Selecting the ideal laser marker for glass is a critical decision for artisans, manufacturers, and business owners. The right machine transforms plain glass into elegant, personalized, or professionally branded items. However, the wrong choice can lead to poor results, material damage, and wasted investment. There is no single “best” laser for glass; the key is finding the most suitable machine for your specific needs. This guide will help you navigate the technical landscape and make an informed choice, highlighting how a versatile Dual-Laser Machine can be the perfect all-in-one solution, especially for beginners.

Define Your Glass Marking Requirements

Before comparing machines, clarify your project’s demands.

Desired Outcome & Process: What visual effect are you aiming for?

-

Deep Frost/Etch: For a deep, tactile, frosted engraving, a CO2 laser is the standard choice.

-

Fine Detail & Micro-Marking: For intricate graphics, serial numbers, or delicate designs—especially on crystal or coated glass—a UV laser offers ultra-fine, cold-processing precision.

-

High-Contrast Black Marking: Achieving a permanent black mark often requires a laser marking spray (like Cermark or Thermark) used with either a CO2 or a Fiber laser.

Material Type: Not all glass is the same.

-

Soda-lime/Borosilicate (common glass): Works well with CO2 lasers.

-

Crystal, Coated, Tempered, or Colored Glass: These often require the gentle, high-precision approach of a UV laser to prevent cracking or burning.

Production & Business Needs:

-

Budget: CO2 lasers are generally more affordable upfront than UV systems.

-

Speed & Volume: For larger batches, the faster processing of a CO2 laser may be preferable. UV lasers, while precise, can be slower for complex work.

-

Versatility: Do you plan to mark other materials like wood, acrylic, metal, or plastic? If yes, you need a machine capable of handling multiple materials.

Understand Laser Technology Types

The core of the machine is its laser source. Each has distinct advantages.

CO2 Laser Markers:

The workhorse for general glass engraving machine. They use a gas tube to produce a wavelength (10.6μm) highly absorbed by glass, creating a deep, frosted etch. Ideal for text, logos, and decorative patterns on common glass. They are cost-effective and efficient but lack the finesse for ultra-fine details on sensitive materials.

UV Laser Markers:

The masters of precision. Their shorter, ultraviolet wavelength (355nm) interacts with materials in a “cold process,” removing material at a microscopic level without thermal stress. This makes them perfect for extremely intricate designs, fragile glass, and crystal, producing a smooth, fine, often frosted finish. The trade-off is a higher initial cost.

Fiber Laser Markers:

Primarily designed for metals and plastics. Their wavelength (1.06μm) typically passes through bare glass without interaction, making them ineffective for direct glass marking. They are only used on glass with a special marking coating.

Dual-Laser Machines (The Integrated Solution):

This system integrates two laser sources in one unit, enabling flexible processing across diverse materials—glass (deep etching/frosting with CO₂, fine detail with UV), wood, metal, and plastics. With a compact, portable design and user-friendly software, it delivers the capabilities of two specialized machines at a fraction of the combined cost and space, offering exceptional value for startups or workshops with varied project needs.

Evaluate Machine Performance & Configuration

Beyond the laser type, assess these practical aspects:

-

Marking Area & Precision: Ensure the worktable size fits your largest item. Resolution (measured in DPI) determines detail clarity.

-

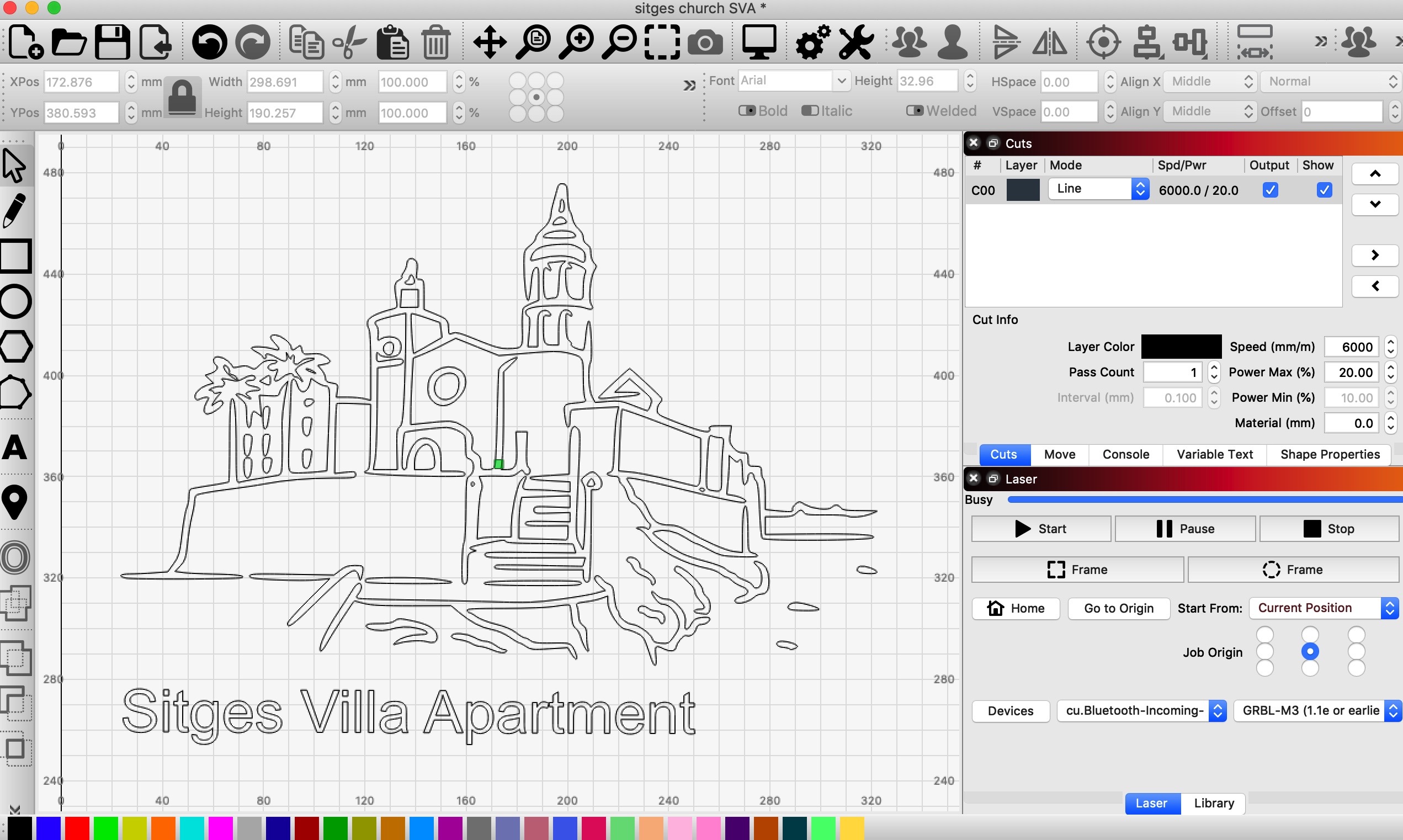

Software & Usability: User-friendly software (like LightBurn or EzCad2 compatibility) is crucial for design import and operation.

-

Cooling System: Proper cooling (air or water) is essential for laser stability and longevity during extended operation.

-

Safety & Compliance: Look for essential safety features like enclosed workspaces, protective viewing windows, and emergency stops. Laser marking machine should meet relevant safety certifications.

Glass Laser Marker Selection Guide

Below is an overview of mainstream glass laser marking equipment currently available on the market for your reference and selection.

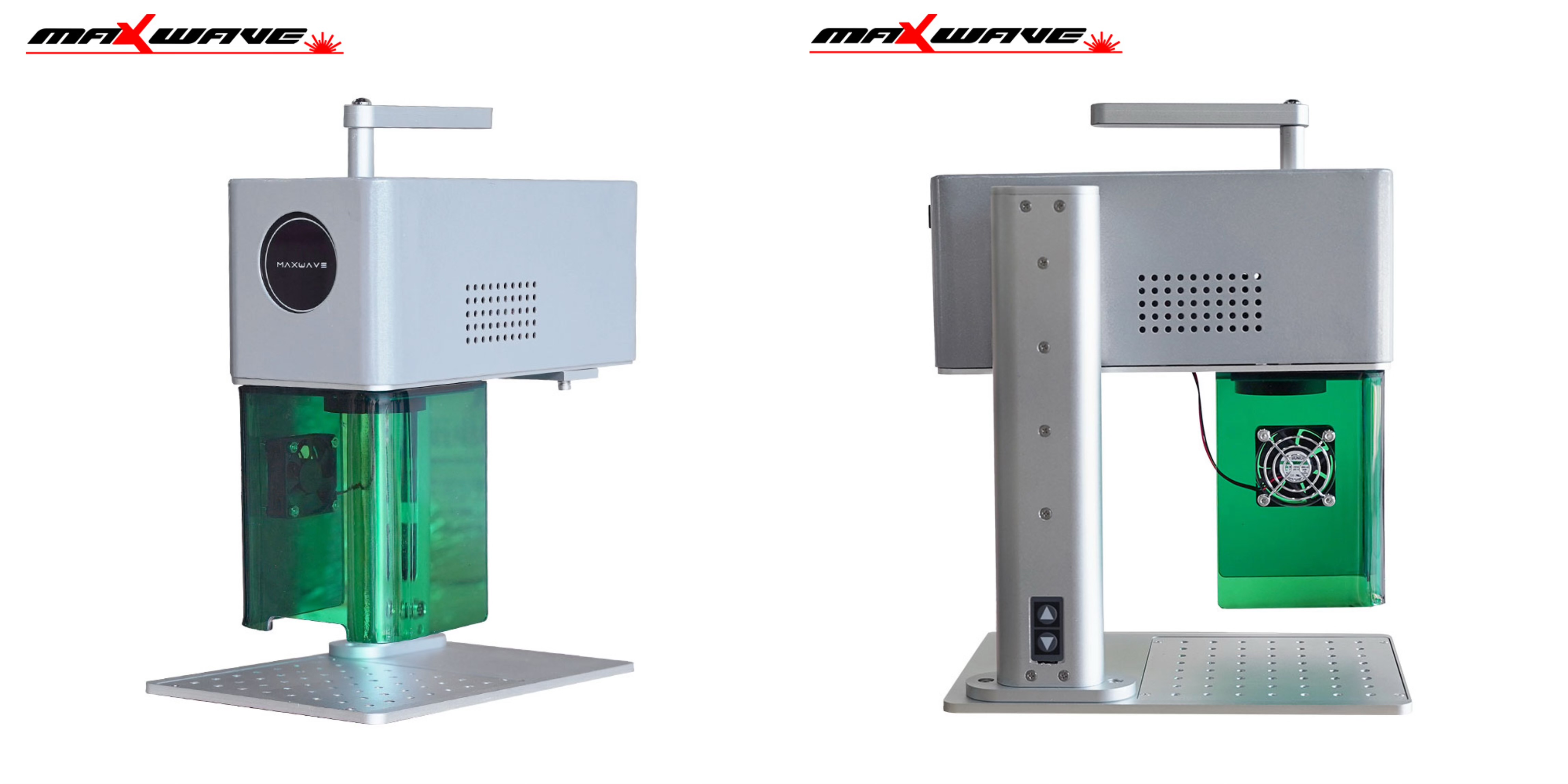

1. Dual-Laser All-Rounder ( MaxWave MW-F25CA Style)

-

Key Features: Integrates two laser sources (e.g., red and blue lasers) in one machine, capable of efficiently processing both non-metallic (glass, wood) and metallic materials.

-

Best For: Small studios or e‑commerce businesses needing to process a variety of materials (e.g., glass bottles and metal caps) on a single device.

-

Price Range: Approx. $800 – $1,200

-

Who Should Choose It: Suitable for users with limited space who work with mixed materials and prefer a one-time investment for multiple applications.

2. Portable Entry-Level ( Atomstack M4 Pro Style)

-

Key Features: Lightweight, desktop design with high cost performance. Can achieve fine “frosted” surface etching on glass.

-

Best For: Craft workshops, mobile creation, or small‑batch customization.

-

Price Range: Approx. $1000 – $1500

-

Who Should Choose It: Ideal for hobbyists and startups with limited budget and space, focusing on small‑batch decorative surface marking.

3. High-End Desktop Workhorse (Epilog Zing – CO₂ Laser)

-

Key Features: Reliable brand, large working area, high resolution enabling photo‑realistic engraving.

-

Best For: High‑end gift customization, trophies, large‑format glass panel etching.

-

Price Range: Approx. $4,000 – $6,000

-

Who Should Choose It: Suitable for studios focused on mid‑to‑high‑end customization and small‑ to medium‑scale production, valuing output quality and brand support.

4. High-Precision UV Specialist (Sunine UV Laser Style)

-

Key Features: Uses ultraviolet “cold” laser with minimal heat impact, enabling micron‑level precision and preventing glass cracking.

-

Best For: Micromachining and damage‑free marking on mobile cover glass, optical lenses, ultra‑thin glass, etc.

-

Price Range: Approx. $5,000 – $10,000

-

Who Should Choose It: Recommended for manufacturers in electronics, medical devices, or precision optics requiring crack‑free, high‑precision marking.

5. Industrial Line Speed Solution (Videojet 7610 – Fiber Laser Style)

-

Key Features: Designed for 24/7 operation with high protection rating (e.g., IP67), extremely fast marking speed and high reliability.

-

Best For: High‑speed automated filling lines in beverage, pharmaceutical, or cosmetics industries for marking batch codes, dates, barcodes, etc.

-

Price Range: Approx. $15,000 – $25,000+

-

Who Should Choose It: Suitable for large‑scale manufacturers needing to integrate marking systems into automated production lines for reliable, high‑speed marking on thousands of containers daily.

How to Make Your Final Decision: Your Guided Choice Path

Quickly identify the most suitable machine type based on your primary needs and business context.

Primary Need: Processing Multiple Materials (e.g., Glass + Wood/Metal)

-

Ideal For: Small studio or e-commerce seller needing to customize products from various materials.

-

Recommended Type: Dual-Laser All-Rounder

-

Why: Integrates two laser sources in one machine to efficiently process mixed materials like glass, wood, metal, and plastic. It saves space and cost, making it ideal for diverse project needs.

Primary Need: Glass Surface Decoration / Small-Batch Creation

-

Ideal For: Hobbyist, startup, or small craft shop with limited budget and space, focusing on surface marking, etching, or small-batch customization on glass.

-

Recommended Type: Portable Entry-Level

-

Why: Offers the best value and compact size. Capable of creating fine frosted effects and patterns on glass, serving as a practical starting point for entry-level and light applications.

Primary Need: Professional-Grade Glass Customization & Processing

-

Ideal For: Professional customization studio that prioritizes superior quality, detail, and efficiency for mid-to-high-end projects like trophies, gifts, and art glass.

-

Recommended Type: High-End Desktop Type (CO2 Laser marker)

-

Why: Delivers a larger work area, higher precision, and reliable performance for complex designs and high-quality surface finishing, ensuring professional results.

Primary Need: Damage-Free Marking for Precision Components (Electronics, Medical, etc.)

-

Ideal For: Involved in precision micromachining on ultra-thin or fragile glass for mobile cover glass, optical lenses, medical devices, etc.

-

Recommended Type: High-Precision UV Specialist

-

Why: UV “cold” processing minimizes heat impact, enabling clear, micron-level markings with virtually no stress or cracking, making it essential for precision industries.

Primary Need: High-Speed Marking Integrated into Automated Production Lines

-

Ideal For: Large-scale manufacturer requiring reliable, high-speed marking (e.g., batch codes, dates) on thousands of glass containers daily on beverage, pharmaceutical, or cosmetic filling lines.

-

Recommended Type: Industrial Line Speed Solution

-

Why: Built for 24/7 continuous operation with high ingress protection, marking speed, and system reliability. Designed for direct integration into industrial environments to meet high-volume production rhythms.

Final Tip: Whenever possible, always request a sample test on your actual material. This is the most reliable way to verify if the machine meets your specific needs.

Conclusion

In conclusion, there’s no “best” marker, only the “rightest” solution: the Dual-Laser for all-round versatility, and the High-Precision Professional for flawless expertise. Your unique needs define the ultimate choice.Ready to see the difference? Contact us now for a free sample test and expert consultation to start your professional marking journey.