The automotive industry is in the midst of a revolutionary shift, driven by demands for lighter weights, superior strength, and unparalleled precision. In this high-stakes environment, traditional welding methods are being outpaced by the need for speed, consistency, and innovation. Enter the Max 1500W Laser Welding Machine—a powerhouse of technology designed to meet these challenges head-on. This isn’t just an upgrade; it’s a transformative tool that is redefining how vehicles are built, from the chassis up. By delivering pinpoint accuracy and incredibly strong, clean welds, the Max 1500W is moving from the advanced factory floor to becoming an indispensable asset in the modern automotive supply chain. Let’s explore the ten key applications where this machine is setting new standards for quality and efficiency.

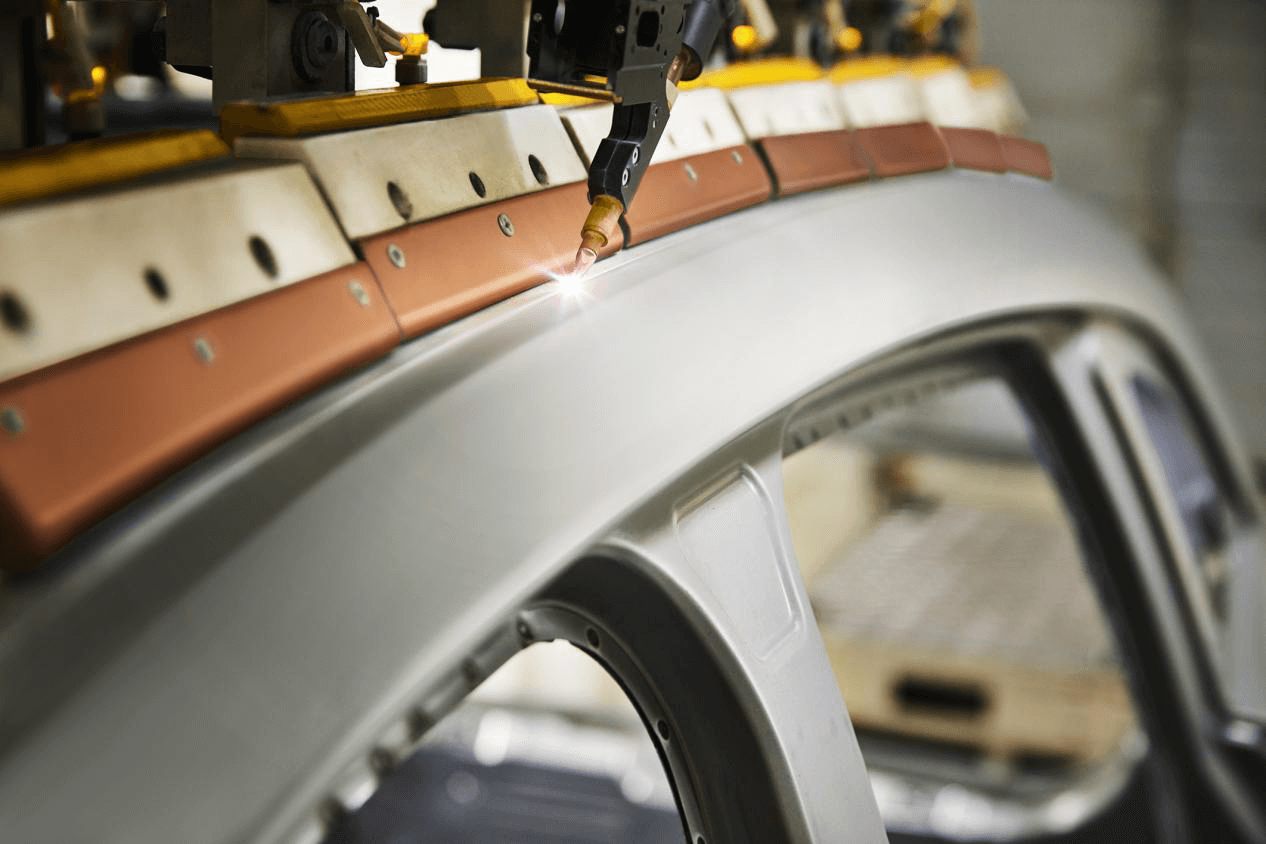

1.Automotive Frame Welding

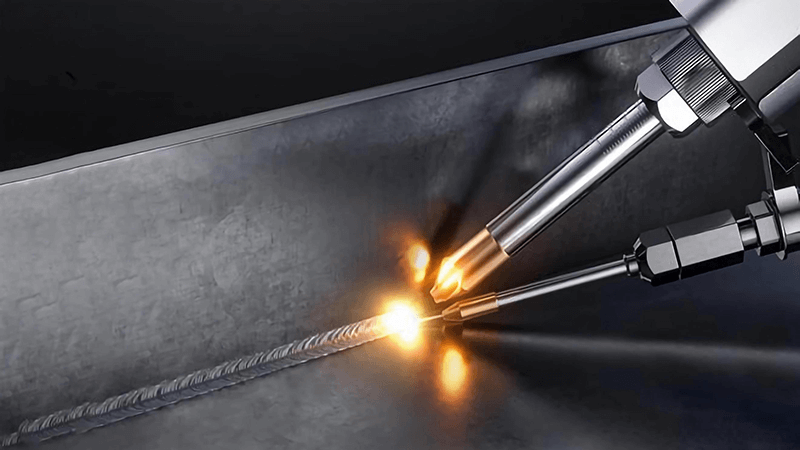

The Max 1500W Laser Welder excels in constructing the vehicle’s core framework, or automotive frame. It creates seamless, high-strength joints between roof panels, side frames, and underbody components.

Key Applications:

-

Roof to Side Panel Welding: Creates continuous, aesthetically pleasing welds that are both strong and leak-proof.

-

Door Hinges and Reinforcements: Precisely welds high-stress components, ensuring door alignment and long-term durability.

Why We Recommend the Max 1500W:

Its high power and focused beam result in minimal thermal distortion. This means panels retain their shape and fit, drastically reducing the need for post-welding rework. The weld seams are not only stronger than the base material but also ready for painting with minimal finishing.

Ideal For:

- Automotive OEMs

- Automotive frame suppliers

We strongly recommend the Max 1500W for its ability to deliver distortion-free, high-strength welds that are critica l for modern vehicle safety and aesthetics.

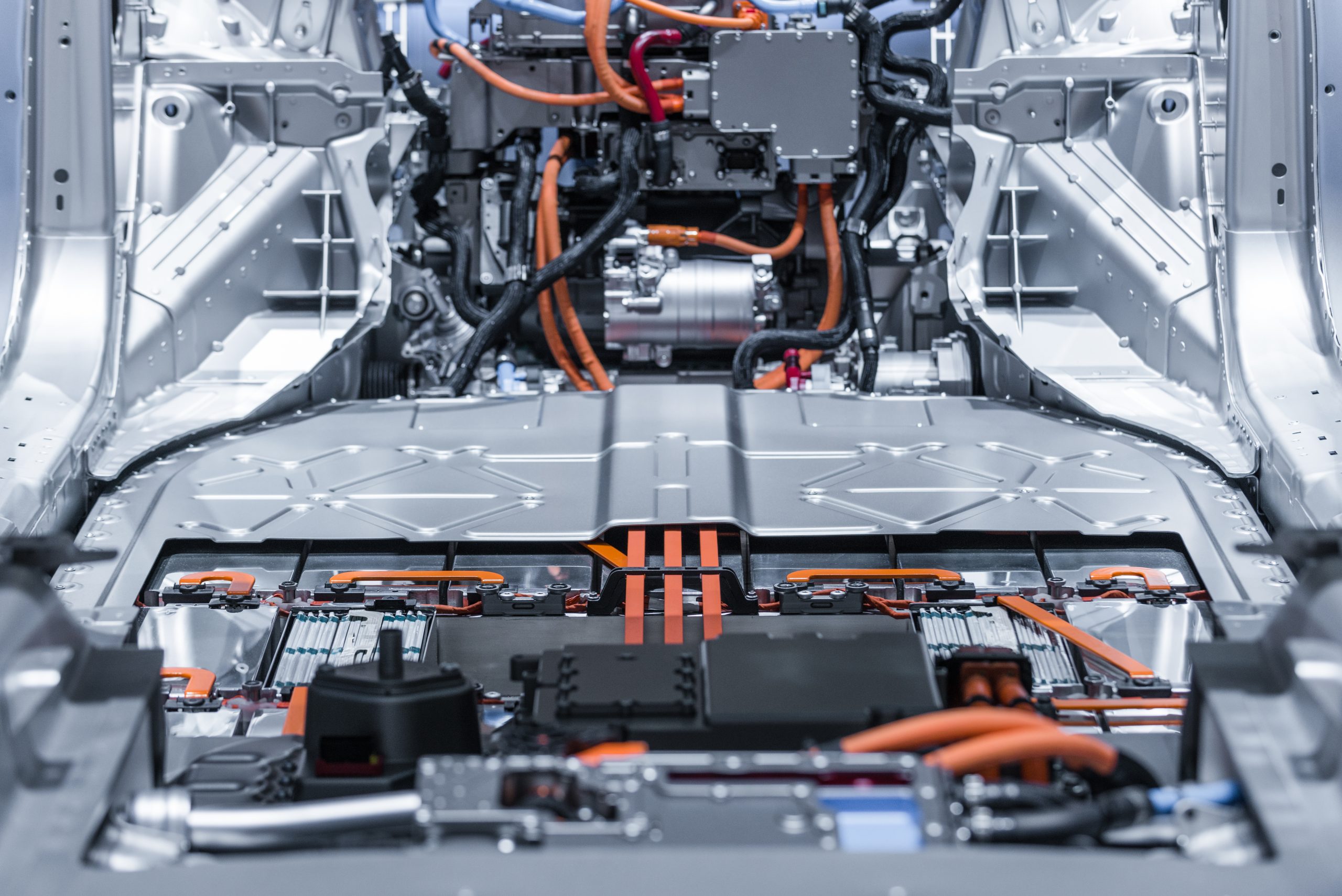

2.EV Battery Tray Welding

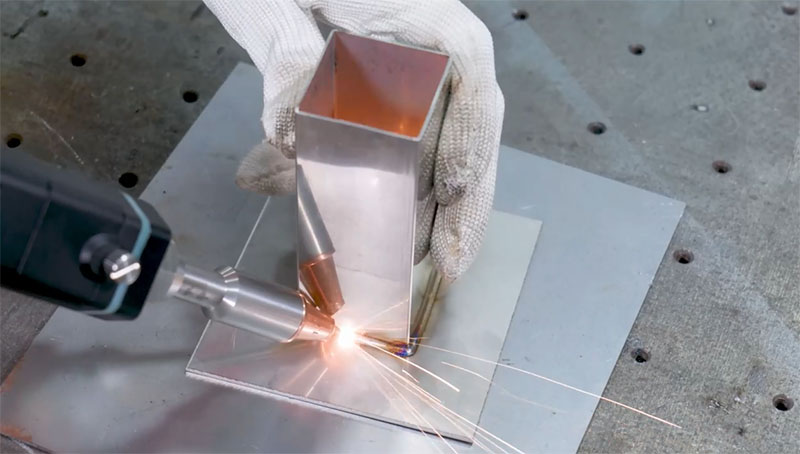

The heart of an electric vehicle is its battery pack, and the tray holding it must be perfectly sealed and structurally sound. The Max 1500W is ideal for this critical task.

Key Applications:

-

Aluminum/Steel Enclosure Welding: Produces deep penetration welds on lightweight materials, creating a robust and rigid frame.

- Cooling Plate Integration: Seals cooling channels within the tray with hermetic welds, preventing coolant leakage into the battery compartment.

Why We Recommend the Max 1500W:

It achieves hermetic (air-tight) seals that are crucial for protecting sensitive battery cells from moisture and contaminants. The precision welding minimizes heat input, preserving the integrity of the battery cells and nearby electronics.

Ideal For:

- Electric vehicle manufacturers

- Battery pack assembly plants

Investing in the Max 1500W is a strategic move for any EV manufacturer aiming for superior battery safety, longevity, and compliance with stringent sealing standards.

3. High-Temperature Exhaust System Welding

From manifolds to complex catalytic converter assemblies, exhaust systems endure extreme temperatures and vibrations.

Key Applications:

-

Manifold Sections: Welds thin, heat-resistant stainless steel sheets with precision, preventing warping and ensuring gas-tight integrity.

-

Flexible Pipe Connectors: Creates durable joints in corrugated sections that can withstand constant flexing.

Why We Recommend the Max 1500W:

The laser weld is exceptionally clean and consistent, reducing the risk of microfractures that can lead to exhaust leaks over time. The high-speed welding is perfect for high-volume production lines.

Ideal For:

- Exhaust system manufacturers

- Powertrain component suppliers

Upgrade to the Max 1500W to achieve leak-proof, durable welds that withstand extreme thermal cycling, significantly reducing warranty claims and improving system reliability.

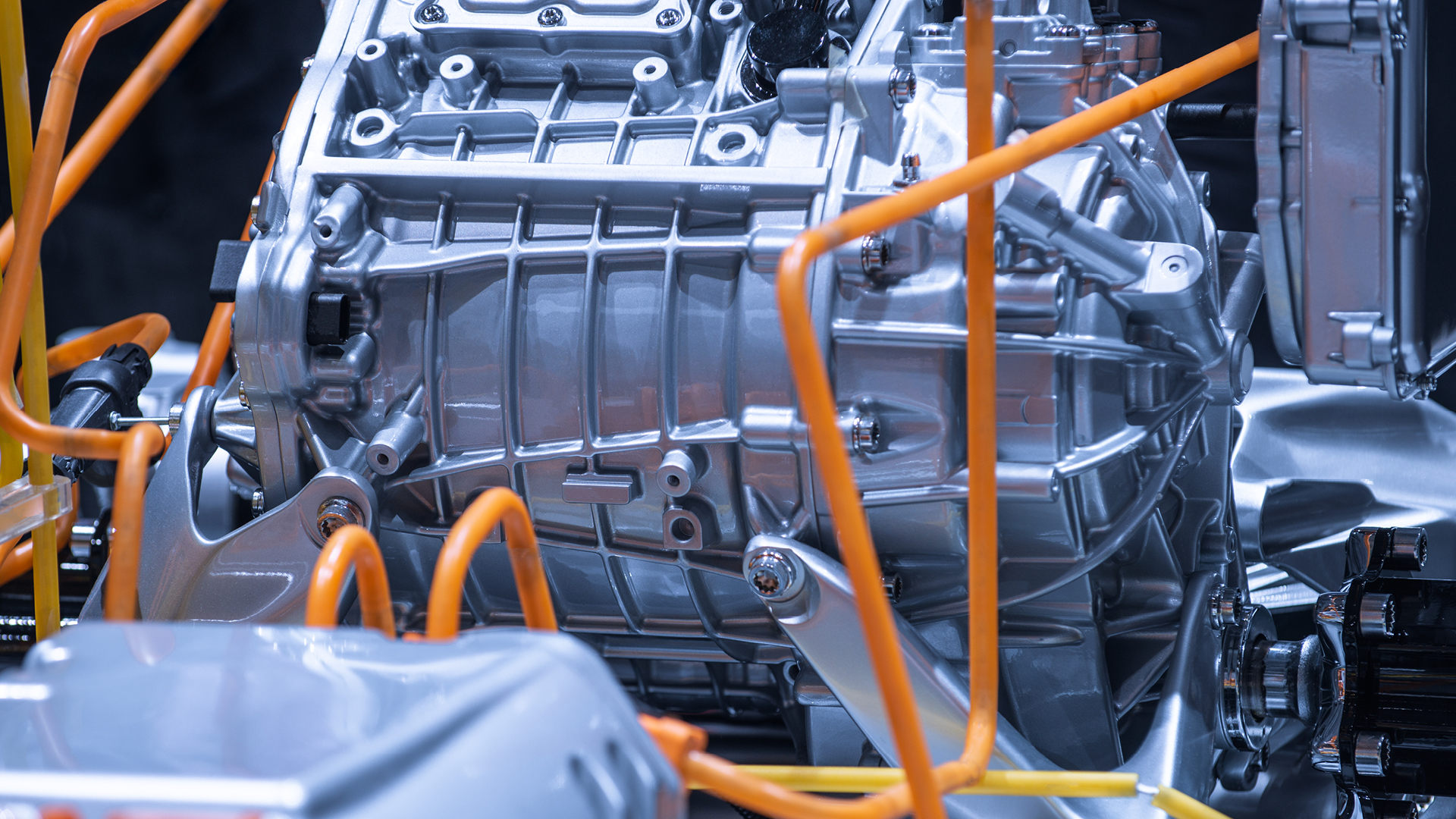

4. Powertrain Components Welding

Transmissions require components that can withstand immense torque and stress. Laser welding provides the reliability needed for these critical systems.

Key Applications:

-

Gear Assemblies: Welds gears to shafts with minimal heat, preserving the temper and hardness of the metal.

-

Clutch Housings: Creates strong, consistent welds around the circumference of housings, ensuring they remain sealed under pressure.

Why We Recommend the Max 1500W:

The deep weld penetration achieved by the 1500W laser creates joints that are as strong as or stronger than the components themselves. This eliminates a key point of failure in the powertrain.

Ideal For:

- Transmission manufacturers

- Drivetrain component specialists

For powertrain components where failure is not an option, the Max 1500W provides the unparalleled joint integrity and consistency required for peak performance and durability.

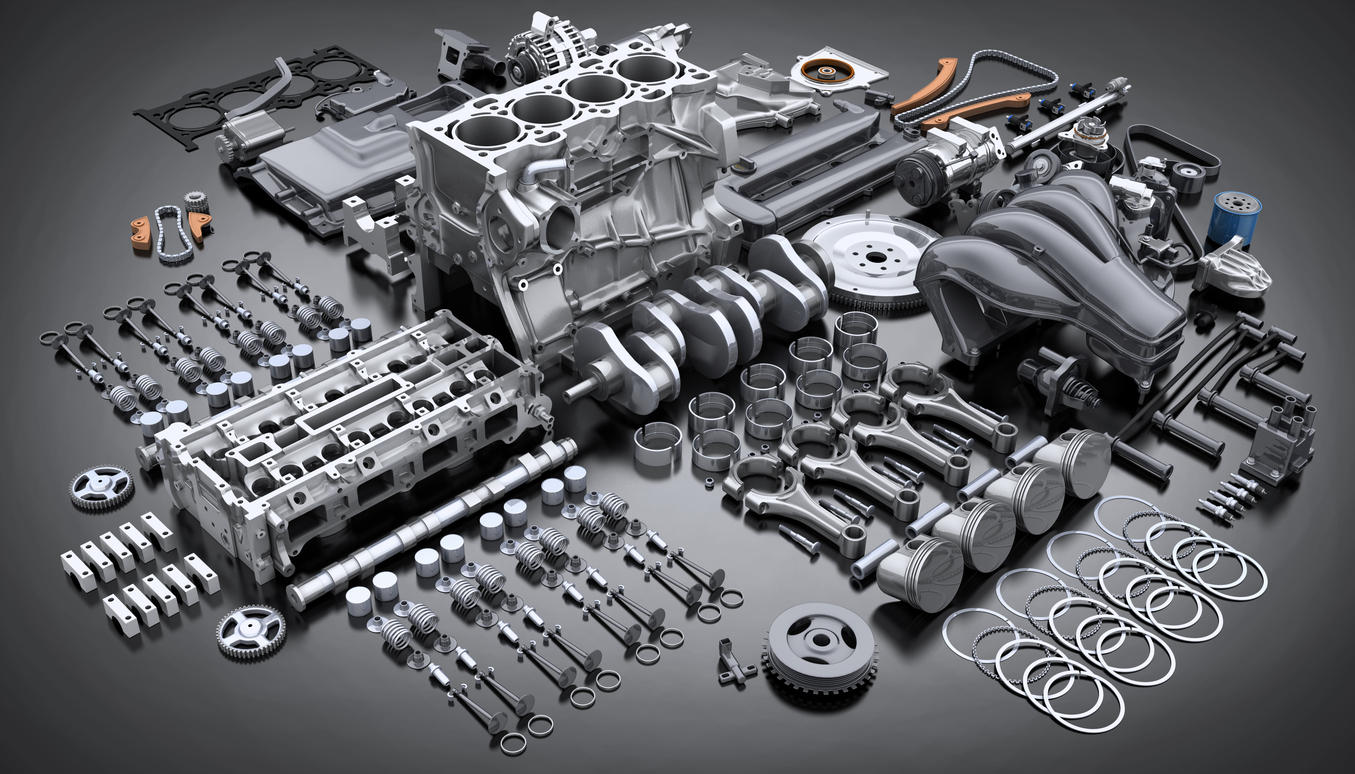

5. Precision Engine Parts Welding

Even in the age of EVs, internal combustion and hybrid engines demand the highest level of precision for components like turbochargers and fuel systems.

Key Applications:

-

Turbocharger Housings: Seals the complex, thin-walled sections of turbo housings, capable of withstanding extreme heat and pressure.

-

Fuel Injector Bodies: Performs micro-welds on delicate injector parts without damaging internal components.

Why We Recommend the Max 1500W:

Its pinpoint accuracy allows for welding in incredibly confined spaces without collateral heat damage. This results in higher reliability and longer component life.

Ideal For:

- Engine manufacturers

- Turbocharger and fuel system suppliers

We recommend the Max 1500W for its precision in handling delicate and complex engine parts, enabling higher performance standards and reduced component rejection rates.

6.Safety-Critical Structural Welding

Safety is paramount. The Max 1500W is used to integrate high-strength steel reinforcements into the vehicle’s safety cell.

Key Applications:

-

A-Pillar and B-Pillar Reinforcements: Welds ultra-high-strength steel tubes and plates to create a survival cell for occupants.

-

Crash Boxes: Attaches engineered crumple zones to the chassis, ensuring they deform predictably in an impact.

Why We Recommend the Max 1500W:

It can weld advanced, high-strength materials without compromising their metallurgical properties. The consistency of every weld ensures predictable and reliable performance in every crash scenario.

Ideal For:

- Automotive safety component makers

- Chassis fabricators

Adopting the Max 1500W is essential for producing safety-critical components with guaranteed weld consistency, directly contributing to higher crash test ratings and passenger protection.

7. High-Finish Aesthetic Welding

The aesthetic quality of welds is critical in luxury vehicles and custom builds, where components may be visible.

Key Applications:

-

Visible Seam Welding on Frames: Produces consistent, beautiful weld beads on custom motorcycle frames or roll cages.

-

Stainless Steel Trim and Accents: Joins decorative elements with virtually invisible seams.

Why We Recommend the Max 1500W:

It delivers “show-quality” welds that require little to no polishing or grinding. This saves significant time and labor in finishing high-end vehicles.

Ideal For:

- Luxury car manufacturers

- Custom automotive and motorcycle workshops

For luxury and custom builders, the Max 1500W is the tool of choice to merge exceptional strength with flawless aesthetics, adding significant value to every vehicle.

8. Sealed Fluid Line Welding

Commercial vehicles and heavy machinery rely on complex networks of hydraulic lines that must be absolutely reliable.

Key Applications:

-

Tube-to-Fitting Welding: Creates strong, leak-proof connections for brake, fuel, and hydraulic lines.

Why We Recommend the Max 1500W:

The laser process ensures a clean, contamination-free weld, which is vital for the longevity of sensitive hydraulic valves and pumps. It eliminates the weaknesses often associated with brazing or conventional welding.

Ideal For:

- Commercial vehicle manufacturers

- Hydraulic system integrators

Implement the Max 1500W to eliminate leaks at the source, ensuring the absolute reliability of fluid systems and preventing costly downstream failures in commercial vehicles.

9. Sensor Bracket Precision Welding

Modern vehicles are filled with sensors for ADAS (Advanced Driver-Assistance Systems). Their mounting must be precise and secure.

Key Applications:

-

LiDAR/Radar Bracket Welding: Precisely attaches small, complex brackets to vehicle frames without distortion.

-

Camera Housing Assembly: Seals housings for backup and surround-view cameras.

Why We Recommend the Max 1500W:

The low heat input prevents misalignment of sensor brackets, which is critical for the accurate functioning of ADAS. The process is fast and easily automated for high-volume sensor installation.

Ideal For:

- ADAS and electronics suppliers

- Automotive assembly lines

The precision of the Max 1500W is non-negotiable for ADAS sensor integration; it ensures mounting accuracy that is vital for the functionality of autonomous and safety systems.

10. Door and Closure Panel Welding

Doors, hoods, and tailgates are complex assemblies of inner and outer panels with integrated hinges and latches.

Key Applications:

-

Inner-to-Outer Panel Welding: Joins panels with a continuous, distortion-free weld.

-

Hinge and Latch Reinforcement Welding: Secures high-wear components with robust, durable welds.

Why We Recommend the Max 1500W:

Its speed and precision are perfect for the high-volume production of closure panels. The minimal thermal distortion ensures perfect panel gaps and alignment right off the production line.

Ideal For:

- Door module assembly plants

- Final assembly stations

Integrate the Max 1500W into your closure line to achieve perfect panel gaps and superior build quality right from the start, elevating the customer’s first impression and satisfaction.

Summary

The potential of the Max 1500W Laser Welding Machine to revolutionize automotive manufacturing is not a future promise—it is a present-day reality. From ensuring the structural integrity of an EV’s battery to crafting the invisible seams on a luxury car frame, this machine delivers unmatched quality, speed, and return on investment. It empowers businesses to streamline production, slash rework costs, and build a reputation for unparalleled quality.

If you’re ready to weld your way to a stronger, more efficient, and more competitive future, now is the time to act. Don’t let your manufacturing process be left in the past. Contact us today to get a personalized quote and discover how the Max 1500W Laser Welding Machine can transform your automotive production line.