In the competitive wire fabric industry, operational efficiency is crucial. Laser welding technology is transforming production through superior energy efficiency and economic benefits. This article explores how this advanced process provides a competitive edge by slashing energy use, boosting throughput, and reducing waste.

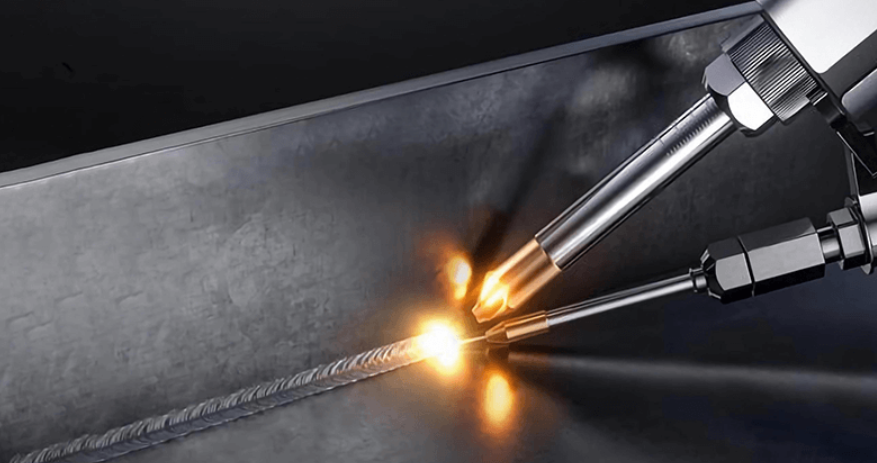

Laser Welding Delivers Unmatched Energy Efficiency

Laser welding establishes a new benchmark for industrial energy performance, delivering unparalleled electrical efficiency compared to all conventional joining methods. This fundamental advantage stems from the technology’s precision energy delivery, optimized power conversion, and elimination of energy-intensive ancillary processes, resulting in dramatically lower operating costs.

Less energy consumption

The superiority of laser welding is unequivocally demonstrated in direct energy consumption metrics per meter of weld.

-

Minimal Power Demand: Laser welding consumes a remarkably low 0.8–1.2 kWh per meter of weld, setting the standard for efficiency.

-

Outperforming Conventional Methods: This consumption is less than half that of TIG welding (2.0–2.5 kWh/m) and MIG welding (1.8–2.2 kWh/m), and represents a 75-80% reduction compared to arc welding (3.5–4.2 kWh/m).

Fundamental Mechanisms of Energy Savings

The dramatic energy savings are achieved through core physical and operational principles that minimize waste.

-

Precision Energy Coupling: The laser beam’s ability to focus energy onto a极小焦点 results in extremely high thermal efficiency, with the majority of electrical input converted directly into useful melting energy at the weld joint.

-

Near-Zero Idle Losses: Modern laser power supplies incorporate high-efficiency regimes and automatic shutdown during non-processing times, virtually eliminating standby power consumption that plagues continuously running traditional systems.

-

Process Consolidation: The technology’s deep penetration capability often eliminates multi-pass welding, while its low heat input removes preheating requirements, cutting the total energy consumed per part by eliminating these ancillary steps.

Precision Welding Minimizes Heat and Material Waste

The exceptional energy efficiency of laser welding is fundamentally rooted in its pinpoint accuracy. This focused energy delivery systematically eliminates waste across multiple facets of the production process, most notably in thermal management and material usage.

Drastically Reduced Heat-Affected Zone (HAZ)

Compared to arc welding, laser welding reduces the HAZ by 80–90%,and a 60–75% reduction compared to TIG and MIG processes. This minimal thermal input delivers two critical advantages for product quality:

-

Elimination of Thermal Distortion:By preserving the base material’s metallurgical integrity, laser welding virtuallyeliminates warping and heat damage. This is paramount for maintaining the dimensional stability and flatness of delicate or thin-gauge wire fabrics.

-

Superior Weld Integrity:The controlled, pinpoint melting processminimizes defectssuch as spatter, undercut, and porosity, ensuring high-integrity welds with excellent consistency right from the start, thereby reducing the need for rework.

Enhanced Material Utilization

The principle of precision that minimizes the HAZ extends decisively to material processing, fundamentally optimizing raw material efficiency. Laser systems achieve this by concentrating energy to make exceptionally narrow cuts, thereby converting a greater proportion of raw material into finished product.

- Direct Cost Reduction:Achieves up to 92% material utilization with a kerf width of just 0.2 mm.Maximizing the usable output from each raw material unit lowers direct material costs and reduces expenditures associated with scrap handling and disposal.

-

Sustainable Resource Management:Typically achieves only 68% utilizationdue to a significantlywider kerf and dross formation. The drastic reduction in scrap minimizes the embedded energy wasted in the production and transportation of raw materials that never reach the final product, contributing to a more sustainable manufacturing lifecycle.

High-Speed Welding Boosts Productivity and Sustainability

Laser welding delivers a dual competitive advantage: it significantly boosts manufacturing throughput while concurrently reducing the environmental footprint of production. This synergy between productivity and sustainability is achieved through faster cycle times, intelligent energy management, and reduced consumable dependency.

Accelerated Production Speed

The most direct impact of laser welding is a dramatic increase in processing speed.

-

Higher Welding Speeds: Laser systems operate at 2 to 5 times the speed of conventional MIG or TIG welding. This translates into a substantial reduction in machine operating time for a given production volume.

-

Reduced Total Energy Draw: Shorter processing cycles directly lead to a lower total energy consumption over a full production shift.

Significant Reduction in Environmental Impact

The operational efficiencies of laser welding directly translate into measurable environmental benefits.

-

Lower CO₂ Emissions: The drastic reduction in electricity consumption directly cuts carbon emissions. Laser welding emits approximately 2.1 kg of CO₂ per hour, which is only a fraction of the 9.6 kg CO₂ per hour generated by a typical arc welding system.

-

Minimized Consumable Usage: The process is exceptionally lean on resources. Its precision allows it to use as little as 1/20th the shielding gas required by TIG welding, and it often eliminates the need for filler wire. This not only reduces operational costs but also minimizes the environmental impact associated with the production and logistics of these consumables.

Beyond direct energy savings, a significant and often underestimated advantage of laser welding lies in its ability to streamline the entire production workflow. By delivering superior weld quality from the outset, it systematically eliminates or drastically reduces the need for energy-intensive and time-consuming downstream processing steps.

Virtual Elimination of Secondary Operations

The minimal heat input and exceptionally small Heat-Affected Zone (HAZ) characteristic of laser welding result in a finished product of remarkably high dimensional and surface quality. This largely eliminates the need for several traditional post-weld activities:

-

Mechanical Straightening: The near-absence of thermal distortion prevents warping in wire mesh, removing the requirement for corrective straightening.

-

Abrasive Grinding: The process produces clean, virtually spatter-free welds, making grinding to remove imperfections unnecessary.

-

Thermal Stress Relief: The low total heat input minimizes residual stresses, often eliminating the need for subsequent stress relief heat treatments.

Drastic Reduction in Rework and Resource Use

The exceptional consistency and inherent quality of laser welds lead to a profound reduction in defects. This high first-pass yield translates into direct operational advantages:

-

Minimized Rework: The requirement for re-welding or repairing faulty joints is drastically reduced.

-

Lower Resource Consumption: This reduction in rework saves not only energy but also materials (e.g., filler wire, grinding discs) and the labor costs associated with quality correction.

-

Enhanced Production Flow: A more predictable and reliable process accelerates overall throughput, reducing bottlenecks and simplifying production planning.

Efficient Welding Reduces Multi-Pass and Preheating Requirements

Laser welding introduces profound efficiencies by fundamentally simplifying the welding procedure itself. It challenges and often eliminates two of the most resource-intensive requirements of conventional welding: multi-pass techniques and preheating.

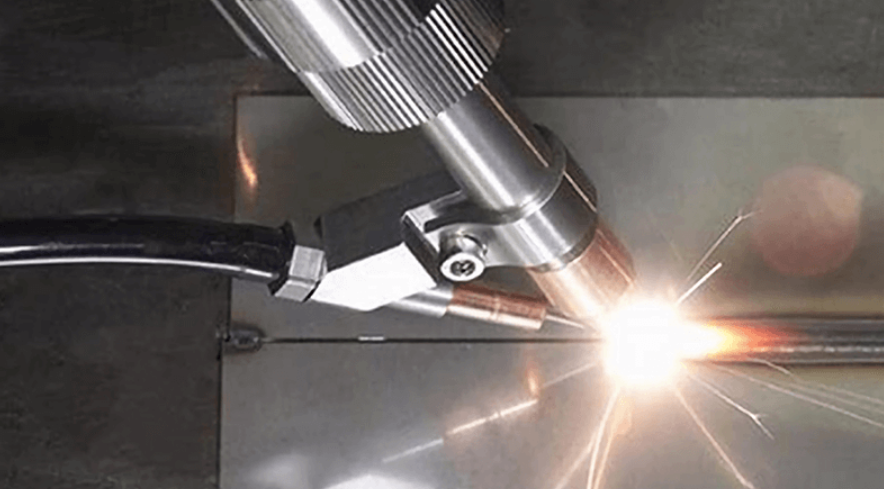

Single-Pass Welding Capability

The exceptionally high energy density of the laser beam is a key differentiator. It enables deep penetration and complete fusion in a single, high-speed pass, a feat unattainable for traditional methods on thicker materials.

-

Technical Advantage: Laser welding achieves a high depth-to-width ratio (deep penetration with a narrow weld), allowing it to join thick wire mesh and sheets in one pass.

-

Operational Impact: This can reduce the number of required weld passes by 30–50% compared to the multi-pass strategies essential in MIG or TIG welding for the same material thickness.

-

Cumulative Benefit: Each eliminated pass translates to direct savings in cycle time, energy consumption, shielding gas, and labor, compounding the overall efficiency gain.

Elimination of Preheating Procedures

In traditional welding, preheating the base material is often a mandatory step to prevent issues like hydrogen-induced cracking or to ensure proper fusion in high-strength steels. Laser welding’s concentrated heat source fundamentally changes this requirement.

-

Reduced Thermal Stress: The rapid, localized heating and minimal HAZ significantly lower the risk of thermal cracking, rendering the preheating step largely unnecessary.

-

Direct Cost Savings: This eliminates the energy consumption of preheating equipment (e.g., oxy-fuel torches or induction heaters) and the associated time and labor, streamlining the workflow.

-

Enhanced Operational Flexibility: By removing this preparatory step, production can commence faster, simplifying logistics and improving response times for custom or just-in-time orders.

Summary

Laser welding delivers exceptional energy savings for wire fabric production. Its precise energy focus minimizes heat loss and material waste, significantly reducing the heat-affected zone and preventing workpiece distortion. The technology offers fast welding speeds, shorter equipment operation time, and intelligent power management. Additionally, it substantially cuts carbon emissions and consumable usage while streamlining processes by eliminating multi-pass welding, preheating, and post-weld treatments like straightening and grinding.