized entry. You must follow ISO 10218:2025 for most industrial settings.

-

Presence-sensing safety devices: Install light curtains, laser scanners, or pressure-sensitive mats. These systems detect when people get close. They stop or slow the arm right away. These measures support safe collaborative operation without closing off the arm.

-

Accessible emergency stop devices (E-Stops): Place visible, quick-access E-Stop buttons and pull-cord E-Stops around the area. People must be able to reach them from any spot near the robotic arm. One press triggers full system shutdown.

-

Strong guarding and shielding systems: Use welded mesh cages or polycarbonate shields with standard, lockable access points. This protects personnel during operation and maintenance.

-

Integrated runstop/quick-stop controls: Add emergency stop buttons on the arm (including mobile units) and handheld controllers. This allows instant interruption of any movement in critical situations.

9. Prototyping and Testing of Extendable Robotic Arms

I recommend starting with a solid prototyping and testing phase, which is crucial for ensuring your design meets reach, payload, precision, and durability requirements. After completing the design, create a scaled-down prototype using 3D printing, aluminum profiles, or modular kits.Testing should include:

-

Payload Performance: Verify the arm’s ability to handle different loads.

-

Extension Smoothness: Check that the arm extends and retracts smoothly without sticking or shaking.

-

Stability at Full Extension: Assess structural stability and vibration when the arm is fully extended.

-

Motor Heat Dissipation: Monitor motor temperature under continuous or heavy loads to ensure proper cooling and prevent overheating.

Based on my experience, quick iteration matters. So does standard testing. Focus on measuring reliability and control. This approach leads to extendable robotic arms that are strong, precise, and ready for real use.

10. Real-World Uses of Extendable Robotic Arms

I’ve seen extendable robotic arms work well in many real scenarios. They adapt easily, reach far, and control tasks with precision. I recommend them for many industries. Here are key areas where they shine, with current data and examples.

Automotive Industry: Extendable robotic arms play a key role in tasks such as assembly, welding, and painting.

Minimally Invasive Surgery: Robotic arms perform precise surgical operations with errors under 0.5 mm, reducing patient risk and speeding recovery.

Automated Storage and Retrieval: Extendable arms navigate crowded warehouses and high shelves, reducing item retrieval times by up to 60%.

Adaptive Inspection Systems: Arms equipped with vision tools inspect parts from multiple angles, increasing defect detection rates by 30% and reducing return rates.

Retail Automation: Extendable robotic arms perform picking and sorting tasks in vending machines and automated retail setups, improving efficiency and customer experience.

My Take: I’ve watched industry data and worked hands-on with these systems. Extendable robotic arms boost efficiency, flex, and safety. Their role grows fast. They handle delicate surgery, heavy factory lifting, and dangerous tasks. I recommend them for businesses looking to scale smart.

Conclusion

Designing an extendable robotic arm combines mechanical engineering, electronics, programming, and safety. With careful planning of the structure, telescopic mechanisms, drive systems, and control algorithms, you can create a reliable, precise, and scalable arm for any application. Whether for education or industry, strength, precision, adaptability, and safety are key—contact us today to see how robotic arm can transform your operations.

FAQ About Extendable Robotic Arms

Q1. What applications are extendable robotic arms suitable for?

They are used in manufacturing, welding, assembly, logistics, warehousing, medical surgery, labs, and retail automation.

Q2. How do I choose the number of degrees of freedom (DOF)?

Simple tasks may need 4–5 DOF, while industrial or precision operations usually require 6–8 DOF for flexibility and accuracy.

Q3. How much payload can a robotic arm handle?

Payload varies by model: small prototypes handle 0.5–5 kg, industrial arms up to 50 kg or more. Choose based on your application and safety margin.

Q4: Can I build a robotic arm using Arduino?

A: Yes, Arduino is a great choice for prototyping and small-scale extendable robotic arms due to its easy programming and sensor compatibility.