Laser welding and arc welding are two powerful methods for joining metals, each with its own philosophy. Arc welding uses a powerful electric arc to melt the workpiece and a consumable electrode, a time-tested approach known for its strength and versatility. Laser welding, on the other hand, employs a highly focused beam of light to create a precise and incredibly neat weld.

The choice between these two technologies is more than just a matter of preference; it’s a strategic decision that can impact your product quality, efficiency, and bottom line.In this blog post, we’ll break down the 10 most critical factors you should consider before deciding if laser welding is the right investment for your operation.

1.Evaluating Material Thickness for Welding Applications

The suitability of your material thickness is a primary concern. Laser welding demonstrates superior performance with thin sheets and precision parts ranging from 0.2 to 5 mm, where its concentrated energy excels. However, for joining very thick plates exceeding 8-10 mm, arc welding often maintains a practical advantage in single-pass penetration depth, making it a robust choice for heavy structural work, though laser can still handle thicker materials with specialized multi-pass techniques.

2. Assessing Weld Quality Requirements in Your Welding Process

Your project’s quality standards are paramount. Laser welding achieves exceptional results characterized by near-zero spatter, an extremely narrow heat-affected zone of 0.5 mm or less, minimal distortion, and a high-precision appearance. This makes it the more suitable technology if your application demands “cosmetic welds,” “micro-welds,” or reliable “sealed welds” where aesthetics and precision are critical.

3. Determining Production Efficiency Needs in Welding Operations

The required production speed is a key differentiator. Laser welding operates at remarkable speeds, capable of reaching 200-500 cm/min, which far exceeds the travel rates of conventional MIG or TIG processes. If your production line requires faster cycle times and greater throughput, laser welding presents a significant opportunity to enhance overall efficiency and output.

4. Considering Labor Dependency in Welding Implementation

The availability of skilled labor is a crucial operational factor. Laser welding offers a distinct advantage with its shorter learning curve, allowing operators to grasp basic operations typically within just 1-2 hours. This contrasts sharply with MIG and TIG welding, which require skilled welders possessing hundreds of hours of experience to produce consistent, high-quality results. For workshops facing a shortage of skilled labor, laser technology provides a viable and efficient solution.

5. Accounting for Post-Welding Treatment Costs

The hidden costs of post-processing must be considered. A significant benefit of laser welding is its ability to produce clean welds with almost no spatter, thereby requiring minimal grinding or finishing work. This translates to substantial savings in labor hours and associated costs. If your current manufacturing process involves high post-welding treatment expenses, investing in laser technology can lead to a faster and more substantial Return on Investment.

6. Understanding Financial Investment in Welding Equipment

A clear financial perspective is essential. While laser equipment entails higher initial purchase costs compared to MIG or TIG setups, it offers compelling long-term economic benefits. These include the elimination of consumable electrode costs, significantly lower rework rates, faster project delivery times, and higher overall production capacity. For many businesses, these advantages converge to deliver a typical Return on Investment within a period of 6 to 18 months.

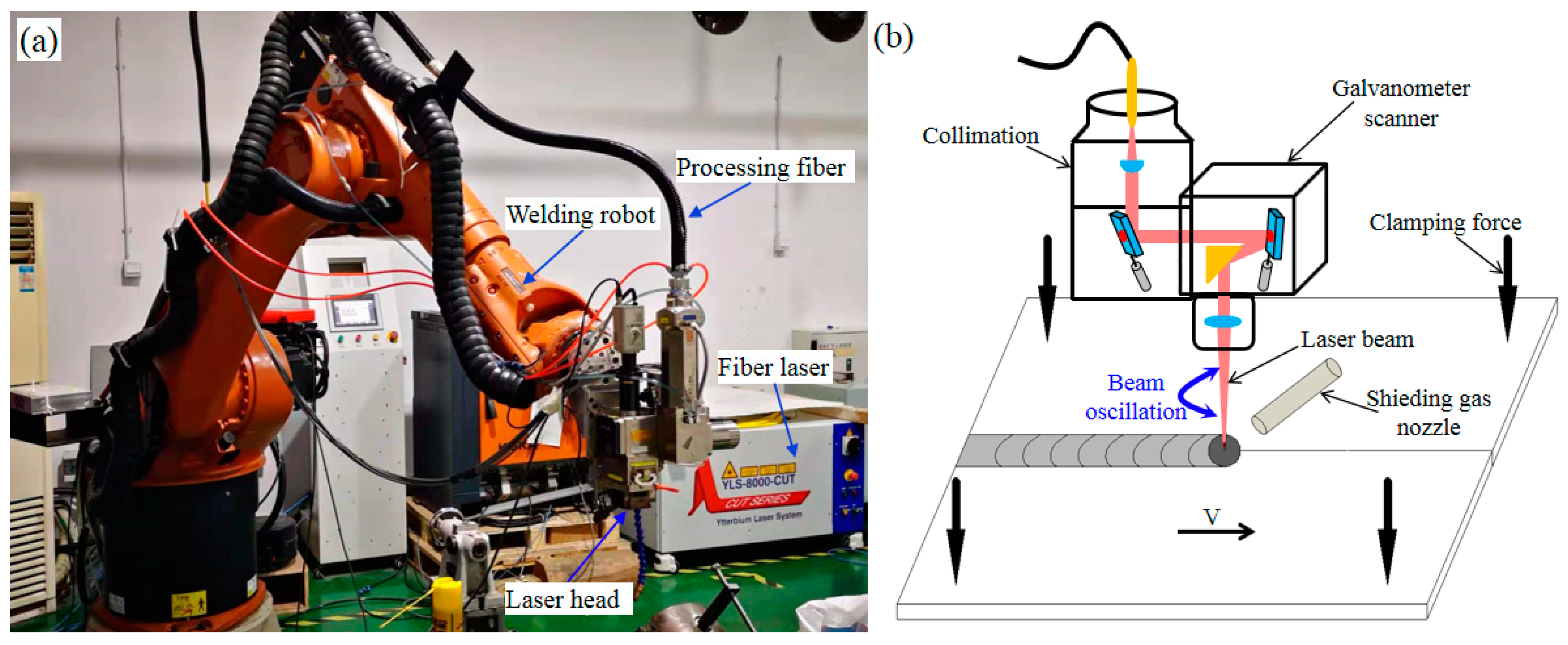

7. Planning for Automation in Welding Systems

Your future automation strategy should guide your choice. Laser welding is inherently more suited for integration into automated environments, including collaborative robot welding cells, industrial robotic systems, and smart production lines. Its beam delivery via flexible fiber optic cables and lightweight welding heads simplifies robotic integration. If you are planning to upgrade towards a “lights-out” manufacturing capability, laser systems provide a more seamless and future-proof path forward.

8. Matching Workpiece Type to Welding Technology

The specific materials you work with determine compatibility. Laser welding delivers optimal results on materials like stainless steel, carbon steel, aluminum alloys, copper, and various precision metal components commonly found in electronics, and kitchen and bathroom products. It is important to note that for heavily contaminated, rusty, or painted materials, or for large-area welding of galvanized sheets, the process demands near-perfect joint fit-up and clean surfaces, necessitating a thorough evaluation to ensure a successful application.

9. Ensuring Safety Compliance in Welding Environments

A proper safety setup is non-negotiable. Implementing laser welding technology requires specific safety measures, including protective machine covers, mandatory laser safety goggles for operators, designated laser safety areas within the workshop, and appropriate fume extraction systems to manage emissions. If your current workshop cannot readily provide this fundamental laser safety infrastructure, it is essential to factor in the necessary planning and potential modifications before adoption.

10. Controlling Heat Input in Precision Welding

The level of thermal control is a decisive technical factor. Laser welding drastically reduces heat input by 70% to 90% compared to traditional arc welding. This significant reduction is key to minimizing undesirable effects such as material deformation, residual thermal stress, the formation of micro-cracks, and the need for subsequent repairs. This characteristic is particularly crucial for manufacturers whose products have strict requirements for quality, structural integrity, and dimensional stability.

Summary

While arc welding has its place in specific scenarios, the future of manufacturing belongs to laser welding. It’s not just an alternative; it’s a strategic upgrade that unlocks new levels of quality, efficiency, and capability.

Laser Welding: The Clear Choice for Modern Manufacturing

Stop seeing the higher initial investment as a cost, and start seeing it as your gateway to a competitive edge. When you choose laser welding, you are investing in:

-

Unmatched Precision: Produce flawless, aesthetically superior welds that elevate your product quality and brand perception.

-

Revolutionary Speed: Dramatically increase your throughput and slash production cycles, allowing you to take on more work and deliver faster.

-

Minimal Rework: Virtually eliminate costly post-weld distortion correction and cleaning, saving you time and labor.

-

Seamless Automation: Easily integrate into robotic cells to create a future-proof, high-efficiency production line that runs with minimal intervention.

Forget outdated methods. The future of efficient, high-quality fabrication is here. While arc welding still has its niche, laser welding isn’t just an upgrade—it’s your key to unparalleled precision, speed, and a cleaner, more automated workflow.Stop compromising on quality and productivity. Make the strategic shift to laser welding. Contact us now to discover the perfect system that will pay for itself in no time!