Choosing the right laser marking machine can make or break your production workflow. Industrial and small business models serve very different purposes, and picking the wrong one could slow you down or waste money. In this guide, I’ll break down the key differences in speed, power, versatility, and cost, helping you figure out which machine is perfect for your needs—whether you’re running a busy factory or a small workshop.

Brief Table: Industrial Vs Small Business Laser Marking Machines

| Feature | Industrial Machine | Small Business Machine |

| Price | $10,000 – $70,000+ | $1,200 – $5,000 |

| Best Use | Mass production, deep/traceable marks | Prototypes, small batches, personal use |

| Power & Speed | 20–100W+, up to 6000 mm/s | 3–20W, 300–2000 mm/s |

| Materials | Metals, plastics, glass, ceramics | Metals, wood, leather, acrylic |

| Work Area | Large, supports batch jobs | Small, for crafts/products |

| Features | Advanced automation, IoT, 3D marking | Basic, low automation |

| Durability | Long life, minimal downtime | Shorter life, more upkeep |

| ROI | High upfront, strong long-term savings | Low cost, easy start |

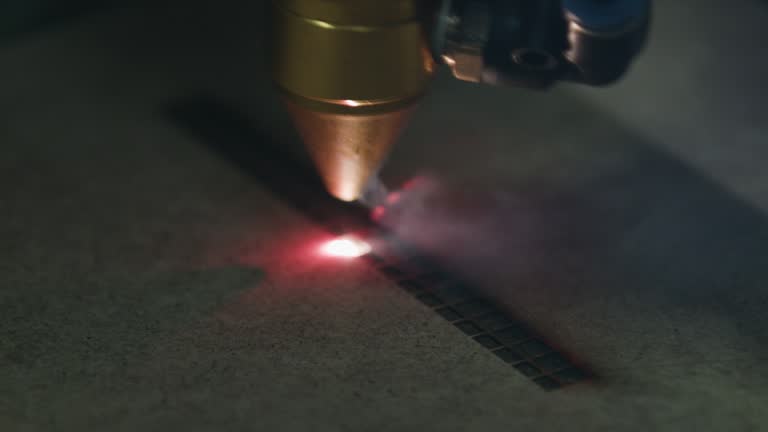

Industrial Vs Small Business Laser Marking Machines Core Difference 1: Power Output and Marking Speed

From my experience, when you’re deciding between an industrial and a small business laser marker, the two most important things to compare are power output and marking speed.

Power Output: Industrial vs. Small Business

Industrial Laser Marking Machines

– Their typical power output is 30W, 50W, 75W, or 100W using fiber lasers.

– This high energy is great for a few things:

– It allows for deep engraving on tough materials. This includes stainless steel, titanium, and tool steel.

– It also creates permanent, clear marks required by demanding global industries.

– For example, a 50W fiber laser can engrave deep, readable marks in seconds. I find this ideal for parts used in harsh conditions.

Small Business Laser Marking Machines

– I’ve seen these typically come with 10W or 20W fiber lasers.

– Here’s what that means for you:

– They have lower energy. I’d suggest them for marking on a surface or for light engraving (no deeper than 0.2mm).

– They are well-suited for metals, simple barcodes, plastic tags, and putting logos on products.

– In my opinion, these are perfect for startups, light craft work, and short production runs.

Marking Speed & Application Scenarios

Industrial Laser Marking Machines

Industrial machines deliver marking speeds up to 3,000 mm/s (900+ m/min) with advanced optics, offering high throughput that allows multiple parts or lines to be marked within seconds. They are widely used in automotive, aerospace, and large-scale electronics production.

Small Business Laser Marking Machines

Small business machines reach speeds of up to 900 m/min, making them better suited for customization, single items, or small batches. I recommend them for promotional items, retail signs, nameplates, and other small-scale products.At-a-Glance Comparison Table

At-a-Glance Comparison Table

| Feature | Industrial Laser (50W+) | Small Business Laser (10-20W) |

| Power Output | 30W, 50W, 75W, 100W or higher | 10W, 20W |

| Typical Marking Speed | Up to 3,000 mm/sec or 900+ m/min | Up to 900 m/min |

| Engraving Depth | Medium to deep | Shallow (≤0.2mm) |

| Application Focus | Deep, durable marks for heavy industry | Surface marks for crafts, promo, retail |

| Example Industries | Automotive, Aerospace, Steel | Promotional items, light crafts |

Which Should You Choose?

For simple, cost-effective marking needs that you only do occasionally, a small business laser is a great choice. It provides enough speed and flexibility without the large investment.

I suggest you go with an industrial laser if you need fast, deep, and durable marks. This is the right choice for high-volume production or for parts in harsh environments.

Industrial Vs Small Business Laser Marking Machines Core Difference 2: Production Volume and How Often It Can Run

Looking at production volume and duty cycles, you can see a big difference between industrial and small business laser engravers. In my opinion, this is where the distinction is most clear.

Industrial Laser Marking Machines: My Take on High-Volume and 24/7 Work

From my experience, industrial laser marking machines are built for non-stop, high-volume work. I’ve seen them perform perfectly in places where you can’t afford to stop, such as the automotive, electronics, medical, aerospace, and defense industries.

Industrial laser marking machines are built for 24/7 operation, delivering millions of marks per year with 10–100W laser sources and components lasting up to 100,000 hours. Permanently installed on production lines, they ensure high speed, reliability, and minimal downtime, while requiring little human intervention—often running for years without major service.

Real-World Example:

A factory making electronic components might use a 50W fiber laser engraver. I’ve seen these mark over 10,000 pieces per day, every day. Because it’s so tough, major service is needed only after years of continuous use.

Small Business Laser Marking Machines: My View on Flexibility and Lighter Use

I find that small business laser markers are different. They are made for low to medium production. They are not intended for constant, all-day operation.

Desktop and portable laser marking machines are great for workshops and small shops, offering easy setup and quick custom jobs. However, with lower power (10–30W), they’re best for lighter workloads—dozens or hundreds of parts per week, not continuous 24/7 use. They also need regular care, including cool-down periods and servicing, to avoid overheating or faster wear.

Example Use Case:

A custom gift shop could use a 20W desktop laser marker for a few hours each day. This would let them produce personalized items in small groups. The initial cost is much lower, but I believe these systems are best for light to medium jobs.

Duty Cycle and Volume Comparison Table

| Feature | Industrial Laser Marking | Small Business Laser Marking |

| Duty Cycle | 24/7, non-stop operation | A few hours each day |

| Typical Annual Volume | Millions of parts | Dozens to hundreds/week |

| Maintenance | Minimal, service every few years | Manual, needs more attention |

| Power/Lifespan | 10–100W, up to 100,000 hours | <10–30W, shorter lifespan |

| Best for | Mass production, automation | Custom work, startups, flexibility |

My Recommendations for Your Needs

- I recommend an industrial-grade laser marking machine if you need top productivity. It is your best choice if you plan to operate all day, every day. It delivers the toughness, speed, and consistency your production line requires.

- If you prefer flexibility, have lower output needs, or want a lower starting cost, I think a desktop or portable machine is a great fit. Just be aware that you will get lower output and cannot run it non-stop.

Industrial Vs Small Business Laser Marking Machines Core Difference 3: Operator Skill and Software Complexity

In my experience, there’s a big difference in the skills needed for industrial versus small business laser engraving machines. This gap affects your training costs, hiring, and your shop’s daily workflow.

Operator Skill Requirements: Industrial vs Small Business

Industrial Laser Marking Machines: Operating industrial laser marking machines requires 2–5 years of experience, strong CAD/software skills (e.g., SolidWorks), and the ability to read blueprints, calibrate machines, and solve technical issues quickly. Operators must also follow strict safety rules and keep up with continuous training as systems evolve.

Small Business Laser Marking Machines: Operating small business or desktop laser marking machines requires minimal technical experience, often learnable in a day. They use easy software with built-in templates, so operators mainly handle basic setup, material selection, and routine tasks. Little to no programming or CAD skills are needed, and training focuses on simple operation and problem-solving.

Work and Responsibilities

- Industrial Machines: Operators change laser focal points based on job requirements. They handle complex program uploads. They also calibrate equipment for large batches and do detailed inspections.

- Small Business Machines: An operator’s main task is loading items and choosing a template. They verify the settings and start the job. I believe these systems are perfect for staff without a deep technical background.

Key Skill Comparison

| Requirement | Industrial Operator | Small Business Operator |

| Experience Needed | 2–5 years, advanced technical and software skills | As little as 1 year, basic training |

| Software Complexity | Advanced (CAD, custom programming, specialized controls) | Simple (touchscreens, presets) |

| Troubleshooting | Extensive, multi-level | Basic, limited scope |

| Technical Reading | Blueprints, schematics | Follows user manual/instructions |

| Maintenance & Setup | Multi-step, regular, complex | Quick setup, minimal maintenance |

| Safety Practices | Strict, monitored | General safety awareness |

| Training Time | Weeks–months, ongoing refreshers | One day or less |

Main Takeaway:

Here is my recommendation. If your business runs high-precision, automated production, you should hire experienced technicians. Be prepared to invest in ongoing training for your industrial laser machine. For custom jobs, small batches, or shops with less technical staff, I suggest a small business laser system. They are easy to use with simple interfaces and have almost no skill barrier. Matching the operator’s skills to your production needs will result in fewer errors, lower training costs, and better productivity.

Summary

At the end of the day, the best laser marking machine is the one that fits your workload, budget, and goals. For high-volume production, deep engraving, and industrial reliability, an industrial system is a long-term investment that pays off. For smaller batches, prototypes, or custom projects, a small business or desktop machine delivers fast setup, low maintenance, and excellent value. Choose wisely, and you’ll get a tool that not only marks your products but also powers your business growth. Ready to learn more? Contact us now for expert advice on laser engraving machines.