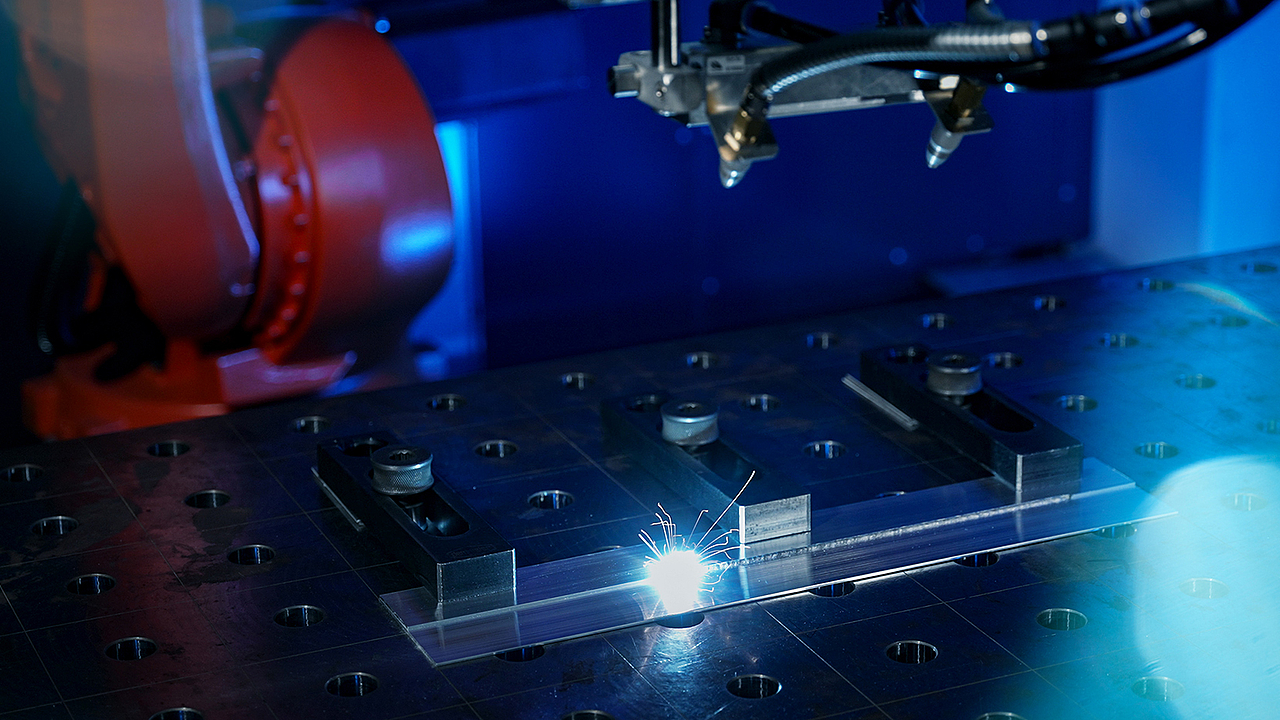

For prismatic battery cells—the backbone of most electric vehicles—every weld counts. These high-density packs must survive thousands of charge cycles, extreme temperatures, and constant vibration. Thin aluminum and copper tabs are easily damaged, but modern laser welding delivers pinpoint accuracy in under 100ms, protecting sensitive chemistry while automated systems churn out dozens of flawless welds per minute. Discover how the best industrial welding solutions make prismatic EV batteries safer, stronger, and ready for high-volume production.

Why Fiber Laser Welding Leads the Industry

Manufacturing floors worldwide have switched to fiber laser systems. They outperform every alternative by clear margins. These machines create battery tab welding processes that combine speed, precision, and reliability. Other technologies can’t match this.

- Speed transforms production economics: Fiber lasers complete over 12 connections per second (720 welds/min), outperforming resistance welding by 3–4x. For a facility producing 100,000 packs annually, this speed advantage slashes production time by 65–75%, significantly lowering labor costs and accelerating ROI.

- Precision eliminates the quality lottery: By focusing energy into 0.1mm spots with ±2% heat variance, fiber lasers ensure stable results for nickel strip welding batteries and busbar welding battery modules. This precision maintains contact resistance below 0.1mΩ and limits capacity loss to <0.3%, far superior to the 2–5% loss seen in conventional methods.

- Automation integration happens smoothly: Modern automated battery welding systems combine lightweight laser heads with vision-guided robotics for real-time monitoring. This closed-loop setup detects defects in under 50ms, ensuring a first-pass yield of 99.7–99.9% in high-volume manufacturing environments.

- Low-resistance connections boost pack performance: Low-resistance joints—as seen in Tesla’s 4680 and CATL’s Qilin architectures—boost total pack efficiency by 1.2–1.8%. These laser-welded connections remain stable over 5,000+ cycles, adding 7–12 miles of range to a 100kWh pack without requiring any changes to cell chemistry.

- Heat-affected zones shrink to microscopic levels: By completing fusion in just 50–100ms, fiber lasers restrict the thermal impact to a microscopic 0.15–0.3mm. This protects sensitive separators and electrolytes from heat damage, resulting in a weld strength that typically exceeds the base material strength by 15–25%.

Key Welding Technologies & Methods

Three core technologies, including laser welders, drive most prismatic battery cell production today. Each addresses specific challenges, with the right choice depending on cell design, production volume, and quality requirements.

Fiber Laser Welding Systems

Extreme Precision: Full power range (500W–6kW) with $M^2 < 1.1$ and focus spot size <0.15mm.

Thermal Safety: Low heat input (15–25J) limits temperature rise to <15°C at 3mm, protecting separators and electrolyte.

Dissimilar Metal Joining: Limits Al-Cu brittle layers to 2–5μm with resistance <0.08mΩ over 8,000+ cycles.

Dual-Beam Laser Technology

Core Principle: 7:3 power split between center and ring beams ensures deep fusion and a leak-free 10–15 year lifespan.

Intelligent Control: 2ms real-time monitoring compensates for thickness variations, keeping seal width within ±0.05mm.

Maximum Efficiency: Speeds of 200–400mm/s cut cycle times by 40–50% and reduce porosity to <0.5%.

Superior Heat Control: Lowers peak welding temperatures by 80–120°C, minimizing thermal impact.

Industry Standard: Helium leak rate of $1 \times 10^{-9}$ mbar·L/s; adopted by Tier-1 makers like LG and Samsung SDI.

Gantry-Based Laser Systems

Long Seam Precision: Optimized for 200–600mm welds; positioning accuracy of ±0.02mm prevents stress-induced deformation.

Deep Penetration Stability: Speeds of 30–80mm/s allow single-pass welding of 1.5–2.5mm thick components.

Extreme Rigidity: ±0.01mm repeatability eliminates vibration errors typical of robotic arms, ensuring joint reliability.

Smart Monitoring: Integrated 5,000 fps cameras detect defects within 100ms, driving reject rates below 0.8%.

Essential Features for Prismatic Cells

Prismatic cells need equipment that handles their flat, rectangular shape. This shape brings unique challenges. Production welding systems must maintain quality across millions of units.

High-Speed Automation Integration

Automated welding machines must keep pace with modern production, supporting high-tempo lines of 200–400 PPH. Feeding mechanisms position cells within ±0.05mm tolerance while vision systems scan tabs in 150ms, keeping total cell changeover times under 2 seconds. Furthermore, inline quality inspection catches defects right away using AI algorithms to analyze the fusion zone in 120ms, ensuring a first-pass yield exceeding 99.5%.

Precise Beam Delivery Systems

Scanning systems add dimensional coverage via 8,000mm/s galvanometers, essential for laser beam welding lithium batteries. The system scales from pouch cell welding methods to busbar welding battery modules (0.1–0.8mm spot size). Real-time auto-focus compensates for height variations within 10ms.

Material Versatility Across Battery Components

Crucial for battery pack manufacturing welding, the system identifies metals to adjust power by 30–40% for copper/aluminum joints. A “dual-pulse” process cleans coatings before fusion, ensuring ultra-low contact resistance and spatter-free results for nickel strip welding batteries.

Real-Time Process Monitoring

Multi-sensor tracking corrects parameters within 10ms as photodiode arrays measure plasma emissions to ensure weld stability. The system detects porosity (>0.1mm) via 20–80kHz ultrasonic monitoring and uses thermal imaging to limit the heat-affected zone to 0.5mm, guaranteeing cell safety.

Why Laser Welding Wins

As traditional joining reaches its limits, laser welding has become the industry-standard battery welder, delivering the speed and precision needed to maximize electrical efficiency while protecting the battery’s delicate internal chemistry.

1. Superior Conductivity & Efficiency

Laser welding achieves an ultra-low contact resistance of <0.05 mΩ, a 40-60% improvement over resistance spot welding. For a 100kWh pack, this reduces heat loss by 180-250W, extending driving range by 8-14 miles per charge without altering cell chemistry.

2. Non-Contact Flexibility

As a non-contact method, lasers easily reach recessed areas and narrow gaps where bulky electrodes cannot fit. The beam delivery system maintains 0.02mm precision over a 200mm range, eliminating the need for complex, high-pressure clamping systems.

3. Zero Mechanical Stress

Unlike resistance welding, which applies 50-200 psi that can deform thin-walled cans or damage internal separators, laser welding uses light absorption to melt metal. This zero-force process preserves the cell’s internal structure, typically reducing QC rejection rates by 35-45%.

4. Aerospace-Grade Hermetic Sealing

Moisture levels as low as 50 ppm can slash battery cycle life by 30%. Laser welding creates a robust fusion zone with a helium leak rate below $1 \times 10^{-9}$ mbar·L/s. This airtight barrier protects the electrolyte, ensuring a service life of 12-15 years.

5. Long-Term Process Consistency

While resistance welding electrodes degrade after 5,000–15,000 cycles, laser optics maintain stable performance for 3-5 years with less than ±3% deviation. This ensures that your 1st battery pack is identical in quality to your 500,000th.

Conclusion

Selecting the right welding solution for prismatic cells is a strategic investment in your productivity, product longevity, and market leadership. As traditional methods hit their limits, our automated laser systems deliver the extreme precision and speed necessary to slash heat loss, boost yields, and accelerate your time-to-market. In an industry where every milliohm defines performance, upgrading to laser technology ensures your production line remains future-proof and your battery quality stays world-class. Ready to revolutionize your manufacturing? Contact us today for a custom process audit and let’s engineer the perfect welding solution for your production goals.