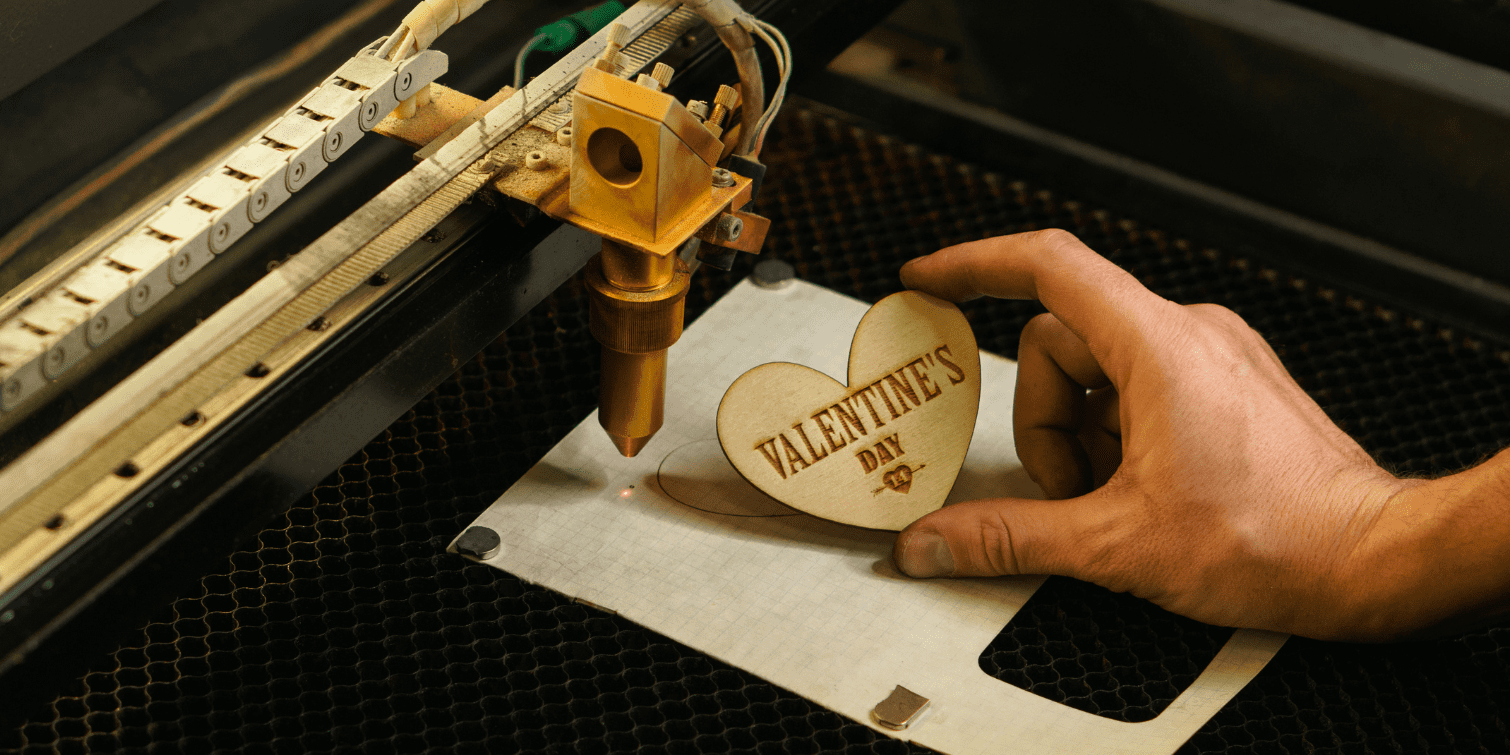

Standing before the vast choice of laser engravers, a critical question emerges: does investing in a professional machine truly pay off, or is a budget-friendly model the smarter entry point? This guide cuts through the marketing claims to directly compare what you pay with what you get, helping you determine where real value lies for your projects and wallet.

Comparison Table: Cheap vs. Professional Wood Laser Engravers

| Dimension | Cheap Diode Laser Engraver | Professional CO₂ Laser Machine |

| Price Reality | Low upfront cost, high hidden costs. | High initial investment, predictable long-term cost. |

| Speed & Precision | Slower, inconsistent quality. | Fast, consistent high precision. |

| Material Handling | Limited (thin wood, no clear acrylic). | Versatile (thick wood, acrylic, leather). |

| Durability & Support | Light-duty, higher failure rate, community support. | Industrial, reliable, professional support & warranty. |

| Software & Safety | Basic software, user-managed safety. | Advanced software, integrated safety features. |

Cheap Wood Laser Engravers: What They Can and Can‘t Do

Budget diode laser engravers occupy a specific niche. Understanding their true capabilities and inherent limitations is crucial to set realistic expectations and avoid costly mistakes.

Core Specifications & Performance

These machines typically use 2.5W to 10W diode modules, measured as optical power. They offer compact work areas, commonly around 400x400mm, suitable for standard-sized projects but not for large-scale production. Spot size varies significantly, affecting detail and speed; finer details require smaller spots but result in slower cutting.

Real-World Cutting & Engraving Data

-

Engraving Speed: Can reach up to 600mm/s on surface engraving, matching professional rates for this specific task.

-

Cutting Capacity: Heavily dependent on power and material. For example, a 10W model may cut up to 20mm basswood in a single pass under ideal conditions, but performance drops by 30-50% on hardwoods like oak.

-

Precision: Can achieve around 0.05mm accuracy with a stable frame and proper calibration, allowing for basic depth variation.

Key Limitations You Must Consider

-

Material Constraints: Maximum effective cutting thickness is limited, especially for hardwoods. Even 10W machines often struggle with material over 10-15mm.

-

Fire Risk: Engraving/cutting wood generates heat and flames. Most budget models lack integrated safety features like flame sensors, making added air assist and vigilant supervision mandatory.

-

Frame Stability: Lower-cost constructions can lead to vibration during operation, compromising precision and edge quality on longer or faster jobs.

Hidden Costs & Long-Term Value

-

Maintenance: Requires regular lens cleaning and mechanical adjustments. Diode life is typically 500-1000 hours, with replacement costs adding up.

-

Essential Add-ons: Ventilation and air assist systems are not optional for safe operation, adding $150-$300+ to the initial investment.

-

Reliability: Expect a higher first-year failure rate (20-30%) for components like control boards, and prepare for potential speed reductions versus advertised claims when cutting dense materials.

Professional Wood Laser Machines: What You’re Paying For

Professional systems, primarily using CO₂ laser technology (CO₂ laser marking machines), represent a significant investment starting around $2,600 and scaling far beyond. The premium price translates into superior technology, industrial reliability, and business-ready capabilities.

Core Specifications & Performance

These systems employ 30W to 150W+ CO₂ laser tubes, specifically optimized for organic materials like wood and acrylic. They feature large work beds (often 1000x600mm or more) for batch processing. The technology delivers a powerful, consistent beam for both high-speed operation and deep cutting capacity that diode lasers cannot match.

Real-World Cutting & Engraving Data

-

Engraving & Cutting Speed: Consistently operates at 300-500mm/s, maintaining high precision and clean edges even at maximum speed.

-

Cutting Capacity: Effortlessly handles 6-10mm plywood in a single pass. Through multi-pass strategies, it can process materials 20mm+ thick with excellent finish quality across all wood types.

-

Precision & Repeatability: Advanced motion systems and auto-focus maintain ±0.05mm precision over continuous production runs, essential for professional results.

Key Professional Advantages

-

Material Versatility & Speed: Designed for production throughput, they drastically reduce job time and handle a wide range of materials and thicknesses with ease.

-

Built-in Safety & Stability: Feature fully enclosed Class 1 safety designs with interlocks and robust cooling systems, enabling 24/7 operation and ensuring a safe, compliant workshop environment.

-

Advanced Automation: Integrated features like CCD camera positioning and nesting software minimize setup time and maximize material utilization, boosting overall efficiency by 200-300%.

Cost Analysis & Long-Term Investment

-

Initial Investment Breakdown: The price reflects high-quality components: the laser tube (30-40%), a precision motion system (20-25%), safety enclosure & cooling (15-20%), and advanced software (10-15%).

-

Total Cost of Ownership: While upfront costs are high, operational costs over 5 years (including power, maintenance, and tube replacement) must be factored. For a business, this investment is justified by unmatched productivity, superior quality, and the ability to scale, translating into a faster return on investment and greater profit potential.

Cheap Wood Laser Engravers Vs Professional Machines

The divide between budget and professional laser engravers is defined by five critical dimensions. Understanding these fundamental differences is key to making an informed investment that aligns with your goals, rather than facing costly limitations.

Price Reality: Beyond the Sticker Shock

-

Cheap Engravers: Characterized by a low initial purchase price. However, this is accompanied by significant hidden costs, including essential add-ons like ventilation systems, safety gear, and software licenses. Users also face ongoing expenses from frequent consumable replacements and potential DIY repairs.

-

Professional Machines: Command a substantially higher upfront investment. This cost includes integrated systems like cooling and exhaust, professional-grade software, and robust construction. The total cost of ownership is more predictable, with lower long-term failure rates and minimal need for user-added modifications.

Speed and Precision: Where Time Equals Money

-

Cheap Engravers: Exhibit slower processing speeds, especially for cutting, often requiring multiple passes for materials over 3mm. Precision and edge quality can be inconsistent, particularly on longer jobs or with unstable frames, making detailed or production work challenging.

-

Professional Machines: Deliver high throughput speeds with single-pass cutting capabilities for many materials. They maintain exceptional cut consistency and edge quality across thousands of cycles, thanks to superior motion systems and stable construction, directly translating to higher productivity and professional results.

Material Handling: Defining Project Possibilities

-

Cheap Engravers: Best suited for thin materials like wood under 6mm and surface engraving. They face significant material limitations; for example, they often cannot cut clear acrylic and struggle with dense hardwoods, restricting the range of projects and client work you can undertake.

-

Professional Machines: Offer extensive material versatility, cleanly cutting and engraving a wide array of materials including thick wood, clear acrylic, leather, and more. Their high power and advanced optics overcome the inherent restrictions of budget technology, unlocking commercial opportunities.

Durability and Support: Production Reliability

-

Cheap Engravers: Often feature open-frame designs with components rated for intermittent, light use. They typically have higher first-year failure rates for mechanical and electronic parts, and rely primarily on community forums for troubleshooting support.

-

Professional Machines: Are built with enclosed, rigid frames and industrial-grade components designed for continuous operation. They are backed by comprehensive manufacturer warranties and dedicated technical support, ensuring reliability for business-critical production and minimizing costly downtime.

Software, Safety, and Operational Ecosystem

-

Cheap Engravers: May use limited free software or require paid upgrades for full functionality. Safety is largely the user’s responsibility, with open beams requiring strict personal vigilance. The learning curve often involves navigating hardware limitations and workarounds.

-

Professional Machines: Include powerful, feature-complete software for advanced design and automation. Integrated safety features like full enclosures, interlocks, and monitoring systems are standard. The ecosystem is designed for operational efficiency, reducing setup time and allowing users to focus on creation rather than machine management.

How to Choose the Right Laser Engraver

Selecting the ideal machine isn’t about finding the “best” one overall, but the right laser engraver for your specific needs. A smart choice starts with a clear assessment of your primary projects, budget, and long-term goals.

When a “Cheap” Machine is Worth It:

A budget engraver represents a smart choice if your work centers on hobbyist exploration and low-volume projects. It is worth the investment if you have a strict budget, plan only for occasional use on thin woods and approved materials, and value portability over speed. This path is also suitable if you enjoy the technical tinkering involved in assembly, maintenance, and workarounds, accepting the associated inherent limitations in material thickness, production speed, and fire safety management as part of the learning process.

When a “Professional” Machine is Worth It:

A professional system becomes a justifiable investment the moment your work requires commercial reliability. It is worth the significant upfront cost if you depend on the machine for business revenue, engaging in high-frequency use or batch production for clients. The investment pays off by granting access to a wider material library (like clear acrylic and thick hardwoods), ensuring consistent, high-quality results, and providing the safety compliance and robust support necessary for a professional workshop. It is the clear choice for scaling operations and treating the equipment as a true capital asset.

Conclusion

Ultimately, determining “worth” is not about finding an objectively superior machine, but about identifying the tool whose total cost of ownership aligns with your specific workflow. By weighing the critical differences in performance, capacity, and long-term reliability, you can move beyond initial price to make an investment that delivers true value and supports your goals for years to come. Ready to determine which laser engraver is the right financial and operational fit for you? Contact our team for a detailed analysis based on your project needs.