The global manufacturing landscape is undergoing a profound shift towards sustainability. Driven by stricter environmental regulations, growing consumer preference for “green” products, and the rising importance of ESG (Environmental, Social, and Governance) criteria for investors, companies are actively seeking ways to minimize their ecological footprint. In this context, traditional welding processes, such as MIG and TIG, reveal their significant shortcomings. While workhorses of the industry, they are often characterized by high energy consumption, substantial material waste, and the generation of fumes and pollutants. This is where the Max 1500W Laser Welding Machine emerges as a revolutionary solution. It is engineered not only to enhance productivity and precision but also to directly address these environmental challenges, positioning itself as a cornerstone for the future of eco-friendly manufacturing.

Precision Welding for Minimal Material Waste

The cornerstone of the Max 1500W’s eco-efficiency lies in its unparalleled precision, which drastically cuts down on material waste.

A Highly Focused Energy Beam for Pinpoint Accuracy and Minimal HAZ

Unlike the broad arc of traditional welding, the laser beam boasts an exceptionally high energy density and a tiny spot diameter. This means heat is concentrated with surgical accuracy, melting metal only where it’s needed. The result is an extremely narrow weld seam with a minimal heat-affected zone (HAZ). This precision significantly reduces thermal distortion and damage to the base material, ensuring that virtually every gram of material is used effectively, with almost no excess loss from warping or unnecessary melting.

Seam Tracking and Automated Control for Flawless Execution

The precision of the Max 1500W is augmented by intelligent seam tracking and vision systems. These systems automatically detect the joint position in real-time, making micro-adjustments to the laser head’s path. This eliminates human error and ensures the weld is placed with perfect accuracy every time, even on complex or curved workpieces. By guaranteeing the weld is always on the seam, it prevents costly mistakes and material waste from misplaced welds, further solidifying the “right-first-time” manufacturing principle.

Superior Weld Quality for Fewer Defects and Rework

The consistency and quality of welds produced by the Max 1500W are exceptional. It produces uniform, robust, and aesthetically pleasing seams with a drastically lower incidence of common defects like porosity or undercut. This high consistency in welding quality means a dramatic reduction in the rate of rework and product rejection. Every weld is near-perfect the first time, which directly translates to saved materials, energy, and labor that would have been wasted on fixing or reproducing faulty parts.

Energy-Efficient Welding for a Lower Carbon Footprint

When it comes to power consumption, the Max 1500W laser welding machine sets a new standard for efficiency, directly contributing to a lower carbon footprint.

The Inherent Efficiency of 1500W Laser Welding

While the 1500W power rating might seem substantial, the key lies in the high electro-optical conversion efficiency of fiber laser technology. A significantly larger portion of the incoming electrical power is converted into the actual laser beam energy used for welding, compared to the substantial energy lost as heat and light in traditional welding arcs. This means the Max 1500W does more work per kilowatt-hour, effectively reducing the electricity required for each welding operation.

Faster Welding Speeds for Reduced Operational Time

Laser welding is remarkably fast, often achieving speeds 2 to 5 times faster than conventional MIG or TIG welding. Completing the same weld seam in a fraction of the time means the machine’s operational duration is drastically shortened. This directly translates to lower energy consumption. Furthermore, the increased throughput accelerates the entire production line, indirectly reducing the energy used by auxiliary systems like workshop lighting and ventilation, which now operate for a shorter period to accomplish the same output.

Cleaner Welding for a Healthier Workshop

The benefits of laser welding extend beyond the workpiece to the very air your employees breathe, creating a safer and more sustainable work environment.

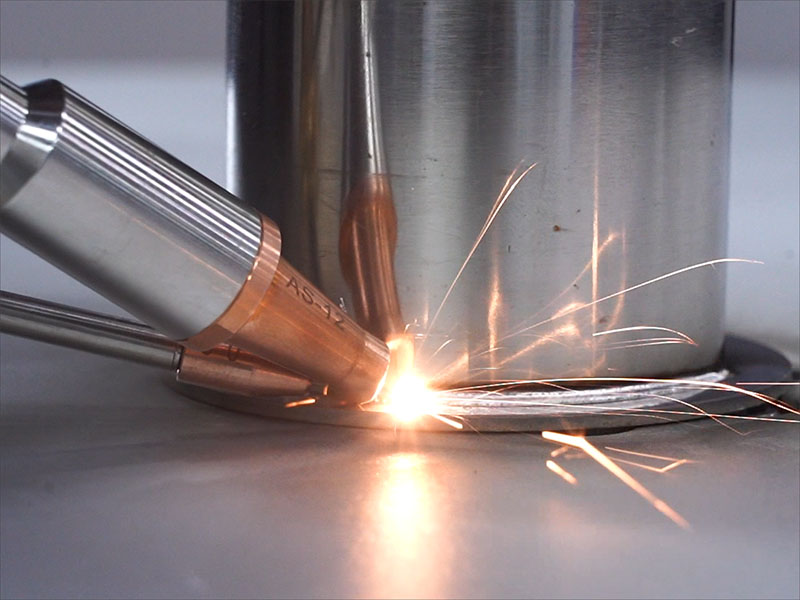

A Cleaner Welding Process with No Spatter or Slag

The non-contact welding nature of laser technology, combined with stable melt pool dynamics, ensures an exceptionally clean process. Traditional arc welding is notorious for producing spatter—tiny droplets of molten metal that scatter around the weld zone—and slag, the hardened layer of flux residue. The Max 1500W laser welder virtually eliminates spatter and slag. This not only saves time and consumables associated with post-weld cleanup but also prevents workpieces from being contaminated and scrapped due to spatter, directly reducing metallic solid waste.

Significantly Reduced Fumes and Sparks

The controlled and precise nature of the laser welding process results in dramatically lower fume generation. By concentrating heat efficiently, it minimizes the vaporization of metals and the creation of harmful aerosols. Independent studies show that laser welding can reduce fume volume by 80-90% compared to MIG welding. This leads to a visibly cleaner workshop with far fewer airborne particulates, protecting operator health and reducing the risk of respiratory illnesses.

Reduced Load on Ventilation Systems and Enhanced Productivity

The drastic reduction in welding fumes directly translates to lower demands on local exhaust ventilation (LEV) systems and general workshop air handling units. These systems are significant energy consumers in a manufacturing facility. By reducing fume volume by 80-90%, the Max 1500W allows for the operation of these systems at lower speeds or for shorter durations, leading to substantial secondary energy savings. A cleaner and safer environment also contributes to higher operator morale and reduced absenteeism, fostering a more productive and sustainable workforce.

Filler-Free Welding for Maximum Material Savings

In numerous applications, the Max 1500W enables a remarkably efficient welding technique that further bolsters its green credentials.

The Autogenous Welding Advantage

For many butt and seam welding applications, the Max 1500W facilitates autogenous welding—a process that fuses the base materials together without the need for any filler wire. This eliminates an entire category of consumables from the production equation. The environmental impact is twofold: it completely avoids the resource consumption and carbon emissions associated with the production, transportation, and packaging of filler wires, and it fundamentally eradicates the waste generated from wire stubs and leftover spools.

Streamlined Process and Enhanced Weld Purity

Eliminating the filler wire also simplifies the entire welding operation. There is no need for wire feeding mechanisms, associated calibrations, or concerns about wire jamming. This streamlines the process, reduces maintenance requirements, and opens the door to higher levels of automation. Furthermore, by fusing only the base materials, the resulting weld is often of higher purity and corrosion resistance, as there is no risk of introducing incompatible alloying elements from a filler wire. This leads to longer-lasting products and reduces the need for future repairs or replacements.

Sustainable Welding Through Long-Lasting Equipment

True sustainability also considers the lifecycle of the equipment itself. The Max 1500W is built to last, minimizing its long-term environmental impact.

An Exceptionally Long Laser Source Life

At the heart of the machine is a high-quality fiber laser source with a rated operational life exceeding 100,000 hours. Coupled with its robust construction and durable key components, the machine is designed for decades of reliable service with minimal maintenance. This longevity is a direct application of the “Reduce” principle from the core sustainability mantra of “Reduce, Reuse, Recycle.” By investing in a durable machine that rarely needs replacement, you dramatically cut down on the electronic waste and industrial scrap that would otherwise be generated from frequently replacing less durable equipment.

Modular Design for Easy Maintenance and Upgradability

The Max 1500W is engineered with a modular architecture. Key components such as the cooling system, protective lenses, and motion modules are designed for easy access and replacement. This extends the machine’s operational life even further by making repairs quick and cost-effective. It also future-proofs your investment; as your production needs evolve, the system can be updated with new software or hardware modules instead of requiring a complete machine replacement. This approach adheres to the “Reuse” principle, minimizing the generation of electronic waste over the equipment’s entire lifecycle.

Conclusion: Why MaxWave Helps You Build a Greener Factory

The Max 1500W Laser Welding Machine is more than just a tool; it is a comprehensive eco-friendly manufacturing strategy. By systematically addressing the five pillars of waste reduction, energy efficiency, a cleaner workshop, material savings, and equipment longevity, it provides a clear and actionable path to a more sustainable and responsible operation. Choosing MaxWave is not just an ethical decision; it is a shrewd business investment. The significant reductions in electricity bills, material costs, scrap rates, and occupational health management expenses deliver a compelling return on investment, proving that profitability and planetary responsibility can go hand in hand.

Ready to transform your welding operations and build a greener, more profitable future? Contact our MaxWave experts today for a FREE, no-obligation welding sample test and a personalized assessment of your production line’s eco-potential.