Stainless steel welding presents unique challenges that demand specialized solutions. With its low thermal conductivity and high expansion coefficient, this material requires precise heat management to prevent distortion and maintain corrosion resistance. While traditional methods like TIG and MIG welding have been industry standards for decades, laser welding technology has emerged as a game-changing solution that addresses these fundamental challenges while delivering unprecedented precision and efficiency.

| Parameter | TIG Welding | MIG Welding | Laser Welding |

| Typical Speed | 10-15 cm/min | 30-60 cm/min | 200-500 cm/min |

| Heat-Affected Zone | 2-5 mm | 3-7 mm | 0.1-0.5 mm |

| Thinnest Practical Material | 0.5 mm | 1.5 mm | 0.1 mm |

| Operator Skill Requirement | Very High | Moderate | Low |

| First-Pass Success Rate | 85-92% | 80-90% | 98-99.5% |

| Post-Weld Cleaning Required | Minimal | Significant | Minimal to None |

| Energy Efficiency | 30-45% | 60-75% | 85-95% |

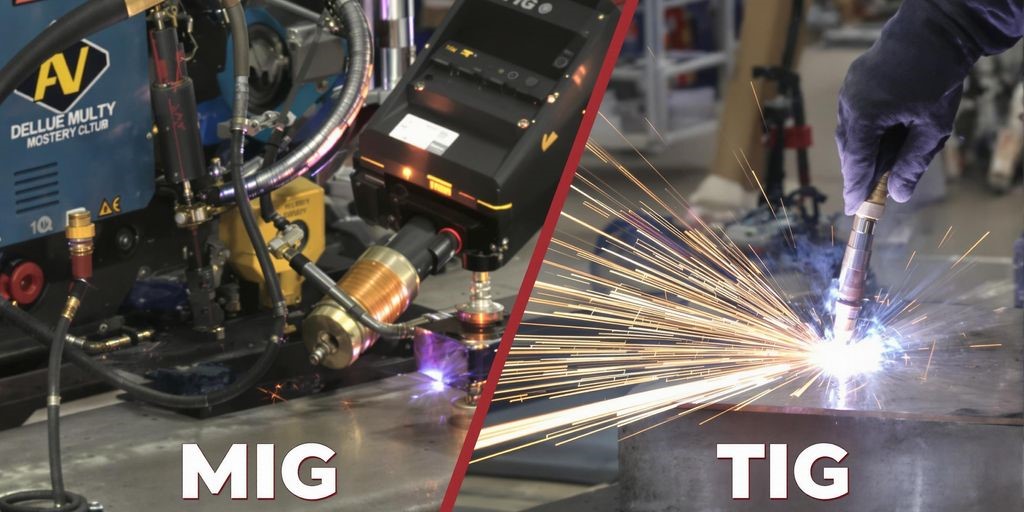

TIG Welding: The Artisan’s Approach with Inherent Limitations

• Exceptional Material Versatility

Successfully handles diverse stainless steel grades including standard 304 and 316, plus specialized duplex and super-austenitic varieties with equal proficiency.

• Precision Heat Control

Utilizes non-consumable tungsten electrodes generating arcs up to 3,500°C, with skilled operators achieving remarkable precision through foot pedal amperage control for perfect weld appearance.

• Superior Aesthetic Results

Produces visually perfect welds with consistent coloration and minimal discoloration, making it ideal for applications where appearance is paramount – architectural features, high-end products, and visible structures.

• Critical Speed Limitations

Demonstrates inherently slow deposition rates of 0.5-2.5 pounds per hour, creating significant production bottlenecks that become increasingly costly at scale.

• Extreme Operator Dependency

Requires hundreds of training hours to develop necessary muscle memory and technical intuition, introducing unavoidable quality variations based on operator fatigue and concentration levels.

• Significant Thermal Impact

Generates substantial heat-affected zones extending 2-5mm, potentially compromising corrosion resistance through carbide precipitation in sensitive stainless grades.

MIG Welding: The Production Workhorse with Quality Compromises

Enhanced Production Speed

Delivers significantly higher deposition rates of 5-15 pounds per hour, making it ideal for longer welds, thicker sections (3mm+), and throughput-focused manufacturing environments.

• Reduced Operator Demands

Features continuous wire feed mechanisms that minimize operator fatigue and lower skill requirements compared to TIG’s manual processes.

• Advanced Process Control

Modern pulsed MIG systems employ sophisticated waveform control, alternating between high peak and low background currents for improved stainless steel welding performance.

• Substantial Spatter Issues

Generates significant spatter requiring extensive post-weld cleaning operations, adding substantial time, labor, and consumable costs to manufacturing processes.

• Extensive Thermal Damage

Creates wide heat-affected zones (3-7mm) that significantly alter metallurgical structures and potentially diminish corrosion resistance in critical applications.

• Limited Thin-Material Capability

Struggles with materials below 1.5mm thickness, producing inconsistent results with poor appearance and inadequate distortion control compared to advanced processes.

Laser Welding: The Manufacturing Revolution with Transformational Benefits

• Revolutionary Speed & Precision

Combines unmatched processing speeds with microscopic precision using highly concentrated laser beams from high-efficiency fiber laser sources.

• Minimal Thermal Distortion

Creates extraordinary energy densities millions of times greater than conventional processes, producing a “keyhole” effect with minimal thermal spread and heat-affected zones of just 0.1-0.5mm.

• Perfect Process Consistency

Incorporates advanced integrated monitoring with multiple sensors tracking penetration depth and thermal profile in real-time, ensuring identical results from first to thousandth weld.

• Unprecedented Production Speeds

Achieves 200-500 cm/minute welding speeds – ten times faster than TIG – while maintaining perfect control over even the most thermally sensitive stainless grades.

• Zero Post-Processing Requirements

Virtually eliminates distortion and preserves base material properties, removing need for corrective operations and delivering previously unattainable quality levels.

The Compelling Economic Advantages of Laser Welding

The quantitative benefits of laser welding extend far beyond basic speed comparisons to encompass transformative economic advantages that fundamentally alter manufacturing cost structures. The exceptional process stability of laser systems results in first-pass success rates exceeding 99%, compared to 85-92% for TIG and 80-90% for MIG welding. This dramatic improvement in right-first-time performance virtually eliminates rework costs while significantly reducing material waste – particularly valuable when working with expensive stainless steel alloys.

The minimal thermal distortion characteristic of laser welding translates to dramatically reduced fit-up and alignment issues in subsequent assembly operations, often eliminating entire manufacturing steps dedicated to straightening and rework.

Perhaps most significantly in today’s challenging manufacturing environment, the rapid learning curve associated with laser welding addresses the critical skilled labor shortage facing industries worldwide. Where TIG welding typically requires 3-6 months to develop basic proficiency and 2-3 years to achieve true mastery, our laser systems can be operated effectively after just 3-5 days of training. This democratization of expertise allows manufacturers to maintain consistent quality levels despite workforce turnover while simultaneously reducing dependence on increasingly scarce and expensive welding specialists.

When combined with the virtual elimination of post-weld cleanup – which typically consumes 30-50% of total manufacturing time in conventional welding – laser welding delivers not just incremental improvement but transformational competitive advantage that justifies the higher initial investment through compelling return-on-investment typically achieved within 12-18 months of implementation.

Making the Right Welding Choice

Selecting the appropriate welding technology requires careful analysis of both current needs and future growth plans. For research and development facilities, prototype shops, and operations focused on highly customized one-off pieces, TIG welding offers sufficient capability with manageable initial investment. The process’s flexibility and relatively simple equipment requirements make it ideal for environments where weld configurations change frequently and production volumes remain low. Similarly, operations focused on thicker sections (generally above 6mm) and long, continuous welds may find MIG welding provides the best balance of speed and equipment cost.

However, manufacturers dealing with high-volume production, stringent quality requirements, and thin materials will discover that laser welding delivers compelling advantages that extend far beyond speed improvement. The technology’s consistency and repeatability eliminate the variation that plagues manual processes, while the minimal post-processing requirements create dramatic savings in labor, consumables, and factory space. The rapid return on investment – typically 12-18 months in production environments – combined with the strategic advantage of achieving quality levels inaccessible to conventional methods makes laser welding not just an equipment purchase but a transformational business decision.

Why Choose Our Laser Welding Solutions?

Our commitment to advancing laser welding technology extends beyond equipment manufacturing to encompass complete process solutions tailored to specific industry challenges. Our fiber laser systems incorporate patented beam delivery technology that maintains consistent focus and intensity across the entire working area, eliminating the edge effects that compromise weld quality in conventional systems. The modular architecture of our equipment facilitates seamless integration into existing production lines while providing scalability for future expansion. Perhaps most importantly, our comprehensive support ecosystem includes everything from initial process development and operator training to remote diagnostics and preventive maintenance, ensuring that our customers achieve not just theoretical performance but sustained real-world productivity.

The sophistication of our systems is most evident in features like real-time weld monitoring that tracks penetration depth and quality at processing speeds, automatically flagging any deviation from parameters and preventing the production of non-conforming components. Our intelligent process database contains optimized welding parameters for hundreds of material and thickness combinations, dramatically reducing setup time and ensuring optimal results from day one. For manufacturers facing the dual challenges of rising quality expectations and increasing cost pressure, our laser welding solutions provide not just an equipment upgrade but a fundamental competitive advantage.

Proven ROI: Our clients typically achieve 100% return on investment within 12 months through:-70% reduction in labor costs;-90% decrease in material waste;-50% faster production cycles-99% reduction in rework expenses

Zero-Risk Implementation:-Free process validation with your materials;-Comprehensive operator training program;-24/7 remote monitoring and support;-Performance guarantee with SLA

Summary

The evolution of stainless steel welding continues to accelerate, with laser technology leading the way in precision, efficiency, and reliability. While traditional methods retain their place for specific applications, manufacturers seeking competitive advantage must consider the transformative potential of laser welding. Contact our technical team today to schedule a process demonstration using your actual components, and discover how our solutions can transform your production capabilities.