Automation isn’t just for giant factories anymore — affordable robot arms are changing the game. Whether you’re running a small workshop, launching a startup, or upgrading your production line, today’s low-cost robotic arms deliver precision, speed, and reliability once reserved for big-budget operations. In this guide, we’ve reviewed the Top 10 best cheap robot arms for sale, helping you find the perfect balance between performance and price. Ready to see which models bring true industrial power without breaking the bank? Let’s dive in.

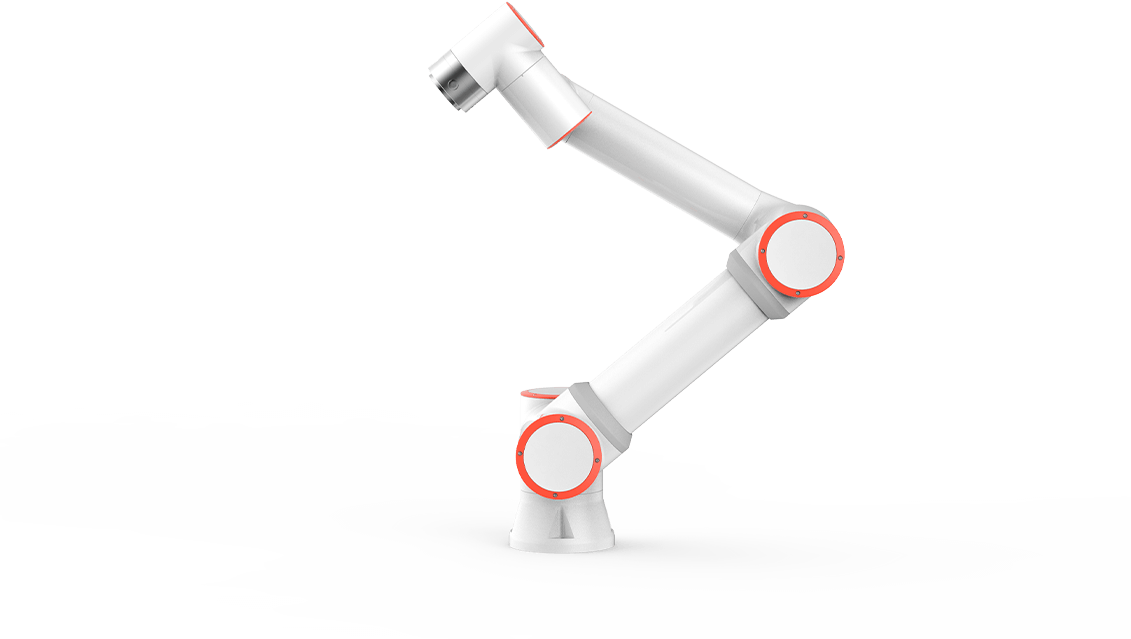

1. MaxWave FR5: Affordable 6-Axis Collaborative Robot Arm

I recommend the MaxWave FR5 robot arm for buyers on a budget. It offers great value. This 6-axis model gives you good flexibility and precision for many industrial tasks.

Key Features and Technical Specs

- Payload Capacity: 5 kg typical, up to 7 kg max

- Reach: 922 mm

- Repeatability: ±0.02 mm (ISO 9283 standard)

- Robot Weight: About 22 kg (some models up to 40 kg)

- Noise: Low, works well in shared workspaces

- IP Rating: Built for industrial environments

Popular Applications

The MaxWave FR5 works well across many industries. It’s versatile and safe for people to work alongside. Based on my experience, common uses include: – Assembly tasks – Machine tending – Packaging and material handling – Painting and automated dispensing – Precise picking and placing – Welding applications – Electronics and medical device manufacturing – Food and logistics automation

Example Use Cases

The MaxWave FR5 works well across many industries. It’s versatile and safe for people to work alongside. Based on my experience, common uses include:

- Precision assembly in electronics: Automates complex tasks that need repeatable accuracy.

- Material handling in logistics: Improves throughput. Speeds up order fulfillment.

- Spraying and Automated Dispensing: Ensure consistent and precise coating or dispensing while reducing human error.

- Pick & place in food packaging: Ensures consistent, sanitary, and rapid handling.

- Welding in manufacturing: Produces high-quality welds. Needs minimal operator help.

Industry Feedback & Value

Users praise the collaborative robot arm for its fast deployment, easy integration, and support for various languages and APIs. Its compact design fits existing lines easily, and it is more affordable than similar models. Overall, it effectively reduces labor costs and improves precision.

Pricing Insight

I suggest the MaxWave FR5 for companies seeking reliable automation on a budget. Priced at $4,900, it ranks among the best cheap robot arms for sale, offering quality without high costs.

2. Fairino FR5: Best Budget 6-Axis Collaborative Robot Arm

The Fairino FR5 stands out as a compact, affordable 6-axis collaborative robot arm. With a 5 kg payload and a reach of 922 mm, it’s built for high-precision work. The ±0.02 mm repeatability means you get the same result every time. I recommend this for tough industrial jobs.

Key Features & Technical Specs

- Type: 6-Axis Collaborative Robot Arm

- Typical Payload: 5 kg

- Max Reach: 922 mm

- Repeatability: ±0.02 mm

- Max Speed: 1000 mm/s

- Max Angular Speed: 180°/s

- Robot Weight: Lightweight and compact, ideal for limited spaces

Example Use Cases for Small Manufacturing

It’s perfectly suited for: – Electronic circuit board assembly – Automated loading and unloading for CNC machines – Fast and precise pick & place in packaging lines – High-quality welding in metal workshops – Surface finishing and polishing for uniform products

Affordable Applications in Industry

The Fairino FR5 works well for many industrial jobs:

- Electronics assembly: Gives you high accuracy for delicate and repeat tasks

- Machine tending and pick & place: Handles parts fast and with confidence

- Packaging and material handling: Speeds up production lines. Cuts down errors.

- Welding, polishing, and surface finishing: Gives you the same quality every time

Price Range & Value

The Fairino FR5, priced at $4,900, is ideal for buyers who watch costs. It delivers advanced features and industrial reliability at a fair price, making it a top choice for those seeking the best cheap robot arm for sale.

Industry Praise & User Feedback

Users appreciate the collaborative robot arm for its easy installation and simple programming. Its compact design allows it to fit into tight spaces without compromising performance, while its proven accuracy helps reduce waste and maintain high product quality.

3. Epson LS3-B SCARA Robot Arm: High-Precision Small-Parts Work on a Budget

I recommend the Epson LS3-B SCARA Robot for tasks that need high accuracy in small-parts work. This robot arm carries up to 3 kg and reaches 400 mm. It fits well in spaces where precision and speed count.

Key Features & Technical Specs

- Type: SCARA Robot Arm

- Typical Payload: 3 kg

- Reach: 400 mm

- Repeatability: High precision for fine work

- Weight: Built for compact industrial setups

Applications & Use Cases

I find it ideal for: – High-precision electronic work – Small part sorting and handling – Automated testing – Pick & place tasks that need accuracy – Packaging of miniature products

Example Use Cases

-

Microcomponent Assembly on Circuit Boards: Automates complex electronic component assembly with high precision and repeatability.

-

Precision Testing of Electronic Sensors: Ensures consistent and reliable sensor performance while minimizing human error.

-

Fine Packaging of Medical Device Components: Guarantees fast, hygienic, and highly consistent packaging processes.

Price Point & Value

At around $11,275, I believe the Epson LS3-B robot arm robot gives strong value. You focus on quality in specialized production. This price makes it a competitive choice. You need repeatable, tight-tolerance automation. You don’t want to overspend.

Industry Feedback & Strengths

Users praise the robot arm for its reliability and accuracy during continuous operation. Its compact footprint fits easily into crowded workspaces, and it offers short setup times along with strong after-sales support. Overall, it helps reduce human error in precision-focused processes.

4. Niryo NED2: 6-Axis Collaborative Robot Arm for Education, Research, and Prototyping

I recommend the Niryo NED2 as a versatile 6-axis collaborative robotic arm ideal for education, research, and small-scale industrial prototyping. It’s designed to bring real-world automation concepts into classrooms and labs. With its 300 g payload and 440 mm reach, the NED2 provides a realistic, safe, and open environment for developing robotic applications and testing automation processes.

Key Features & Technical Specs

-

Type: 6-Axis Collaborative Robot Arm

-

Typical Payload: 300 g

-

Reach: 440 mm

-

Repeatability: ±0.5 mm for accurate, repeatable motion

-

Weight: Around 7 kg, easily transportable

-

Control Options: Python, Blockly, ROS, Modbus TCP/IP, and API integrations

-

Materials: Metal structure with smooth motion control and precise servos

Best Application Scenarios

I suggest the NED2 for diverse applications that emphasize education, research, and innovation: – Robotics programming and engineering courses – University and lab automation experiments – AI vision and machine-learning integration – Lightweight assembly and inspection testing – Small-scale pick-and-place and material handling research

Example Use Cases

-

STEM & Engineering Education: Students learn motion planning, robotic kinematics, and coding through practical robotic control.

-

Research & Development Labs: Enables prototyping of vision-guided systems, grasping algorithms, and automation workflows.

-

Light Assembly Work: Handles repetitive small-part placement or testing tasks safely and efficiently in a lab environment.

Pricing & Value Insights

The NED2 is priced around $4,620, offering premium educational and research-grade performance at a fraction of industrial cobot costs. It’s a cost-effective choice for schools, research institutions, and small businesses seeking hands-on robotic automation.

Industry Strengths & User Feedback

Users value the NED2 for its intuitive software ecosystem, open-source compatibility, and stable 6-axis motion control. It’s praised for bridging the gap between educational robotics and industrial automation, allowing users to learn and prototype with real-world precision. Educators highlight its plug-and-play setup and wide programming support, making it one of the most accessible yet capable collaborative robot arms for learning and innovation.

5. Elephant Robotics myCobot 280: Compact 6-Axis Collaborative Robot Arm for Education and Light Automation

6. NACHI CZ10: Reliable 6-Axis Collaborative Robot Arm for Industrial Automation

I recommend the NACHI CZ10 as a dependable 6-axis robot arm designed for modern manufacturing environments. With a 10 kg payload and 1200 mm reach, this cobot strikes a strong balance between power and precision. It’s built for continuous industrial use, supporting both stand-alone and integrated automation setups across multiple production lines.

Key Features & Technical Specs

-

Type: 6-Axis Collaborative Robot Arm

-

Typical Payload: 10 kg

-

Reach: 1200 mm

-

Repeatability: ±0.03 mm (high accuracy for assembly and handling tasks)

-

Weight: 41 kg (robust and stable under load)

-

Safety: Built-in torque sensors in every joint for safe human–robot collaboration

-

Control System: NACHI CFD Controller with intuitive programming and fast integration

Best Industrial Applications

I suggest the NACHI CZ10 for diverse automation roles in demanding industrial settings: – Machine tending and part loading/unloading – Assembly and precision component handling – Metal fabrication and laser welding assistance – Material transfer and packaging operations – Palletizing and production line support

Example Use Cases

-

Automotive Assembly: Positions and installs medium-weight car parts with consistent accuracy and minimal downtime.

-

Electronics Manufacturing: Handles delicate components safely with torque-based collision detection.

-

Logistics Automation: Assists in packing, labeling, and moving boxes in warehouse environments.

Pricing & Value Insights

The NACHI CZ10 is priced competitively within the mid-range collaborative robot market, typically between $20,000–$30,000 USD. It delivers strong industrial reliability, making it a practical choice for medium to large manufacturers seeking safe automation without excessive investment.

Industry Strengths & User Feedback

Users value the CZ10’s smooth motion, fast setup, and superior joint sensitivity, which ensure worker safety during close collaboration. Its compact footprint and modular controller simplify integration into existing lines. Many operators highlight its stability under heavy workloads and precision during repetitive tasks—making it a trusted tool for scaling up automation while maintaining operational safety and accuracy.

7. Fanuc CRX-5iA: Versatile 5 kg Collaborative Robot Arm for Industrial Automation

I recommend the Fanuc CRX-5iA as an easy-to-use, affordable industrial robot arm. It’s built for small and medium-sized factories needing automation. With its 5 kg payload and 994 mm reach, it handles a wide range of tasks. It works well even in tight work areas.

Key Features & Technical Specs

- Type: Collaborative Robot Arm (Cobot)

- Typical Payload: 5 kg

- Reach: 994 mm

- Repeatability: High accuracy for precision tasks that repeat

- Robot Weight: Light enough to move and set up in different cell layouts

Flexible Industrial Applications

The CRX-5iA performs well in: – Light part handling and putting parts together – Automated packaging – Pick & place tasks – Machine tending – Testing and inspection lines – Product sorting and labeling

Example Use Cases

- Electronics Work: It automates delicate tasks or testing. Steady, repeatable movement matters here.

- Packaging Lines: Rapid pick & place increases output for consumer goods and e-commerce warehouses.

- Quality Control: It does precise, repeating part inspection. It rejects bad parts on manufacturing lines.

- Retail Order Fulfillment: It picks and sorts products fast. You can reprogram it for different SKUs with ease.

Pricing & Value

I suggest the FANUC CRX‑5iA as an affordable cobot solution, priced at around $43,000 for the entry model. It’s ideal for companies mindful of costs but needing reliable automation. While pricing varies with integration and accessories, the total investment remains much lower than that of traditional industrial robots with similar specifications.

Industry Feedback, Strengths & Real-World Experience

Industry users praise the FANUC CRX‑5iA for its drag-and-drop interface, which reduces programming time from days to hours. Its compact, lightweight design allows easy placement in tight spaces and quick relocation between lines. Known for Fanuc reliability, it requires minimal maintenance and integrates smoothly with a variety of end-tools and factory software through simple plug-and-play setup.

8. ABB IRB 1100: High-Speed Industrial Robot Arm With Superior Precision

The ABB IRB 1100 stands out in the affordable robot arm market. It blends industrial-grade performance with a compact, lightweight build. I like how this 6-axis robot delivers lightning-fast cycle times. Its exceptional repeatability impresses me. It works well with many automation setups.

Key Features & Technical Specs

- Type: 6-Axis Industrial Robot Arm

- Typical Payload: 4 kg

- Reach: Up to 580 mm (model dependent)

- Repeatability: ±0.01 mm (among the highest in this class)

- Weight: Lightweight, starting from around 20 kg (model specific)

- Design: Ultra-compact, fits small workspaces

- Speed: Among the fastest in its payload category

Versatile Industrial Applications

I find the ABB IRB 1100 ideal for businesses needing affordable automation. It’s strong. It’s reliable. Typical uses include: – High-precision assembly and electronics production – Machine tending in compact cells – Laboratory automation – Material and component handling in tight spaces – Small parts insertion and micro-assembly tasks

Practical Example Use Cases

- Electronics Assembly: This robot automates micro-component installation on PCBs. Repeatability is critical here.

- Pharmaceutical Handling: It speeds up laboratory pipetting and vial sorting. It follows strict hygiene requirements.

- Precision Pick & Place: The robot handles complex sorting and placement tasks at high speeds. It has almost no error rate.

Pricing Insight & Value

The ABB IRB 1100 brings premium ABB performance to the entry-level market. Based on my research, price points start in the upper mid-range for affordable industrial robots. SMEs can afford it. Large enterprises can too. You get dependable automation without paying luxury prices.

Why Industry Users Choose the ABB IRB 1100

- Top Speed & Accuracy: I recommend this robot for its top speeds. It delivers tight repeatability in a small package.

- Space-Saving: It fits into tight production lines. It works in limited work cells. It’s ideal for upgrades.

- Long-Term Reliability: ABB offers global support. The robot has proven industrial quality. You get low maintenance and high uptime.

- Flexible Deployment: It has versatile mounting options. Control options adapt quickly to various tasks and factory layouts.

Prominent Example

In a consumer electronics facility, several ABB IRB 1100 arms improved pick-and-place speeds by over 20%. Defect rates dropped by half thanks to superior repeatability (±0.01 mm). The company cut labor costs. Downtime was minimal. This drove faster ROI. Quality standards stayed strict. Based on my experience, this makes the ABB IRB 1100 a smart choice. I suggest it for those searching for the best cheap robot arms for sale. You don’t compromise on speed or precision.

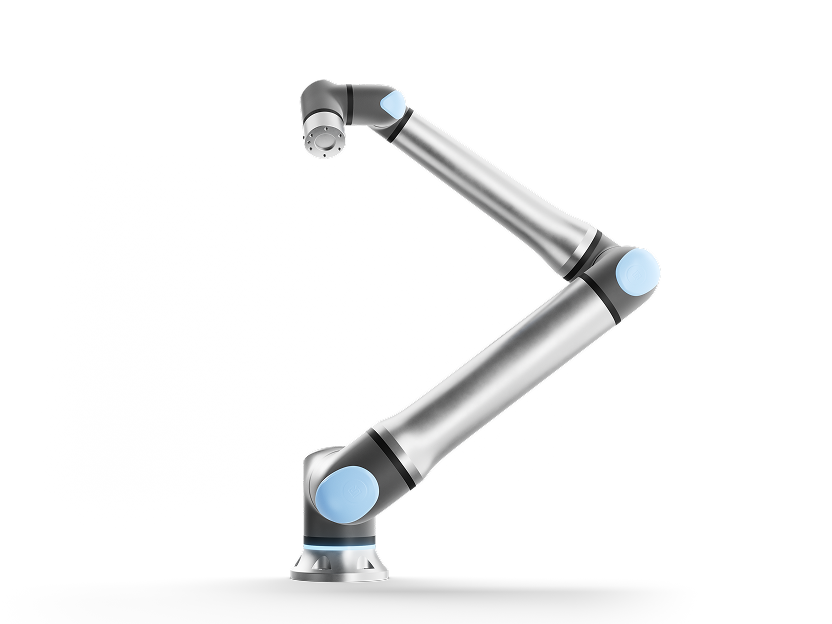

9. Universal Robots UR10: Versatile 6-Axis Collaborative Robot Arm for Industrial Automation

I recommend the Universal Robots UR10 as a reliable 6-axis collaborative robot. It excels in industrial automation with a 10 kg payload and a 1300 mm reach, making it suitable for both heavy-duty and precision tasks. Its compact footprint and flexible programming enable seamless integration into a variety of production environments.

Key Features & Technical Specs

-

Type: 6-Axis Collaborative Robot Arm

-

Typical Payload: 10 kg

-

Reach: 1300 mm

-

Repeatability: ±0.05 mm for high-precision tasks

-

Weight: 28.9 kg (light enough for easy deployment and mobility)

-

Safety: Built-in collaborative safety features for human interaction

-

Control System: Universal Robots PolyScope interface with intuitive teach pendant programming

Best Industrial Applications

I suggest the UR10 for a wide range of automation tasks: – Industrial machine tending and CNC loading/unloading – Pick-and-place of medium to heavy components – Welding, soldering, and material handling – Assembly of large or delicate parts – Palletizing and packaging in factory and warehouse environments

Example Use Cases

-

Automotive Production: Accurately positions engine parts or assemblies on production lines, improving throughput.

-

Electronics Manufacturing: Handles precision assembly tasks without damaging components.

-

Logistics & Warehousing: Moves bulk items and organizes goods efficiently with minimal human intervention.

Pricing & Value Insights

The UR10 is positioned in the mid-range collaborative robot market, with prices typically around $15,000 USD. While slightly higher than some competitors, it provides exceptional reliability, ease of programming, and a strong ecosystem of accessories and software—making it a valuable investment for manufacturers seeking versatile automation solutions.

Industry Strengths & User Feedback

Users value the UR10 for its flexibility, repeatability, and robust safety features, which allow safe operation alongside human workers. Its lightweight design and modular programming system simplify integration into existing production lines. Feedback highlights its stable performance under repeated cycles, consistent accuracy, and ability to adapt to various industrial tasks, making it one of the most trusted collaborative robots on the market.

10. Kawasaki RS010N: Compact 6-Axis Robotic Arm for Industrial Automation

I recommend the Kawasaki RS010N as a versatile 6-axis robotic arm robot designed for industrial automation. It offers a 10 kg payload and a 900 mm reach, making it ideal for medium-duty tasks where precision and reliability are required. Its compact design allows easy integration into constrained workspaces while maintaining high performance.

Key Features & Technical Specs

-

Type: 6-Axis Industrial Robot Arm

-

Typical Payload: 10 kg

-

Reach: 900 mm

-

Repeatability: ±0.03 mm for precise operations

-

Weight: 28 kg (compact yet stable)

-

Control System: Kawasaki FS100 Controller with intuitive programming and fast cycle times

-

Safety: Supports integration with standard industrial safety systems

Best Industrial Applications

I suggest the RS010N for a range of automation applications: – Machine tending and part handling in compact setups – Pick-and-place of medium-weight components – Assembly and inspection tasks requiring high precision – Welding, soldering, and adhesive application – Material transfer and packaging in small production lines

Example Use Cases

-

Electronics Assembly: Positions small to medium components with consistent accuracy and minimal downtime.

-

Automotive Component Handling: Handles medium-weight parts in tight factory spaces efficiently.

-

Packaging & Logistics: Automates small-batch packing or sorting tasks with precision and speed.

Pricing & Value Insights

The Kawasaki RS010N is priced competitively for a mid-range industrial robotic arm, typically around $25,000–$30,000 USD, offering a balance of reliability, precision, and compactness. Its performance and integration ease make it a practical choice for manufacturers needing dependable automation in smaller footprints.

Industry Strengths & User Feedback

Users praise the RS010N for its compact design, fast cycle times, and precise repeatability, which allow it to operate efficiently in limited spaces. Its stable performance under repeated workloads and Kawasaki’s established service network make it a trusted option for medium-duty industrial automation. The arm integrates well into existing production lines, enhancing efficiency while maintaining safety and reliability.

Summary

Choosing the right robot arm isn’t just about saving money — it’s about unlocking new levels of efficiency, accuracy, and productivity for your business. The models we’ve reviewed prove that affordable automation is real and within reach. Whether you need a compact arm for precision assembly or a powerful unit for heavy-duty work, there’s a smart, cost-effective option waiting for you. Take the first step toward smarter production today — your future factory starts with the right robot arm. Contact us now to get a personalized quote or expert guidance on choosing the best robot arm for your needs.