Selecting the optimal welding process is a critical decision that impacts production cost, quality, and efficiency. This guide provides a concise, professional comparison of Laser, MIG, TIG, and Stick welding across key technical and operational parameters to inform your project or procurement strategy.

Comparison Table: Laser, MIG, TIG, and Stick Welding

Below is a quick comparison of laser welding vs. MIG, TIG, and stick welding. I’ve included key metrics like precision, speed, costs, and best uses. This overview helps you spot the strengths and limits of each method. You can use it for your welding project or business needs.

| Feature | Laser Welding | MIG Welding | TIG Welding | Stick Welding |

|---|---|---|---|---|

| Key Strength | Fast & Precise | Fast & Cheap | Best Quality | Weld Anywhere |

| Thickness Range | Ultra-thin ~ Medium (0.02 – 8 mm) |

Medium ~ Thick (1.6 mm +) |

Thin ~ Medium (0.5 – 8 mm) |

Medium ~ Very Thick (3 mm +) |

| Heat Effect | Minimal (0.2-0.5mm) Negligible distortion |

Moderate (2-5mm) Some distortion |

Low (1-4mm) Controllable |

High (3-7mm) High distortion risk |

| Speed | ★★★★★ | ★★★★☆ | ★★☆☆☆ | ★★☆☆☆ |

| Quality | ★★★★★ | ★★★☆☆ | ★★★★★ | ★★☆☆☆ |

| Skill Needed | Very Easy | Easy | Very Hard | Moderate |

| Cost | $1500 | $300 | $800 | $200 |

| Common Uses | Electronics, Medical Devices, Batteries | Car Frames, Steel Structures | Aerospace, Bicycle Frames, Art | Construction Sites, Pipelines |

Welding Speed and Efficiency

Choosing a welding process? Speed and efficiency matter most. This is true for projects where time counts. Production volume and turnaround also play a role.

Laser Welding: The Speed King

Laser welding is the fastest option, operating 4-10 times quicker than TIG. Starting at about 20 in/min on thin metals, it can surpass 200 in/min in automotive mass production, ideal for high-output projects with short cycle times.

MIG Welding: Balanced Choice

MIG is significantly faster than TIG and Stick, with deposition rates up to 15 lbs/hour. While outpaced by laser, it remains a cost-effective solution for large-scale production where extreme precision isn’t critical.

TIG Welding: Precision First

TIG is the slowest process, typically 6-8 in/min. It prioritizes flawless quality and appearance, requiring skilled operators, making it unsuitable for high-volume runs.

Stick Welding: Field Expert

Stick welding has the slowest travel speeds (under 10 in/min). It’s inefficient for production but excels in outdoor repair and demanding field conditions.

Precision and Weld Quality

Precision and weld quality matter when you choose a welding method for your project. Here’s how MIG, TIG, Stick, and Laser welding compare. I’ll look at defect rates, process control, tolerances, and real-world quality monitoring.

Laser Welding: Ultimate Precision

Laser welding delivers the highest precision with bead geometry deviations under 0.1 mm. Through real-time monitoring and automated control, it achieves near-zero defects with full traceability.

MIG Welding: Stability Defines Quality

MIG welding quality depends on stable parameters and is prone to spatter/porosity. With proper control, it achieves good consistency for cost-sensitive applications like automotive.

TIG Welding: Handcrafted Excellence

TIG sets the quality benchmark for traditional welding with near-flawless welds. Its superior craftsmanship meets stringent standards in aerospace, but relies heavily on operator skill.

Stick Welding: Function Over Form

Stick welding offers the lowest precision (0.5-1.0 mm deviation) with defects like undercut. Suitable for structural work where appearance is secondary.

Welding Material Compatibility & Thickness

Choosing the right welding method depends on your base material and thickness. I recommend understanding each process because they have different strengths and limits for material compatibility and thickness range.

Laser Welding: Universal Performer

Laser handles the widest range of materials, from stainless steel to dissimilar metals. Excels with ultra-thin materials (from 0.02mm) to medium plates, perfect for electronics and EV batteries, though requiring precise fit-up.

MIG Welding: Thick Plate Specialist

MIG suits common metals like steel and aluminum. Specializes in medium-to-thick plates (1.6mm+), ideal for structural frames and auto fabrication, but risks burn-through on thin materials.

TIG Welding: Thin Material Master

TIG welds all weldable metals, including reactive ones like titanium. Perfect for thin sheets (from 0.5mm) and precision tubing, essential in aerospace and medical devices.

Stick Welding: Field King

Stick primarily welds carbon steel, stainless & cast iron. Designed for medium to very thick materials (3mm+), irreplaceable in outdoor environments like construction sites.

Thermal Effects of Different Welding Methods on Materials

The heat generated during welding significantly affects base material properties. The following analysis compares the thermal management capabilities of four welding processes through key indicators such as heat-affected zone width and distortion degree.

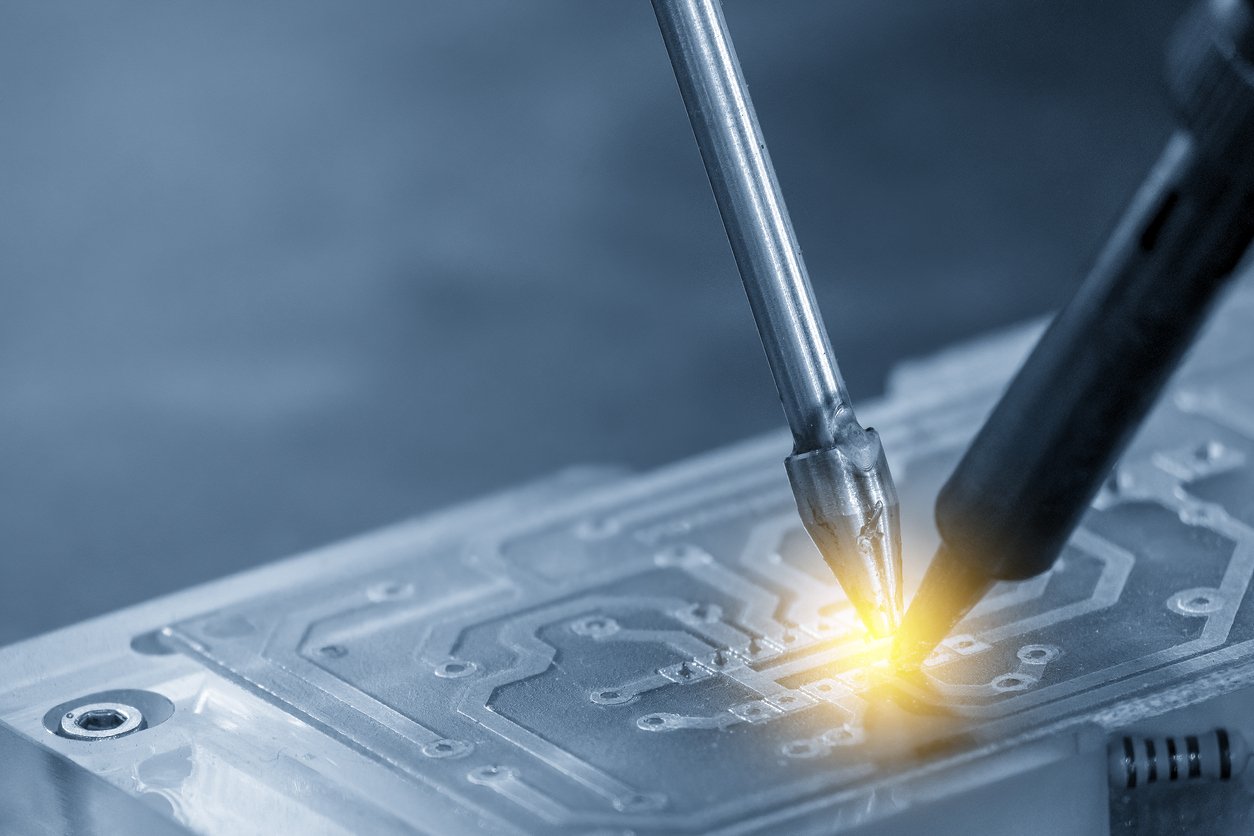

Laser Welding

Laser welding produces an exceptionally narrow heat-affected zone (0.2-0.5 mm), perfectly preserving the base material’s properties. It results in negligible thermal distortion, making it ideal for precision assembly and applications demanding high dimensional stability. With precisely controllable heat input and excellent reproducibility, it is perfectly suited for automated production.

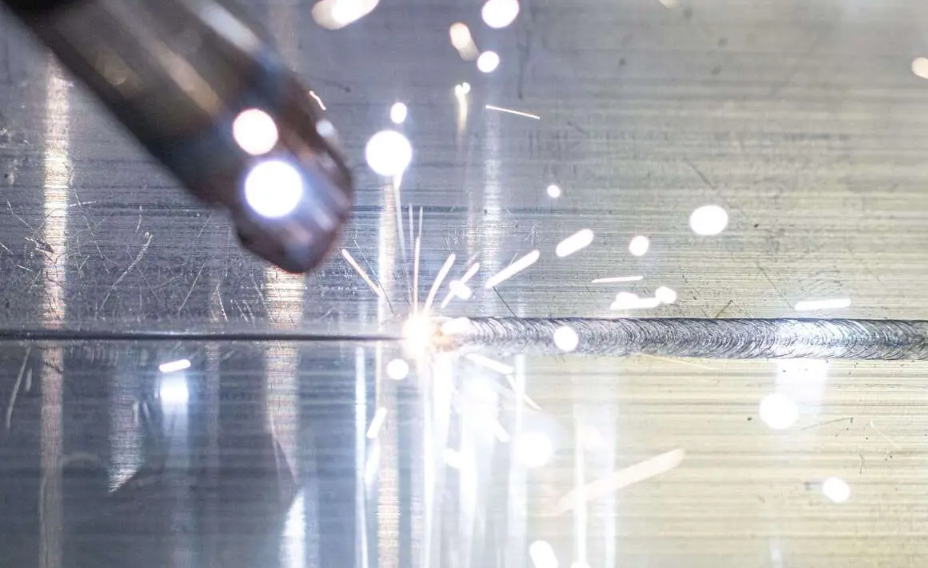

MIG Welding

MIG welding generates a moderate HAZ (2-5 mm), requiring careful attention to heat input control. It produces relatively significant thermal distortion, often necessitating fixture constraints in sheet metal applications. While offering high deposition efficiency, it presents challenges in managing the heat cycle.

TIG Welding

TIG welding creates a relatively small HAZ (1-4 mm) that can be further minimized with pulse technology. It exhibits low thermal distortion, which can be finely managed through parameter adjustment. The process offers high flexibility, being well-suited for manual operation and complex weld joints.

Stick Welding

Stick welding produces the widest HAZ (3-7 mm) with significant alteration to material properties. It causes the most severe thermal distortion, which can be up to three times greater than laser welding in thin sheet applications. The process makes precise heat input control difficult and heavily relies on operator skill.

Which Welding Method Is Best for Beginners?

For beginners or when training new staff, choosing the right welding method is crucial. In terms of ease of use and the learning curve, Laser Welding is the superior choice, far surpassing MIG, TIG, and Stick welding.

Laser Welding: Easiest to Start

With the shortest learning curve, beginners grasp basics in hours. The highly automated process requires no complex skills, produces almost no spatter, and offers high safety – ideal for absolute beginners.

MIG Welding: Relatively User-Friendly

Its semi-automatic nature makes it beginner-friendly. Still requires mastering wire feed and gas shielding, with a steeper curve than laser – suits those with basic welding knowledge.

TIG Welding: Most Challenging

Demands exceptional hand-eye coordination to simultaneously control torch and filler rod. The most challenging method, typically requiring months of professional training.

Stick Welding: Skill-Dependent

Requires manually maintaining arc stability and handling slag cleanup. High skill demands for novices, with progress heavily reliant on individual aptitude and practice.

Welding Equipment Cost & Portability

I recommend looking at equipment cost and portability when you pick a welding process. This is key for small shops, fieldwork, or factory automation. Here’s how MIG, TIG, Stick, and Laser welding compare for upfront investment and onsite flexibility.

Equipment Costs Breakdown

Laser Welding

Equipment starts at around $1,500. While the initial investment is higher, it requires no gas and minimal consumables, offering outstanding long-term cost-effectiveness, ideal for batch processing.

MIG Welding

Entry-level machines start at just $300, but require ongoing purchases of wire and shielding gas. Moderate overall cost makes it a budget-friendly choice for small workshops.

TIG Welding

Equipment starts at $800, plus tungsten, gas, and high labor costs. The total investment is relatively high, mainly targeting professional welding applications.

Stick Welding

Basic equipment can be acquired for just $200, with electrodes as the only consumables. Lowest maintenance cost makes it the top choice for tight budgets.

Portability: A Breakthrough in Laser Welding

Laser Welding

Handheld design offers ultimate portability. Separate main unit and welding gun connected by fiber optic cable enable easy single-person mobility, breaking fixed installation limits.

MIG Welding

Equipment is mobile but requires dragging heavy gas tanks, significantly reducing on-site convenience – better suited for workshop use.

TIG Welding

Like MIG welding, gas cylinder dependency limits outdoor effectiveness, with portability insufficient for frequent mobility needs.

Stick Welding

Lightweight equipment (15-30 lbs) requires no gas cylinders, making it the go-to choice for field emergency repairs in harsh conditions.

Common Welding Applications

I recommend knowing where each welding method works best. This helps you pick the right process for your project or business. Below are the main uses and industries for Laser, MIG, TIG, and Stick welding.

Matching Material Types by Welding Method

- Laser: Use this for thin to medium-gauge metals. It also works on certain plastics. It handles advanced composites.

- MIG: This works best on medium to thick steel. It suits aluminum. It handles stainless steel.

- TIG: I suggest this for fine, thin metals. It works great on aluminum, copper, and magnesium. It handles titanium and stainless.

- Stick: This excels with thick carbon steel. It works on low-alloy steel. It handles cast iron.

Industry Segments by Preferred Welding Process

- Laser: Automotive, aerospace, medical, electronics, jewelry

- MIG: Automotive, construction, heavy equipment, shipbuilding, rail

- TIG: Artistic metalwork, aerospace, bicycles, food & beverage, pharma

- Stick: Construction, heavy industrial, shipbuilding, pipeline, field maintenance

Summary

In the era of precision manufacturing, choosing the right welding technology means gaining competitive edge. Laser welding, with its unmatched efficiency, superior quality and remarkable ease of use, is becoming the preferred choice of industry leaders. Whether you seek shorter production cycles, higher product quality, or lower overall costs, laser welding delivers the perfect solution. Don’t let traditional processes limit your potential – discover how laser welding can transform your production capabilities today!