Laser marking is changing the game for makers and manufacturers alike — but picking the right machine isn’t always easy. Maxwave and Laserax are two top players battling it out with powerful features and bold claims. Ready to find out which one delivers the precision, speed, and value you need? Let’s dive into this showdown and see which laser marking machine wins your business!

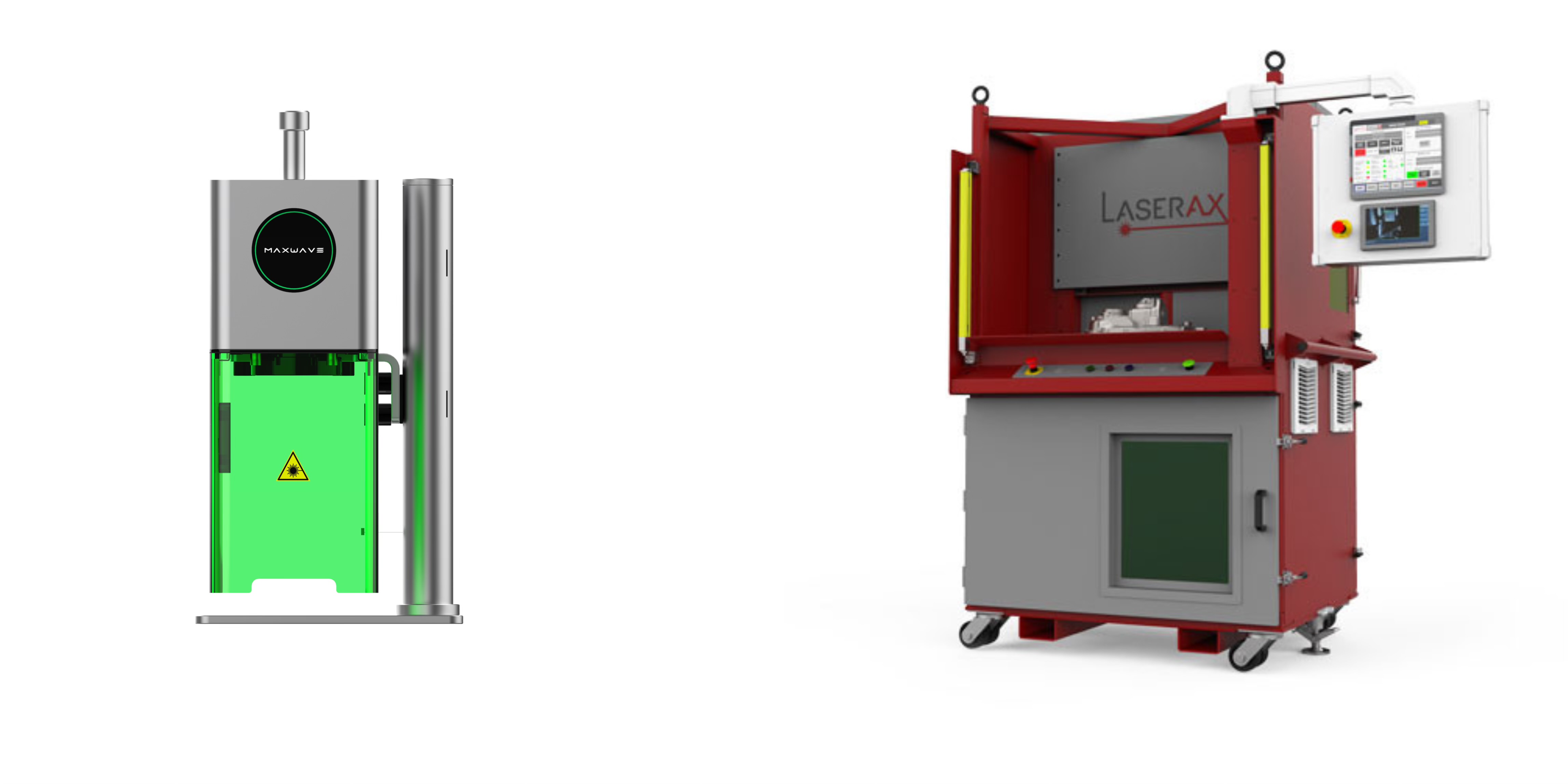

Laser Marking Machine Brand Comparison Maxwave and Laserax Brief Review

| Category | Maxwave | Laserax |

|---|---|---|

| Price | $1,200–$5,000 | $10,000+ |

| Users | Startups, small workshops | Large manufacturers |

| Laser Types | Fiber, CO₂, UV | Fiber |

| Features | Portable, Bluetooth, multi-format software, autofocus | Multi-axis automation, inspection, modular design |

| Service | 2-year warranty, lifetime tech support | Remote monitoring, full industrial support |

| Advantages | Affordable, easy to use | High precision, durable |

My View:

For a shop that needs the lowest upfront cost for basic metal marking, I think Maxwave’s value is hard to beat. For factories that need reliable support, high output, and full integration, I recommend Laserax-class systems. Their higher TCO pays off in productivity and guaranteed uptime. I always tell my clients to include shipping, duties, and other required costs in their final TCO calculation. This gives you a true picture of your investment.

Brand & Market Positioning: Maxwave vs Laserax Laser Markers

Maxwave

Maxwave is known for its innovative fiber laser technology combined with user-friendly design. It serves mainly small to medium-sized businesses in industries like jewelry, electronics, automotive parts, and personalized products. Maxwave focuses on providing reliable, cost-effective laser marking machines, making it popular among startups and manufacturers seeking good value.

Laserax

Laserax targets the high-end industrial market with a robust product lineup including fiber and CO₂ lasers. It is favored by large manufacturers in aerospace, automotive, and heavy machinery sectors due to its durable machines and advanced automation features. With a global presence and strong after-sales support, Laserax is recognized for precision and reliability in demanding environments.

Laser Marking Machine Performance Comparison: Maxwave vs Laserax

Maxwave

-

Laser Types and Power: Primarily offering fiber laser markers with a power range of 20W to 50W, Maxwave also offers CO₂ and UV laser marking systems, optimized for marking metals and hard materials.

-

Marking Speed and Precision: Provides reliable accuracy and competitive marking speeds suitable for small to medium production volumes.

-

Range of Materials: Excels at marking metals such as stainless steel, aluminum, copper, and selected plastics.

-

Durability and Maintenance: Designed for durability with easy maintenance, balancing performance and upkeep ideal for small to medium enterprises.

Laserax

-

Laser Types and Power: Offering fiber and CO₂ lasers, Maxwave offers high-power configurations tailored for industrial-scale applications.

-

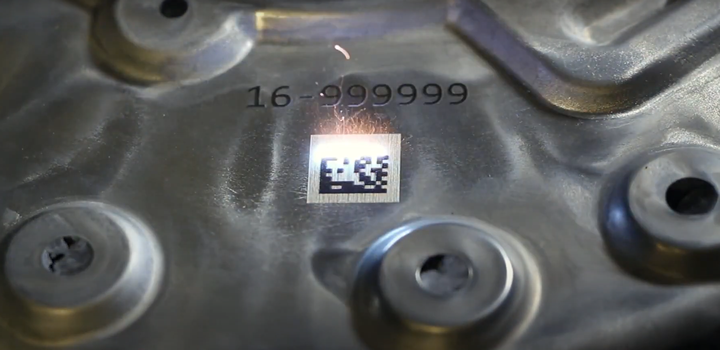

Marking Speed and Precision: Known for faster marking speeds and ultra-high precision, supported by advanced beam control and automation features for high-volume, high-accuracy needs.

-

Range of Materials: Supports a wider variety including metals, plastics, glass, and composites, thanks to diverse laser types and customizable setups.

-

Durability and Maintenance: Features robust construction and heavy-duty components designed for harsh industrial environments and continuous operation.

Features and Technical Specifications: Maxwave vs Laserax Laser Marking Machine

Maxwave

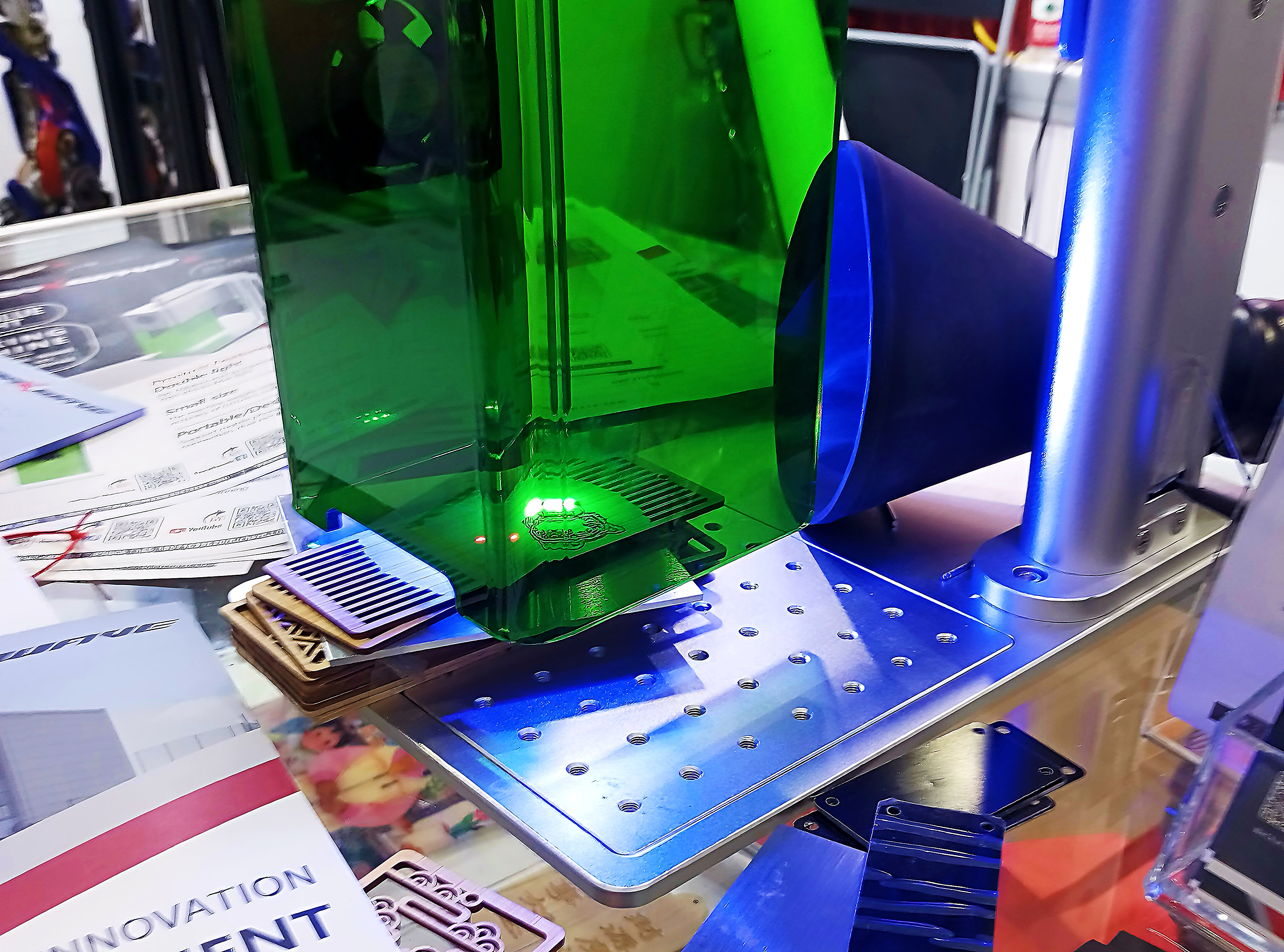

Maxwave’s portable laser marker support multiple file formats like AI, DXF, and PLT, with a user-friendly interface for easy operation and fewer errors. Key automation features include autofocus, rotary axes, and sliding tables to boost efficiency. They are portable and easy to install, perfect for flexible or on-site use. Plus, Bluetooth connectivity allows control via smartphones and computers for added convenience and remote operation.

Laserax

Laserax’s software supports multiple file formats with advanced features for complex workflows and high precision. Its automation includes multi-axis controls and inspection systems for large-scale production. The equipment features modular designs for easy integration. It also offers remote monitoring and comprehensive support to maximize uptime and efficiency.

Pricing and Cost-Effectiveness Analysis of Both Laser Marking Machines

Maxwave

Maxwave’s laser marking machines are affordable, typically priced between $1,000 and $5,000, making them ideal for small to medium businesses and startups. They offer low maintenance costs and easy operation, resulting in a quick return on investment, often within months for small-batch or personalized work.

Laserax

Laserax targets the high-end market, with prices from $10,000 to $50,000+. Their machines provide advanced features and high durability for large-scale, high-precision production. Though the upfront cost is higher, they deliver long-term savings and efficiency, suited for large manufacturers. The ROI period is longer but justified by output quality and volume.

User Feedback and Case Studies: Maxwave vs Laserax Laser Marker

Maxwave

Users generally report high cost-effectiveness and ease of operation, making the Maxwave laser marking system well-suited for small businesses and startups. Many customers in personalized gift production, jewelry engraving, and small-batch part marking note that Maxwave machines are quick to learn and have low maintenance costs, enabling a fast return on investment. Case studies highlight strong performance in mobile operations and versatile, multi-scenario use. However, in environments requiring ultra-long continuous operation or extremely high precision, performance may be slightly below that of top-tier models.

Laserax

Users in the automotive, aerospace, and electronics industries consistently praise its high precision and stability, particularly in large-scale production. Case studies show that Laserax machines excel in high-speed production lines, integrated automated inspection systems, and long periods of uninterrupted operation. While customers acknowledge the higher price, they agree that the durability and consistency deliver significant long-term cost savings and quality assurance.

Buying Recommendations: Maxwave vs Laserax Laser Marking Machine

Maxwave

For buyers with a limited budget, small-batch production needs, or frequent on-site marking, Maxwave is a strong choice. Its affordable price point, portability, and ease of use make it ideal for startups, small workshops, and custom product businesses. When purchasing, consider the power output needed for your materials (e.g., 20W for light marking, 30W+ for deeper engraving), and take advantage of Maxwave’s two-year warranty and lifetime technical support. It’s best to directly consult the manufacturer for tailored configuration suggestions to balance cost and capability.

Laserax

For industries with high-volume production, strict precision standards, or automation requirements, Laserax offers robust, high-performance machines designed for long-term stability. Although its price is higher, the investment is justified for applications like automotive parts, aerospace components, and integrated production lines. When purchasing, assess the required automation level, compatibility with your existing workflow, and potential ROI over years of operation. Contact Laserax for custom engineering solutions to ensure the machine meets exact production demands.

Summary

Based on my experience comparing these two brands, I believe the key is to match your specific needs to the right budget. Maxwave is a more affordable choice, while Laserax offers industrial-grade power. If you choose carefully, either brand can greatly improve your marking process. The most expensive machine is not always the best one. I recommend picking the machine that delivers consistent results for your business. It also needs to fit your budget and your plans for growth. Ready to learn more? Contact us now for expert advice on laser marking machines.