From my experience, choosing a laser cleaner is more than just getting rid of rust. It’s about finding the right tool that matches your work style. I suggest you think about what matters more: a machine that’s easy to carry or a very powerful one.

Have you thought about what works best for your space and your wallet? Should you get a small, handheld unit or a fast, automated one? I believe each option changes how you work and is also good for the environment. Yet, I’ve seen most people miss one critical detail before they make their final decision.

A Guide: Handheld vs. Automated Laser Cleaners

If you’re picking between a handheld and an automated laser cleaner, I think you need to consider a few things. Think about portability, speed, your budget, and the jobs you need to do. Here’s a comparison I’ve put together to help you find the right fit for your work.

| Facture | Handheld Laser Cleaners | Automated Laser Cleaners |

| Portability | Lightweight, easy to carry | Fixed, not portable |

| Operation | Manual control | Automated, robot/PC controlled |

| Precision | High for detailed work | Consistent for repetitive tasks |

| Speed & Volume | Slower, small to medium job | Fast, large-scale production |

| Cost | $5,000–$21,000 | $50,000+ |

| Training | Basic, quick learning | Professional setup required |

| Surface Suitability | Ideal for delicate surfaces | Best for hard, flat surfaces |

Key Aspects ComparisonReal-World Examples

- Handheld 100W Laser Cleaner: This type weighs about 35kg. People use it to remove rust, oil stains, and graffiti. An operator can take it to different sites for maintenance or restoration jobs.

- Automated Industrial Laser System: You might see these on car or electronics production lines. They are part of a robotic system, cleaning hundreds of similar items per shift. These systems can cost over $100,000 but run with almost no human labor.

Key Takeaways

- I suggest handheld laser cleaners if you need a flexible tool you can move around. They are great for varied projects or delicate tasks. They are also a good choice if you have a lower upfront budget.

- In my opinion, automated systems are a great investment where speed and consistency are vital. The higher cost makes sense for mass production or industrial lines where output is key.

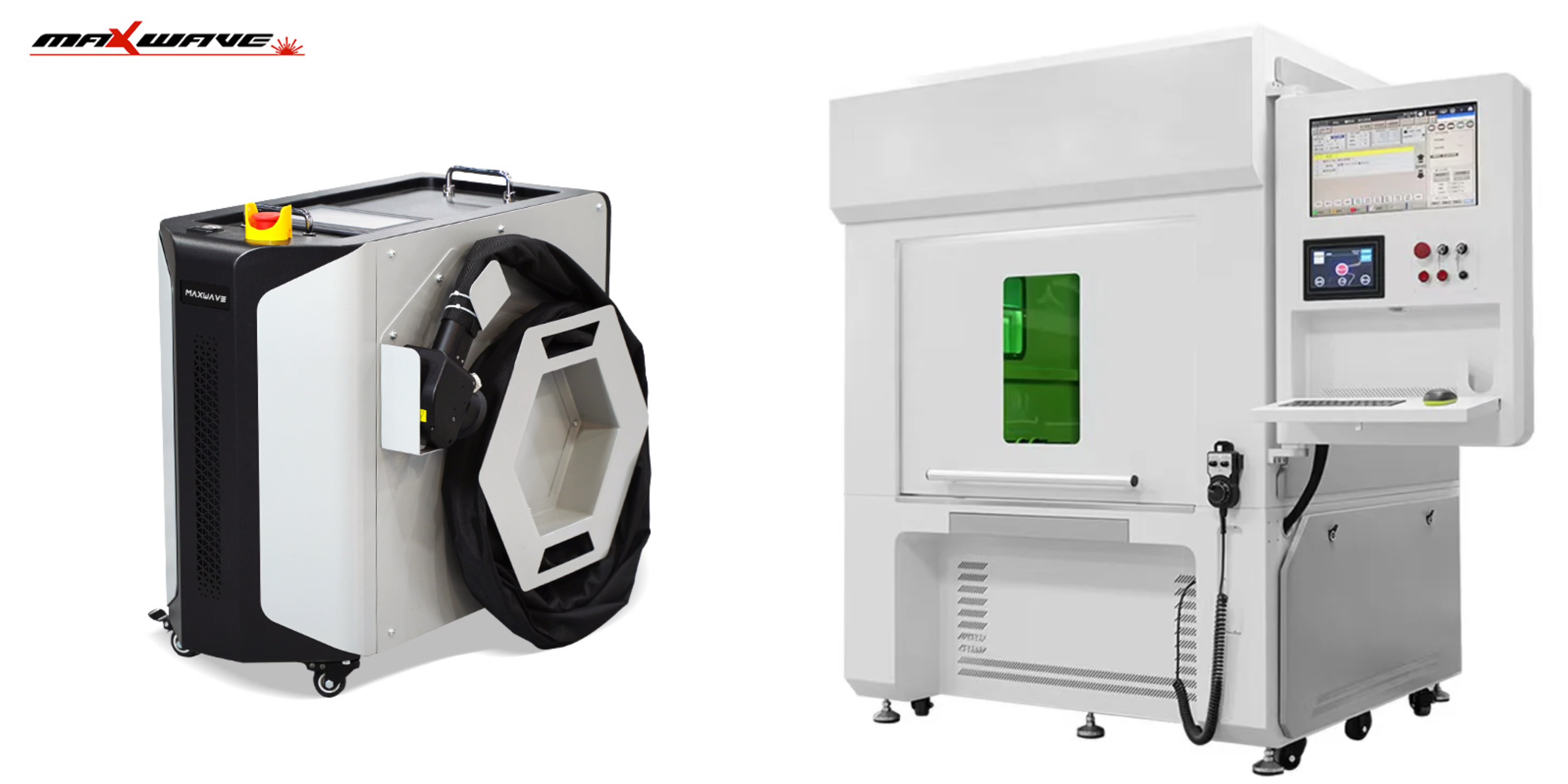

Handheld Laser Cleaners: Features, Advantages, and Use Cases

From my experience, handheld laser cleaners are popular because they are portable, precise, and flexible for many cleaning jobs. Let’s look at what makes these tools special, their main benefits, and how you can use them.

Key Features I Look For in Handheld Laser Cleaners

Handheld laser cleaners are lightweight and compact, with heads weighing 620g–1.5kg and systems from 7.8kg to 27kg, making them easy to use for long periods. Some are smaller than A4 paper, with handles and straps for easy carrying. The 5–10 meter cables allow flexible movement around large or irregular items.

They offer a power range of 100W to 2000W+, with continuous or pulsed fiber lasers for different tasks. Built-in safety features protect users, and they have long lifespans up to 50,000 hours with low maintenance. Some models also run on batteries, ideal for remote work without power.

Why I Recommend Handheld Laser Cleaning

– Portability: You can carry them by hand or put them in a car. This allows you to get them to job sites or into tight spaces quickly.

– Precision Cleaning: Operating by hand gives you fine control over where you clean. I recommend them for delicate or detailed surfaces because you can clean without damaging the base material.

– Versatile Use: These are great for cleaning small spots by hand. You can also mount them for stationary work. I’ve seen the same machine used to clean industrial parts, old monuments, and even fine art.

– Easy to Use: I find they are quick to set up. There is a gentle learning curve, so most technicians and maintenance staff can use them.

– Good for the Environment: You don’t need any harsh media or chemicals. The process creates almost no waste and is safe to use indoors.

Common Uses and Practical Examples

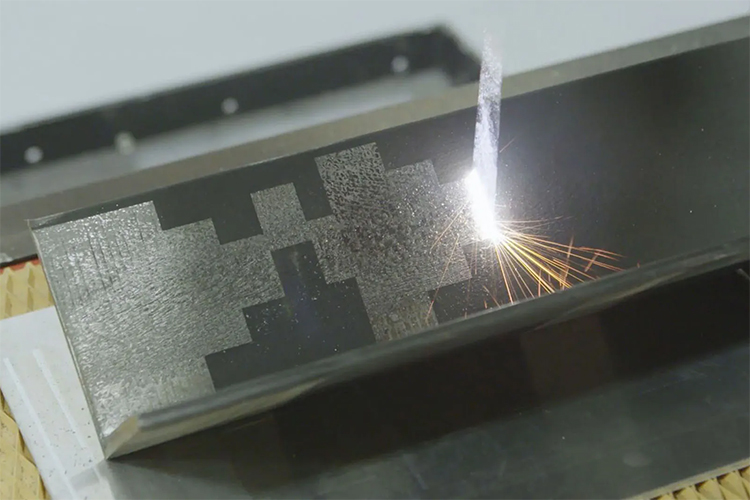

Industrial Rust and Paint Removal: These are very good at stripping layers from metal parts, pipes, and car components of all sizes.

Mold and Die Cleaning: This is critical in the electronics and car industries. The cleaning is non-abrasive, which protects precise technical parts and makes tools last longer.

Weld Seam Cleaning: It removes residue after welding without needing to grind or use strong chemicals.

Restoration and Conservation: I’ve seen these laser rust remover used to clean historic buildings and art. They are so precise you can clean with amazing accuracy without leaving pits or scratches.

Workshop and Production Maintenance: You can clean injection molds, machine parts, and conveyor systems right on the factory floor.

Real-World Examples

- From my perspective, a small 7.8 kg unit with a 650g handpiece is a great fit for small workshops. It’s also easy to move between different job sites.

- For tough rust removal in heavy industry, I suggest high-powered models. A 1500W or 2000W machine, which might weigh up to 137 kg, can handle these jobs.

- Based on my experience, handheld lasers work well in temperatures from 0–40°C. They provide consistent cleaning no matter the work environment.

I believe handheld laser cleaners offer great portability, a comfortable design, and precise results. I think they are a smart choice if you need a tool that is mobile, adaptable, and easy to use for field maintenance, manufacturing, or delicate restoration work.

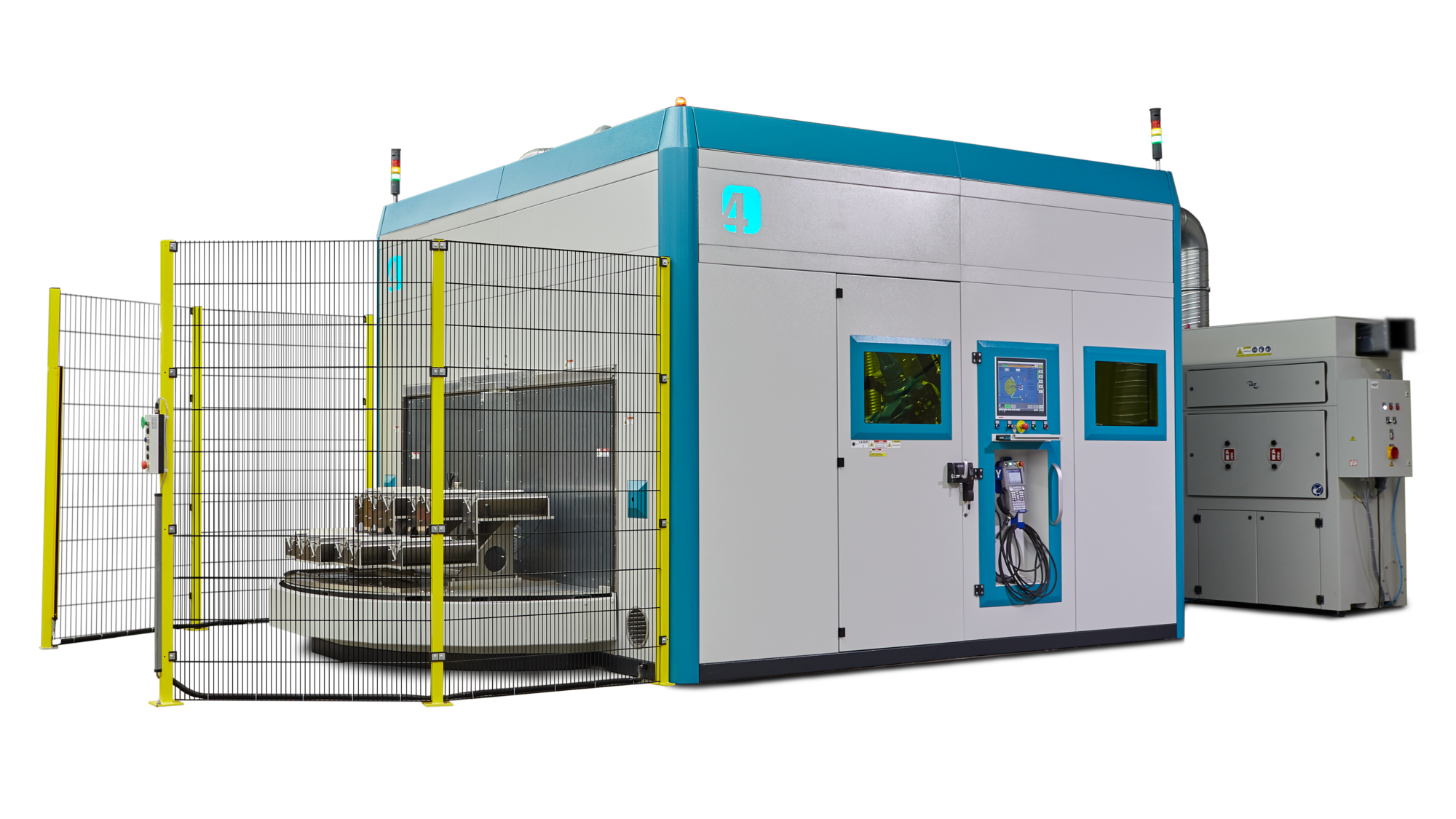

A Look at Automated and Enclosed Laser Cleaners

From my experience, automated laser cleaners are perfect for big factory jobs. They give you steady, fast results and connect easily with your production lines. I recommend them for tough jobs where you need the same result every time and a high output.

Key Features I Think Stand Out

Automated laser cleaners provide full automation with minimal human help, ideal for factories and high-volume work. They integrate with robotic arms for precise 5-axis cleaning of complex shapes. Features include auto-focus, customizable patterns, and strong safety systems with multiple protections and fume extraction.

Built for industrial durability, these machines resist heat, vibration, and dust. The user-friendly interface supports many languages and simplifies tasks. They offer easy connectivity and real-time monitoring with a large screen and software for tracking and data recording.

Performance Data and Cleaning Power

– Cleaning Speed: High-power models, like the 1500W version, can clean up to 50 m²/hour.

– Scan Speed & Width: The scan speeds can hit 7000 mm/s. The cleaning width goes up to 300 mm.

– Material Removal Rate: The best systems can remove material at up to 450 cm²/second. I’ve seen them handle tough rust, paint, or oil on large metal parts with ease.

– Quality of Results: The double pendulum galvanometer systems create a steady, high-gloss finish. This ensures you get reliable results with every use.

Where I Suggest Using Them

Automotive Factories: Use automated cleaning for weld seams. It’s also great for removing oxides from car frames or parts.

Aerospace Industry: I suggest using them for preparing surfaces on aircraft skins, engine parts, and other key components.

Construction & Shipbuilding: You can remove large amounts of rust and scale from steel structures, ships, and bridges.

Electronics Manufacturing: They offer very precise cleaning. This is useful for circuit boards and other intricate electronic parts.

Production Lines: We use them for inline surface prep before painting or coating. You can clean hundreds of components in a single shift.

Based on my experience, automated and enclosed laser cleaning tools provide factory-grade cleaning. They are safe, efficient, and give you steady results, which I believe makes them essential for any place that needs high output and top quality.

Handheld vs. Automated Laser Cleaners: My Comparison

Are you choosing between a handheld and an automated laser surface cleaning machine? I find the best choice depends on what you need, how much you have to clean, and your budget. Let’s compare them. I’ll cover key features, real-world uses, and data to help you pick the right one for your work.

Handheld vs. Automated Laser Cleaning Machines: A Feature Breakdown

Handheld laser cleaners

Handheld laser cleaners are known for their lightweight and flexibility, typically weighing less than 20 kg, making them easy for one person to carry — ideal for on-site work and tight spaces. Manually operated, they allow angle adjustments during cleaning, making them perfect for artifact restoration, fine details, and custom tasks. Their precision has even been used on historic sites like the Parthenon.

Easy to set up and suitable for small to medium jobs, 200W–300W models can clean 3–6 m² per hour. They work on various materials, are affordable (starting around $5,000), require minimal training, offer easy maintenance, and are ideal for sensitive surfaces. Plus, they’re eco-friendly and highly adjustable.

Automated laser cleaners

Automated laser cleaners excel in high-efficiency, large-scale cleaning, installed in fixed positions or integrated with robots and production lines. Pre-programmed operation ensures consistent results, commonly used in automotive, aerospace, and industrial production.

System prices start at $50,000, with advanced models exceeding $200,000. They require professional installation and programming. Built for industrial use, laser heads last up to 100,000 hours, ideal for hard, flat surfaces with limited flexibility. Equipped with advanced exhaust and filtration, they are safe, eco-friendly, and meet industrial safety standards.

Key Performance Numbers

Handheld Cleaner Speed: A 200-300W model removes rust at 3–6 m²/hour. The rate can change based on the amount of rust.

Automated Speed: Conveyor systems can handle 80–100 car panels per hour. This speed supports factory-level output.

Key Factors: How to Choose the Right Laser Cleaner For Your Needs

If you’re picking between a handheld or an automated laser cleaning system, I think you need to look at a few key factors. This helps you get the right machine for your work now and for what you plan to do later.

What Are You Cleaning and What Is It Made Of?

Choose your laser based on the material: metals need high power (1500W–3000W fiber lasers), plastics and glass need low-power or UV lasers (avoid PVC/ABS), and wood or rubber require low-power or CO₂ lasers to prevent burning. Also, heavier dirt like rust or paint needs more laser power.

Do You Need to Move Around or Automate the Work?

Handheld laser cleaners are fantastic when you need to move around. I suggest them for maintenance, work in the field, or cleaning objects with odd shapes.

Automated laser systems, like those on a conveyor or robot arm, are built for factory work. I use them for high-volume, repetitive jobs that need a consistent finish every time.

Speed, Area, and Fitting Into Your Workflow

I find 1000W handheld systems ideal for small or spot jobs with minimal heat damage risk. For fast cleaning of large areas, 2000W+ automated units are best, especially on production lines. Match your machine to your workflow: use portable units for mobile work and automated ones for fixed stations.

Thinking About Your Budget

Handheld units don’t cost as much upfront. I think they are a great choice for contractors, small shops, or if your workload changes a lot.

Automated cleaners cost more to buy, but I have seen them save money over time. They lower labor costs, increase output, and give you very consistent results. They are well-suited for large-scale industry.

Summary

Based on my experience with laser cleaning, picking the right tool depends on your specific needs. You might choose a flexible handheld unit, or you could go with an efficient automated system. In my opinion, both are smart investments in cleaner and safer technology. Either option will give you great results and is better for the environment. I recommend matching the tool directly to your goals. This will completely change how you work. Ready to learn more? Contact us now for expert advice on laser cleaning machine.