In today’s fast-evolving world of laser technology, choosing the right laser marking machine can feel like navigating a high-tech maze. Whether you’re engraving intricate designs, adding serial numbers, or branding products, the choice between CO₂ and UV laser marking machines can make all the difference. Each offers unique strengths and is tailored for specific materials and applications — but which one truly fits your needs? Dive in as we break down the key differences, helping you pinpoint the perfect laser solution that brings precision, efficiency, and stunning results to your projects.

Key Takeaways: CO2 vs UV Laser Marking Machine

When choosing between a CO2 laser marking machine and a UV laser marking machine, your decision depends mainly on the material, precision, and application needs.

| Item | CO₂ Laser Marking Machine | UV Laser Marking Machine |

|---|---|---|

| Wavelength | 10.6 μm | 355 nm |

| Materials | Wood, paper, plastics, glass, leather, ceramics | Most materials, ideal for plastics, glass, metal coatings, electronics |

| Precision | Medium, for larger fonts/patterns | High, for tiny text and fine details |

| Method | Thermal processing | Cold processing |

| Applications | Packaging, textiles, crafts, wood, signage | Electronics, chips, medical devices, cosmetic & food packaging |

| Maintenance | Low | Higher |

In summary, if your work demands precision, minimal material damage, and fine details, a UV laser marking machine is more suitable despite higher initial costs. For broader use with less sensitive materials and tighter budgets, a CO2 laser marking machine offers good value.

Best-fit Applications of CO₂ and UV Laser Marking Machines

When choosing between CO₂ and UV laser markers, understanding their best-fit applications is key to making the right decision for your marking needs.

UV Laser Marking Machine Applications

Delicate Electronics and Semiconductors

Ideal for marking IC packages, connectors, sensors, and flexible PCBs. The UV laser’s 355 nm wavelength ensures high absorption and minimal heat, protecting internal components. This makes it perfect for traceability codes and micro-features without damaging delicate parts.

Medical Devices and Pharmaceutical Packaging

UV lasers produce permanent, high-contrast marks on polymer hubs, catheters, and syringes with very little heat impact. This supports UDI compliance and resists corrosion on coated metals and plastics, making it essential in healthcare product marking.

High-Contrast Marking on Plastics and Resins

Materials like ABS, PC, PE, PET, and painted or anodized surfaces are marked cleanly with UV lasers due to “cold” photolytic ablation. This prevents warping or whitening, ensuring clear and precise marks.

Fine-Feature Logos and Micro Text

UV lasers excel in producing small text (1-2 mm), dense 2D codes, and precision marks on thin films, labels, LCD glass, and silicon wafers. It can also create micro-holes without damaging substrates.

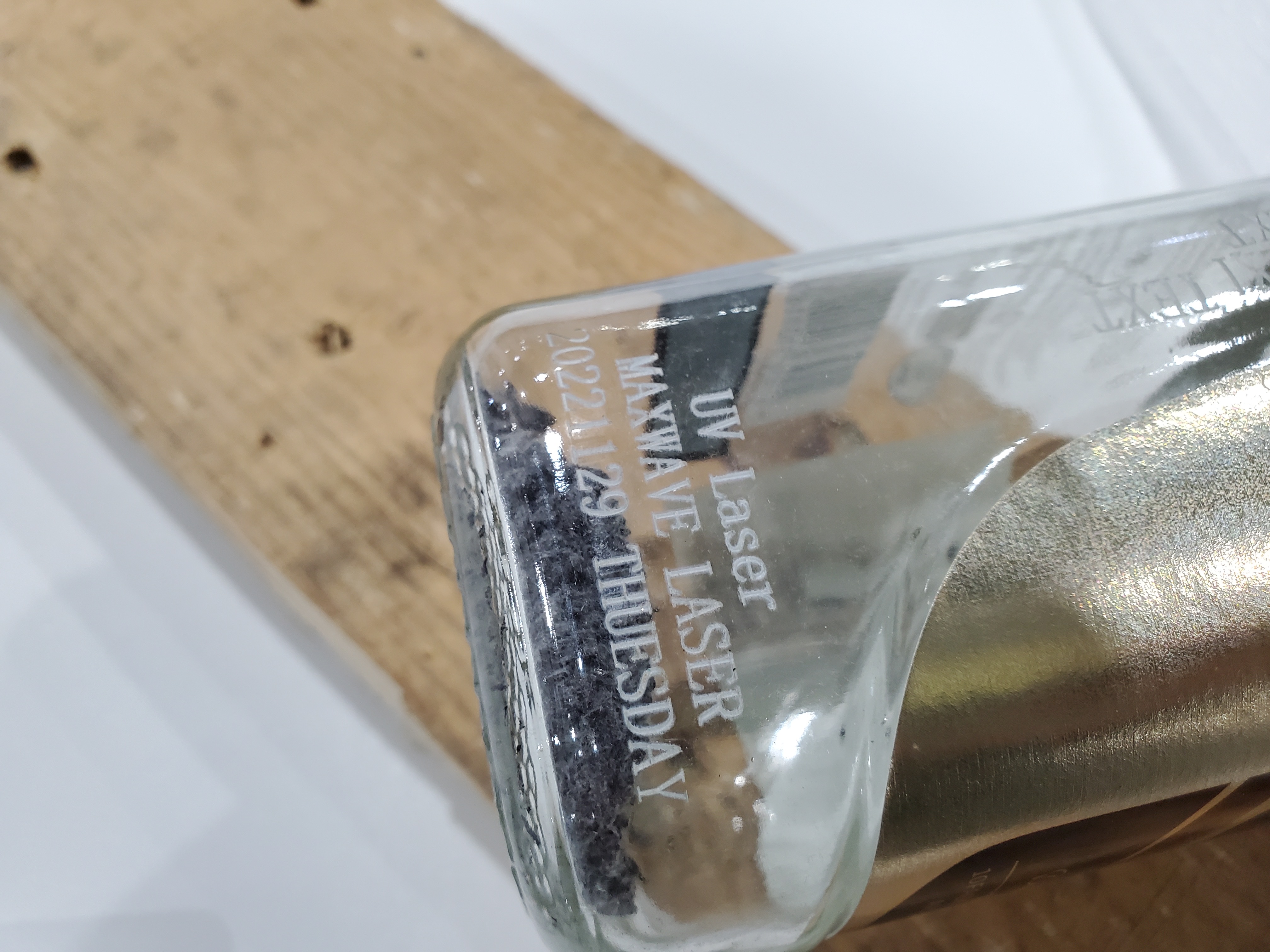

Brittle or Transparent Substrates

For materials like quartz and standard glass, UV lasers provide clean, visible marks while reducing the risk of cracking.

UV Laser Use Cases

- Marking plastic hub tube connectors on a conveyor with a 5 W UV source and integrated vision for inline quality checks.

- Scribing flexible PCBs and QR codes on LCD glass and creating micro-holes in silicon wafers.

- Corrosion-resistant marking of titanium or stainless steel medical parts.

CO₂ Laser Marking Machine Applications

Organic Non-Metal Materials

Best for high-speed marking on wood, paper, cardboard, leather, rubber, and acrylic. The CO₂ laser marking machine‘s ability to carbonize or ablate surfaces creates clear, high-contrast marks.

Packaging and Signage

Widely used in packaging lines for date codes on cartons and in producing acrylic displays or wooden signs. It suits light engraving and kiss-cutting where speed is a priority.

Versatile Production and Job Shops

CO₂ lasers efficiently mark moving webs, boxes, and various substrates in industrial environments, offering economical and fast marking with low consumable costs.

CO₂ Laser Use Cases

- Fast alphanumeric and date code marking on FMCG cardboard packaging lines.

- Engraving logos on wooden housings and rubber gaskets.

- Etching decorative designs on coated glass.

How to Choose: Key Considerations

Use UV lasers if your project requires: – No heat damage – Micro-scale readability – Marking thin resins, films, or fragile transparent materials

Use CO₂ lasers if your focus is: – Fast and economical marking – Organic packaging and signage materials – Light engraving or cutting with minor thermal effects

Selecting the right laser depends largely on your material type and production priorities such as speed, precision, and heat sensitivity.

Two Laser Marking Machines Material Compatibility at a Glance

Choosing between a CO₂ laser and a UV laser marking machine largely depends on the materials you need to mark. Here’s a clear overview to help you decide which technology suits your application best.

Metals

UV laser markers (355 nm) are ideal for marking coated or anodized metals like black anodized aluminum and painted steel with high-contrast, fine details. They can also mark bare metals with surface pretreatment (e.g., blackening or thin oxide layers), minimizing the heat-affected zone (HAZ), which is especially important for heat-sensitive parts in medical devices and electronics housings.

In contrast, CO₂ laser markers (10.6 μm) have poor absorption on bare metals and usually require marking sprays or coatings to produce visible marks, which tend to be faint and less durable. For example, on stainless steel, UV lasers can create clear ID marks on pre-coated surfaces with low heat, whereas CO₂ lasers need auxiliary materials to mark effectively.

Plastics and Resins

UV lasers produce crisp, high-contrast, and damage-free marks on various plastics like PE, PP, ABS, and PC. Using photochemical interaction with minimal heat, they are ideal for thin films, pouches, and electronics plastics, and widely used in medical devices and electronics requiring micro text or UDI codes.

CO₂ lasers can mark plastics such as acrylic, ABS, PET, and HDPE but often cause slight melting and a larger heat-affected zone. They are suitable for applications where moderate contrast and faster marking speeds are acceptable.

For example, UV lasers create highly visible marks on PE resins and pouches, while CO₂ lasers produce less visible marks on pouches but work well on cartons and harder materials.

Organics

CO₂ lasers are a strong choice for marking and cutting organic materials, quickly producing dark, deep engravings on wood, paper, cardboard, and leather. With proper settings, they can also cleanly cut thin materials.

UV lasers provide more precise marks with finer detail and less burning or discoloration, but have lower cutting speed and throughput compared to CO₂ lasers.

For example, on leather, CO₂ lasers create deeper, darker marks, while UV lasers produce finer marks with minimal discoloration.

Glass and Ceramics

CO₂ lasers are commonly used for etching and marking glass and many ceramics because they effectively heat the surface. They work well for items like beverage glassware and tiles.

UV lasers are best for delicate or micro marking on glass and ceramics, using low heat and fine spot sizes to avoid thermal damage, microcracks, and spalling. This makes them ideal for pharmaceutical vials and lab glass where preserving material strength is critical.

For example, CO₂ lasers are preferred for transparent glass marking, while UV lasers are favored when low-damage, high-precision micro marking is required.

Practical Selection Tips

- Use CO₂ lasers for organic materials (wood, leather, paper) and many glass or ceramic tasks, especially when cutting is needed.

- Use UV lasers for engineering plastics, high-precision marking on coated/anodized metals, thin films, and glass or ceramics requiring minimal heat damage. UV lasers are optimal for medical and electronics traceability applications.

By matching the laser marking system type to your material, you ensure the best mark quality, durability, and processing efficiency.

Maintenance, reliability, and uptime of Both Laser Marker

When choosing between CO₂ and UV laser marking machines, understanding their maintenance needs, reliability, and uptime is crucial.

Maintenance requirements and downtime

UV laser marking devices (solid-state, 355 nm DPSS) require lower routine maintenance because they have no gas tubes. Daily or weekly tasks mainly involve keeping optics and galvo windows clean, inspecting beam path covers, and changing air filters as needed. These quick tasks result in minimal planned downtime and fewer service interruptions.

CO₂ laser marking devices (gas lasers, 10.6 μm) require more frequent and extensive maintenance: – Regular cleaning of mirrors and lenses, often daily or weekly in dusty environments like packaging or woodworking. – Checking and realigning the beam path when laser quality drops. – Cooling system upkeep, including chillers and water loops. – Monitoring and eventual replacement of the gas laser tube, a costly and time-consuming process. – These actions result in increased downtime compared to UV lasers.

Reliability and component life

UV lasers have longer service life and higher mean time between maintenance (MTBM) since they avoid gas tube wear and have fewer sensitive parts. This improves uptime, especially in precise applications like electronics or medical device marking.

CO₂ lasers are more vulnerable to contamination from dust and fumes, which cause mirror fouling and require more frequent cleanings. This lowers their effective uptime, especially in particulate-heavy environments like wood, paper, or corrugated materials.

Consumables and spare parts impact on uptime

UV lasers mostly need occasional replacement of protective windows, galvo windows, or air filters. They do not require gas refills or laser tube replacements, supporting predictable and higher uptime.

CO₂ lasers require frequent lens and mirror cleaning, periodic laser tube replacements, and maintenance of cooling consumables. These contribute to both scheduled and unscheduled downtime.

In summary, UV lasers generally offer lower maintenance, higher reliability, and better uptime, making them ideal for precision and clean environments. CO₂ lasers demand more upkeep, affecting their availability but remain suitable for marking materials requiring higher interaction, despite more frequent downtime.

Cost and Total Cost of Ownership

When choosing between a CO₂ and a UV laser marking solution, understanding both the initial cost and ongoing expenses is key to making a cost-effective decision.

Initial Purchase Price Comparison

- CO₂ laser marking systems are generally more affordable upfront, with prices ranging from $2,000 to $8,000 depending on power and size. Complete systems including controls and accessories typically fall within this range.

- In contrast, UV laser marking systems tend to have a higher initial price, commonly between $10,000 and $30,000 for industrial models. Smaller UV units (3–5 W) designed for labs or small shops start around $3,000 to $9,000.

- The price difference mainly reflects the technology type and intended use. CO₂ lasers offer a lower entry cost, making them cost-effective for many applications, while UV lasers come with a premium due to their advanced capabilities.

Example Price Points

- A typical MaxWave UV laser mraking machine lists for roughly $7,300.

- MaxWave CO₂ laser engraver can range from $2,100 to over $5,400 depending on size and power.

Summary

Choosing the right laser marking machine isn’t just about technology—it’s about elevating your product quality, boosting production efficiency, and gaining a competitive edge in the market. Whether you opt for the cost-effective CO₂ laser or the ultra-precise, low-heat UV laser, making the right choice is your first step toward success. Take action now and invest in a laser marking solution tailored to your business needs—deliver sharper, more professional marks and unlock a new level of efficient production! Ready to learn more? Contact us now for expert advice on laser marking machines.