Imagine a world where machines work tirelessly alongside humans, handling tasks with pinpoint accuracy and unmatched speed. From assembling complex electronics to helping in your kitchen, robot arms are transforming both industry and everyday life. Whether it’s boosting productivity in factories or making daily chores easier at home, these mechanical marvels are no longer science fiction—they are here, reshaping the way we live and work.

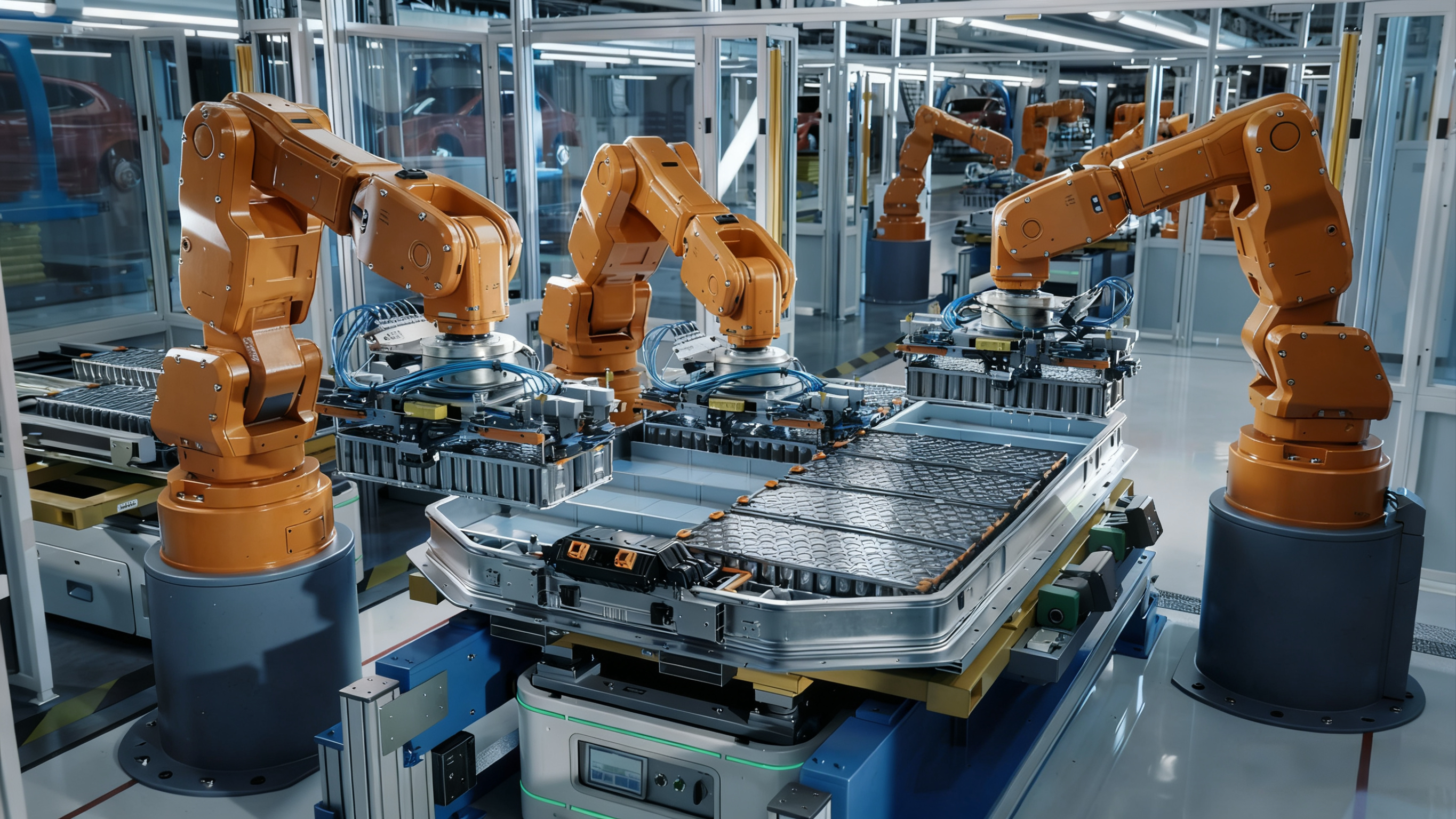

1. Assembly with Robot Arms

Robotic arms do important work on modern production lines. They are fast and accurate. This has changed how we build products. Production is now quicker and more reliable. Human mistakes happen less often.

Uses in Cars and Electronics

- Car Industry: Robotic arms build car frames. They install engines. They handle delicate wiring. This cuts down on mistakes and makes better vehicles.

- Electronics Making: Robotic arms place tiny parts on smartphones and circuit boards. They do this with great accuracy. Devices work better. Factories can make more products.

Why Robotic Arm Production Helps

Automated robotic systems boost production efficiency and consistency. Because machines repeat tasks exactly the same way, errors drop and product quality improves. Meanwhile, automated lines run day and night, cutting manufacturing time. With robotic arms performing consistently for long hours, every product meets the same high standard.

Industries Using Robotic Production

- Car makers

- Electronics firms

- Home appliance makers

- Consumer goods plants

I recommend these industries use robotic arms to stay ahead. Based on my experience, they help companies create new ideas faster. They also help deliver better products to buyers.

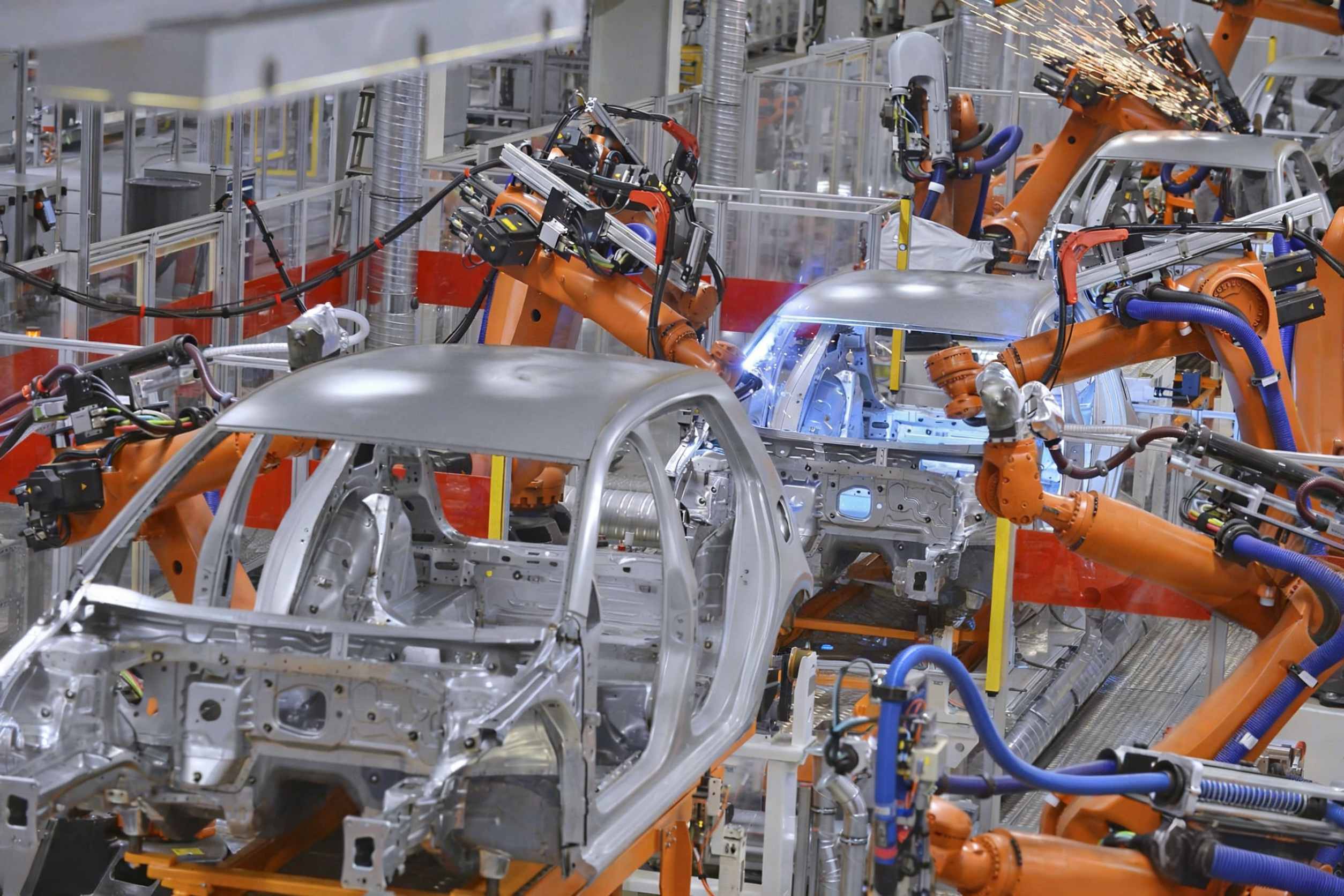

2. Welding with Robot Arms

Robotic arms change welding work in big ways. They do tough and risky jobs like arc welding and spot welding. Each weld stays the same. Each weld stays strong. Each weld meets safety rules. These machines never get tired. Every weld looks the same, even after hours of work.

Where Robotic Welding Works Best

- Automotive Industry: Robotic arms weld car bodies, steel frames, and aluminum parts. They fit into tight spaces. They help build strong, safe cars.

- Shipbuilding: Robots do large welding jobs in shipyards. These jobs are too risky or tiring for workers. Ships get built faster. Quality goes up.

- Aerospace and Heavy Machinery: Robots weld airplane parts and big building tools. They manage tricky designs and heavy materials easily.

Why I Recommend Robotic Welding

Robotic welding improves both safety and product quality. Robots take on hot, risky, and repetitive tasks, keeping workers safer. They also apply precise settings and timing for every weld, creating stronger, more reliable joints. And because robots don’t make mistakes or lose focus, weak spots are minimized and weld quality stays consistently high.

Industries I Suggest

- Automotive factories

- Aerospace companies

- Makers of building equipment

- Shipyards

I think buying robotic welding arms makes sense for industries that need exact, high-quality welds. Yes, the first cost is high. But you get safer workspaces. You get better output quality. Based on my experience, this investment pays off.

3. Material Handling with Robot Arms

Robot arms have changed how factories and warehouses move materials. They lift, sort, and transport raw materials, parts, or finished products with precision. This keeps workflows smooth. It also reduces the risk of worker injuries from lifting heavy or unsafe items.

Key Uses of Robotic Arm Material Handling

- Loading and Unloading Conveyor Belts: Arms place parts onto moving belts or remove finished goods. This keeps production lines running without delays.

- Moving Delicate or Hazardous Materials: Robots handle fragile items or dangerous substances without breakage or exposure risks. This boosts product safety. It also protects worker health.

- Transferring Parts Between Machines: Robotic arms pick up parts from one machine. They deliver them to the next step in the process. This reduces wait times. It speeds up overall production.

Why I Recommend Robotic Material Handling

Robotic material handling improves safety, speed, and consistency. Robots take on heavy, repetitive, or unsafe tasks, lowering injury risks. They move materials with precision, reducing product damage and workflow delays. With automated robotic arms managing inventory—shelving products, tracking stock, and picking items accurately—operations stay organized. And because robots don’t get tired or distracted, they keep workflows stable around the clock.

Industries I Suggest

-

Logistics companies

-

Warehouses and distribution centers

-

Manufacturing plants

-

Pharmaceutical and medical product facilities

I think investing in robotic material handling makes sense for any business. Based on my experience, safer workplaces and faster order fulfillment are worth the investment. The price of these systems varies. But I suggest looking at the long-term savings and safety benefits. They are worth it.

4. Packaging and Palletizing with Robot Arms

Robotic arms do important work in packaging and palletizing. They pack and stack products automatically. This makes the process faster and more exact. Efficiency goes up. Damaged goods during storage or shipping go down.

Key Uses of Robotic Packaging and Palletizing

- Filling Boxes and Sealing Cartons: Robotic arm fill boxes with products and seal them for shipment. Every box gets packed the same way. This cuts errors. Product safety improves.

- Stacking Products on Pallets: These robots arrange goods on pallets. They maximize space and keep stacks stable. Products stay secure during transit and storage. Items won’t shift or fall.

Why I Recommend Robotic Packaging and Palletizing

Robotic packaging systems greatly boost efficiency in handling perishable foods. Automated robotic arms process high volumes of packages with speed and accuracy, reducing turnaround time and improving order quality. They also maximize pallet space, keep stacks stable, and protect goods during transport, ensuring safer and more reliable delivery.

Industries I Suggest

-

Food and beverage companies

-

Logistics and warehousing centers

-

Retail and e-commerce fulfillment operations

I recommend robotic arms for companies with high-volume packaging. I also suggest them for businesses with frequent large shipments. Based on my experience, automated packaging and palletizing saves manual labor. It improves package quality. Warehouse safety gets better too.

5. Painting and Coating with Robot Arms

Robotic arms have changed painting and coating in many industries. They spread paints or protective coatings evenly. This replaces manual work. Workers stay safe from toxic fumes. Surface finishes look the same every time.

Key Applications in Painting with Robotic Arms

- Vehicle Body Painting: Robots spray paint on car bodies. They reach every curve and corner. Each finish looks the same. Factory workers avoid harmful chemicals.

- Coating Electronics Enclosures: In electronics plants, robotic arm robots coat casings and circuit boards. Each part gets even coverage. This stops coating gaps that could cause device failure.

- Industrial Equipment and Furniture Coating: Robots spread finishes on machines and furniture. Every product looks good. Products last longer too.

Why Use Robotic Arms for Painting and Coating

Workers stay protected because robots handle areas with strong fumes or spray mist, eliminating the need for extensive human protective gear and reducing labor protection costs. Each product receives the same, perfectly even coating thickness, ensuring consistent results. Robots also use only the needed amount of paint, cutting waste and saving money.

Major Industries Adopting Robotic Painting

- Automotive factories

- Electronics manufacturers

- Furniture producers

- Aerospace companies

Based on industry data and my experience, I recommend robotic painting systems despite the high upfront cost. The investment pays back fast. I’ve seen how they cut workplace risks. They deliver high-quality, uniform results. This builds trust in products. From what I’ve observed, companies that switch to robotic painting see better output and happier workers.

6. Machine Tending with Robot Arms

Robot arms load and unload machines. These machines include CNC machines, presses, and injection molding equipment. We call this task machine tending. It keeps factories running well. Robots place raw materials into machines. They remove finished parts without breaks. This increases uptime and productivity.

Key Machine Tending Applications

- Loading and Unloading Parts: Robots put raw materials into machines. This starts the next production step. Robotic arms remove finished parts. This prevents bottlenecks. It keeps the workflow steady.

- Servicing Multiple Machines: One robot arm can manage several machines at once. This boosts efficiency. You don’t need extra staff. I’ve seen this work great for 24/7 production.

- Handling Different Parts: Robotic tending arms switch between different product types. Downtime is minimal. This flexibility supports varied manufacturing needs.

Why Machine Tending Robots Matter

With automated operations, production efficiency increases significantly because robots run continuously, reduce downtime, and boost output. At the same time, robots handle loading and unloading with precision, ensuring products consistently meet high standards. Automation also lowers labor costs, as fewer workers are needed for repetitive or dangerous tasks, creating a safer workplace. Although the initial investment is higher, improved efficiency and product quality lead to a faster return on investment, making the overall benefits substantial.

Industries Using Machine Tending Robots

- Metalworking

- Plastics Manufacturing

- Electronics Production

- Machinery Fabrication

I recommend investing in robotic machine tending. It’s smart for manufacturers who want to increase output. It helps you stay competitive. Robots cut downtime. They improve safety. They fit well into small factories. They fit well into large-scale factories too.

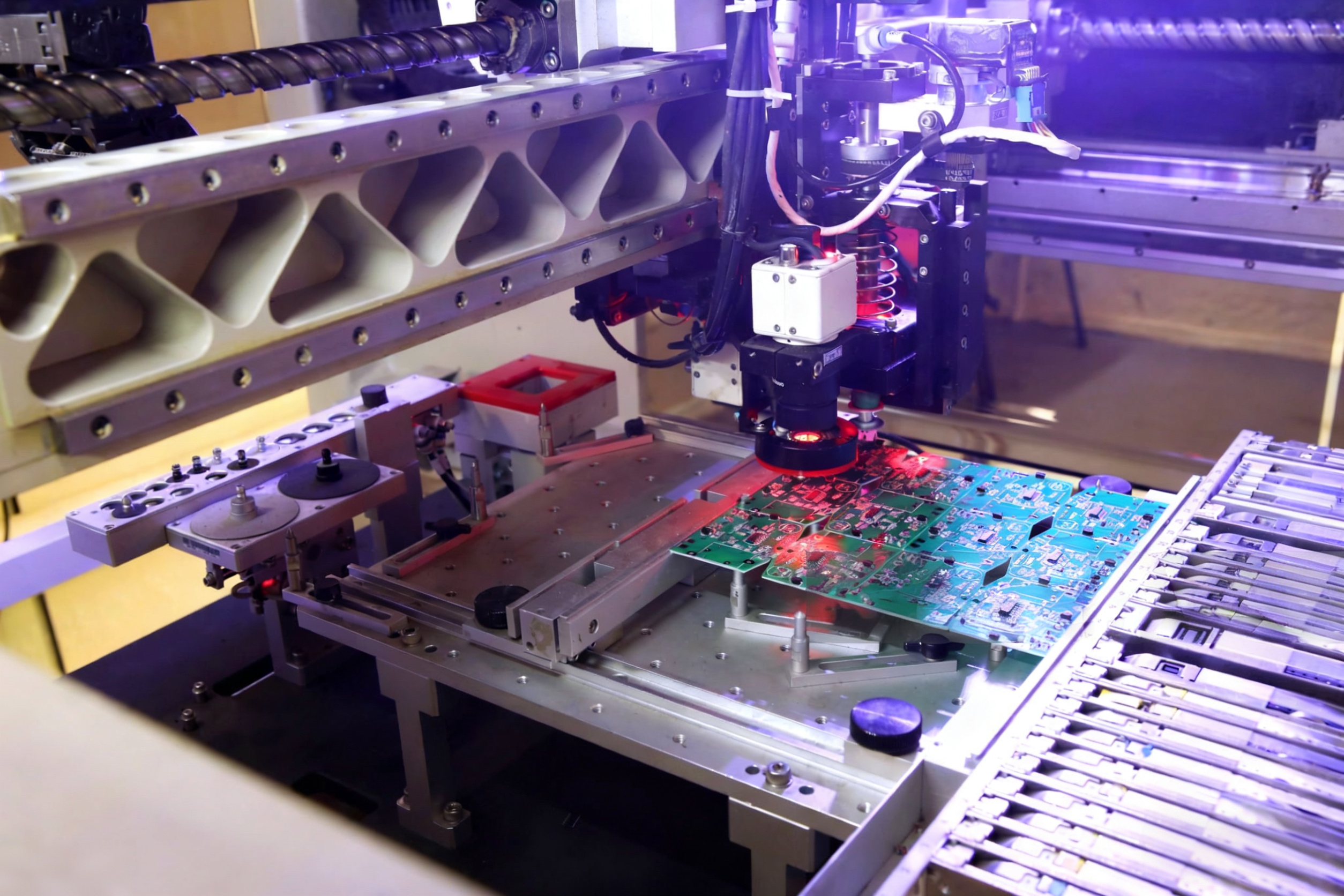

7. Inspection and Quality Control with Robot Arms

Robotic arms change how we do inspection and quality control. They measure fast and with high precision. Manual checks can’t match this speed. The robots scan products for defects. They analyze each item. Every product must meet strict standards before it ships. I believe automated inspection is now essential in smart manufacturing.

Key Applications in Quality Inspection

- Vision-Based Inspection: Armed robots use high-resolution cameras and sensors. They spot tiny defects. Surface scratches, color mismatches, or assembly problems don’t escape them. In electronics manufacturing, I’ve seen robotic arms check connectors and solder joints. They catch errors the human eye can’t see. This happens in seconds.

- Dimensional Measurement: Advanced robotic systems measure dimensions and tolerances. They work far faster than manual tools. In the automotive industry, robots verify the exact fit of body parts in seconds. This prevents expensive rework later. Based on my experience, this saves companies thousands of dollars.

- Automated Sampling: Robots select samples for regular quality checks. This makes process control more reliable. It also keeps results consistent. Food, beverage, and pharmaceutical factories need this. Quality and safety rules are strict in these industries. I recommend automated sampling for any regulated environment.

Benefits of Robotic Inspection and Quality Control

Robotic inspection arms greatly enhance accuracy, speed, and process control. They perform the same precise checks every time, reducing human error and ensuring consistent product quality. They also work quickly, inspecting hundreds of items per hour to prevent bottlenecks and keep production flowing. Meanwhile, inspection software gathers detailed data, helping manufacturers spot trends, trace issues, and improve processes before products reach customers.

Real-World Use Cases

- Consumer Electronics

- Automotive

- Pharmaceutical and Medical Devices

Automated inspection is now a must for industry leaders. I think reliability matters more than ever. Real-time defect detection helps companies avoid expensive mistakes. It keeps customers satisfied. Robots make quality control faster and more reliable. They prepare your factory for the future. From my experience, companies that adopt this technology stay ahead of competitors. They build trust with customers. That trust translates to repeat business and growth.

8. Laboratory Automation with Robot Arms

Robotic arms are changing how labs work. They boost speed, precision, and safety. These machines handle boring and delicate tasks. Scientists can now focus on more important work.

Key Applications of Robotic Arms in Laboratories

- Sample Preparation: Robotic arms prepare and sort samples with care. They cut down errors in DNA sequencing or chemical analysis.

- Mixing and Reagent Dispensing: Automated arms add exact amounts of liquids or chemicals for tests. This cuts contamination risk. All tests run under the same conditions.

- Automated Testing: Robots move test tubes, plates, or vials between instruments. High-throughput screening needs this. Blood analysis needs this too.

Why Invest in Laboratory Automation?

Robotic systems greatly improve lab throughput and reliability. Many labs now use robots to process thousands of samples per day, from genomics to virus testing. They also provide precise, repeatable actions without fatigue, ensuring accurate movements and measurements. And by reducing human contact, they lower the risk of cross-contamination in sensitive work.

Industries and Scenarios Benefiting from Lab Automation

- Biotechnology

- Pharmaceuticals

- Medical Diagnostics

- Research Laboratories

I recommend installing robotic arms for lab automation. Based on my experience, they speed up scientific progress. Labs can meet rising demand. Quality stays high. Safety stays high. I suggest pharmaceutical and biotech labs invest in this. Reliability matters in these fields. Accuracy matters for product development. Patient safety depends on it.

9. Food Handling and Processing with Robot Arms

Robot arm robots are changing how we handle and process food. They keep things clean. They boost speed. They help companies meet strict food safety rules.

I’ve seen how automated systems now handle many key steps in making food. They cut down on contamination risks. They also reduce labor costs.

Key Applications of Robotic Food Handling

- Packing and Sorting: Robotic arms pack pastries, fruits, and vegetables into trays with care. They sort products by size, shape, and quality. This keeps output fast and uniform.

- Cutting and Slicing: Robots prune, slice, and portion food items with exact precision. Every cut matches the set standard. Waste goes down. Quality goes up.

- Tray Placement and Arrangement: Automated arms place food products into packages or onto trays for shipping. This speeds up workflows. It also keeps human contact to a minimum.

Why Invest in Robotic Food Handling?

Robots can improve hygiene by reducing direct human contact, lowering the risk of contamination, and making it easier for companies to comply with sanitation regulations. At the same time, automated systems operate efficiently, meeting high-volume demands and ensuring on-time delivery, while product quality remains consistent, helping to build a trustworthy brand.

Industries Using Robots in Food Processing

- Food and Beverage Production

- Packaging Plants

- Meat Processing

Based on my experience, robotic food handling is fast becoming a standard across the food industry. I believe investment in these systems improves food safety. It saves money over time. It allows producers to scale up fast. These are critical advantages for staying competitive in modern food markets. I suggest companies explore these options now.

10. Surgical and Medical Assistance with Robot Arms

Robot robotic arms are changing medicine. They give surgeons better precision and control. This means smaller cuts during surgery. It also automates repeat medical tasks. Patients get safer and more reliable results.

Key Applications of Robotic Arms in Medicine

- Robotic-Assisted Surgery: I’ve seen systems like the Da Vinci Surgical System help surgeons work through tiny cuts. These robots stay steady. They don’t get tired. Patients face fewer problems. They recover faster.

- Medication Dispensing: Robotic arms sort and give out medication in pharmacies and hospitals. This cuts down on human mistakes. The dose is right every time. Patient safety goes up.

- Hospital Automation: Robots move medical supplies, samples, or food between departments. This makes hospitals run better. It lowers infection risk. Staff can spend more time caring for patients.

Benefits in Healthcare and Medical Environments

Robotic systems enhance precision and skill, allowing surgeons to perform delicate tasks, such as stitching tiny blood vessels, that are difficult for human hands. They enable smaller incisions, which reduce pain, speed up recovery, and lower infection risk, allowing hospitals to treat more patients efficiently. Additionally, robots handle routine tasks like preparing medication and transporting supplies, freeing doctors and nurses to focus on critical patient care.

Major Sectors Using Medical Robotics

- Hospitals

- Surgical clinics

- Healthcare automation providers

- Pharmaceutical companies

Based on what I’ve seen, I recommend investing in robotic arms for medical use. Clinics and hospitals gain a strong advantage. Yes, the initial costs run high. But the benefits make it worth it. You get better patient outcomes. You see fewer errors. Staff work more efficiently. These benefits pay off over time. As technology grows, I believe robotic help will become standard in modern healthcare.

Summary

As robot arms continue to evolve, the possibilities are endless. Businesses can streamline operations and cut costs, while individuals can enjoy smarter, more convenient living. If you’re ready to experience the power and precision of robotic technology firsthand, now is the perfect time to invest in a robot arm and take your efficiency to the next level. Don’t wait—discover how a robot arm can transform your work and life today! Contact us now to get a personalized quote and start your journey.