I know you want to raise your jewelry shop’s quality and profits without overspending. From my experience, the right jewelry laser welder is the key. You will face a big decision when choosing between modern Chinese brands and high-end German makers. You might think you have found the perfect machine for your needs. But I have learned there is often a hidden factor that can completely change your decision.

Chinese Jewelry Laser Welder Brands

From my experience, Chinese jewelry laser welders offer a great balance of price, technology, and practical features. I find they are a solid choice for both individual jewelry artists and large manufacturers. These leading companies show the main benefits of this market segment.

A Look at Chinese Laser Welder Brands & What They Offer

MaxWave Laser

MaxWave Laser’s jewelry welders offer strong cost-performance, ±0.02mm precision, and compact diode or fiber models ideal for fine jewelry repairs and production.

Baison Laser

Baison’s jewelry welders focus on energy efficiency and consistent performance. Their machines are well-suited for delicate metalwork with stable output and clean welds.

Han’s Laser

Han’s Laser provides high-end jewelry laser welders with advanced control systems and long lifespan. Their models are trusted for micro-welding in high-volume settings.

Dapeng Laser

Dapeng’s jewelry welders are known for affordability and ease of use. They’re a solid choice for small studios handling light repairs and everyday welding tasks.

Technical Specifications (Example: MaxWave’s Laser W150G)

- Laser type: YAG, 1064 nm

- Max Output: 60-200 W

- Pulse frequency: 0.1–20Hz

- Spot diameter: 0.1mm

- Power input: 110-220V, 50-60Hz

- Weight: 200 kg

- Cooling: forced air

- Dimensions: 1610x290x430mm

- User features: I find the microscope targeting, advanced safety, and real-time feedback very useful.

Where I’d Use Them

In my opinion, they are perfect for gold, silver, platinum, titanium, and other high-value jewelry. They are also excellent for micro-welding things like electronic leads, battery tabs, sensors, and doing precision repairs on watches or small appliances.

Key Value Advantages

Chinese laser welders are typically 20–50% more affordable than comparable German models, while still offering a wide range of compact, customizable options. Replacement parts are easy to source globally, and after-sales support from major brands like Han’s, Baison, and Hymson continues to improve year by year.

Market Performance

Inside China, these brands are leaders for small and mid-sized jewelry companies. I’ve also seen them become more popular in export markets. From my perspective, their success is simple: the machines perform well, have strong features, and come at a competitive price.

German Jewelry Laser Welder Brands: Precision, Reliability, and Innovation

From my experience, German brands making laser welders for jewelry are known worldwide. They are famous for their precision, reliability, and new technology. I find that these brands serve both individual jewelry makers and large-scale factories. They offer features that meet high technical and quality levels.

Leading German Laser Welding Brands for Jewelry

TRUMPF

TRUMPF jewelry laser welders are known for exceptional precision, ideal for micron-level welding—especially on precious and highly reflective metals. They are durable and built for continuous, high-load production.

ROFIN (Coherent)

ROFIN, now part of Coherent, offers a wide range of laser welding solutions perfect for intricate and detailed jewelry work. Their systems support automated control, producing clean welds with minimal heat impact.

Jenoptik

Jenoptik laser systems excel in smart control and outstanding beam quality, making them ideal for delicate metal joining tasks like jewelry repair and customization. Their compact designs suit studio use and offer flexible operation.

Value and Technical Advantages of German Laser Welding Machines

- Precision with minimal heat-affected zones. This helps maintain the look and strength of fine jewelry.

- Reliability for the same results every time. This applies to both large production runs and single items, thanks to automation.

- High material versatility. I find they work on thin, thick, reflective, or mixed metals without causing warping.

- They have a strong build quality for busy production workshops.

- Example technical specs:

- Power range: 500–6000 W

- Weld thickness: can handle 0.5 – 6 mm

- Output frequency: adjustable from 50 Hz to 5000 Hz

Why High-End Jewelers Choose German Brands

Based on my experience, German jewelry laser welders are a preferred choice for jewelers and part makers. They choose these brands because they need repeatable, top-quality welds, modern automation, and machines that will last a long time.

Core Technology Comparison: Chinese vs German Jewelry Laser Welders

I’m looking at the core tech in Chinese and German jewelry laser welders. From my experience, a few key things really matter. These are the laser type, automation features, reliability, and new ideas. These factors define their value and how well they work in a real shop.

Laser Source and Efficiency

- Chinese Brands: Chinese brands mainly use fiber and diode lasers. Diode lasers are compact, energy-efficient, and ideal for delicate jewelry work with minimal heat damage. For thicker or more conductive metals, fiber lasers offer better efficiency and precise control, even for complex designs.

- German Brands: German fiber laser machines are designed for high precision, durability, and industrial automation. Brands like TRUMPF excel in handling tough metals and delivering consistent, deep welds in demanding factory environments.

Customization, Automation, and User Experience

- Chinese Machines:

I find that Chinese machines are known for a few things. You can customize their features, they take up less space, and they are more affordable. With brands like MaxWave, jewelers can adjust the settings for their specific jobs. This makes them a practical choice for workshops. I suggest them for anyone needing a portable or starter laser welder. - German Machines:

German machines really stand out to me. They have advanced automation and smart control systems. They are built for tough, high-volume work. In my opinion, German models are great for full factory automation. This helps get more work done and reduces mistakes when making large batches.

Lifespan and Reliability

In my experience, both Chinese and German makers use quality fiber laser sources. These are rated for up to 100,000 hours of use. This means you can count on their top-tier machines for a long time.

AI Optimization and Sensor Technology

AI is rapidly improving laser welding systems in both China and Germany. Advanced models now reach up to 99.8% weld consistency by using real-time sensor data to adjust power and focus. German machines lead in factory-level automation and quality checks, while Chinese brands are catching up fast—especially with smart handheld welders that offer advanced monitoring and feedback.

Precision and Performance: A Look at Chinese vs. German Jewelry Laser Welders

Based on my experience with jewelry laser welding machines, I see big differences in precision between Chinese and German brands. This matters a lot if you are a professional working on intricate, valuable jewelry.

German Brands Offer Superb Precision

German laser welders—like those from TRUMPF—are known for exceptional precision, reliability, and clean welds. They’re ideal for tough materials like platinum and reflective metals, offering up to 100,000 hours of lifespan, minimal distortion, and micro-level accuracy—perfect for detailed jewelry work. From my experience, they also use less power, which helps protect heat-sensitive materials.

Chinese Advances in Precision and Flexibility

Chinese jewelry laser welders have improved significantly. Top models now offer ±0.02mm accuracy, suitable for fine jewelry work. They’re energy-efficient, compact, and affordable—great for both small studios and large-scale production. However, performance can vary between brands, especially on complex jobs.

My Practical Summary

Here is my recommendation. If you need the absolute best precision and performance for high-end jewelry, I suggest using German machines as your benchmark. I think Chinese brands offer strong value and advanced features for many jobs. You just need to select a model carefully from a leading manufacturer. In my experience, their top-tier models perform very well and now compete with established international standards.

User Experience and Features: Comparing Chinese and German Jewelry Laser Welders

I believe understanding the user experience and features of these jewelry welders is important. It helps you see which one offers better value. I’ll focus on how they affect your workflow, how easy they are to use, and your customization options.

User Interface and Ease of Use

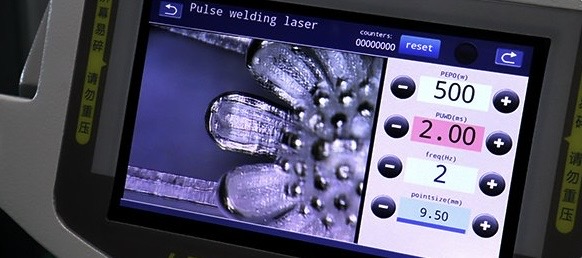

Chinese models focus on simple, easy-to-use interfaces. In my opinion, their digital touchscreens and clear controls are a big plus. They make training new users fast and simple, even for someone with no experience. The included guides help your staff learn fast. I find this is great for small shops where new people might be operating the machine.

German brands build their machines for deep process control. I’ve seen that their interfaces are more complex. They allow experts to adjust hundreds or thousands of settings. This gives you amazing control and consistent results. You should know, this can mean a longer training time. Their features can connect with automated production lines, which benefits large manufacturers or skilled professionals.

Customization Options

Chinese manufacturers offer a wide range of standard models. They are also ready to provide custom machines, often within 7–20 days. Based on my experience, this helps small custom shops and large producers get the exact equipment they need, including branding and special functions.

German brands, like TRUMPF, focus on modular designs. I believe this is a smart approach. It allows you to add features over time by adding compatible modules. This creates a scalable solution that can grow with your specialized industrial workshop.

Multi-Functional Features and Automation

I like that many modern Chinese laser welders are integrated 4-in-1 machines. They combine welding, cutting, cleaning, and post-weld cleaning. Having all these functions in one unit simplifies your work. It also means you don’t need to buy multiple machines.

You’ll find that Chinese systems work well with automated platforms. You can connect them to CNC or robotic arms. They support programmable weld paths and visual recognition. I’ve seen these features help even small shops handle difficult, high-volume jobs.

I also suggest looking at the after-sales support from Chinese brands. They design it for reliability and often offer 24/7 technical help. They also provide long warranties, like MaxWave’s 2-year warranty. This helps keep your machine running with little downtime.

Price, Value, and Investment

Chinese models are often more affordable and flexible. For example, the MaxWave series costs $2,350–$5,000. These machines offer energy up to 100 J per pulse and a multi-functional design. I think this lower price and the rich features make them a great choice for new businesses or those upgrading on a budget.

German models, like the LZR35 at $9,900, cost more. In my opinion, the higher price is fair. You get precise process controls, superior build quality, and they work with advanced automation. I would recommend them if you need maximum control, long-term durability, and accuracy for high-value work.

Breaking Down the Costs: Chinese vs. German Jewelry Laser Welders

A Look at Jewelry Laser Welder Prices

-

Chinese jewelry laser welders:

- For a starter machine (100W–200W), you’ll pay between $3,000 and $8,000.

- More powerful mid-range machines (500W–1000W) cost from $10,000 to $25,000.

- For top-tier power or CNC models, prices start at $30,000 and can go over $100,000.

- I’ve seen compact portable machines just for repairs costing $3,700 to $6,399.

- Advanced Chinese systems, like a high-precision MaxWave QW, are good value buy at around $3,300 to $4,400.

-

German jewelry laser welders:

- Standard models will cost you about $30,000 or more.

- Industrial systems can go up to $180,000+. Based on my experience, this price gets you full automation, better controls, and advanced cooling.

How They’re Used in the Real World

Chinese brands (e.g., MaxWave, ACCTEK): From what I’ve seen, small jewelry makers and repair shops often choose compact Chinese welders for their low maintenance, reliable air cooling, and multi-metal capability—key factors that help boost their profits.

German brands: High-volume manufacturers and businesses that export a lot tend to choose German brands. They justify the cost because the machines almost never go down. This ensures very strict quality control and few mistakes, which is vital for high-end production.

Summary

I’ve used jewelry laser welders from both China and Germany. From my experience, the best choice really comes down to your budget and specific tasks. I found that Chinese brands, like MaxWave and Han’s, give you excellent value for the price. They have modern features, and I think their reliability is just as good as any international brand.

On the other hand, German machines are superior for jobs needing extreme precision. They are also great for automation in high-volume workshops. I believe you can get professional results from both. It’s just a matter of picking the right machine for your workshop’s current needs and future growth. Ready to learn more? Contact us now for expert advice on jewelry laser welder.