Marking large, fixed items can be a real challenge. I think it’s often because you have to use bulky equipment for the job. The type of laser marker you pick makes a huge difference. This is true if you are adding serial numbers out in the field or processing batches of parts for production. You have two main options: handheld machines and desktop machines. From my experience, there is one critical factor that can make or break your decision. I find that most people overlook this point until it’s too late.

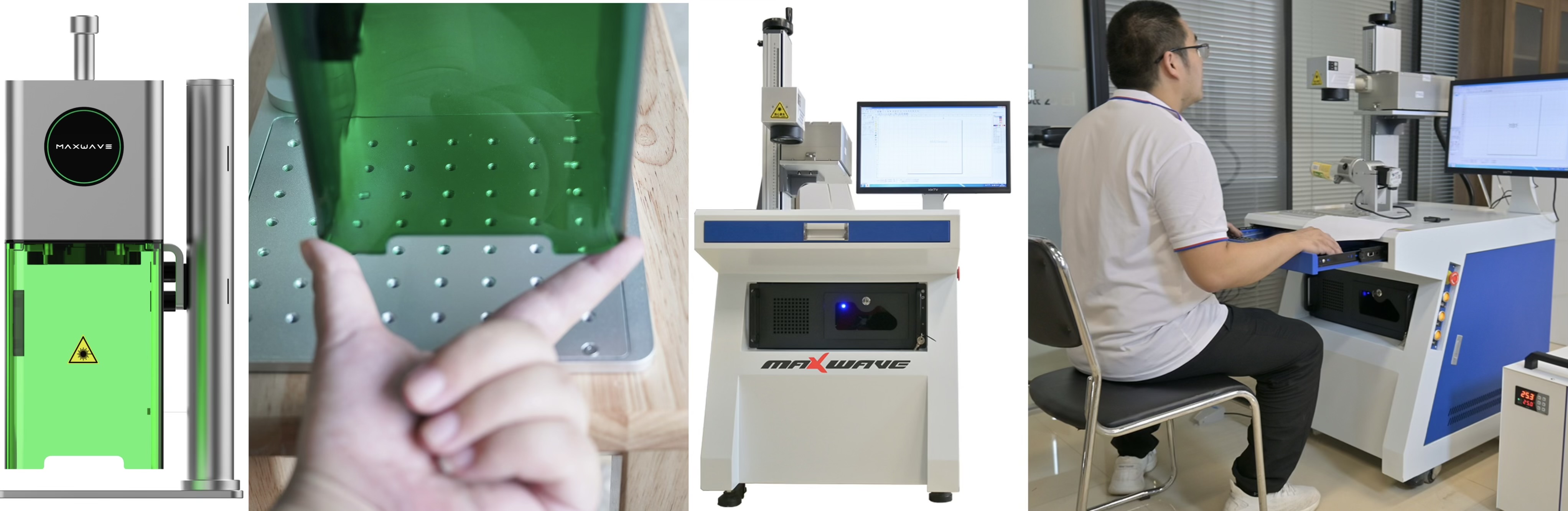

Quick Comparison: Handheld vs. Desktop Laser Marking Machine

When choosing between handheld and desktop laser markers, several key factors help determine which fits your needs best.

| Feature | Handheld Laser Marker | Desktop Laser Marker |

| Portability | Lightweight, mobile (<10kg) | Heavy, stationary (20–50kg) |

| Max Marking Area | Up to 140×140mm | Up to 450×440mm (A3 size |

| Marking Speed | >7000mm/s | Up to 36,000mm/min (~600mm/s) |

| Material Range | Metals, plastics, ceramics | Metals, wood, acrylic, thick materials |

| Use Scenario | Small batches, fieldwork, studio | Industrial batch, prototyping |

| Cost | Lower upfront cost | Higher upfront cost |

| Maintenance | Operator skill-dependent | Stable and precise |

This quick comparison highlights that handheld laser marking machines excel when mobility and small batch flexibility matter. Desktop laser markers dominate in power, size, and speed, fitting high-volume and complex engraving needs.

Portability & Flexibility: Handheld vs. Desktop Laser Marker

Handheld laser marking machines excel in portability and flexibility. Weighing around 6 kg with marking heads as light as 0.8–1.25 kg, they are easy to carry and operate by one person. This makes them perfect for marking large, fixed, or hard-to-move items on-site or in the field.

Lightweight Design and Mobility

Compact and lightweight, most units weigh under 6 kg, significantly reducing operator fatigue during extended use. With integrated carrying solutions such as dual shoulder straps, protective carrying cases, or even rolling luggage designs, these machines are built for easy and efficient transport across job sites.

Battery and Power Features

Equipped with high-capacity internal batteries (up to 8700mAh), these machines support 4–8 hours of cordless marking, and can even operate while charging, ensuring minimal downtime and maximum productivity.

Wireless and Offline Operation

The MaxWave MW-F25CA features USB, Wi-Fi, and Bluetooth connectivity, enabling flexible use without a desktop computer. Its touchscreen control and one-key marking system offer an intuitive experience, making it easy even for beginners.

Adaptability and Work Environment

Versatile marking capabilities make it effective on metals, plastics, ceramics, and even curved or hard-to-reach surfaces. Its environmental adaptability allows use on factory floors or outdoor sites where traditional desktop machines fall short.

Speed and Productivity

In contrast, desktop laser marking machines are heavier, fixed in place, and require dedicated workspaces and power supplies. This limits their flexibility and mobility, especially for large or immobile parts. Overall, handheld laser marking machines provide unmatched portability and operational flexibility thanks to their light weight, battery power, wireless control, and adaptable design.

Workpiece & Engraving Area: Handheld vs. Desktop Laser Marking Machine

When choosing between handheld and desktop laser markers, the size of your workpiece and the required engraving area are key factors to consider.

Handheld Laser Markers: Small Marking Area, Large Workpieces

- Marking area: Typically between 70 × 70 mm and 200 × 200 mm.

- Best for: Marking logos, serial numbers, or small designs directly on large, heavy, or fixed workpieces.

- Ideal scenarios: On-site marking of metal pipes, machinery, or industrial equipment that cannot be moved easily.

- Precision: Suitable for small to medium markings with flexibility in hard-to-reach or immobile locations.

Desktop Laser Marking Machines: Larger Engraving Area, Batch Processing

- Engraving area: Usually ranges from 110 × 110 mm up to 400 × 400 mm or more.

- Suitable for: Medium to large parts, multiple pieces in one batch, or continuous marking on long objects with passthrough features.

- Examples: OMTech 20W Fiber Laser: Marking area of 175 × 175 mm.

If you need to mark big, fixed items fast and right on-site, go for a handheld machine. But if you’re doing batch work, need fine detail, or want a stable setup with more automation, a desktop machine is the better choice.

Speed & Efficiency: Handheld vs. Desktop Laser Marking Machine

When choosing between handheld and desktop laser marking machines, speed and efficiency are crucial factors to consider.

Handheld laser marking machines

It have speeds ranging from 600mm/s to 7000mm/s, depending on the model and power. Entry-level handhelds (diode 5W) mark at 6mm/s to 600mm/s, with a preview speed up to 3750mm/s. More powerful handheld fiber lasers (20W to 50W) can reach speeds as high as 7000mm/s, able to mark up to 800 characters per operation depending on material.

Desktop laser marking machines

They can go faster, with speeds up to 9000mm/s. These are designed for high-throughput production lines. They provide automatic, continuous marking with larger marking areas (e.g., 110x110mm+) and deeper marking per pass (up to 0.3mm on metals).

Material Compatibility: Handheld vs. Desktop Laser Marking Machine

When choosing between handheld and desktop laser marking machines, material compatibility is a key factor. The type of laser—fiber, CO2, or UV—largely determines what materials can be effectively marked.

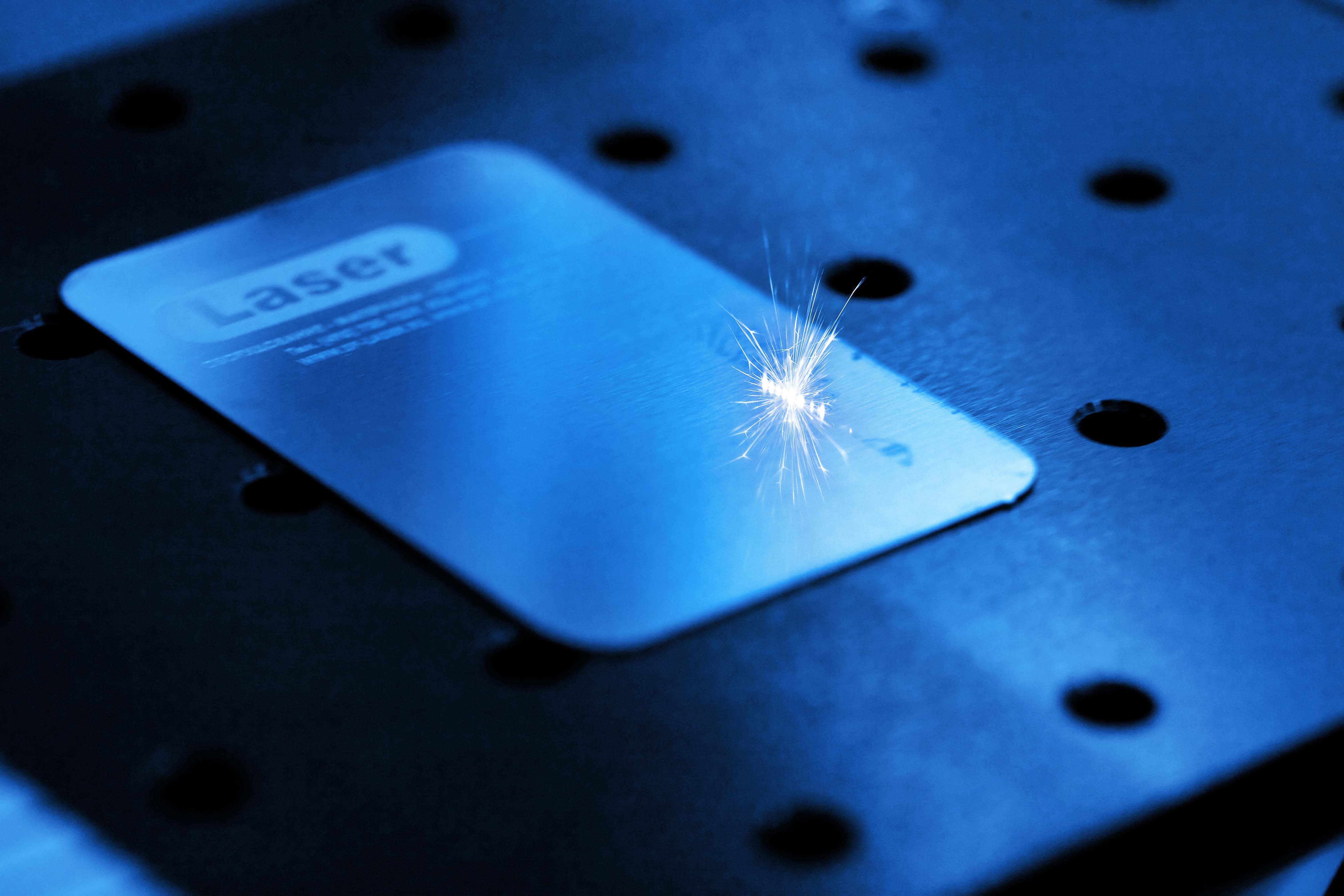

Handheld Laser Marking Machines

Fiber laser markers are best for metals like stainless steel, aluminum, titanium, gold, and silver. They can mark some industrial plastics, but results vary. Not recommended for wood, glass, or acrylic without special treatment. Commonly used for asset tags and serial number engraving on metal parts.

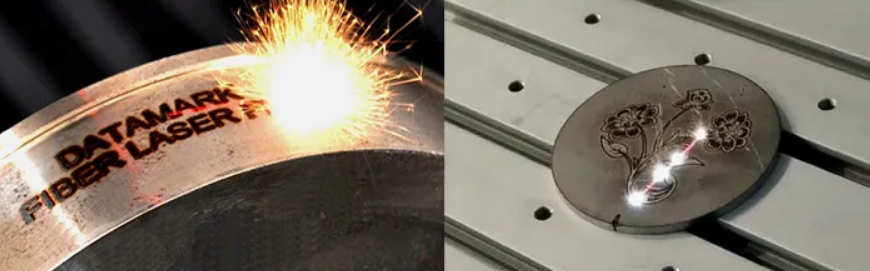

Desktop Laser Marking Machines

Laser markers support fiber, CO₂, and UV types, each suited for different materials. Fiber lasers are ideal for metals and hard plastics, CO₂ excels with wood, glass, leather, and acrylic, and UV handles heat-sensitive plastics, ceramics, and fine metal marking. They’re commonly used for jewelry, signs, and circuit boards.

Power and Marking Capabilities

– Fiber (handheld): Power 20–50W; marking depth 0.01–0.5 mm on metals.

– CO2 (desktop): Power 40–150W; can cut up to 10–20 mm thick wood/acrylic; not for untreated metals.

– UV (desktop): Power 3–15W; ultra-fine markings with minimal heat effect.

Cost Considerations for Laser Marking Machines

When choosing between handheld and desktop laser marking systems, the cost is a major factor to consider. Prices can vary greatly depending on the type of machine, its power, and the features offered.

Initial Purchase Price

- Handheld laser marking machines are usually more affordable. Entry-level models like the LaserPecker LP2 start at about $699, while others such as the WAINLUX Z4 range from $1,089 to $1,099.

- Mid-range handheld or dual-mode options like the MaxWave MW-F25CA cost between $1,200 and $1,299.

- Desktop laser marking machines typically cost more. Prices generally begin at $3,500 and can go as high as $70,000 depending on laser type (fiber, CO₂, or UV), power, and advanced features.

Operating Costs

Handheld diode and fiber lasers usually have low maintenance and do not require consumables, reducing long-term ownership costs. Desktop machines vary, but many premium models are designed for low maintenance.

My Point

Handheld machines cost less upfront and are great for portable, light tasks, while desktop models need more investment but excel at heavy, high-volume work. Both have low maintenance and running costs, keeping overall expenses manageable.

Application Scenarios: Which Laser Marking Machine Is It For?

Handheld and desktop laser marking machines serve different user needs and environments. Understanding who benefits most from each can help you choose the best fit.

Handheld Laser Marking Machines: Portable and Flexible Use

Handheld mini laser markers are perfect for users who need mobility and ease of use. They suit tasks where marking must happen on-site or directly on large or fixed objects. Typical users and applications include:

- Field technicians and maintenance teams: Mark vehicle parts like VIN numbers or machinery components without moving heavy objects.

- Artists and small businesses: Personalize jewelry, gifts, and crafts with logos or custom designs.

- Industrial and manufacturing workers: Mark serial numbers, barcodes, and inspection codes on tools, electronic parts, and hardware.

- Medical and aerospace professionals: Ensure durable, compliant markings on instruments made from stainless steel, titanium, or other metals.

- Logistics and warehouse operators: Use for asset tracking and anti-theft marking, improving inventory management.

- Creative studios: Mark metals, plastics, ceramics, or glass for small-batch or unique artworks.

Key benefits:

– Weigh less than 10 kg, easy to carry.

– Mark objects in under 1 second per spot, improving work speed.

– Compatible with many materials, including stainless steel, aluminum, gold, plastics, ceramics, and carbon fiber.

– No need for fixed installation or environmental controls.

– Perfect for small workshops, startups, or on-demand marking.

Desktop Laser Marking Machines: High Precision for Mass Production

Desktop laser markers fit users requiring high-volume, precise, and automated marking in controlled environments. Typical scenarios include:

- Mass production lines: Electronics, battery, and semiconductor sectors demand micron-level precision and speed.

- Medical, aerospace, and food industries: Require consistent quality marks integrated into large manufacturing workflows.

- Companies needing automation: Desktop systems connect easily to production lines for continuous operation.

Key traits:

– Stationary setup with dedicated space.

– High throughput and fixture control.

– Often integrated with robotic arms or conveyors for hands-free operation.

Summary

Choosing between a handheld and desktop laser marker depends on your workflow, materials, and budget. Handhelds are best for on-the-go jobs with more flexibility, while desktops suit production lines needing speed and accuracy. Both are effective; it’s about finding the right fit for your current needs and future plans. Ready to learn more? Contact us now for expert advice on laser marking machines.