In today’s fast-paced manufacturing world, efficiency and precision are everything. Industrial robot arms are quickly becoming the “super employees” every factory wants—they work tirelessly, deliver pinpoint accuracy, and operate at incredible speeds. Whether it’s material handling, assembly, or welding, choosing the right robot arm can dramatically boost productivity while cutting labor costs and minimizing errors. In this article, we’ll explore the top 10 industrial robot arms on the market, helping you find the perfect automation solution for your production needs.

1. MaxWave 1820 Robot Arm

The MaxWave 1820 Robot Arm works well for industrial automation. It handles high-precision tasks in manufacturing, warehousing, and automated logistics. I recommend it for businesses that want to improve output and cut down on manual work.

Industrial Positioning

MaxWave 1820 robot arm works best on high-volume production lines. It also fits advanced automated processes. The strong build and easy programming make it perfect for automotive parts work, large-scale material handling, and precision stacking. In my view, this arm performs well in standalone cells. It also excels in integrated smart factories.

Build Quality & Durability

The MaxWave 1820 features a reinforced high-grade steel frame with double-sealed bearings at key joints, providing excellent stability, vibration resistance, and a compact footprint for crowded factory spaces. With an IP65 rating, its sealed design protects gears and motors from dust, coolant, and spray, performing reliably in tough metalworking or chemical production environments. Rated for 30,000 hours MTBF, the robot supports 24/7 operation with minimal unplanned stops, and its smart lubrication system reduces joint wear and extends maintenance intervals.

Performance Metrics

- Payload Capacity: This robot arm handles up to 20 kg per cycle. It works well for parts loading, carton stacking, and tool carrying.

- Reach and Motion Range: The MaxWave 1820 reaches out to 1850 mm. This gives it a large working area. It can serve multiple production stations from one mounting point.

- Repeatability and Accuracy: Repeatability reaches ±0.05 mm. I find this makes it reliable for tasks that need speed and precision. Product packaging works great. So does parts work.

- Working Speed: Axis speed hits 240°/sec on major joints. This keeps cycle times short. It supports high-output goals in automated warehouse cells.

Industrial Applications

I suggest the MaxWave 1820 for:

– Automated rack stacking and warehouse palletizing

– CNC machine loading/unloading

– Medium-part work in automotive or appliance manufacturing

– Conveyor-based pick-and-place lines

Case studies show strong results in electronics packaging. Heavy e-commerce picking environments also benefit.

Cost Efficiency & ROI

The MaxWave 1820 robot arm has a competitive price of around US $5,000 including software and basic setup. Its modular build keeps maintenance demands low, and users in logistics and mid‑sized manufacturing often report ROI within 15–20 months. In my opinion, the low setup cost plus strong 24/7 performance make this robot a smart choice — particularly for businesses that need to scale automation quickly.

2. FANUC M-20iD/25 Robot Arm

Industrial Positioning

The FANUC M-20iD/25 is a versatile industrial robot arm. It handles medium-payload tasks well. I recommend it for automotive, electronics, and general manufacturing industries.

Build Quality & Durability

The M-20iD/25 robot arm is made from high-grade industrial materials, ensuring stability even at maximum payload. Its IP67-rated wrist protects against dust, moisture, and harsh conditions. Designed for continuous operation, it runs for long periods with minimal downtime, boosting productivity in demanding industrial environments.

Performance Metrics

- Payload Capacity: The M-20iD/25 handles loads up to 25 kg. I suggest it for machine tending, putting parts together, and material handling.

- Reach and Motion Range: It reaches 1831 mm. This covers large work areas and supports multi-point tasks.

- Repeatability and Accuracy: The robot repeats positions within ±0.02 mm. This ensures precise placement for high-accuracy applications.

- Working Speed: High axis speeds create fast cycle times. This improves line efficiency in volume production.

Industrial Applications

I recommend the M-20iD/25 robot arm for:

– Putting parts together automatically

– Packaging and palletizing

– CNC machine tending

– Material handling and logistics tasks

You can use it in high-volume automotive lines. It also works well in precise electronics workshops.

Cost Efficiency & ROI

The initial investment may be higher than entry‑level models, but the FANUC M‑20iD/25 is listed at around US $37,500 for the robot alone. It delivers strong ROI by reducing downtime, running fast, and staying reliable. Many industry users recover costs quickly. Lower maintenance needs and consistent high performance lead to operational savings. Based on my experience, this robot pays for itself faster than you might expect.

3. ABB IRB 1100 Robot Arm

Industrial Positioning

The ABB IRB 1100 is a compact and fast robotic arm. I find it ideal for small parts assembly, electronics manufacturing, and precise handling tasks. Its design maximizes productivity in tight workspaces.

Build Quality & Durability

The IRB 1100 is built with high-strength aluminum alloy, keeping it lightweight while maintaining strong structural integrity for stable, quick movements. It features IP40 protection, upgradeable to IP67, with sealed joints that guard against dust and moisture, extending its lifespan. Designed for continuous operation, the robot delivers steady performance over long cycles with extended service intervals, minimizing downtime and ensuring reliable long-term production.

Performance Metrics

- Payload Capacity: It handles 4 kg or 5 kg payloads. Based on my experience, this makes it perfect for lightweight tasks like electronics assembly and lab automation.

- Reach and Motion Range: You can choose between 475 mm or 580 mm reach. This flexibility helps you fit it into crowded production layouts. It supports tasks that need close, precise manipulation.

- Repeatability and Accuracy: The robot achieves ±0.01 mm repeatability. I like this level of precision for pick-and-place operations and micro-assembly work. It meets the strict demands of electronics and intricate part handling.

- Working Speed: This is one of the fastest robots in its class. The IRB 1100 cuts cycle times by up to 35% compared to older ABB models. Its agile performance boosts output for businesses that need quick, repeatable motion.

Industrial Applications

I suggest the IRB 1100 for:

– Small component assembly in electronics

– Lab automation and material handling

– Fast, high-precision pick-and-place operations

– Screwdriving and light machine tending tasks

These uses show its strengths: speed, repeatability, and flexibility for high-mix, low-volume production.

Cost Efficiency & ROI

The ABB IRB 1100 is not the cheapest entry‑level robot at around US $76,532, but I believe it offers strong value through speed, precision, and reliability. Many manufacturers praise its rapid deployment and low maintenance. These factors save money. Quick returns happen where throughput and consistent accuracy boost overall productivity. The investment pays off through reduced cycle times and minimal downtime. This speeds up ROI in demanding, space‑limited industries.

4. Yaskawa GP25 Robot Arm

Industrial Positioning

The Yaskawa GP25 is a high-speed, multi-purpose industrial robot arm. It’s built for tough manufacturing environments. I often see it in automotive plants and metal fabrication shops. These industries need flexible automation. The GP25 robotic arms works well on production lines. It also performs great as a standalone robotic workstation.

Build Quality & Durability

The GP25 features a strong cast-iron frame and high-quality components, providing stability even under frequent, heavy-duty use, while its compact design saves installation space. With an IP67 wrist and IP54 body, it is well-protected against dust and water, performing reliably in harsh environments like welding workshops and machining cells. Built for 24/7 operation, the GP25 offers steady performance, minimal maintenance thanks to its simple grease lubrication system, and low total cost of ownership.

Performance Metrics

- Payload Capacity: The GP25 handles payloads up to 25 kg. This puts it in the medium-payload category. It can manage many different parts and tools. Stability stays solid.

- Reach and Motion Range: The reach is 1730 mm. It covers large work areas. It stretches across conveyor belts and production lines. The six-axis design gives wide, flexible motion.

- Repeatability and Accuracy: Repeatability is rated at ±0.02 mm. I recommend the GP25 for precision work. It handles welding and material handling where accuracy matters.

- Working Speed: The GP25 runs up to 25% faster than older Yaskawa models. High axis speeds mean faster product throughput. Line efficiency improves.

Industrial Applications

Based on my experience, I suggest the Yaskawa GP25 for:

– Arc welding and spot welding

– Machine tending for CNC lathes and presses

– Parts building and packaging

– Palletizing and material handling tasks

Many automotive makers and metalwork shops use the GP25. They choose it for accuracy and strength under heavy workloads.

Cost Efficiency & ROI

The Yaskawa GP25 sits in the mid‑to‑high price range at around US $25,000–30,000 for new units. It boasts excellent energy efficiency and low servicing demands, which reduce operating costs over time. Many users recover their initial investment in 18‑24 months by saving on labour and minimizing downtime. For operations where cycle speed and reliable automation are crucial, the GP25 delivers strong returns.

5. KUKA KR QUANTEC Robot Arm

Industrial Positioning

The KUKA KR QUANTEC is a powerful robot robotic arm built for heavy loads. I’ve seen it handle demanding industrial automation tasks with ease. The automotive industry uses it often. Metalworking and large-scale manufacturing also rely on it. From my research, I recommend it for jobs that need versatility and strength. It also delivers long-term stability.

Build Quality & Durability

The KR QUANTEC is built with reinforced steel and high-quality mechanical parts, providing excellent torsional rigidity and long-lasting performance even under continuous stress. Its fully enclosed structure offers IP65 protection, with the wrist upgradeable to IP67, allowing reliable operation in dusty, wet, or harsh environments. Designed for 24/7 use, it maintains stable performance with long maintenance intervals, well-sealed joints, minimal wear, and high uptime.

Performance Metrics

- Payload Capacity: The KR QUANTEC series handles 90 kg to 300 kg. This depends on the model. I suggest it for heavy part transfer. Tool handling works great. Resistance spot welding is another good use.

- Reach and Motion Range: Models reach between 2496 mm and 3904 mm. This range covers large work cells. Think car body lines. Heavy palletizing areas also benefit.

- Repeatability and Accuracy: Repeatability hits ±0.06 mm. That’s accurate enough for precise welding. Positioning is exact. Large parts fit together correctly.

- Working Speed: Powerful servo drives move the axes fast. Cycle times beat older models. Real-world tests show up to 25% faster cycles.

Industrial Applications

I recommend the KR QUANTEC for:

– Automotive spot welding and body-in-white production

– Heavy part palletizing and material transfer

– Die casting and forging

– Laser or plasma cutting for large metal sheets

– Loading and unloading heavy machine tools

Cost Efficiency & ROI

The initial cost runs above average. But users recover their investment fast. Maintenance costs stay low. Energy savings add up. Productivity is outstanding. Service intervals are long. Downtimes are rare. I’ve found this valuable for facilities that need high throughput. Businesses in high-volume settings report ROI in 18-24 months. Heavy-industry operations see even better returns.

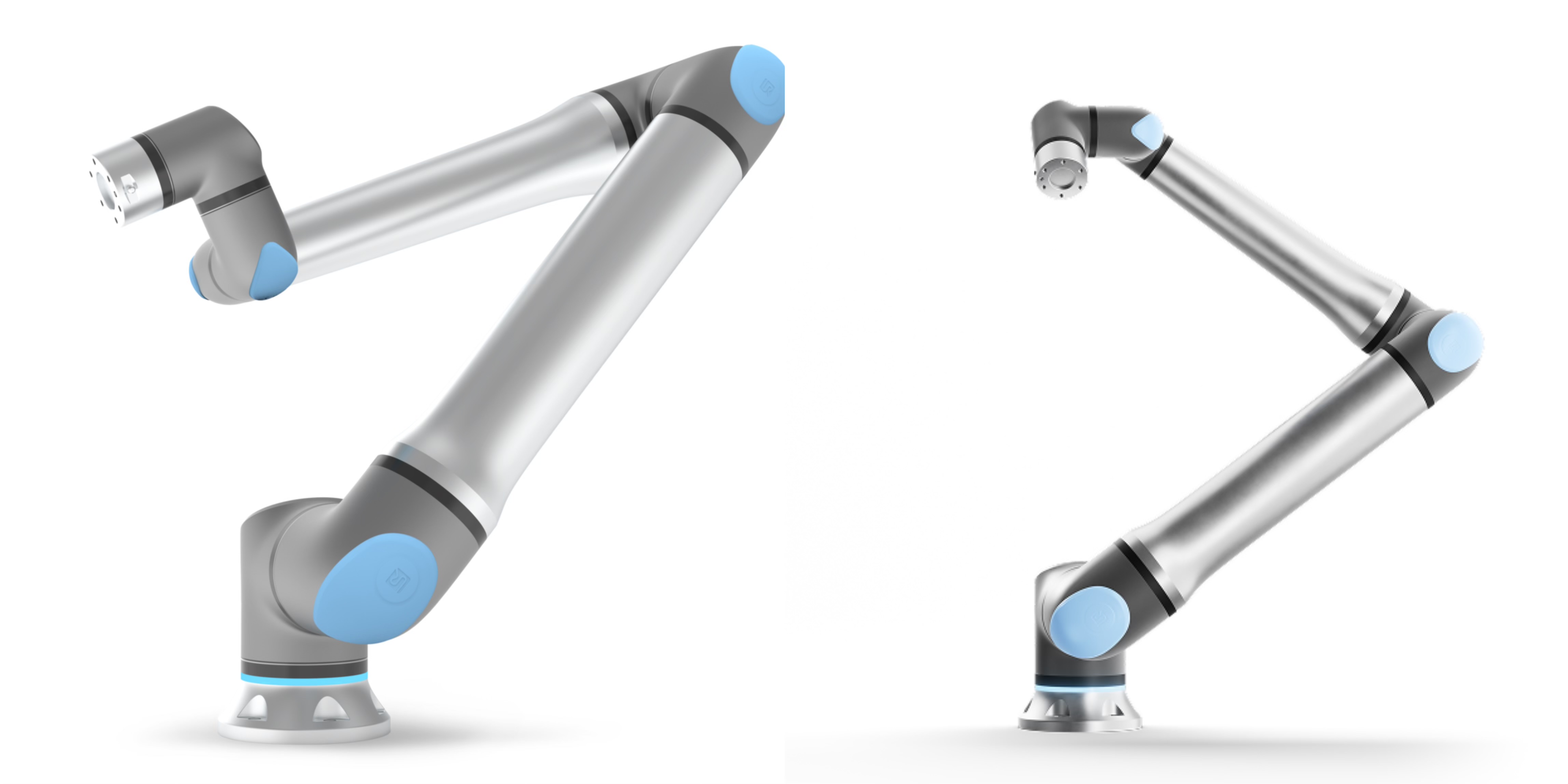

6. Universal Robots UR20 Robot Arm

Industrial Positioning

The Universal Robots UR20 is a next-generation collaborative robot arm. I find it works best for flexible automation. It serves industries like packaging, welding, palletizing, and precision assembly. Safe human-robot collaboration is key in these fields. The design works for high-mix, low-volume production. It also handles automated processes that need adaptability.

Build Quality & Durability

The UR20 is made from lightweight, high-strength materials, offering a slim, stable design that fits well in crowded factory spaces. With an IP54 rating, it resists dust and water splashes, making it suitable for general manufacturing, packaging lines, and workshops. Built for continuous operation, the UR20 boasts a 35,000-hour MTBF, simple maintenance, and long-term reliability with minimal downtime.

Performance Metrics

- Payload Capacity: The UR20 handles payloads up to 20 kg. This is a big jump for collaborative robots in its class. It supports applications that need to move larger parts or heavier tools.

- Reach and Motion Range: The maximum reach is 1750 mm. This wide working envelope helps the UR20 handle tasks across large pallets or workspaces. It doesn’t need to shift position.

- Repeatability and Accuracy: Repeatability is rated at ±0.05 mm. This ensures precise and repeatable movements. I suggest it for automation tasks that need high accuracy.

- Working Speed: Joints move up to 210 degrees/second. This enables fast cycle times in pick-and-place and packing. The speed and smooth motion keep productivity high. Collaborative safety stays intact.

Industrial Applications

Based on my experience and industry use cases, the UR20 excels at:

– Collaborative palletizing of boxes and bags up to 20 kg

– Automated welding (this includes MIG/MAG welding setups)

– Machine tending for CNCs and presses

– Large-parts pick-and-place and packaging

– Material handling in electronics, automotive, and logistics

Many manufacturers choose the UR20 where large payloads and extended reach are critical. Human-robot collaboration can’t be compromised. I recommend it for these scenarios.

Cost Efficiency & ROI

The initial cost runs above average. But users recover their investment fast. Maintenance costs stay low. Energy savings add up. Productivity is outstanding. Service intervals are long. Downtimes are rare. I’ve found this valuable for facilities that need high throughput. Businesses in high‑volume settings report ROI in 18–24 months. The UR20 is currently priced around US $62,990, making that investment justifiable.

7. Kawasaki RS025N Robot Arm

Industrial Positioning

The Kawasaki RS025N is a strong and flexible industrial arm robot. I recommend it for busy production sites. It works well in automotive, general manufacturing, and logistics. I suggest it because it handles precision and repetitive work with ease. This makes it perfect for automated assembly lines and parts handling.

Build Quality & Durability

The RS025N features a dense, high-strength steel frame, providing excellent mechanical stability in a compact design that fits easily on crowded factory floors. With an IP67 wrist and IP65 body, it is protected from dust, coolant, and water spray, performing reliably in wet and dusty environments like CNC machine tending. Built for 24/7 operation, the RS025N runs long production cycles with minimal wear, smart cable management, and reduced maintenance, resulting in fewer unscheduled stops.

Performance Metrics

- Payload Capacity: The RS025N handles up to 25 kg. This capacity suits heavy automotive parts. It moves jigs and industrial tools with ease.

- Reach and Motion Range: It reaches up to 1,885 mm. This covers a wide work area. The wide reach supports multi-point operations. The robot can serve multiple machines at once. I find this boosts line efficiency significantly.

- Repeatability and Accuracy: Its repeatability is rated at ±0.03 mm. The RS025N balances high precision with rugged operation. I find this critical for quality-sensitive assembly work. It also excels in welding tasks.

- Working Speed: The six-axis design delivers fast joint speeds. This enables short cycle times. Motion smoothness has improved over earlier versions. It still maintains high output.

Industrial Applications

I recommend the Kawasaki RS025N for:

– Engine component assembly in automotive lines

– CNC machine tending and part transfer between stations

– Automated welding and sealing

– Heavy parts palletizing and logistics management

– High-mix, low-volume precision manufacturing

Based on my experience, manufacturers value the RS025N for its adaptability. They trust its reliability for medium-load operations. It delivers both speed and precision.

Cost Efficiency & ROI

he Kawasaki RS025N sits at a mid‑tier price among 25 kg‑class robots (≈ $42,300). Its strong build means less downtime. Long service intervals keep maintenance costs low. Multiple manufacturers report payback periods of 18‑24 months. This comes from its energy‑efficient drives. Reduced labor costs add to the savings. In my analysis, the RS025N delivers fast returns. I recommend it for operations needing reliability. It offers a strong balance of speed and accuracy.

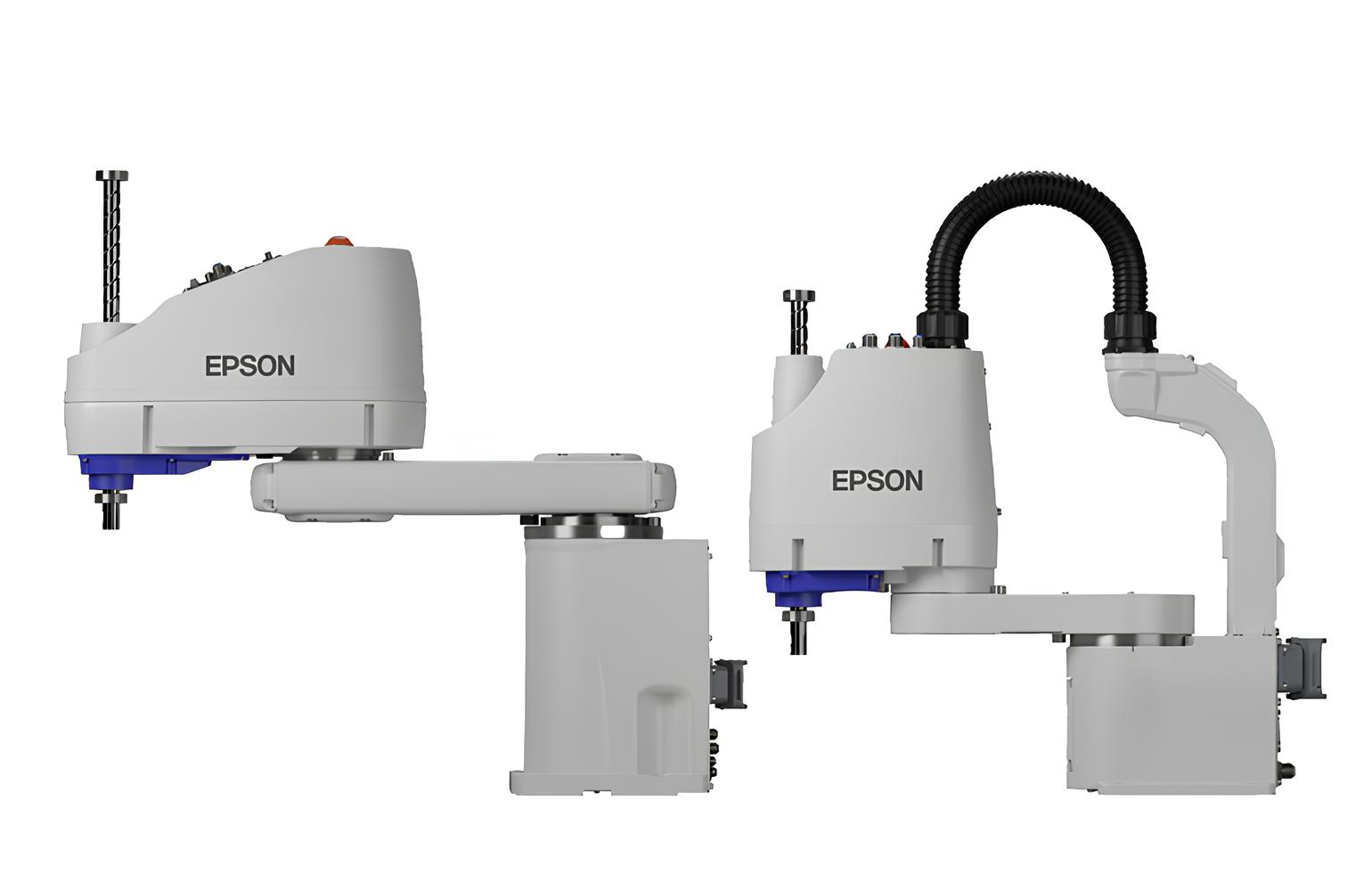

8. Epson SCARA Series Robot Arm

Industrial Positioning

The Epson SCARA Series Robot Arms lead in precision work and fast automation. I recommend it for electronics manufacturing, semiconductor fabrication, life sciences, and consumer device production. The design is compact. It fits high-density production lines perfectly. Most users praise its agility and precision. It excels at tasks that need tight tolerances.

Build Quality & Durability

The Epson SCARA series is built with lightweight, rigid alloys, enabling high-speed motion with minimal vibration, while articulated joints and sealed drives enhance mechanical reliability. With IP54 or IP65 protection on select models, the robots resist dust and fluid exposure, ensuring safe operation in clean, controlled environments. Designed for extended 24/7 operation, the SCARA series offers an MTBF over 30,000 hours and simple, infrequent maintenance, providing reliable long-term performance.

Performance Metrics

- Payload Capacity: The Epson SCARA lineup covers payloads from 3 kg to 20 kg in its higher-end models. This flexibility suits delicate micro-production tasks. It also handles heavier parts packaging jobs.

- Reach and Motion Range: The arm’s reach options range from 175 mm to 1,000 mm, depending on the model. Short-reach versions fit micro workcells. Long-reach arms span multiple conveyor points.

- Repeatability and Accuracy: Repeatability ranges from ±0.01 mm to ±0.02 mm. This tight tolerance supports electronics placement, soldering, and screwdriving. It delivers consistent results every time.

- Working Speed: Cycle times are among the fastest in this class. Some models achieve cycle times as low as 0.29 seconds. In my experience, this speed makes a real difference in high-volume throughput.

Industrial Applications

I recommend the Epson SCARA Series for:

– High-speed pick-and-place in electronics production (such as PCB handling)

– Automated dispensing and soldering of fine components

– Small parts testing and quality inspection in the pharmaceutical industry

– Packaging and sorting of consumer devices

Case studies from electronics manufacturers show setup times reduced by 30%. Defect rates drop after SCARA cell deployment. In life sciences, the SCARA arm’s cleanliness and speed make it ideal. I suggest it for lab automation and precision reagent dispensing.

Cost Efficiency & ROI

Prices for Epson SCARA robots range from $10,000 to $25,000, depending on specifications. The initial cost is moderate. Rapid deployment and low maintenance mean operations see payback in 12–18 months. Several users report labor savings of up to 40%. They also see improved line yields. In my analysis, the SCARA series’ speed and accuracy accelerate ROI. This is true for small-parts production and high-cycle-run lines.

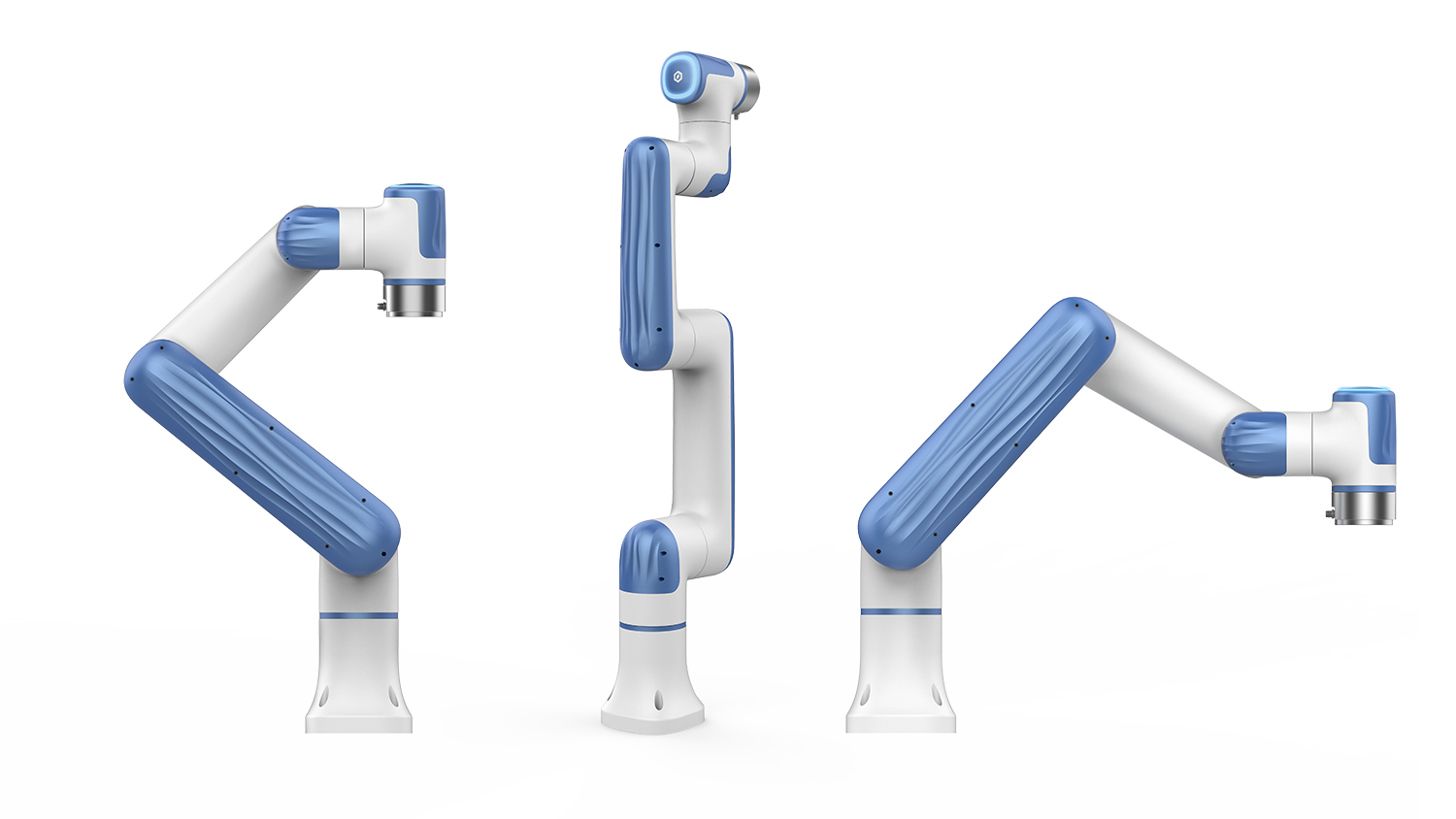

9. Dobot Nova2 Robot Arm

Industrial Positioning: Lightweight Collaborative Robot for Commercial Automation

The Dobot Nova2 is a compact robot arm. It works well for light-duty tasks and commercial use. I find it perfect for retail, service, and small-batch production. The design is simple. The plug-and-play features help businesses new to robotics. It fits companies that want flexible automation outside industrial settings. Nova2 handles customer-facing tasks, basic assembly work, and educational robotics.

Build Quality & Durability

The Nova2 is built with strong, lightweight alloys, keeping it stable while weighing only about 10 kg, making desktop or counter installation easy and allowing non-technical staff to handle it quickly. With an IP40 rating, it is suited for clean commercial spaces, labs, or schools rather than harsh factory floors. Designed for light daily automation, the Nova2 requires minimal maintenance and can operate for months with little downtime, making it ideal for retail or customer-facing environments.

Performance Metrics

- Payload Capacity: Nova2 carries up to 2 kg. This works for pick-and-place jobs, product demos, or simple lab tasks. It won’t handle heavy loads. But it does great with repeated handling of small items.

- Reach and Motion Range: It reaches 625 mm. This covers tabletop packaging, retail displays, or assembly tasks with multiple pick points.

- Repeatability and Accuracy: Repeatability hits ±0.05 mm. This gives the precision you need for electronics handling, light assembly work, or teaching programming.

- Working Speed: The Nova2’s joints move up to 200 degrees/second. This creates fast cycle times in pick-and-place or customer interaction. It keeps efficiency high in interactive displays or commercial workflows.

Industrial Applications

I recommend Nova2 for:

– Customer interaction robots in retail. Think automated coffee prep or product demos.

– Light assembly or pick-and-place tasks in electronics workshops.

– Interactive teaching setups in schools or training centers.

– Sample handling in labs or clinics.

These uses show Nova2’s strengths. It operates safely around people. Setup is fast. You can reconfigure it for changing workflows.

Cost Efficiency & ROI

Nova2 costs less than traditional industrial cobots. Units sell for under $8,000. Installation and setup are fast. This keeps setup costs low. Based on my analysis, small businesses see ROI within 6–12 months. You save money by reducing labor for repetitive service tasks. Customer experience improves, which helps in retail or front-office automation. Nova2 needs minimal maintenance. You can reuse it for different jobs (seasonal displays, temporary pop-ups). I believe this boosts value for budget-conscious operations.

10. Mitsubishi RV20FRD Robot Arm

The Mitsubishi RV20FRD is a flexible, high-precision industrial robot arm. It automates tasks in manufacturing, electronics, and production lines. Speed and accuracy are what it does best.

Industrial Positioning

I see the Mitsubishi RV20FRD robot arm robot as my top choice for manufacturers. They need fast, repeatable automation in mid-to-high payload tasks. It adapts well to different production setups. You can use it for precision work in electronics. You can also use it for part handling in general manufacturing. I find the robot versatile. It works great as a standalone unit. It also fits well into integrated automated cells.

Build Quality & Durability

The Mitsubishi RV20FRD features a strong industrial alloy frame that balances weight and mechanical strength, offering durability and agility in a slim design that fits tight production spaces. With an IP67 wrist and IP65 body, it is protected from dust, coolant, and water splashes, performing reliably in harsh environments like metal machining or electronics production. Built for 24/7 operation, its high-efficiency motors and sealed gears reduce wear, extend maintenance intervals, and ensure stable, long-term performance with minimal downtime, maintaining consistent production output.

Performance Metrics

- Payload Capacity: The RV20FRD handles payloads up to 20 kg. This fits moderate to heavy part work. I recommend it for material handling, machine tending, and automated production tasks.

- Reach and Motion Range: Maximum reach is 1,318 mm. The wide working area supports multi-point operations. Cell design stays flexible. The six-axis structure gives broad motion freedom. It covers varied production needs.

- Repeatability and Accuracy: Repeatability is ±0.02 mm. This precision is critical for press-fitting, electronics production, and small-part joining. Even minor misalignment can cause problems. This robot avoids that.

- Working Speed: The RV20FRD achieves high joint speeds. This supports fast cycle times. Throughput improves in demanding manufacturing settings.

Industrial Applications

I recommend the RV20FRD for:

– Automated production of electronic devices and small appliances

– CNC machine tending in metals and plastics factories

– High-speed tray handling and material transfer

– Palletizing, deburring, and basic inspection automation

These use cases show its flexibility. It handles repetitive, high-speed pick-and-place. It also does precision joining and machine loading. Users in electronics and medium-part manufacturing tell me they see sharp productivity gains.

Cost Efficiency & ROI

The Mitsubishi RV20FRD sits in the mid‑range price bracket at around US $73,298 for new units. Among 20 kg‑class robots, it’s competitive. Its energy efficiency and sealed components keep operating and maintenance costs low. Industry users often see payback periods of 18–24 months. Its speed and reliability reduce labor costs and downtime, especially in facilities with long shifts. Overall, the RV20FRD balances upfront cost and long‑term savings well, making it a strong choice for manufacturers aiming to maximize automation ROI.

Summary

Investing in a high-performance industrial robot arm isn’t just about upgrading equipment—it’s about investing in your factory’s efficiency and profitability. From speeding up production to reducing mistakes, these top-rated robot arms are redefining manufacturing standards. If you’re ready to elevate your operations and optimize your workflow, take a closer look at our carefully curated list—contact us today to get a personalized quote and find the perfect robot arm for your business!