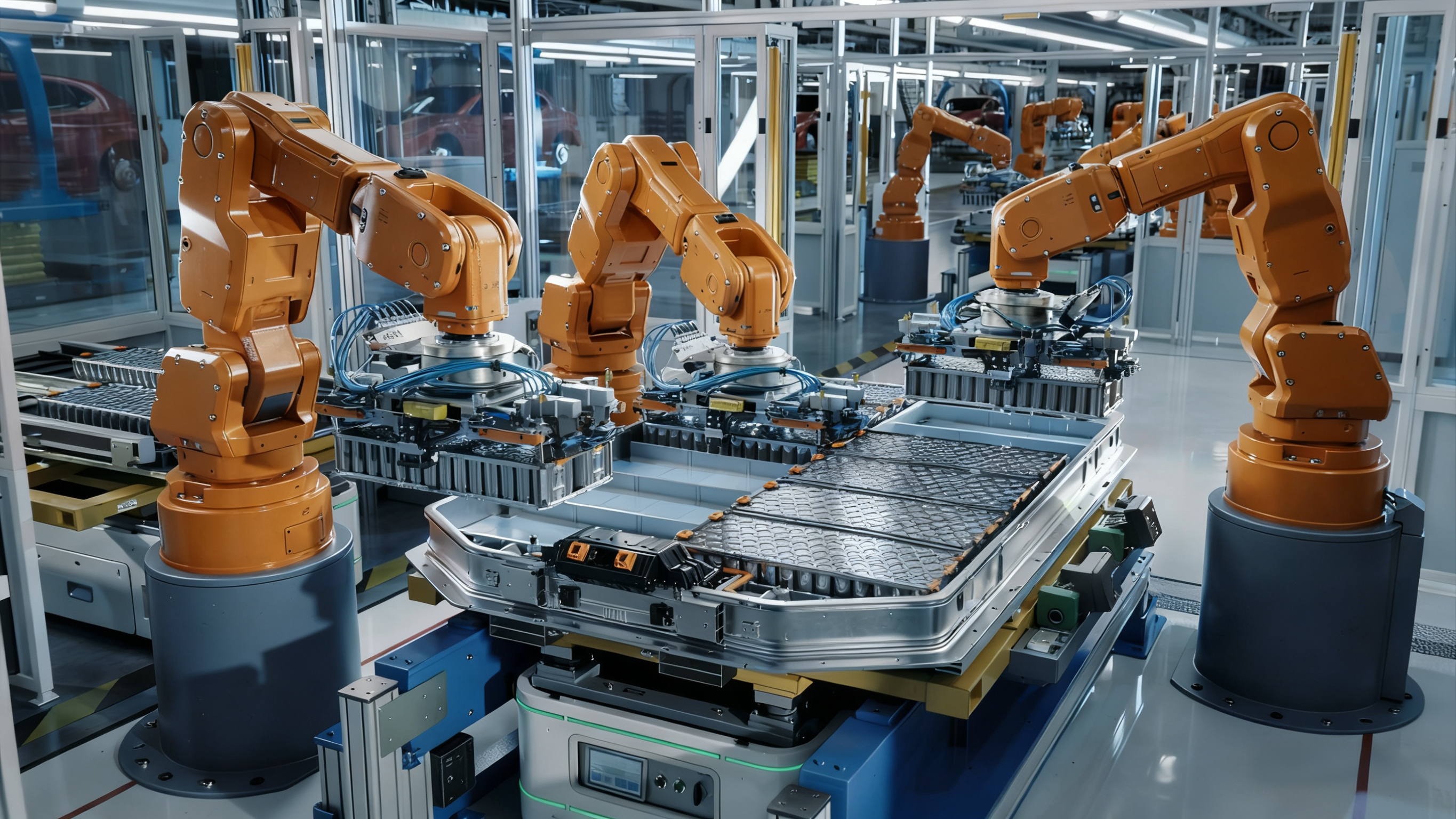

Imagine an automotive production line where hundreds of high-precision robots handle every task—from welding and assembly to moving heavy parts—without relying on manual labor. Every weld is flawless, every component is assembled in the optimal sequence, and production runs faster, more accurately, and more efficiently than ever before. In this article, we’ll dive into real-world cases to explore how industrial robot arms are transforming automotive manufacturing, turning traditional factories into smart, automated hubs of innovation.

Tesla – Fremont Factory Model 3 Body Production with Robot Arms

At Tesla’s Fremont Factory in California, industrial robots do the main work in producing Model 3 vehicles. The production line uses advanced robotic automation. I find this approach most effective for welding and putting together the car body.

Robotic Welding and Production System

Tesla employs advanced industrial robots throughout its vehicle production line to automate essential processes such as welding, joining, and handling heavy components. By integrating these modern robotic systems, the company significantly enhances production speed, precision, and overall efficiency.

Key Performance Metrics and Outcomes

- Robotic automation builds a Model 3 body in as little as 45 seconds per unit.

- Robots work at speeds that manual labor cannot match.

- Automation gives consistent build quality. It lets Tesla ramp up production without sacrificing standards.

Strategic Advantages

At Tesla’s Fremont Factory, robots play a crucial role in supporting mass production by maintaining exceptional precision throughout the manufacturing process. From my observation, this automation strategy enables Tesla to rapidly scale its operations, efficiently meeting the strong demand for the Model 3 while ensuring consistent quality and productivity.

Volkswagen – Zwickau Plant Full-Scale Automation with Robot Arms

I believe Volkswagen’s Zwickau plant in Germany sets a clear benchmark for industrial robot arm use in car making.

Wide Robotic Integration in Electric Vehicle Production

The factory operates with more than 1,700 industrial robots integrated into both the body shop and assembly lines, automating nearly every stage of electric vehicle production—from welding the car body to assembling the final components—ensuring a seamless and efficient manufacturing process.

Boosted Capacity and Efficiency

Automation has driven a significant increase in production capacity, which now reaches between 1,350 and 1,500 vehicles per day—an impressive improvement over previous levels that demonstrates the powerful impact of large-scale robot deployment on overall factory output. Moreover, automation has optimized labor allocation, allowing employees to concentrate on higher-value and more specialized tasks.

Quality Control and Sustainability Benefits

Robotic precision has greatly enhanced product quality and significantly reduced defects. From my analysis, Volkswagen’s adoption of automation has also minimized material waste across the production process—a crucial achievement as the company transitions toward electric vehicles and more sustainable manufacturing practices.

Ford – Kentucky Truck Plant Robotic Welding by Robot Arms

Ford’s Kentucky Truck Plant in Louisville uses robotic welding as the core of its truck body and chassis production.

Deployment of Robotic Welding Systems

The plant employs advanced robotic welding systems specifically engineered for heavy-duty truck bodies and chassis, taking over welding tasks that were once performed by manual workers or semi-automated machines, thereby enhancing efficiency and consistency in production.

Energy Efficiency and Performance Gains

Robotic automation has reduced energy consumption by 25% compared to older production methods, resulting in significant savings on operational costs. In my view, this approach is an effective way to lower overhead while simultaneously boosting production output.

Enhanced Weld Quality and Vehicle Reliability

Automation provides superior weld precision and uniformity, ensuring that each weld meets stringent quality standards. This leads to greater vehicle reliability and safety on the road, as robotics deliver consistent results, giving every truck body the same high-quality construction. From my perspective, this level of consistency is what distinguishes modern production methods from older approaches.

Key Takeaway

I view Ford’s adoption of robotic welding as a strategic decision that enhances both efficiency and product reliability on a large scale. From my observations, this approach serves as a strong example for the broader automotive industry.

Grupo Antolin – Burgos Plant AMR and Cobot Robot Arms Integration

Grupo Antolin’s Burgos plant in Spain uses advanced robotic arms. I’ve seen how this sets a new standard in automotive interior manufacturing. The plant uses OMRON LD-250 autonomous mobile robots (AMRs) and TM12 collaborative robots (cobots) for automated logistics and assembly.

Robotic Logistics and Assembly Automation

- OMRON LD-250 AMRs transport up to 250kg of plastic injection-molded interior parts. They move these parts from the injection area to assembly lines. No facility changes are needed. The robots use natural feature navigation.

- MaxWave FR20 cobot robots have integrated vision systems. They handle precision assembly, loading, and inspection. The cobots recognize patterns, colors, and objects. They work safely next to humans using advanced safety lasers.

- No safety fences are needed. Robots work close to operators. This enables efficient human-robot collaboration.

Key Benefits and Performance Outcomes

The intralogistics system is 100% automated, with robots handling all transfers of crafted parts, eliminating repetitive manual labor and reducing forklift traffic. This allows employees to take on more complex, higher-value roles, driving greater innovation and productivity. The system ensures continuous and reliable throughput, minimizing downtime and process bottlenecks, while digital workflow integration improves material traceability and reduces error rates. It also scales effectively to support future Manufacturing 4.0 objectives. Additionally, the automation brings sustainability benefits by lowering energy consumption and optimizing factory space through the reduction of redundant manual handling.

Expert Perspective

“Cobots and AMRs coexist. This makes the system independent. It connects the injection area to the assembly area. We achieve automation that replaces labor-intensive processes. Safety and efficiency increase.”

— Jaime Ruiz Alonso, Engineering Manager, Grupo Antolin

I recommend looking at Grupo Antolin’s use of integrated AMRs and cobots. It sets a real-world benchmark. This applies to robotic logistics, flexible automation, and the shift to the smart, digital factory.

Key Metrics Enhanced by Robotic Arms in Automotive Manufacturing

Robotics has changed car manufacturing. It brings real improvements across many core areas. I recommend looking at these key metrics. They show where industrial robots make the biggest impact in modern auto plants.

Production Throughput and Speed

Plants such as Volkswagen’s Zwickau facility demonstrate the power of full-scale robotic integration, achieving production capacities of 1,350–1,500 vehicles per day and highlighting how robotics enable factories to meet global demand. At Tesla’s Fremont plant, robotic lines assemble a Model 3 body every 45 seconds, with faster cycle times becoming the benchmark for leading factories as robotics automate and synchronize production processes.

Quality Improvement and Defect Reduction

Machine vision and AI technology integrated with robotics have reduced defect rates by up to 75% in critical welding and assembly processes. AI-driven quality control systems, such as the MaxWave FR20, can detect flaws smaller than 50 microns, ensuring that only top-quality parts move down the production line. Real-time robotic inspection and correction further increase first-pass yield while minimizing costly rework.

Operational Cost and Resource Efficiency

Ford plants utilizing robotic welding report a 25% reduction in energy consumption, thanks to improved motion control and precise process management, which lowers overall factory energy costs. In the U.S., automotive automation reduces total production expenses by 15–30% through decreased material waste, fewer errors, and more efficient use of assets. Reflecting this focus on efficiency, the global automotive robotics market is projected to reach $3.04 billion in 2025, underscoring the industry’s commitment to productivity and cost optimization.

Workforce Impact and Labor Redeployment

Plants such as Grupo Antolin leverage robots and autonomous mobile robots (AMRs) to automate material transfers, freeing workers from manual handling and allowing them to transition into skilled roles in support, supervision, and robotics maintenance. Facilities that use collaborative robots (cobots) have seen injury incidents in robotic work cells drop by up to 40%, while AMRs and cobots eliminate the need for manual heavy lifting, further reducing safety risks.