Choosing the right automatic welding machine for battery manufacturing can feel like finding the perfect piece in a complex puzzle. It’s not just about the latest technology; it’s about matching your unique needs, budget, and long-term goals. In this guide, we’ll dive into the key factors that will empower you to make the best choice and elevate your production to the next level. Let’s get started!

Understanding Your Battery Welding Requirements

Battery welding isn’t one-size-fits-all. Your cell chemistry, production volume, and end application decide what you need from an automatic welding machine for battery.

Match Performance Specs to Your Cell Type

-

Tensile Strength: Small cylindrical tabs need a minimum of 30–50 N, while structural EV busbars jump to 80–100+ N. Always perform pull tests.

-

Electrical Resistance: High-current packs demand less than 100 µΩ per link. Any excess resistance creates heat that degrades battery life.

-

Sealing Precision: This requires a tight balance. Sealing nails must hold over 1.1 MPa, yet safety vents need to burst between 0.4–0.7 MPa. This narrow window strictly limits you to high-precision welding methods.

Speed Requirements Shape Equipment Choice

Modern lines hit 200 mm/s for prismatic welding; anything less than 70 is just for R&D. Same with modules: the pros do 15 cells/s, while standard lines do 4. Do the math on your target output—the numbers will tell you what machine you need. Most jobs are just 8mm circular welds, so focus on a machine that can handle that volume without quitting.

Material Pairings Eliminate Whole Process Categories

Aluminum is used on positive terminals and copper on negative ones. Tabs can be nickel, nickel-plated steel, copper, aluminum, or nickel-plated copper, and the material combinations determine which welding technologies are suitable.

– Internal electrode foils demand ultrasonic welding. The thin copper and aluminum layers are simply too fragile for thermal heat.

– Copper-to-aluminum joints don’t mix with lasers. You get brittle compounds that crack under vibration. Stick to ultrasonic or resistance welding—most automotive standards practically insist on it.

– Same-metal pairs (like Cu-Cu or Al-Al) give you flexibility. Fiber laser is the speed king here. Micro-TIG works for thick copper nuggets, while standard resistance welding handles basic tabs reliability.

– Multi-layer stacks are where laser welding shines, easily punching through 1.0 mm+ sandwiches. Resistance welding struggles here without complex, custom force profiles.

Tab Thickness Dictates Process Modifications

Nickel tabs 0.18 mm or thinner weld without special setup using resistance spot welding. Thicker nickel—up to 1.0 mm—requires edge relief cuts, slots, or pre-forming. These changes control current flow and nugget formation.

Laser welding punches through 1.0 mm+ material in most battery metals. It handles multiple layers in one pass—critical for welding tab stacks to busbars.

Micro-TIG targets thick copper jobs where you need a single solid nugget.

Control Features Separate Production Machines from Lab Tools

DC inverter resistance welding needs fast, controlled pulses with real-time monitoring and polarity switching for even welds. Advanced systems track electrode force and displacement, while standards like NASA require formal WPS. Laser welding is non-contact, consumable-free, and 5–10× faster on thin cells. Define your cell design first to get the right equipment.

Comparing Core Welding Technologies for Battery Manufacturing

Four welding technologies lead modern battery production lines. Each handles specific jobs better than the others. Your choice of battery pack welding equipment affects throughput, joint quality, material compatibility, and production costs over time.

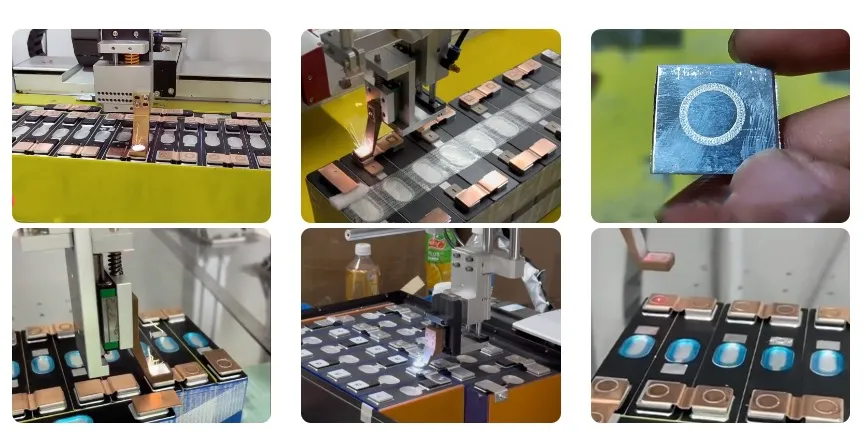

Resistance Spot Welding: The Workhorse for Tab and Terminal Joints

Resistance spot welding presses metal parts together and sends high current through to form a solid nugget in milliseconds. It’s cheap, simple, and widely used for battery tabs and terminals. Modern systems control nugget size and monitor force, but electrodes wear out and thin materials can buckle. In EV packs, RSW is often combined with structural adhesive for long-term strength and moisture protection.

Ultrasonic Welding: Mandatory for Thin Internal Foils

Ultrasonic welding bonds thin, heat-sensitive foils without melting, making it ideal for tab pre-welding—fast, clean, and easy to automate. But for final tab welding, it struggles with thicker stacks and multiple materials. The best solution is a hybrid approach: ultrasonic for pre-welds and laser for final welds, giving stronger joints and more design flexibility.

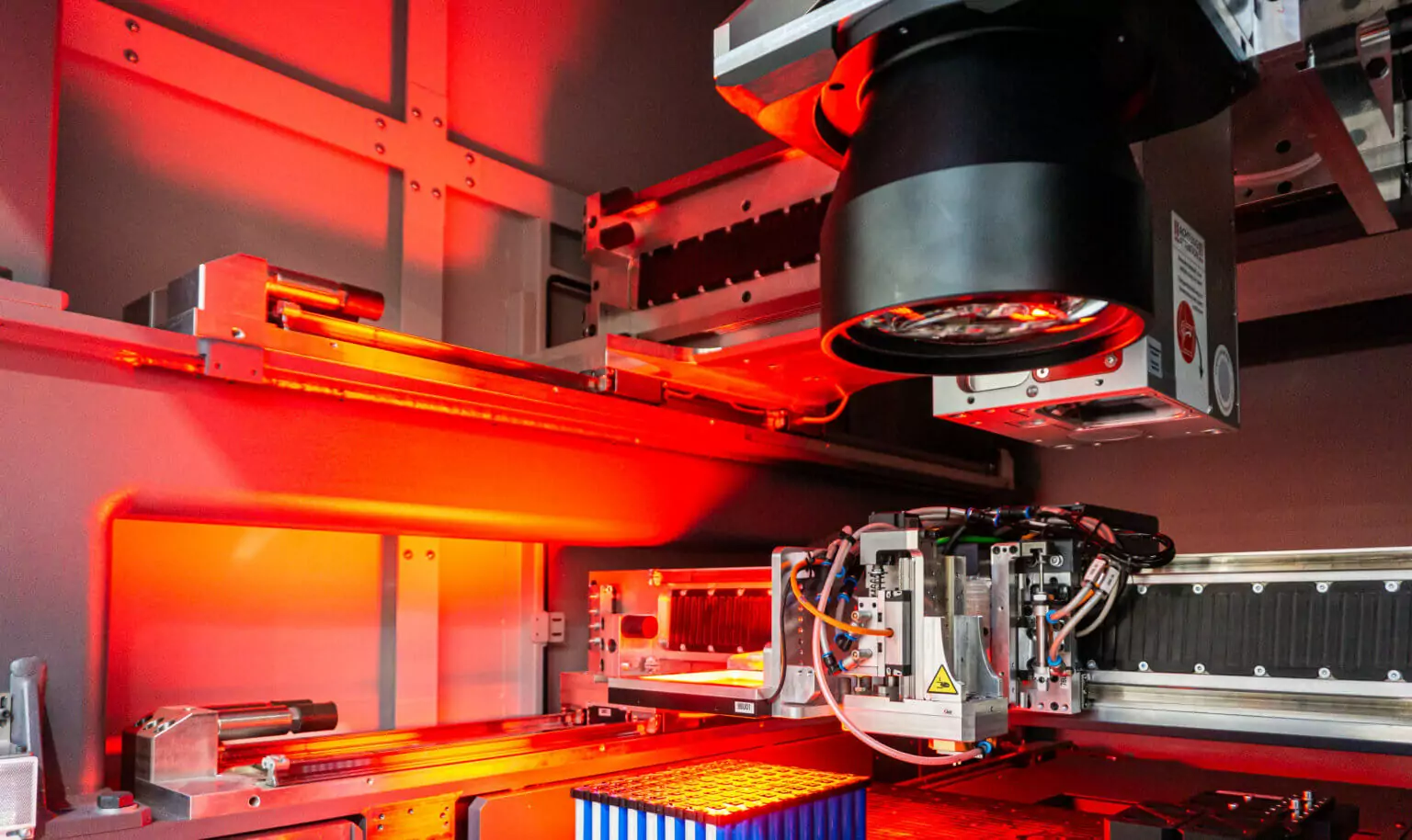

Laser Welding: Speed, Precision, and Market Dominance

Laser welding melts metal quickly and without contact or consumables, making it fast, precise, and low-maintenance. Adoption is booming, with fiber lasers handling copper, aluminum, nickel, and steel at high speed, and blue/green lasers improving copper/aluminum absorption and weld quality. Pulsed lasers give tight heat control, CW lasers maximize throughput, and brazing or wire-fed lasers let you join different metals or build thick busbars without brittle welds.

Choosing Based on Application and Scale

Internal electrode foils? Ultrasonic is your choice. Tab final welds on thick stacks? Laser wins. High-volume seam welding on prismatic cells? Fiber laser or blue laser for copper-heavy designs. Structural enclosure joints? RSW-bonding pairs speed with long-term durability.

Energy use per meter of weld, automation compatibility, and monitoring integration all shift the economics. Laser systems cost more upfront but cut out consumables and run faster. Resistance welding keeps capital low but adds ongoing electrode costs. Ultrasonic fits specific niches where nothing else works.

The best automatic welding machine for your battery line matches your material pairings, production volume, and quality needs—not the technology a vendor happens to sell.

Conclusion

Choosing the right welding machine isn’t about the newest tech—it’s about what fits your production, budget, and goals. Understand your needs, compare laser vs. resistance welding for speed, precision, and cost, and don’t rush—request demos, analyze bottlenecks, and talk to experts who know your battery type. Ready to boost your line? Contact us today to find the perfect welding system for your production!