I often wonder how planes are made lighter and stronger. Airlines, I know, also want better fuel savings. From my experience, how their parts are joined is a big part of the answer. I’ve seen laser welding bring big changes to aerospace manufacturing. It has many advantages over older methods. For example, I believe it helps make planes lighter. Build times also seem shorter. And, I think it improves reliability. These improvements are happening, but I feel they aren’t always well-known. I suggest there’s a key factor driving new designs that we often don’t spot…

Introduction to Laser Welding Machine in Aerospace

I believe laser welding machine is now a key tool in the aerospace field because it’s very flexible and exact. I see that this method can join many materials. This includes the special metals frequently part of building and maintaining aircraft.

The Growing Role of Laser Welding in Aerospace Manufacturing

From my understanding, manufacturers now make over half the parts in modern aircraft engines by welding them together. This number, in my opinion, really shows how important laser welding is for new ideas and efficiency when making aerospace items.

Advantages Over Traditional Joining Techniques

I find that laser welding machine has some big benefits over older ways, like riveting the body panels of planes:

Big Weight Savings: For instance, welded panels are lighter. I think this is very important in aerospace since every kilogram counts.

Stronger, Smooth Joints: I observe this process makes strong bonds in thin parts. So, you don’t need heavy bolts or glues. This saves weight and makes putting things together easier, in my experience.

Better Production Speed: I suggest that by making the joining steps smoother, makers can cut costs and produce more.

Steady Quality & Safety: My experience shows that less bending, smaller heat-damaged areas, and even weld quality are very important. These help meet the tough safety rules in aerospace.

Versatility and Broader Application

I find that laser welding machine does more than just join parts. I see its flexibility is useful for:

Laser Cleaning and Peening: I believe this is key for getting surfaces ready and making them stronger.

Additive Manufacturing and Drilling: In my view, it helps with new ways of making things, like those used in today’s aerospace factories.

I observe that using laser welding is greatly changing how people design, make, and look after aircraft and spacecraft. I think it gives engineers more options. It helps them create aerospace systems that are lighter, safer, and work better.

Key Benefits of Laser Welding Machine in Aerospace

In my view, laser welding machine offers many great benefits to the aerospace industry. I think this makes it a top choice for joining materials.

Material Versatility

Aerospace materials like titanium, nickel alloys, and aluminum are tough to weld using traditional methods. In my experience, laser welding handles aluminum alloys, stainless steel, and other aerospace metals with minimal defects, resulting in stronger, more reliable joints.

Weight Reduction for Improved Fuel Efficiency

Reducing weight is key in aerospace for better fuel efficiency and lower costs. Laser welding supports this by enabling the use of thinner, lighter materials while maintaining strong, durable joints—allowing lighter designs without sacrificing safety or longevity.

Boosting Efficiency and Productivity

Handheld laser welding machine cuts prep time by 50% and removes setup time completely. One company saw total operation time drop by half after switching from traditional methods. Laser welding is 4–5 times faster than TIG or MIG, often finishing joints in one pass. Cleanup and straightening time dropped from two days to just two hours.

Deep and Narrow Welds

I like how laser welding machine creates deep, narrow welds—ideal for hard-to-make joints like lap joints. This allows for smaller flanges, unlike the larger ones needed in resistance spot welding, helping reduce weight further.

Low Distortion and Minimal Heat Input

Laser energy is focused into a tiny spot, forming a precise keyhole with minimal heat transfer. This reduces distortion, preserves the metal’s original structure, and limits heat-affected areas.

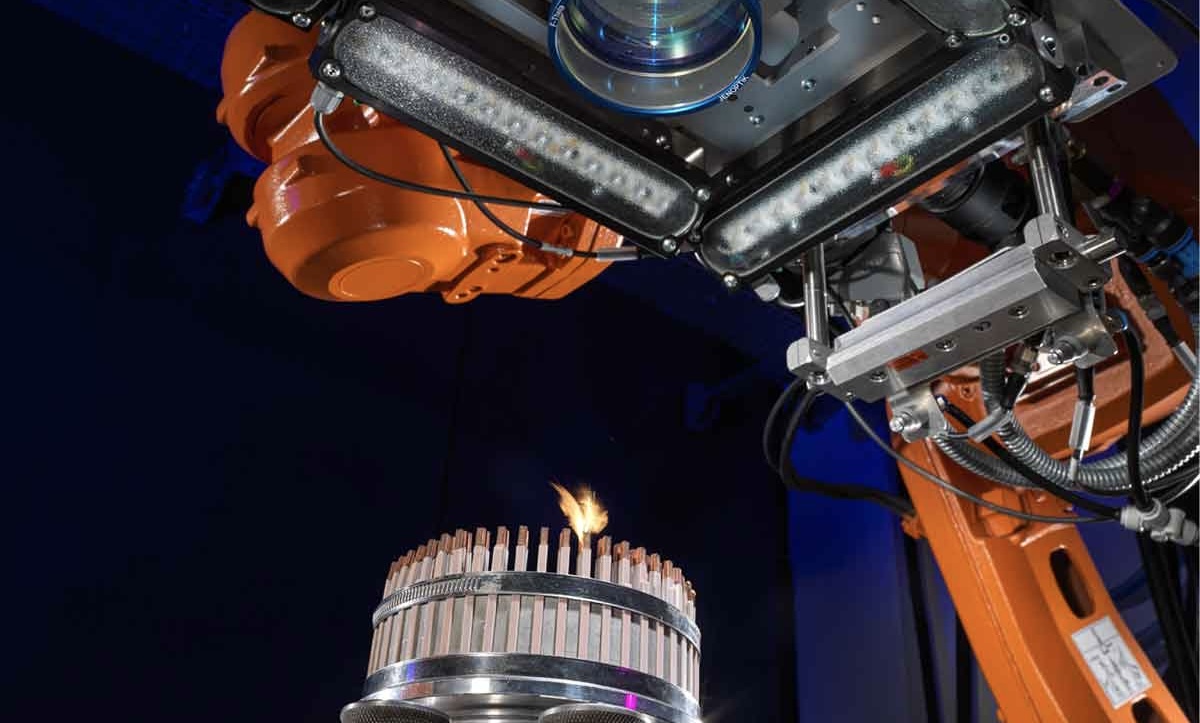

High Power Density and Great Flexibility

Laser welding machine delivers power density 1,000 times higher than traditional arc welding, enabling faster, more efficient production. Fiber-delivered automated beams, controlled by robots, give manufacturers greater flexibility for handling complex aerospace assemblies.

Precision and Quality Control in Aerospace Laser Welding Machines

I find laser welding machine is a top choice in aerospace. This is because it’s so precise and offers great quality control. From my experience, this accuracy is key. It helps keep the important mechanical features and the strength of modern aerospace alloys and light materials.

Exact Heat Management for Aerospace Materials

Laser welding offers tight control over heat input, creating a very small heat-affected zone—crucial for preserving the strength and durability of delicate aerospace alloys. By concentrating energy on a tiny spot, it minimizes distortion and thermal damage, helping metals like titanium and aluminum retain their original properties after welding.

Automated and Handheld Solutions: Repeatable, Reliable Results

Automated laser welding delivers uniform, high-quality welds by precisely controlling power, beam focus, and speed—even on complex designs. In my experience, handheld systems also offer accurate settings and movement, significantly reducing human error. This leads to safer, stronger aerospace components with consistent performance.

Data-Driven Process Improvements

Laser welding delivers up to 1,000 times the power density of traditional arc welding, enabling faster welds with minimal heat spread. This dramatically improves productivity. One aerospace company that adopted handheld laser welding cut weld prep time by 50% and reduced post-weld cleanup and straightening from two days to just two hours—an impressive boost in efficiency.

Weight Reduction Benefits of Laser Welding Machine

In my experience, laser welding machine provides significant weight reduction in making aerospace parts. I believe it’s a top choice for today’s aircraft design. It allows engineers to use thinner, lighter materials. Crucially, this doesn’t weaken the joints. So, laser welding helps create lighter airframes and parts.

How Much Weight Can We Save with Laser Welding?

Based on what I’ve seen: – You can save 15-20% in weight. This is when you compare it to older methods like riveting. – Laser welding works well even with materials just 0.2mm thick. And the structure stays strong. – I find the drop in fasteners impressive. You’ll use up to 80% fewer fasteners if you change from rivets to welds.

How This Affects Aircraft Efficiency

I’ve observed that this major weight saving has clear advantages in the real world: – Aircraft become more fuel-efficient. This happens because the total mass is lighter. – Airlines and operators see lower operating costs.

Let me share an example. A top aircraft maker started using laser welding for aluminum fuselage panels. I think this was a smart move. It reduced drag. It also made the panels structurally stronger. This really set a new standard for future aircraft.

Due to these points, I understand engineers can use thinner materials with lower safety margins. This allows for even more weight savings. Importantly, safety and structural strength are still maintained. From my perspective, this truly advances efficient aerospace design.

Laser Welding Machines Boost Aerospace Production and Speed

In the aerospace world, I’ve seen laser welding machine really shine because it’s so efficient and fast. A single laser welding system can work 4–5 times faster than the usual TIG and MIG welding. What I find impressive is that this speed boost is due to its non-contact process. This process increases productivity, helps shrink the manufacturing space needed, and also cuts down on regular maintenance expenses.

How I See Processes Get Smoother and Putting Things Together Becomes Simpler

I think laser welding makes building things much simpler because it means you don’t need as many mechanical fasteners and rivets. When you use fewer parts, the lines where things are put together can move quicker. I’ve also noticed that maintenance becomes much easier. Making processes smoother like this is really important for meeting the quick turnaround times needed in modern aerospace manufacturing.

My Take on Automation and Getting Consistent Quality in Big Production Runs

I’ve observed that modern laser welding can be automated quite a bit. This is great because it ensures you get repeatable, high-quality welds each time. This consistency is super important for large aerospace projects. In my experience, shorter lead times have a big impact on productivity and how competitive a company can be. For example, I’ve seen reports where manufacturers cut their post-weld cleanup and straightening times drastically—from two days down to just two hours. This often happens when they use new handheld laser welders that have built-in cleaning features, which I think is a smart innovation.

My Thoughts on Market Growth and How the Industry is Adopting It

The laser welding market was worth $1.96 billion in 2021. It’s expected to grow to $2.79 billion by 2029. I believe this growth happens because the aerospace industry is increasingly choosing high-speed, efficient ways to produce goods.

Why I Think Tracking and Quality Checks Are Key

I find it very practical that built-in in-process monitoring within laser welding machines lets manufacturers check each weld joint immediately. In my view, this reduces errors and minimizes rework. This leads to quick production that you can trace easily, all while making sure structures meet top-quality standards. I suggest that these benefits are crucial for aerospace manufacturers. They help them hit their productivity goals and follow strict industry rules.

Summary

Looking back at laser welding in aerospace, I am amazed how far this technology has developed. I see it is more than just joining metals these days. I believe it is changing how we build aircraft. This approach makes them lighter, stronger, and more efficient. We face bigger environmental problems. I think these manufacturing improvements are very important. They will help make air travel better for the environment. Laser welding is precise, efficient, and flexible.

I feel these qualities are more than just technical wins. From my perspective, they show our industry wants to innovate and create a more eco-friendly aerospace future. For more details about laser welding machine or to get a quote, contact us today!

Recent Comments