I’ve often wondered if we can keep surfaces spotless without harming our planet. I’ve noticed that with new, tougher rules and more people caring about the earth, companies are looking for cleaning methods that are safer and greener. In my opinion, this major switch to chemical-free laser cleaning is not just about shiny results. I believe it helps companies cut waste, spend less, and improve safety. But I think there’s one important impact most people still miss…

Laser Cleaning with Chemical-Free Operation

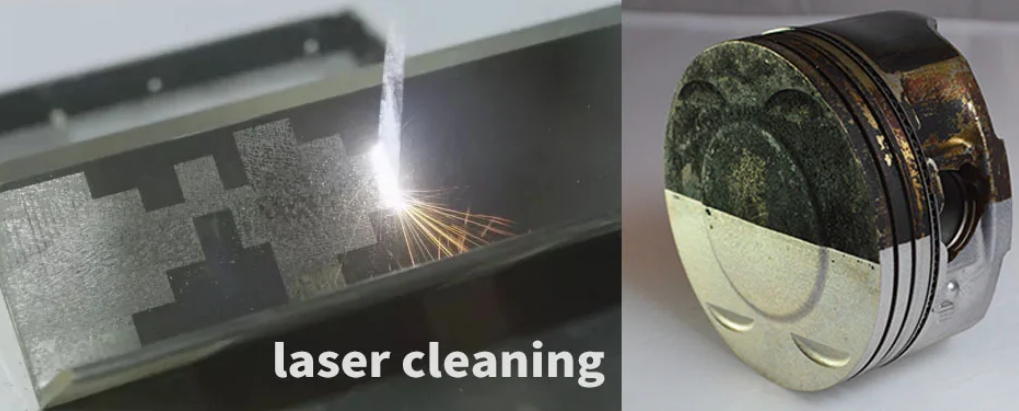

I find laser cleaning impressive because it’s a chemical-free cleaning method. This means it doesn’t use the toxic solvents and detergents that I often see in older surface cleaning ways. I like that instead of chemicals, laser cleaning uses focused, strong light pulses. These pulses remove things like rust, grease, paint, and varnish. This process is called laser ablation. The unwanted materials either turn into vapor or break away from the surface. I appreciate that this leaves the main material safe and undamaged.

Environmental and Workplace Advantages

From my perspective, the benefits for the environment and workplace are clear:

– Zero toxic residues: I think it’s great that it produces no dangerous byproducts. This means you don’t have to worry about neutralizing, collecting, or getting rid of chemical waste.

– No chemical runoff: Because it eliminates chemical use, laser cleaning stops pollution of soil and water. I believe this is vital for places with strict environmental rules.

– Worker safety improved: I am pleased that with no harmful fumes or splashes, there’s less risk of chemical burns or exposure. Operators can work more comfortably, without needing heavy protective gear or intense ventilation systems.

– Lower compliance and disposal costs: I’ve noticed companies save money. They face fewer costs from environmental safety rules. This can really cut down total cleaning expenses over time.

Industry Use Cases

I see that industries needing extreme cleanliness, like aerospace and microelectronics, truly appreciate laser cleaning. Why? Because it leaves no residue. Even a tiny bit of chemical residue can spoil product quality. So, I recommend laser surface preparation and restoration; they are essential solutions in these fields.

I believe that because it offers eco-friendly cleaning and makes workplaces safer, chemical-free laser cleaning is setting a new standard. It’s becoming the go-to for sustainable and efficient work.

Laser Cleaning: Less Waste, More Efficiency

I find that laser cleaning really shines in cutting down waste and using resources better. Traditional methods often need extra materials. Laser cleaning, in my experience, doesn’t. It is media-free. This means no extra stuff like grit or chemicals to manage or throw away. So, you don’t have the typical waste or storage problems you get with older cleaning ways.

Energy Savings and Emission Reduction

I’ve noticed laser cleaning uses less energy. Why? Because you’re not moving or getting rid of lots of cleaning agents or hazardous waste. This also means a big reduction in CO2 emissions, which I think is a great benefit. When industries use laser cleaning, I see their operations get cleaner. They also support global efforts for sustainability.

High Processing Speeds and Industrial Efficiency

The laser cleaning machine offers extremely high processing speeds, quickly removing surface dirt, rust, and coatings, significantly improving industrial cleaning efficiency. With its precision and power, it can clean large areas in a fraction of the time required by traditional methods. For example, laser cleaning can reduce cleaning time by up to 70% compared to manual or chemical cleaning processes, leading to less downtime and higher throughput in production environments. This makes it an ideal solution for industries that require fast, effective, and environmentally-friendly cleaning.

Adoption in Key Industries

I find that the waste-free nature of laser cleaning is important for sectors that need precision and want minimal impact on the environment. In 2023, the automotive industry was a leader. It accounted for 45% of the total laser cleaning market revenue. I think this shows that industries serious about both efficiency and waste reduction are choosing laser solutions.

Market Growth and Sustainability Trends

The global market for laser cleaning is growing because of these advantages, in my view. In 2023, its value was USD 0.66 billion. I see it’s projected to grow to USD 1.15 billion by 2032. That’s a growth rate (CAGR) of 6.36%. I believe this growth happens because industries are focusing more on environmental sustainability. They are also using smart manufacturing practices like Industry 4.0.

Manufacturers can see measurable cost benefits. They’ll have lower non-quality costs and use resources better. I suggest this encourages more adoption of this clean and sustainable technology.

Laser Cleaning in Industry Applications and Sustainability

I see laser cleaning technology offering big sustainability benefits in many industries. It’s changing how we approach surface cleaning. To me, it’s a precise, green alternative to old cleaning methods. It gives clear environmental and operational pluses.

Key Sustainability Advantages in Industrial Use

Water Conservation: I’ve observed that older wet cleaning processes can use about 165 kg of water to remove just 1 kg of contaminant. Laser cleaning, in contrast, uses no water. From my perspective, this saves a large amount of water in every application.

Waste Reduction: I know that chemical cleaning produces about 9 kg of waste for each 1 kg of contaminant taken out. Grit blasting makes around 4 kg of solid waste. With laser cleaning, you only get the removed material. There are no extra waste streams or other kinds of contamination, which I think is a big plus.

Energy Efficiency: I’ve found that laser cleaning systems often use far less electrical energy than other industrial cleaning methods. Sometimes, they use up to seven times less. This is a considerable saving, in my view.

Industry-Specific Benefits

Manufacturing and Automotive: I’m impressed that laser systems can degrease or clean a metal surface the size of standard printer paper in only 0.2 seconds. This means they can cover over 1,200 square meters per hour. I believe this leads to faster work, lower costs, and better sustainability.

Food Processing: In the food and beverage industry, I see laser cleaning as valuable. It can get rid of bacteria and viruses. This creates a clean result with no chemical traces left.

Hazardous Environments: For industries like nuclear power or places with radioactive materials, they use remote-controlled laser cleaning. I think this cuts the risk to workers. It helps keep them away from dangerous stuff and unsafe areas.

Laser Cleaning Adoption in Major Sectors

I notice several industries are now switching to or using more laser cleaning. These include:

– Steelwork

– Food production and processing

– Naval and defense sectors

– Railway and transportation maintenance

– Automotive manufacturing and bodywork

– Packaging and footwear production

– Building and construction

Elimination of Environmental Impact

From my experience, laser cleaning means you no longer need:

– To buy chemicals or handle them on your site.

– Water cleaning plants and the costs to run them.

– Treating and disposing of wastewater.

– Air pollution, due to active filters and fume vents.

– To use dry ice. Dry ice makes greenhouse gases and is bad for people’s health.

By switching to laser cleaning, companies can quickly achieve sustainability goals more effectively. They get excellent cleaning results without consumables, while also reducing waste and emissions. To me, this is a major step forward for greener and more cost-efficient industrial operations.

Summary

Looking at the future, I see laser cleaning as a major step for industries wanting to be more eco-friendly. I feel this is a very significant development. I personally care a great deal about protecting our planet while also making sure businesses run well. That’s why I’m so pleased with this technology. It avoids using chemicals and still achieves excellent cleaning. Many different industries are starting to use it.

For me, this demonstrates that we can run cleaner businesses effectively, without sacrificing quality. I believe this development is more than just a new cleaning method. It’s actually changing how we approach industrial work. It proves that we can be environmentally responsible and productive at the same time. Based on what I’ve seen, this is a very positive direction. For more details about laser cleaning machine or to get a quote, contact us today!

Recent Comments