When marking glass, the choice between UV and CO₂ lasers is fundamental. It’s a decision between core principles: the precision of photochemical “cold processing” versus the transformative power of thermal “hot processing.” One acts like microscopic surgery, altering material at the molecular level; the other, like controlled craftsmanship, using heat to create a frosted finish. Understanding this essential divide is key to selecting the right tool. The following comparison will detail their performance to guide your decision.

UV vs CO₂ Laser Technical Comparison

| Parameter | UV Laser (Cold Processing) | CO₂ Laser (Hot Processing) |

| Working Principle | Photochemical reaction, breaks molecular bonds | Thermal effect, creates micro-cracks |

| Heat-Affected Zone (HAZ) | Minimal (5–15 μm) | Larger (50–200 μm) |

| Marking Speed | Very Fast (7,000–8,000 mm/s) | Fast (1,500–2,000 mm/s) |

| Marking Fineness | Ultra-Fine (15–20 μm spot) | Standard Fine (80–120 μm spot) |

| Capital Investment | From ~$3,000 | From ~$2,000 |

UV Laser for Glass Marking

UV laser technology operates at a 355nm wavelength, which is the third harmonic of the base 1064nm infrared wavelength. This specific wavelength is highly absorbed by glass surfaces, enabling a unique “cold processing” mechanism. Unlike thermal-based methods, UV laser marking works primarily through a photochemical reaction that breaks molecular bonds in the glass with minimal heat transfer.

Core Technical Specifications

Modern UV laser systems for glass are designed with precision-oriented parameters:

-

Power Output: 3W to 5W continuous-wave equivalent sources

-

Pulse Frequency: 30–150 kHz range (advanced systems: 20–200 kHz)

-

Pulse Duration: 12–13 nanoseconds for controlled energy delivery

-

Beam Quality: M² < 1.2 (near-diffraction-limited), enabling micro-scale marking

-

Wavelength Stability: 355nm ±10nm tolerance

The high beam quality allows for a smaller focused spot size compared to fiber lasers, which reduces mechanical stress and keeps the heat-affected zone extremely narrow—critical for delicate glass substrates.

Marking Performance & Capabilities

In practical applications, UV lasers demonstrate significant speed advantages. Tests on glass bottles show that UV systems can complete the same patterns up to 63% faster than CO₂ lasers, while maintaining superior edge sharpness and contrast.

Scanning Speed: 3,000–8,000 mm/s (dependent on system configuration)

Marking Field: Adjustable via lens selection:

-

F160 lens: 110×110mm area | 185mm working distance

-

F254 lens: 175×175mm area | 285mm working distance

-

3D systems: up to 330×330mm with dynamic focus

Typical Mark Depth: ≤0.3mm, suitable for permanent IDs, logos, and fine decorative patterns.

Key Advantage: True Cold Marking

The 355nm wavelength directly breaks molecular bonds in the glass via photochemical interaction, altering the surface structure with negligible thermal diffusion. This results in high-contrast, sharp marks without the micro-fractures, yellowing, or burrs typical of thermal-based laser marking. The minimal heat-affected zone preserves the structural integrity of the glass, enabling precision as fine as 3.5μm positioning accuracy for micro-features.

CO2 Laser for Glass Marking

CO₂ laser engraving machine operate at a 10.6μm wavelength in the infrared spectrum (with advanced models at 9.3μm), which is readily absorbed by glass. This efficient absorption enables a fundamentally thermal marking process. The beam rapidly heats the glass surface, causing localized thermal shock. Due to glass’s low thermal conductivity, this creates a sharp temperature gradient between the heated surface and the cooler substrate, generating controlled micro-fractures that result in a permanent, frosted mark.

Core Technical Specifications

Modern CO₂ laser systems for glass are configured with the following key parameters:

-

Power Output: 10W, 30W, 60W, 100W

-

Maximum Line Speed: Up to 2,000 mm/s

-

Positioning Accuracy: 3.5μm

-

Standard Marking Area: 140×140mm (with 200mm lens)

Systems in the 10-30W range typically operate on standard 110/220 VAC power. The high positioning accuracy ensures consistent mark placement, while the variety in power output allows for selection based on desired mark speed and depth.

Marking Performance & Capabilities

In application, CO₂ lasers are effective for creating high-contrast, frosted marks on glass. Key performance data includes:

-

Print Speed: Capable of marking up to 2,000 characters per second.

-

Marking Field Flexibility: The work area can be expanded using different lenses; a 450mm lens enables an area of approximately 331×331mm.

-

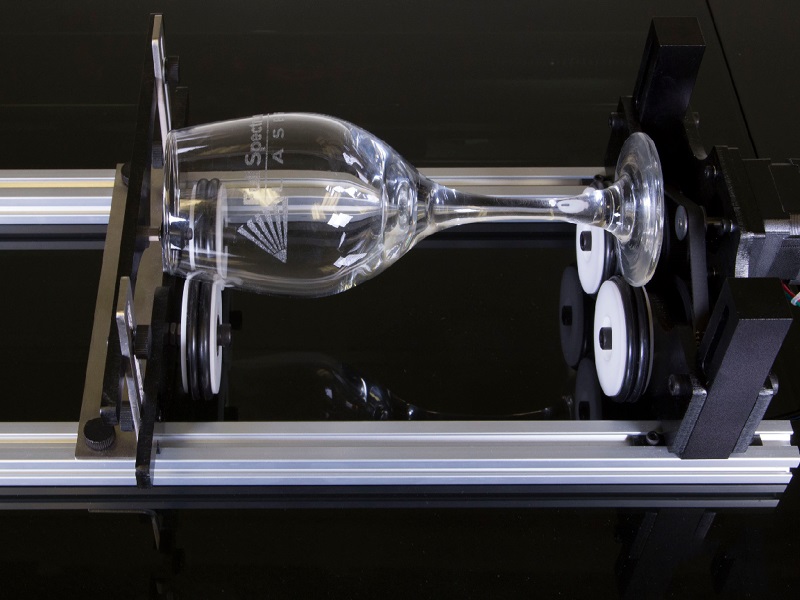

3D Surface Marking: Equipped with dynamic focusing modules, modern systems can maintain focus on curved surfaces such as bottles and cylindrical containers, ensuring uniform mark quality across complex shapes.

Key Advantage: Robust Thermal Marking & Cost-Effectiveness

The thermal process is highly effective for creating visible, durable marks on glass without the need for additives. While managing thermal stress is a consideration to prevent unwanted cracking, this same mechanism provides excellent mark contrast. Furthermore, CO₂ laser technology offers significant cost advantages in both initial investment and operation compared to UV and fiber lasers, and its wavelength is inherently compatible with clear glass, making it a versatile and economical choice for a wide range of industrial marking applications.

Key Laser Marking Technical Comparison Parameters

Choosing between UV and CO₂ lasers for glass marking boils down to five key parameters that directly impact results and cost.

Wavelength and Material Interaction

The fundamental distinction begins with wavelength. A UV laser’s short 355nm light carries high photon energy (~3.5 eV), directly breaking molecular bonds in glass via a photochemical “cold” process. In contrast, a CO₂ laser’s long 10.6μm wavelength carries low energy (~0.12 eV), which glass absorbs as heat, creating marks through thermal shock and micro-fracturing—a “hot” process.

Heat-Affected Zone and Precision

The Heat-Affected Zone (HAZ) size is critical for integrity. UV laser markers, using cold processing, create a minuscule HAZ (5–15 μm) with negligible thermal stress, allowing safe marking on thin or laminated glass. CO₂ lasers create a much larger HAZ (50–200 μm) through intense localized heating (600-800°C), which forms the mark but requires careful thermal management.

Marking Speed and Production Throughput

Marking speed directly dictates throughput. UV lasers achieve very high speeds (7,000–8,000 mm/s), completing a standard DataMatrix code in ~1 second. CO₂ lasers operate at moderate speeds (1,500–2,000 mm/s), taking ~2.5-3.5 seconds for the same code. In high-volume scenarios, this can give UV systems a significant output advantage.

Beam Quality and Marking Fineness

Beam quality (M²) determines spot size and detail. UV lasers have exceptional beam quality (M² <1.2), enabling an ultra-fine ~20 μm spot for micro-features like tiny text. CO₂ lasers have good beam quality (M² 1.3-1.8) with a ~100 μm spot, ideal for standard graphics and logos.

Capital and Operational Cost Analysis

Cost is a key decision factor. Our products offer exceptional value: the MW-RF35 CO₂ marker starts at ~$2,000, and the UV marker at ~$3,000. Operationally, CO₂ systems have lower source costs but higher power use. UV systems have a higher initial cost but their far greater speed can lower the cost-per-part at high volumes. The best choice depends on your budget, volume, and precision needs.

How to Choose Your Laser Marking Solution — Based on Material & Needs

Choosing between a UV and a CO₂ laser marker fundamentally depends on which technology’s inherent characteristics best align with your project requirements. Use the following decision framework for a quick assessment:

A CO₂ Laser Marker is typically the more suitable and economical choice when:

-

The glass product has a wall thickness generally above 3mm and can tolerate some thermal stress.

-

The desired visual effect is the classic frosted or “ice-like” appearance, and extreme edge sharpness is not critical.

-

The marking content consists of standard-sized (e.g., >1mm) text, logos, or simple graphics.

-

The initial investment budget is limited, and the annual production volume is typically under 400k-500k units.

-

The application involves large-format glass panels requiring a wide marking field.

You should prioritize a UV Laser Marker when:

-

The material is thin-walled (<2mm) or ultra-thin glass where thermal cracking or deformation must be avoided.

-

The product itself (e.g., pharmaceuticals) or its coating is highly heat-sensitive.

-

The marking requirement involves extremely fine micro-codes (<0.3mm), tiny QR codes, or complex graphics demanding exceptionally sharp edges.

-

The production line has very high speed (throughput) demands, and the annual volume is large enough (e.g., >500k units) to amortize the higher equipment cost.

-

The application has strict permanent traceability requirements (e.g., medical, automotive electronics), necessitating marks with superior durability and readability.

The Key Trade-off

The final choice often balances precision, speed, and cost. CO₂ lasers excel with their notable cost advantage and reliable performance for conventional needs. In contrast, UV lasers, with their cold-processing precision, offer an irreplaceable solution for high-end, high-value-added, or high-volume production. If your needs fall within the performance overlap of both technologies, the production scale (often around 400k-500k units annually as a reference) becomes a crucial differentiator: higher volumes better leverage the speed advantage of UV lasers, justifying the higher initial investment.

Conclusion

In summary, the UV vs. CO₂ laser debate for glass marking resolves to a choice between the precision of photochemical cold processing and the robust efficiency of thermal marking. Your specific project requirements—driven by material sensitivity, desired mark quality, production volume, and budget—will clearly point to the optimal technology. Both offer reliable paths to permanent, high-quality results. To explore how these solutions can be tailored to your exact needs and to discover our competitively priced CO₂ and UV laser markers, contact our team today for a personalized consultation and quote.