How much is a jewelry laser welder? The price tag can be stunning, ranging from a few thousand to over $50,000! But here’s the real kicker—what if spending a little extra now could save you thousands in repairs and gold loss down the line? In this guide, we’ll show you why the right investment could make all the difference. Let’s get to the heart of choosing a welder that’s smart, not just cheap!

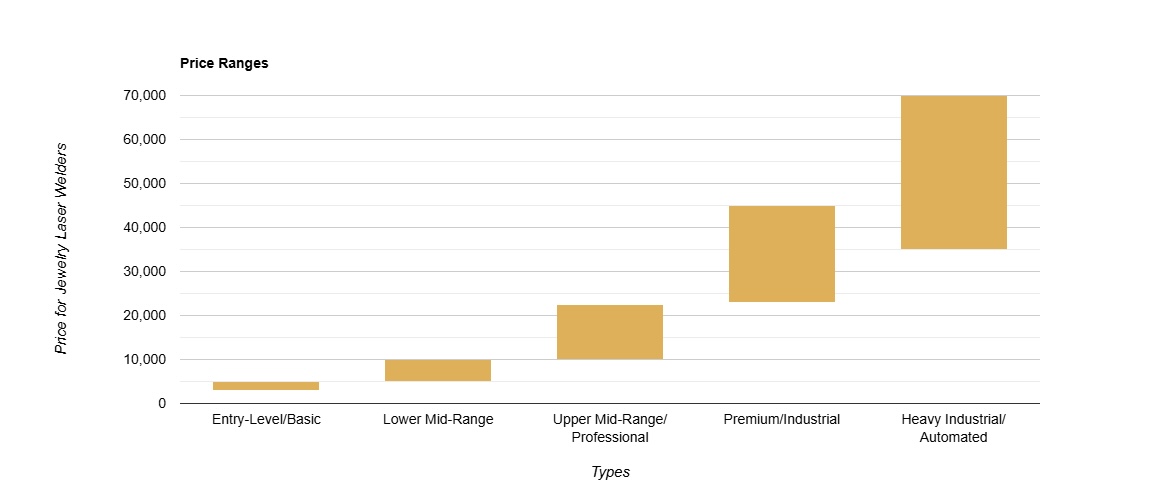

Price Ranges for Jewelry Laser Welders

I find that jewelry laser welder prices vary quite a bit. The cost depends on factors like power, brand, how automatic the machine is, and what features it includes. Let me give you a detailed look at the price groups and what affects the cost.

Jewelry Laser Welder Price Comparison

Entry-Level Welders (Basic/Personal Use): I think these models work well for small repairs or if you’re just starting out as a jeweler. Prices usually range from $3,000 to $5,000.

- Budget desktop laser welders (often from Chinese brands): $3,350–$4,900

- MaxWave desktop integrated units: $3,700–$4,900 (The price changes based on wattage and extra features)

Mid-Range Welders (Professional Bench Units): These are common in most jewelry shops and custom studios. I see the price range here is $5,000 to $15,000.

- Dado portable welder: $5,200–$5,700

- ZAC 200W model: $6,399

- Orion LZR ECO: $10,000–$11,900

Upper Mid-Range and Premium Models: You can find professional benchtop models and European brands in this range. They cost $15,000 to $32,500.

- Orion LZR Pro Series: $15,500–$22,500

- Stuller Orotig Revo X⁺/X²: $23,550–$32,500

- Sisma LM-D Lynx 210: $26,750

- Sisma LM-T 250: $29,995

High-End/Industrial-Grade Welders: These machines are built for constant use. They offer more power and advanced features. Based on my experience, these machines cost between $20,000 and $70,000+.

- Sunstone DL200 Laser Welder: $69,900

- Some automatic systems with CNC and top brands (like TRUMPF, IPG) can cost more than $100,000.

Jewelry Laser Welder Price Summary

Based on my experience, most professional bench jewelers can expect to pay between $5,000 and $15,000 for a dependable jewelry laser welder. You can find basic entry-level units starting around $3,000. Advanced machines for industrial use can cost $70,000 or even more. I suggest you choose based on your specific needs and budget.

What Affects Jewelry Laser Welder Prices

I find that several key specifications and technical details determine the price of a jewelry laser welder. These features impact performance and the final cost. Here’s a look at the main factors:

Laser Type and Power Output

Laser Types: Most jewelry laser welders use YAG, fiber, or diode lasers. – Fiber and Nd (neodymium) lasers often cost more. I believe this is because they offer better efficiency and precision. – YAG lasers are popular for precision. Fiber lasers work well with more types of metals.

Power Output: – Basic machines (60–150W) are good for simple jewelry repairs. I see them priced around $3,800–$5,000. – Mid-range models (150–250W) can handle tougher jobs. You might pay between $3,500–$7,229. – High-power units (200W and above) are built for constant or factory work. These can cost $15,000 or more.

Pulse Control & Spot Size Adjustment

Pulse Adjustability: Machines let you adjust energy, pulse width (0.2 to 20ms), and frequency (up to 50Hz). Better pulse control gives you more accuracy and flexibility. This usually increases the machine’s price.

Spot Size: You need adjustable spot sizes (0.2 to 2.5mm) for detailed jewelry work. Models offering finer control over the spot size will cost more.

Cooling, Viewing, and Automatic Features

Cooling Systems: – Air-cooled machines cost less and generally need less upkeep. I think they are good for lighter work. – Water-cooled machines (like the ZAC 200W at $7,229) work better for heavy, continuous use. However, they cost more.

Observation & Control Systems: Features like CCD cameras, microscopes, and color touch screens increase the price. I find they improve accuracy and make the machine easier to use.

Automation and Extra Features: Automatic pulse control, saved settings, foot pedals, eye protection, and emergency shut-down systems add value. They also increase the price.

Portability, Brand, and Build Quality

Portability: Compact models (some as light as 40kg) are handy for small workshops or studios. Sometimes, these smaller designs can result in higher prices.

Brand & Quality: I know brands like MaxWave, BOGONG, and ZAC have a reputation for durability and good customer service. Their machines often cost more. In my experience, you get better build quality and reliability with these brands.

Example Price Table

| Power (W) | Cooling | Key Features | Price Range (USD) | Example Model |

|---|---|---|---|---|

| 60–150 | Air-cooled | Basic weld/repair | $3,800–$5,000 | MaxWave MW-QW150 |

| 150–200 | Water-cooled | Precision, CCD camera | $3,500–$7,229 | ZAC Jewelry 200W |

| 200+ | Water-cooled | Enhanced automation | $5,000–$15,000 | G5-JLW200WC |

Key Takeaways

More powerful laser welding machine with better adjustability, automation, advanced cooling, viewing tools, and user-friendly controls tend to cost more—features commonly found in professional-grade machines. While basic models are cost-effective for beginners and small workshops, advanced machines are ideal for businesses requiring higher output, flexibility, and precision.

Purchasing Considerations

Plan to buy a jewelry laser welder, I think it’s smart to look at the features and technical details. This helps you find the right welder for your work style and budget. The choices you make will affect the cost and the value you get over time.

Power Capacity & Output Energy

- Most jewelry laser welders have an output energy between 20J and 150J. – For beginners or small studios, I find the Neutec® PulsePoint™ Plus 20 (20J) is often suitable. – For professionals, the Neutec® PulsePoint™ Plus 140 (140J) provides high energy. It handles difficult jobs well.

- You can adjust the pulse width, spot size, and frequency. This gives you flexibility for different metals and jewelry thicknesses. I believe this flexibility is quite useful.

Machine Features & Ergonomics

Some jewelry laser welder offer built-in microscopes and optional cameras to enhance accuracy, with choices like Leica stereo or Clearview (10x or 15x magnification). Touch screens and adjustable controls provide an easy-to-use interface, while ergonomic designs—including adjustable chamber heights and armrests—help improve comfort and reduce fatigue during long work sessions.

Portability & Space Considerations

You can find compact 60W “mini” laser welders that are lightweight, portable, and ideal for small shops or on-the-go use. In contrast, larger benchtop welders provide higher power and are built for durability, making them perfect for workshops with high workloads.

Brand Reputation & Support

I suggest considering reputable brands like MaxWave, Orotig, LaserStar, IPG Photonics, or TRUMPF, as they offer dependable jewelry laser welder with strong warranties (often around one year) and reliable after-sales support. While lesser-known brands may offer lower prices, they often come with weaker support and shorter machine lifespans.

Safety Features

I urge you to check for essential safety features like automatic light shields and emergency shutoffs. Also, ensure that protective glasses are either included or clearly specified. These safety elements are especially important in multi-user shops or busy work environments.

Customization & Observation

Being able to adjust the spot diameter (from 0.2 mm to 2.5 mm) is key. Multiple welding modes are also helpful. Real-time viewing through a camera or microscope helps you weld accurately and safely. I find these observation tools essential.

Metal Compatibility

Make sure the laser welder is compatible with the metals you use, such as gold, silver, platinum, and titanium. It should also be capable of performing fine repairs on prongs, chains, and other delicate parts without causing heat damage to surrounding areas.

Notable Example Models

| Model | Power Output | Cooling | Price (USD) | Notable Features |

|---|---|---|---|---|

| Orotig Evo White | 160J/75W | Water-cooled | ~$6,500–8,000 | High precision, 10x microscope |

| Orotig Revo X² | 280J/150W | Water-cooled | $12,000+ | High output, 10L water tank |

| ZAC 200W Laser Welder | 200W/60J | Water-cooled | $7,229 | CCD observation, touchscreen |

| MaxWave MW-QW120 | 120W | Air-cooled | $4,200 | Compact, cost-effective |

| MaxWave MW-ST250 | 250W | Water-cooled | $4,000 | Value, mid-range performance |

Buyer’s Checklist

Choosing a laser welder, match the power and features to your daily tasks. Stick with trusted brands that offer a good warranty and solid support. Look for comfortable, easy-to-use designs, and pick air- or water-cooled based on how often you’ll use it. Make sure it works well with your preferred metals and jewelry types. Safety first—don’t skip on shields or emergency shutoffs. And remember, a higher upfront cost can pay off in better speed, precision, and long-term value.

Summary

Ready to take your jewelry work to the next level? The right laser welder means better quality, fewer mistakes, and higher profits. Don’t let a cheap choice cost you more later—invest smart, work smarter, and watch your business shine! For more details about jewelry laser welder or to get a quote, contact us today!