Picture the aftermath of a conventional welding session: a workspace blanketed in spatter, partially used spools of welding wire, and a workforce dedicating hours to grinding and rework. This scene is more than just an operational nuisance; it’s a vivid depiction of profit erosion. The waste generated by traditional welding extends far beyond the visible consumables. It encompasses lost time, excessive labor, and diminished throughput. In today’s competitive landscape, such inefficiency is unsustainable. The solution lies in embracing a transformative technology: the laser welder, a tool designed to turn precision into profit.

The High Cost of Conventional Welding Waste

To fully appreciate the value of laser welding, one must first quantify the true cost of the status quo. The financial drain of traditional methods is multifaceted, creeping into every aspect of the production process.

Material Waste: More Wire on the Floor Than in the Weld

Processes like MIG/MAG are notoriously inefficient. It’s estimated that 5-15% of welding wire is lost as spatter—tiny droplets of molten metal that never become part of the weld. Add to this the stub loss from every discarded electrode and the over-welding used to compensate for fit-up inaccuracies, and the cumulative cost of wasted material becomes staggering.

Consumable Waste in Post-Processing

The problems don’t end at the weld joint. The significant spatter and heat-induced distortion force operators into extensive post-processing. This involves grinding, a process that consumes abrasive discs, energy, and countless labor hours. The cost of these consumables and the time spent using them silently inflate the total cost of every welded component.

The Ultimate Cost: Scrap and Rework

The most damaging cost arises from imperfections. Inconsistent heat input can cause warping, burn-through, or weak joints, rendering expensive components unusable. The cost of rework—or worse, scrapping the part entirely—includes not only the raw materials but also the machine time and labor already invested, dealing a heavy blow to project timelines and profitability.

The Laser Welding Advantage: Precision by Design

Laser welding introduces a paradigm shift from subtractive manufacturing to additive precision. Its core principles are engineered to eliminate the very sources of waste described above.

Unmatched Control with Low Heat Input

Unlike the broad heat application of arc welding, laser welders focus energy into an extremely fine point. This minimizes the Heat-Affected Zone (HAZ), the area around the weld that is altered by the heat. The result is a dramatic reduction in thermal distortion. Components retain their shape and dimensions, slashing the need for corrective rework and straightening operations.

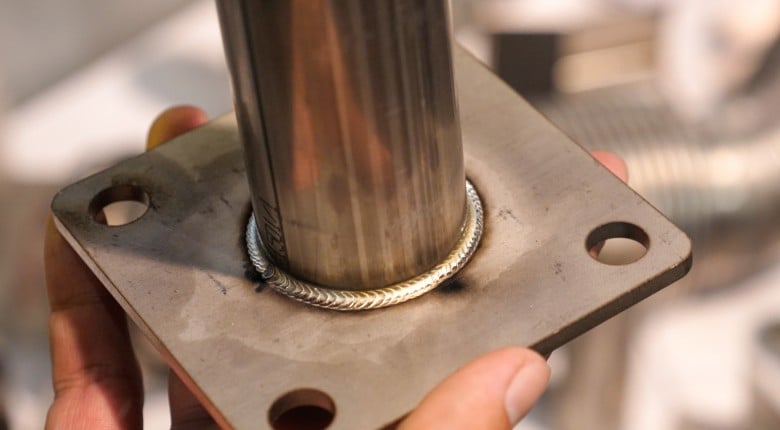

The Near-Zero Spatter Revolution

The key to material savings lies in the laser’s stable keyhole welding process. This method creates a deep, narrow weld with a consistent molten pool, which significantly suppresses the formation of spatter. Virtually all the filler material you feed is deposited precisely into the weld joint. This direct transition from wire to weld is where immediate and substantial material savings are realized.

Superior Weld Quality That Saves Steps

A laser weld is characterized by its aesthetic, narrow, and consistent profile. Because the weld is clean and precise from the start, the need for extensive post-weld grinding is often eliminated or greatly reduced. What used to be a multi-step process of weld-clean-grind can often be simplified to just weld-clean, saving a significant amount of time and consumables.

List of Actual Material Savings in Welding

A Welding Solution Engineered for Your Profitability

Understanding the technology is one thing; implementing the right solution is another. Our laser welders are built with features that directly translate the advantages above into your daily reality.

- Smart Process Control: Our proprietary software ensures optimal parameters for different materials, guaranteeing flawless, low-spatter welds every time.

- User-Friendly Interface: Intuitive controls and pre-set programs significantly reduce the learning curve, getting your team up to speed quickly.

- Comprehensive Support: From installation and training to ongoing maintenance, our expert team is with you every step of the way to ensure a seamless transition and maximum uptime.

Your Top Welding Questions, Answered

-

Q: Is the initial investment in a laser welder too high?

-

A: View it as a strategic capital expenditure. By converting recurring operational waste into a one-time investment, our machines typically achieve a full payback within 12-24 months. Every year thereafter, the savings go directly to your bottom line.

-

Q: How difficult is it for my team to operate this new technology?

-

A: Our laser welders are designed for ease of use. With intuitive interfaces and comprehensive training from our specialists, your operators will be producing high-quality welds in a very short time.

-

Q: Can it weld all the materials we use?

-

A: Our laser welders are highly versatile and excel at joining a wide range of materials including stainless steel, carbon steel, aluminum, and titanium alloys. We can arrange a test with your specific materials to demonstrate this capability.

Summary

The path from relentless consumable waste to streamlined, cost-effective production is clear. Laser welding is more than an equipment upgrade; it’s a strategic investment in the efficiency and profitability of your business. The technology exists today to stop the drain on your resources and start building a more competitive operation.

Stop Funding Waste. Start Investing in Growth.Join the Leaders Who Are Already Saving.