Choosing the right laser engraving machine can feel like standing at a crossroads. On one hand, affordable entry-level models promise quick savings and simple operation. On the other, premium industrial machines boast blazing speeds, versatile material compatibility, and advanced automation—but at a higher upfront cost. Whether you’re a hobbyist, startup, or high-volume manufacturer, understanding the trade-offs between cheap vs. premium is key to finding a machine that truly fits your needs—and ensures every mark you make is precise, durable, and cost-effective.

Price Comparison: Cheap vs Premium Laser Engraving Machines

I’ve seen that the price difference between basic and high-end laser engravers is quite large. Let me give you a detailed breakdown of what you get for your money.

Overview Table: Specs and Price Tiers

| Tier | Price Range | Wattage | Marking Area | Main Use Case |

|---|---|---|---|---|

| Cheap/Entry Level | $499–$5,000 | 20–30W | 110–150mm² | Small parts, light material |

| Mid-range | $3,500–$28,500 | 30–60W | Variable | Moderate use, small business |

| Premium/Industrial | $10,000–$80,000+ | 50–1000W+ | >1000mm² | Industrial, continual heavy-duty use |

Entry-Level (Cheap) Laser Marking Machines

Price Range: $499 to $5,000

Target Users: I recommend these for hobbyists and small businesses. They are also great if you need a portable or desktop machine.

Typical Wattage: 20W–30W

Best For: Light materials, plastic, occasional marking on metals

Marking Area: The marking area is typically 110mm–150mm square. This size works well for small parts and low-volume production.

Popular Brands/Examples:

- SCULPFUN (from $300–$3,000)

- MaxWave MW-SM5 Mini handheld semiconductor laser engraver(only $750)

- MaxWave MW-FDMP20 MPOA laser engravers (for color marking: $2,600)

Professional & Premium Laser Marking Machines

Price Range: $10,000–$80,000+, with top industrial models up to $100,000

Target Users: From my experience, these are built for industrial settings. They handle high-volume production.

Typical Wattage: 50W–1000W+

Best For: Deep engraving, high-speed/high-volume production, durable materials (e.g., stainless steel, brass)

Marking Area: These have much larger marking areas. For example, AP Lazer offers a 62” x 40” engraving area with footprints wider than 100”.

Notable Brands & Sample Prices:

- AP Lazer 100W MOPA: $52,999

- Gravotech: $5,000–$50,000

- Universal Laser: $7,000–$70,000

Key Point:

Price isn’t just about power or size—it also reflects speed, engraving depth, material range, customization, and efficiency. For simple, low-volume work, a cheaper machine is enough. But for demanding industrial jobs, a premium model is best, offering high speed, durability, and reliable performance on tough materials.

Laser Engravng Machines: Comparing Speed, Output, and Efficiency

Based on my experience, comparing cheap and premium laser engraving machines shows a big difference. If you need speed, high output, and efficiency, the right choice becomes clear.

Premium Laser Engraving Machines: My Top Recommendation for Demanding Tasks

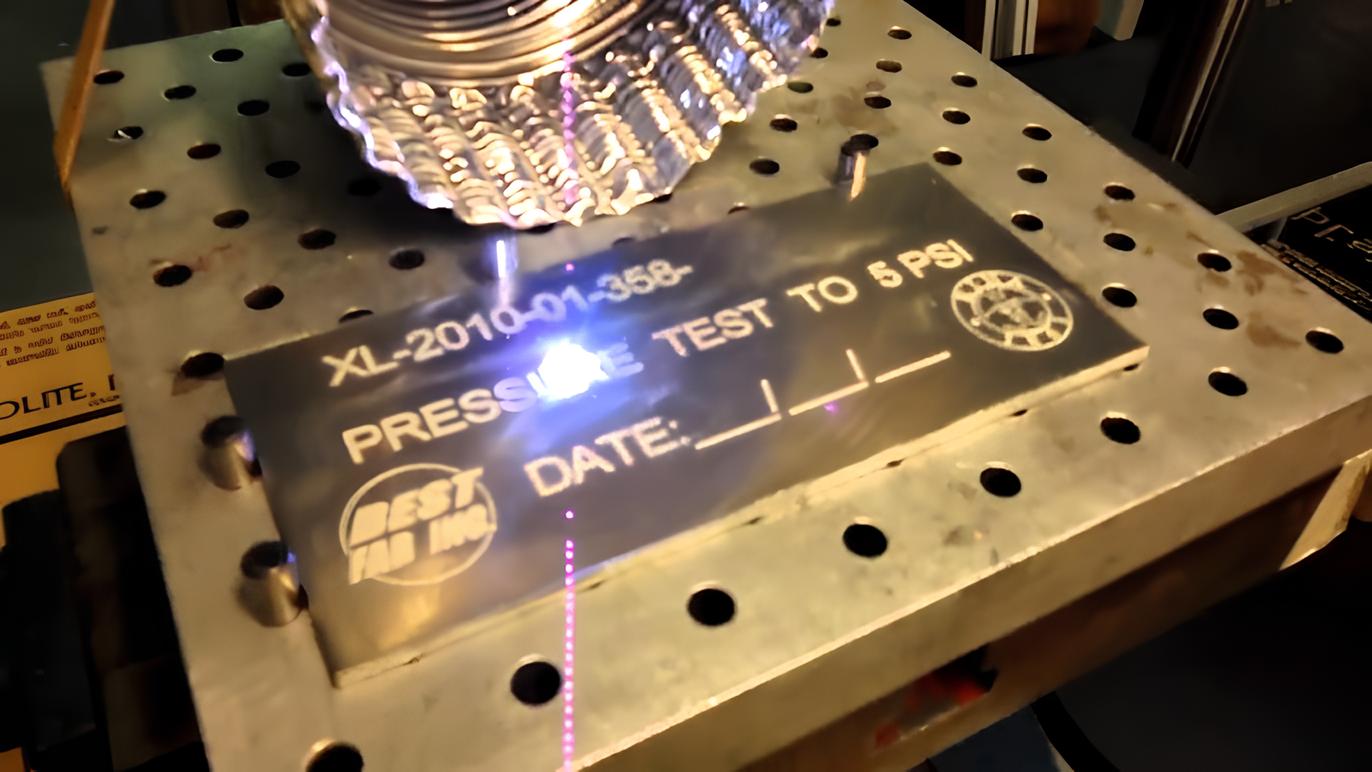

Premium laser engraving machines stand out for their impressive speed (up to 6000 mm/s) and high-volume output—for example, marking 352 acrylic pieces in just 29 seconds each. They deliver flexible material compatibility with deep, durable, and precise marks like barcodes and logos. Thanks to less downtime and long service life (often up to 50,000 hours), they reduce maintenance needs and lower overall costs, making them ideal for demanding industrial production.

Entry-Level Laser Marking Machines: Good for a Start, but with Limits

Cheaper machines run at slower speeds and handle smaller batches, making them unsuitable for large-scale production. Their lower build quality often means more maintenance and downtime, which impacts productivity. With limited material compatibility and precision, they are best for hobby projects, prototypes, or small businesses with lighter needs.

A Few Examples for You to Consider

- MaxWave MW-F25CA Dual-Beam Laser Engraver: This model costs around $1200~$1400. With dual laser sources, it marks most materials, works handheld or desktop, needs almost no maintenance, and delivers long-term value.

- TRUMPF TruMark Series 3000: I recommend this machine for its precision. It handles many materials and is easy to add to a production-focused business.

Summary:

Here’s my final opinion. Premium machines are built for speed, steady uptime, mark quality, and large-scale productivity. This makes them essential for any industry where reliability and high output are required. A cheaper machine can work for lighter jobs where speed and large batches aren’t a priority. They just don’t perform well in places that need to meet modern manufacturing performance standards.

Usability & Application Scope of Cheap vs Premium Laser Engraving Machines

If you are trying to choose between a cheap and a premium laser marking machine, I think you should focus on two key things. First, how easy is the machine to use? Second, what do you need the machine to do? Here is my comparison based on real examples, performance data, and my own practical experience.

Cheap Laser Marking Machines: Usability & Application Scope

Premium Laser Marking Machines: Usability & Application Scope

High-end models like the HeatSign HS-MFL20 and xTool S1 are easy to use, often maintenance-free, and allow precise control via PC or mobile, with broad software compatibility. They deliver 20–45W+ power and speeds up to 6,000 mm/s, enabling fast, deep, and accurate marking for efficient mass production and demanding industrial tasks. With wide material compatibility (metals, plastics, wood, leather, fabric, acrylic), they suit industries like automotive, electronics, and jewelry. Their larger, more flexible work areas support both bulk jobs and custom pieces. Plus, features like air assist, quick lens changes, and advanced limit switches enhance safety, reliability, and efficiency.

Conclusion

So, how do you pick between a cheap and a premium laser marker? I believe it depends on what you need. Consider the level of usability you require, like the ease of setup and software support. Also think about the scope of your applications. This includes material types, speed, precision, and production volume. Based on my experience, a cheaper machine is fine for simple, occasional projects. For serious, high-output, or precision jobs, I suggest that premium laser markers are the better choice.

Conclusion & Recommendation: Which Laser Marking Machine Should You Choose?

I believe choosing between a cheap or premium laser marker depends on your needs, budget, and long-term goals. You must match them with what each machine offers. Let me break it down for you using real examples and data.

Cheap Laser Marking Machines: Best for Budget and Occasional Use

I recommend these machines for hobbyists, startups, and small businesses, or anyone needing occasional marking. Typical prices range from $1,200 to $5,000 (e.g., MaxWave 10+2W dual-laser 30W at $1,200–$1,400). They offer low upfront costs, easy operation, compact size, and immediate usability, making them ideal for short-run projects, jewelry, metal, promotional items, and prototypes. However, they have slower speeds, shallower engraving, shorter lifespans, and fewer features, with limited automation, accessories, and support.

Premium Laser Marking Machines: Built for Production, Speed & Reliability

I recommend these machines for industrial environments and production lines, especially for high-volume, deep engraving, or compliance-tracked work. Typical prices range from $10,000 to $70,000+ for industrial fiber and CO₂ laser systems. They offer faster marking, higher efficiency, and lower per-mark costs (as low as $0.02), with minimal downtime and design for multi-shift operation. Advanced features include IoT connectivity, 3D marking, automation-ready software, and regulatory compliance, along with longer warranties and better support. With larger work areas and upgradeable modules, they adapt as your business grows, providing reliable performance and strong ROI despite higher initial costs.

My final thought is this: I advise you to match the machine to your current and future needs, not just your starting budget. This way, you won’t quickly outgrow your equipment. It helps you get the most value and performance as your business changes.

Summary

Ultimately, the right laser marking machine isn’t just about price—it’s about matching performance with your goals. For small projects or occasional marking, a well-chosen entry-level machine delivers instant results without breaking the bank. For industrial-scale production or demanding tasks, investing in a premium system ensures speed, precision, and reliability that pay off in the long run. Make the choice that keeps your workflow smooth, your marks flawless, and your business moving forward—because every great product deserves a mark that lasts. Ready to learn more? Contact us now for expert advice on laser engraving machines.