Building a high-performance 18650 battery pack feels like a superpower—until your spot welder fails you. We’ve all been there: the frustrating ‘cold welds’ that pop off at the slightest touch, the annoying circuit breaker trips that plunge your workshop into darkness, or worse, the excessive heat that risks damaging your expensive lithium cells. Whether you’re a DIY enthusiast building your first e-bike or a factory owner scaling up for the green energy revolution, your choice of welder is the thin line between a professional-grade power house and a potential fire hazard. In this guide, we strip away the marketing fluff to compare the world’s leading welding solutions—from pocket-sized heroes to high-precision fiber laser giants—to find the perfect spark for your next project.

Comparison of Top 18650 Battery Laser Welding Models

| Model | Tech Type | Welding Thickness (Pure Nickel) | Core Advantage | Target Audience |

| MaxWave New Energy | Portable/Battery | 0.1 – 0.25mm | Ultra-portable, color screen, user-friendly | DIY Hobbyists, Repair Shops |

| Sunkko 709AD+ | AC Resistance | 0.05 – 0.3mm | Power balance, built-in soldering station | Small Studios, Home Repair |

| Glitter 801B | Capacitor Storage | 0.05 – 0.4mm | High peak power, no circuit trips, clean welds | Professional Battery Builders |

| nirsi SWM-10 | Industrial Fast-Welder | 0.05 – 3.0mm+ | Non-contact, joins copper/aluminum | Energy Storage Startups |

| Laserax Battery Welder | Automated Laser | Full Coverage | AI vision monitoring, extreme speed | EV/Large-scale Factories |

| AMADA (Jupiter) | Precision Industrial | High Precision | Extreme consistency & medical-grade reliability | Aerospace, Medical, Automotive |

MaxWave New Energy Laser Welder – The Industrial Benchmark for Intelligent Manufacturing

MaxWave is an industrial-grade laser welding system that integrates high-power fiber laser technology with flexible automation, designed for the large-scale assembly of 18650 and 21700 cylindrical cells and large prismatic cell packs.

Extreme Welding Speed and Precision

Utilizing high-precision servo drives and vision positioning, this machine achieves $\pm$0.03 mm accuracy to prevent battery casing damage. Its 800 mm/s welding speed is several times faster than traditional methods, significantly boosting production throughput.

Superior Heat-Affected Zone (HAZ) Control

The high-energy laser beam reduces the Heat-Affected Zone (HAZ) by 60%, preventing heat from dissipating into the cell. This protects critical internal separators and seals, ensuring the long-term safety and integrity of the battery pack.

Robust Material Compatibility and Strength

Engineered for Multi-Material Welding, it delivers clean bonds on reflective aluminum, copper, and nickel for superior conductivity. Unlike surface-level spot welding, its 3mm deep penetration provides exceptional joint strength and vibration resistance.

Intelligence and Low Operational Costs

The fiber laser system is 40% more energy-efficient than older YAG technology. With a 10,000-hour lifespan and minimal maintenance, it supports 100% automation compatibility for seamless, “lights-out” factory integration.

Best for: High-volume industrial production lines, EV battery module manufacturing, and large-scale energy storage system (ESS) assembly where maximum throughput, deep weld penetration, and 24/7 automated operation are critical.

Price: $165,000 USD

Sunkko 709AD+ – The Professional All-in-One Battery Maintenance Station

The Sunkko 709AD+ 18650 battery welding machine serves as a comprehensive “one-stop” hardware workstation, specifically engineered to streamline the entire workflow of battery pack assembly, from initial structural welding to final circuit integration.

4-in-1 Advanced Functional Integration

This workstation eliminates the need for multiple devices by integrating a high-power spot welder with a built-in temperature-controlled soldering iron, allowing you to seamlessly transition from welding battery cells to soldering BMS (Battery Management System) sampling wires at a single station.

Intelligent Dual-Mode Operation

The system features a fixed, top-mounted pressure-welding head for rapid, high-volume batch welding of standardized packs, alongside a flexible handheld mobile welding pen designed for reaching difficult angles in irregular or oversized battery modules.

High-Reliability Industrial Transformer

At its core is a traditional, heavy-duty industrial transformer that provides a steady and powerful current output, ensuring deep weld penetration and long-term durability in fixed maintenance environments where robust performance is prioritized over portability.

Precision Pulse and Cooling System

Equipped with an adjustable pulse current display and a built-in cooling fan, the 709AD+ allows for fine-tuned control over welding intensity while maintaining stable operating temperatures during extended high-intensity work sessions.

Best for: Small-to-medium repair shops, battery remanufacturing centers, and DIY enthusiasts who need a versatile, all-in-one benchtop station for assembling e-bike or power tool battery packs that require integrated BMS soldering.

Price: $180 – $250 USD

Laserax Battery Laser Welder – Industrial-Grade Power Battery Welding Solution

Laserax is dedicated to providing high-performance laser welding technology for electric vehicles (EV) and energy storage systems. Its equipment is renowned for extreme connection quality and process stability, meeting the most stringent automotive industry standards.

Fiber Laser Core Technology

By utilizing high-power CW or QCW fiber lasers, the system achieves an extremely high depth-to-width ratio. This non-contact method eliminates pin wear and creates exceptionally strong molecular-level bonds on highly reflective metals like aluminum and copper.

In-Line Process Monitoring System

The equipment integrates real-time quality monitoring, capable of instantly detecting melt pool status and heat distribution during the welding process. This “inspect-while-welding” capability ensures every joint meets automotive-grade safety requirements, significantly reducing defect rates in mass production.

Precision Thermal Control

Thanks to the extremely high energy density of the laser beam, the Heat-Affected Zone (HAZ) is compressed to a minimal range. This is critical for protecting the heat-sensitive internal components of 18650 or 21700 cells, effectively preventing damage to individual battery units during the assembly process.

Flexible Automation and System Integration

Laserax provides modular welding units that can be easily integrated into existing automated production lines or rotary tables. The system supports rapid switching of welding paths, offering the flexibility to handle design changes across various modules, from cylindrical to prismatic cells.

Best for: Tier-1 automotive suppliers and EV manufacturers requiring 100% process traceability, automotive-grade safety certifications, and the ability to weld dissimilar metals (like aluminum to copper) in high-speed, fully automated assembly environments.

Price: $185,000 USD

Fnirsi SWM-10 – Portable Mobile Solutions

Field repairs don’t wait for workshop access. The Fnirsi SWM-10 laser welder packs 1200A welding current into a 305-gram unit that runs on battery power alone. No cables. No wall outlets. Just grab it and work anywhere.

True Cordless Freedom

Powered by a 5000mAh lithium cell, this micro spot welder doubles as a power bank with a 5V/2.1A output to charge mobile devices via a USB Type-C port between repairs. Its compact 155x82x28mm frame is ideal for mobile e-bike technicians, featuring a 1.8-inch TFT screen that displays real-time voltage, power levels, and temperature for precise monitoring.

Dual-Pulse Precision for Thin Materials

A pre-pulse setting removes surface oxidation, ensuring reliable bonds on 0.05mm–0.25mm nickel strips. Four power gears and a “dots” repeat mode provide tailored intensity for everything from delicate circuits to 0.15mm bus bars, while integrated safety alerts and overheating protection ensure consistent, damage-free performance.

Best for: Mobile technicians, on-site e-bike or scooter repair services, and hobbyists who need a lightweight, pocket-sized tool for quick field repairs or light-duty battery maintenance without access to a wall outlet

Price: $39 – $79 USD

Glitter 801B – The King of Stability in Capacitor Storage

The Glitter 801B is a high-performance ultracapacitor-based spot welder specifically engineered for home and laboratory power environments. It effectively eliminates the common electrical surge issues associated with high-power industrial devices.

Advanced Ultracapacitor Energy Storage

By utilizing integrated high-capacity capacitors with a “slow charge, fast discharge” logic, the 801B provides massive instantaneous power without causing the light flickering or circuit breaker tripping typically caused by traditional AC spot welders.

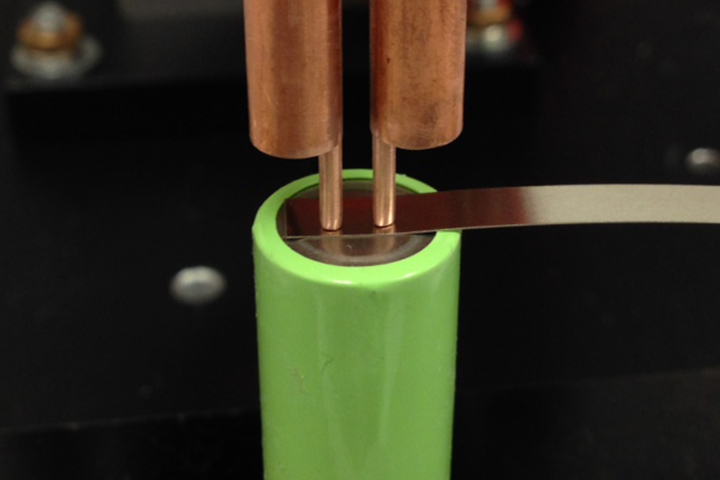

Precision Pressure-Sensing Trigger

This laser welding system features a high-sensitivity pressure induction mechanism that automatically triggers the weld once the pen reaches the optimal contact force, ensuring clean, bright silver weld spots with virtually no spark splash or surface damage.

Superior Industrial Durability

Designed for longevity, the ultracapacitor architecture offers a charge-discharge cycle life that far exceeds that of lithium-ion alternatives, making it a reliable, low-maintenance tool for long-term use in professional workshops.

High-Power Output Performance

With a peak pulse power output of up to 11.6KW, the machine provides enough energy to consistently handle both thin nickel strips and thicker tabs, maintaining stability during repetitive, high-frequency welding tasks.

Best for: Professional workshops, research laboratories, and serious hobbyists operating in residential areas who require industrial-strength welding power without the risk of tripping household breakers or damaging unstable power grids.

Price: $149 – $259 USD

AMADA Battery Welder – The Global Industry Standard for Precision Battery Welding

AMADA WELD TECH (formerly Miyachi) is a world leader in micro-joining, providing battery spot welders renowned for their extreme process control and industrial-grade reliability. Their equipment is specifically designed for battery pack production that demands the highest levels of thermal management and consistency.

Linear DC & Inverter Core Technology

Utilizing advanced inverter power control, AMADA laser welding machines achieve microsecond-level pulse feedback. This technology ensures an extremely smooth welding current output, effectively eliminating weld splash caused by uneven terminal surfaces and guaranteeing medical-grade precision for every joint.

Closed-Loop Real-Time Monitoring

The system integrates patented closed-loop monitoring for current, voltage, and displacement, capturing even the slightest changes in resistance during the weld. This “full-time surveillance” allows the equipment to automatically compensate for material variations, providing 100% process traceability for large-scale automated lines.

Active Force Control System

Paired with high-performance weld heads, AMADA equipment supports precision active force control, ensuring optimal contact pressure between the electrodes and the battery terminal before the weld triggers. This is critical for preventing deformation or micro-cracks in 18650 positive caps during the welding process.

Industrial Scalability and Durability

Built for 24/7 heavy-duty operation, these machines feature internal components designed for the rigors of a factory floor. The equipment supports both manual workstations and seamless integration with complex industrial robots or rotary systems via various communication protocols.

Best for: High-end medical device manufacturing, aerospace applications, and high-precision electronic assembly where absolute consistency, medical-grade quality control, and microsecond-level process monitoring are mandatory requirements.

Price: $50,000 – $150,000+ USD

Purchase Decision Guide Based on Application Scenarios

Match your welding machine to actual workload patterns, not marketing claims. Production volume, material types, and workspace conditions show which equipment delivers results. Some just collect dust.

The Weekend Hobbyist & Repair Tech

-

Focus: Low cost, ease of use, space-saving.

-

Top Pick: Fnirsi SWM-10. Perfect for occasional repairs or small 3S-10S packs.

The Professional Battery Builder

-

Focus: Reliability, heat management, thickness versatility.

-

Top Pick: Glitter 801B or Sunkko 709AD+. These handle daily heavy-duty welding without tripping breakers or overheating.

Small-to-Medium Manufacturing

-

Focus: Consistency, welding speed, busbar capabilities.

-

Top Pick: AMADA or MaxWave High-Precision Fiber Laser System. The step up to laser technology ensures zero electrode wear and clean, industrial-grade results.

High-Volume Industrial Production

-

Focus: Automation, AI quality control, 24/7 operation.

-

Top Pick: MaxWave or Laserax. For when every millisecond and every micron of precision counts.

Common Questions About Battery Welders

Battery welder confuse people with their tech specs and safety rules. These 15 questions cover what builders actually worry about with spot welding gear.

Q1: Can I use a regular soldering iron instead of a spot welder for 18650 batteries?

No. Soldering irons hold heat on the joint for 3-5 seconds. This long heat exposure damages the lithium cell chemistry for good. Internal separators melt at 130°C. Spot welders push energy through in 10-100ms pulses. Heat stays on the nickel strip surface. Cell core temperature rises less than 5°C with correct welding.

Tests show soldered connections hit 2-5 milliohms resistance. Spot welds get 0.3-0.5mΩ. Less resistance means less heat during high-current use. Your battery pack stays cooler. It lasts longer too.

Q2: Can I use a traditional AC spot welder at home without tripping the circuit breaker?

It depends on the machine. Traditional AC welders like the Sunkko 709AD+ draw a massive amount of instantaneous current from the grid, which often trips 10A or 16A home breakers. If you are working in a residential area, we highly recommend a Capacitor Energy Storage Welder (like the Glitter 801B). These machines charge the capacitors first and then release energy, providing higher power without impacting your home’s electrical stability.

Q3: Why should I choose Laser Welding over Resistance Spot Welding for mass production?

While resistance welding (spot welding) is cost-effective for small batches, High-Precision Fiber Laser Systems (like MaxWave) offer three game-changing advantages:

No Consumables: No need to grind or replace copper electrodes.

Material Versatility: It can easily weld copper busbars and aluminum, which are difficult for traditional spot welders.

Speed & Consistency: It’s a non-contact process that ensures every weld is identical, significantly reducing the risk of “cold welds.”

Q4: How does welding heat affect the lifespan of 18650 cells?

Excessive heat during welding can damage the internal separator of the cell, leading to self-discharge or thermal runaway. This is where high-end machines like AMADA or Laserax excel—they use ultra-short pulse durations to create a strong bond before the heat can penetrate the battery casing. Always look for a machine with adjustable pulse settings to minimize the “Heat Affected Zone” (HAZ).

Q5: Do I really need an “Industrial Solution” for a small battery startup?

If your business plan involves high-capacity packs (like E-bikes or home energy storage), you will eventually need to weld Copper Busbars. Traditional spot welders fail here because copper is too conductive. Investing early in a MaxWave Fiber Laser System allows you to handle copper and aluminum from day one, future-proofing your production line and ensuring the highest safety ratings for your products.

Conclusion

The best welder isn’t the most expensive—it’s the one that turns your production into clockwork. Whether you choose the portable Fnirsi or the game-changing MaxWave fiber laser, the right tool pays for itself in safety, speed, and peace of mind. Don’t let a weak connection be the weak link in your project. Choose the machine that fits your ambition and build with professional confidence. Your ultimate battery pack starts with the right spark. For more details about 18650 battery welding machine or to get a quote, contact us today!