From car factories to electronics labs, robot arms are quietly reshaping modern manufacturing. These mechanical powerhouses now handle tasks once thought impossible—welding, assembly, painting, even delicate medical work—with precision and speed that humans can’t match. But not all robot arms are built the same. Each type—articulated, SCARA, Cartesian, Delta, cylindrical, or collaborative—serves a unique role in automation. In this guide, we’ll break down the six main types of industrial robotic arms, showing you how each works and where it delivers the most value for your business.

Overview Table: Arm Types vs. Common Uses

| Type | Key Motions & Specs | Common Uses | Advantages | Limitations |

|---|---|---|---|---|

| Articulated | Multi-jointed, human-like arm. | Welding, painting, assembly. | Maximum flexibility, large reach. | Higher cost, complex programming. |

| Cartesian (Gantry) | Linear X, Y, Z axis movement. | High-speed pick-and-place, 3D printing. | High precision, simple structure. | Linear paths only, large footprint. |

| SCARA | Two parallel rotary joints. | Assembly, screw driving, fast pick-and-place. | Very fast, compact. | Best for flat (2D) tasks. |

| Cylindrical | Operates in a cylindrical space. | High-speed sorting, packaging. | Very high speed and accuracy. | Low payload capacity. |

| Polar/Spherical | Rotational and telescoping arm. | Machine tool handling, stacking. | Compact, reaches tight spaces. | Moderate flexibility. |

| Collaborative (Cobot) | Sensor-enabled for human interaction. | Machine tending, inspection, assembly. | Safe, easy to integrate. | Lower speed & payload. |

Robot Arm Selection Tips: Match Your Needs to Arm Structure

Based on my experience, here’s what I recommend of robotic arms:

- Articulated arms handle complex welding and assembly with great flexibility.

- Cartesian robots offer top precision for CNC and electronics.

- SCARA models are fast and reliable for assembly and packaging.

- Delta robots excel in high-speed pick-and-place tasks.

- Cylindrical and polar arms work well in confined or curved spaces.

- Cobots enable safe, flexible collaboration with human workers.

6 Types Of Robot Arms And Their Applications

You need to pick the right automation solution for your factory. I recommend you start by learning the different types of robot arms. Each type has its own structure and working space. Different industries prefer different types. Here’s my breakdown of the six main types, with real cases and data.

1. Articulated Robot Arms: Most Flexible and Popular

Articulated robot arms are built with multiple rotary joints—typically 4 to 6 axes—that mimic the movement of a human arm. This structure gives them exceptional flexibility, a wide range of motion, and the ability to perform complex 3D operations. They are the most widely used and produced type of industrial robot today, accounting for around 60% of all fixed industrial robots worldwide, with an annual growth rate of 5–10%.

Key Advantages:

-

High flexibility and freedom of motion: Multi-axis design enables the robot to perform complex welding, grinding, assembly, and painting tasks from multiple angles.

-

Strong adaptability: Can be mounted on the floor, wall, or ceiling, supporting various working postures.

-

Wide payload range: Suitable for both lightweight electronics (<1 kg) and heavy automotive components (>500 kg).

-

Excellent process compatibility: Works seamlessly with laser welders, vision systems, and conveyor lines to form fully automated production cells.

Main Application Industries:

-

Automotive manufacturing: Used for body welding, part assembly, painting, and palletizing—making them the backbone of modern car production.

-

Metal processing and welding: Performs high-strength, long-duration precision welding when paired with laser or arc welding systems.

-

Electronics manufacturing: Ideal for repetitive, high-precision tasks such as component insertion, assembly, and inspection.

-

Plastics and composite material processing: Delivers consistent performance in injection molding, polishing, and cutting operations.

Market Position and Leading Brands: Articulated robots dominate industrial automation and are widely deployed across automotive, metalworking, and advanced manufacturing sectors. Leading brands such as MaxWave, FANUC, ABB, KUKA, and Kawasaki have maintained global leadership with reliable control systems and extensive application experience.

Example Application: In automotive production, a 6-axis articulated robot can complete hundreds of welds on a car body per hour—boosting both production speed and weld consistency. For manufacturers seeking high precision, flexibility, and efficiency, articulated robotic arms remain one of the most valuable investments in industrial automation.

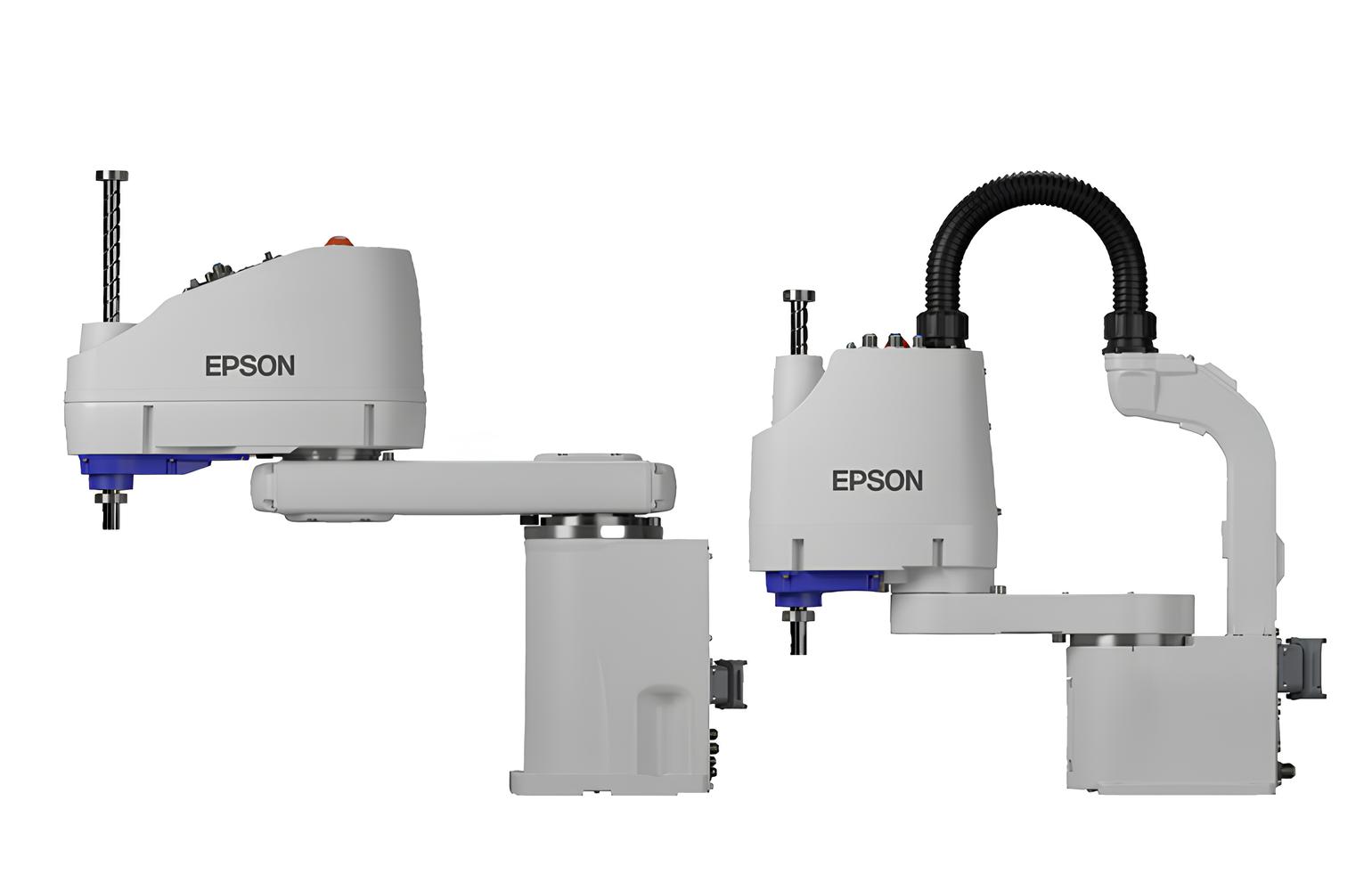

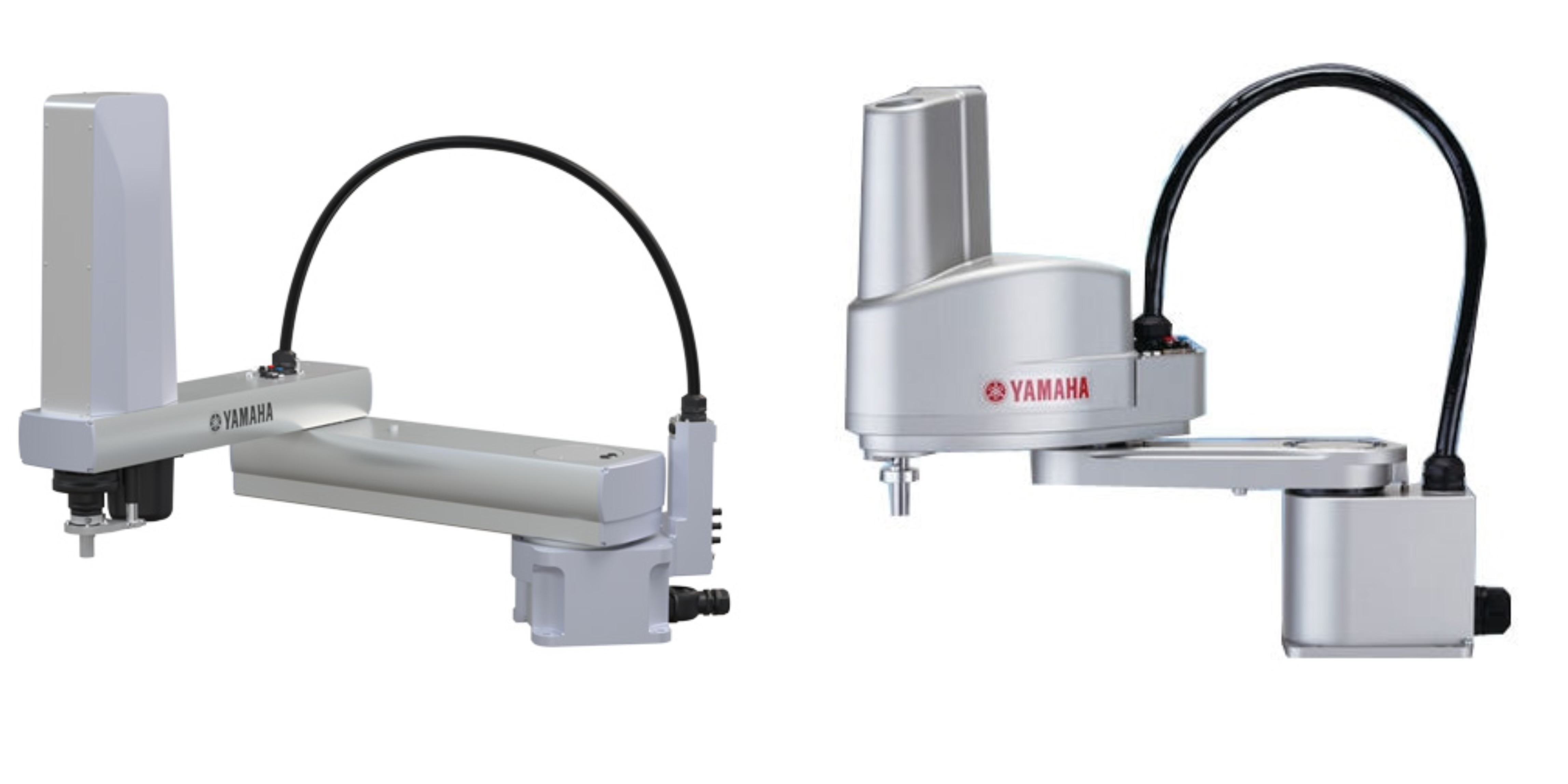

2. SCARA Robot Arms: Fast, Precise, Small

SCARA (Selective Compliance Assembly Robot Arm) robot arms are designed for high-speed, horizontal movements and are particularly strong in precise assembly and pick-and-place operations. With a compact design and lightweight arm, they are ideal for tasks that require fast, repetitive motions in confined spaces. SCARA robots currently account for about 15% of the global industrial robot market and continue to grow steadily due to their balance of speed, precision, and cost efficiency.

Key Advantages:

-

High-speed performance: SCARA robot arms can complete assembly cycles in less than 0.4 seconds, making them one of the fastest robot types available.

-

Excellent repeatability: Their typical repeatability of ±0.01–0.02 mm ensures consistent accuracy in electronics and medical assembly lines.

-

Compact footprint: Vertical design allows easy integration into crowded workspaces or production lines without major layout changes.

-

Low maintenance and easy setup: Simple structure and modular design reduce downtime and simplify maintenance.

Main Application Industries:

-

Electronics manufacturing: Ideal for PCB assembly, soldering, component insertion, and smartphone production, where precision and speed are critical.

-

Pharmaceutical and medical packaging: Handles bottle filling, labeling, and device assembly with hygienic, repeatable motion.

-

Consumer products and small parts assembly: Commonly used for toys, watches, and optical instruments, ensuring reliable and efficient handling.

-

3D printing and light automation: SCARA robot arms enable quick and consistent layer deposition and material handling.

Market Position and Leading Brands: SCARA robot arms are widely adopted in electronics, packaging, and life sciences for their high-speed precision. Leading manufacturers such as Epson, Yamaha, Mitsubishi, and Fanuc dominate the market with compact models that integrate easily into existing production systems.

Example Application: In a smartphone production line, SCARA robots perform micro-component assembly at lightning speed—placing tiny chips or screws with unmatched precision. For businesses seeking fast, space-saving, and cost-efficient automation, SCARA robot arms deliver an ideal balance of performance and reliability.

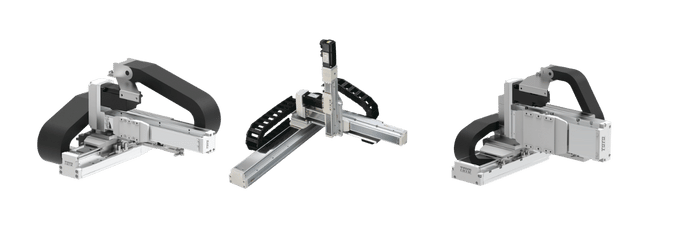

3. Cartesian/Gantry Robot Arms: Accurate, Big Work Areas

Cartesian or Gantry robot arms move along three linear axes—X, Y, and Z—and operate using precise, straight-line motion. Their structure is simple yet powerful, providing exceptional positioning accuracy and stability. Because they can be easily customized in size, load capacity, and configuration, Cartesian robots are widely used in CNC machining, packaging, assembly, and 3D printing. They make up a significant portion of precision automation systems in industries that require exact movement and repeatability.

Key Advantages:

-

High precision and repeatability: Offers positioning accuracy of up to ±0.02 mm, making them ideal for tasks requiring perfect straight-line motion.

-

Large working area: The modular frame design allows for custom lengths and widths—excellent for large or multi-station production lines.

-

Easy programming and control: Motion is linear and predictable, which simplifies setup and reduces operator training time.

-

Stable and durable: Rigid mechanical structure minimizes vibration, ensuring consistency even under heavy payloads.

Main Application Industries:

-

CNC machining and manufacturing: Used for machine loading and unloading, drilling, and milling where straight-line accuracy is essential.

-

Electronics and semiconductor production: Performs precise pick-and-place operations and circuit board handling with excellent repeatability.

-

Packaging and palletizing: Handles large boxes or components efficiently, ensuring smooth integration with conveyors and labeling systems.

-

3D printing and additive manufacturing: Provides a stable framework for layer-by-layer material deposition with micron-level control.

Market Position and Leading Brands: Cartesian robot arms are valued for their customizability, reliability, and precision, especially in large-scale industrial environments. Well-known manufacturers like IAI, Yamaha, Parker, and Bosch Rexroth produce advanced Cartesian and gantry systems tailored to automation and CNC integration.

Example Application: In a car manufacturing plant, a Cartesian robot is often used for automated windshield installation or glass placement. Its linear motion ensures exact alignment without vibration. For companies focused on precision, repeatability, and scalable automation, Cartesian or gantry robots are a smart, long-term investment.

4. Parallel/Delta Robot Arms: Super Fast for Picking

Parallel or Delta armed robots are known for their high-speed and high-precision performance, making them indispensable in industries requiring rapid and repetitive motion. Unlike traditional serial-arm designs, Delta robots use three lightweight arms connected to a common base, forming a triangular parallel structure. This design minimizes moving mass and allows incredibly fast acceleration—often exceeding 150 picks per minute—while maintaining sub-millimeter accuracy.

Key Advantages:

-

Exceptional speed and throughput: Designed for high-frequency pick-and-place operations, ideal for fast-moving production lines.

-

Lightweight and efficient design: Parallel structure reduces inertia, enabling faster cycle times and lower energy use.

-

High precision: Maintains accuracy within ±0.1 mm, suitable for delicate product handling.

-

Compact footprint: Ceiling-mounted design saves floor space, keeping production areas open and efficient.

Main Application Industries:

-

Food and beverage industry: Handles sorting, packaging, and transferring items like candies, bakery products, and snacks.

-

Pharmaceuticals: Performs bottle capping, blister packing, and labeling at high speeds while maintaining hygiene standards.

-

Electronics manufacturing: Used for component sorting, placement, and inspection in assembly lines.

-

Consumer goods and logistics: Supports automated packaging and order picking in light-load distribution environments.

Market Position and Leading Brands: Delta robot arms hold a strong position in industries that prioritize speed and precision over payload capacity. Leading manufacturers such as ABB (FlexPicker series), Fanuc (M-1iA), Omron Adept, and Codian Robotics have developed Delta models that dominate the packaging, food, and electronics sectors.

Example Application:

In a confectionery packaging line, a Delta robot can pick, align, and place individual chocolates into boxes with exact orientation—performing hundreds of cycles per minute. Its high speed, combined with consistent accuracy, makes it one of the most efficient solutions for light-duty, high-volume automation. For factories seeking maximum throughput and precision handling, Delta robots represent a top-tier choice in modern production systems.

5. Cylindrical Robot Arms: Small Market, Small Size

6. Collaborative Robot Arms (Cobots): Safe Work With People

Collaborative robot arms—commonly known as cobots—are designed to work side by side with humans in shared workspaces without the need for safety cages. Unlike traditional industrial robots that require isolation, cobots prioritize safety, adaptability, and ease of use, making them ideal for small and medium-sized enterprises (SMEs) and flexible production lines. Their popularity has surged in recent years, with global market growth rates exceeding 20% annually.

Key Advantages:

-

Human-robot collaboration: Built with advanced force sensors and safety algorithms, cobots automatically stop when they detect contact, ensuring worker safety during operation.

-

Ease of programming: Most cobots feature intuitive drag-and-drop interfaces or hand-guided teaching, allowing users to program tasks in minutes—no expert coding required.

-

Compact and lightweight design: Can be easily relocated to different stations, enabling fast changeovers and low setup costs.

-

Enhanced versatility: Suitable for a wide range of light-duty applications such as assembly, inspection, polishing, and packaging.

Main Application Industries:

-

Electronics and consumer goods: Performs delicate assembly, screwdriving, and component handling without damaging fragile parts.

-

Automotive parts manufacturing: Assists with part inspection, gluing, and polishing—reducing operator fatigue and improving accuracy.

-

Medical and pharmaceutical industries: Used in lab automation, test tube handling, and medical device assembly, ensuring consistent precision and hygiene.

-

Metalworking and machining: Helps with loading/unloading CNC machines and polishing small components in tight workspaces.

Market Position and Leading Brands: Cobots are revolutionizing how factories approach automation by bridging the gap between manual and fully robotic operations. Leading brands such as MaxWave, Universal Robots (UR), FANUC, ABB, and Doosan Robotics dominate the segment with safe, user-friendly designs and flexible software ecosystems.

Example Application: In a small electronics factory, a cobot robot arm can handle circuit board assembly alongside human technicians—working 24/7 to improve throughput while maintaining precise placement accuracy. For businesses seeking cost-effective, scalable, and worker-friendly automation, collaborative robots are the ideal gateway into smart manufacturing.

How to Choose the Right Robot Arm

When selecting a robotic arm, consider:

-

Workspace Size: Evaluate how much physical space your production area offers. Articulated and Cartesian robots need larger operating zones, while SCARA and Delta robots are perfect for compact setups. Cobots, on the other hand, fit easily into existing workspaces without major layout changes.

-

Required Precision and Speed: High-precision industries—such as electronics, CNC machining, or medical device assembly—benefit from Cartesian or SCARA robots. For high-speed pick-and-place or packaging, Delta robots excel. If you need both accuracy and flexibility, articulated arms strike the best balance.

-

Payload Capacity: Choose a robot that can safely handle your materials’ weight. Articulated robots are ideal for heavy-duty lifting and welding, while SCARA and Delta models handle lighter, faster tasks with ease.

-

Integration Complexity: Consider how easily the robot can integrate with your existing systems. Cobots and SCARA robots offer plug-and-play simplicity, while articulated or Cartesian systems may require more programming and calibration—but provide greater customization in return.

-

Safety and Collaboration Needs: If human workers share the workspace, collaborative robots (cobots) are your best option. Built-in sensors and force limits make them safe and compliant with global standards. Traditional robots may require safety cages or separation zones.

Summary

Industrial robotic arms are more than machines—they’re a strategic investment in your factory’s future. The right model can slash downtime, increase throughput, and deliver a fast return on investment. Whether you run a small workshop or a large-scale production line, automation is the key to staying competitive in today’s market. If you’re ready to boost efficiency and upgrade your manufacturing line, contact us today to get expert advice and a customized robotic solution for your business.