I often think about how factories clean their tools. How do they ensure their tools are spotless and also care for our planet? I’ve learned that laser cleaning offers a great answer. Industries can stop using strong chemicals. They don’t need to scrub hard anymore. Laser cleaning is a modern way. It’s gentle on molds. It’s also good for our earth. I find this impressive. When molds are cleaner, the products made are better. Plus, factories don’t have to stop work as often. I see this as a clear benefit for everyone, don’t you? But I think there’s a key benefit of this technology. People often overlook this important point…

How Laser Cleaning Restores Industrial Molds Safely

I’ve seen laser cleaning change how we care for industrial molds. It’s different from rough blasting, chemicals, or ultrasonic ways. Laser cleaning uses controlled energy. This energy turns surface dirt into vapor. The mold stays safe. I find this method works on tough residues. This includes grease, various additives, colorants, lubricants, rubber, plastic, rust, and oxidation. This is key for industries that need exact parts without flaws.

Real-World Benefits I See with Laser Mold Cleaning

Longer Mold Life: Laser cleaning is non-abrasive. Based on my experience, it keeps mold details and exact shapes safe. This helps molds keep their original quality. Their useful life gets much longer.

Better Product Quality: When molds are always clean, I see production cycles make top-quality parts without errors.

Less Production Down Time: Cleaning is fast. Molds don’t need to cool down. There are no long prep steps. So, production lines keep running. We can even spot-clean. This means just the dirty spots get cleaned. This really helps keep things running.

Cost and Environmental Thoughts

Laser cleaning offers big cost savings, as factories no longer need to buy chemicals or blasting materials, and equipment lasts longer with less maintenance and waste disposal. It’s also good for the environment—producing no harmful waste, using no water, and eliminating chemical runoff, which reduces environmental impact and avoids strict handling regulations.

Examples from Industry

- For plastic injection molding, I’ve noticed laser cleaning can keep smaller molds with many details very clean. There’s no risk of scratching the surface or wear over time, like with old methods.

- In the rubber industry, I know companies have less downtime. Molds don’t need long cool-down and heat-up times anymore, which I think is a great advantage. Cleaning specific parts means fewer complete stops. This helps produce more.

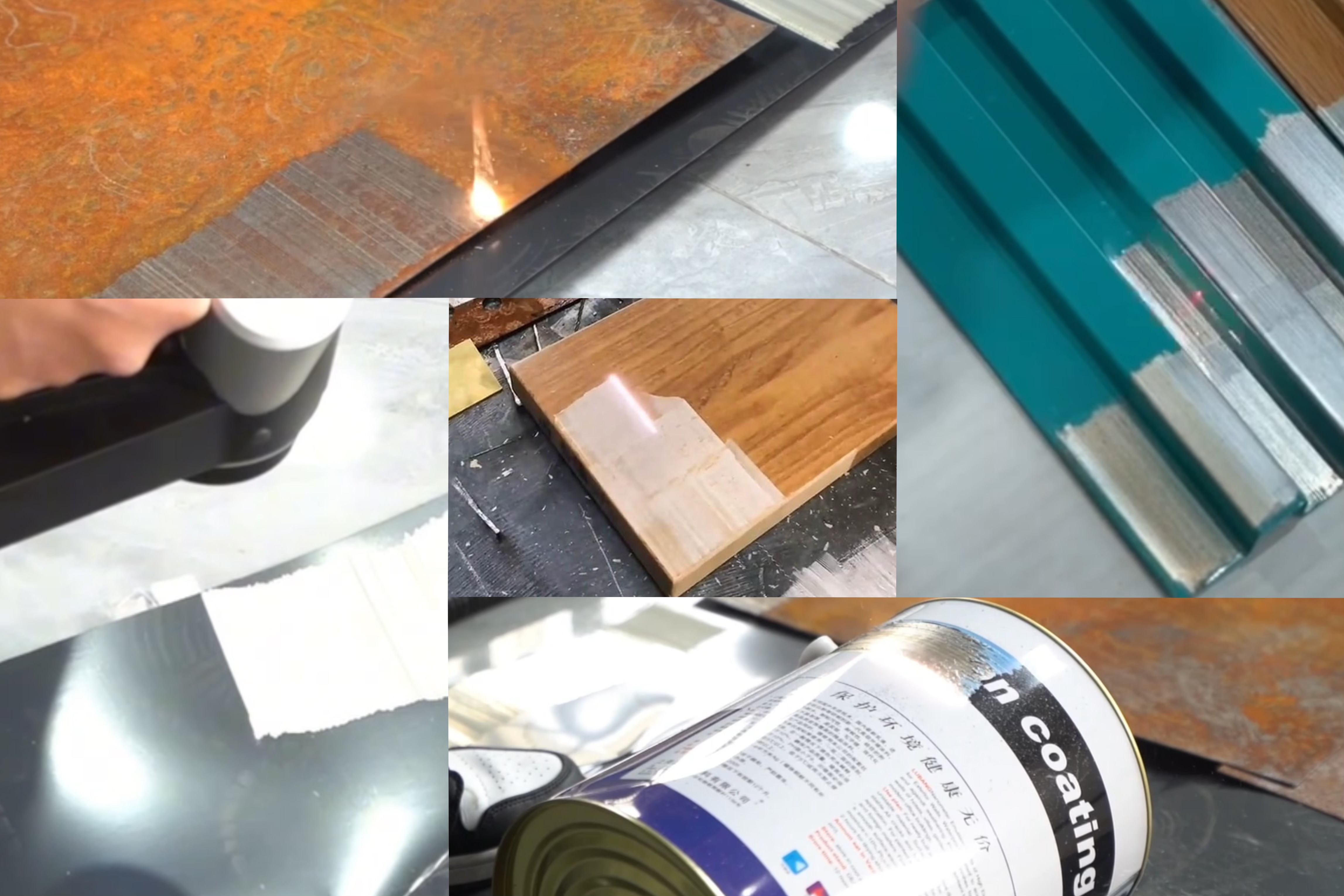

Real Results: How Laser Cleaning Transforms Industrial Mold Restoration

From my experience in industrial settings, laser cleaning effectively restores molds without causing harm. I want to show you some before-and-after examples. These cases reveal how this technology improves mold cleaning, boosts work speed, and lowers expenses.

Injection Mold Restoration: Gentle Cleaning That Works

In injection molding shops, mold buildup from additives, colorants, and lubricants is a common issue. Traditional cleaning methods, which often involve scraping, can wear down molds and shorten their lifespan. With laser cleaning, operators can remove stubborn grime without damaging the mold surface, helping molds last longer.

The result is higher product quality, faster cleaning with no waiting for cooling or heating, and less downtime. Factories also save on maintenance, supplies, and waste disposal, making laser cleaning a cost-effective solution.

Heavy Machinery: Fixing Crankshafts

Heavy parts like crankshafts often accumulate buildup and rust, and traditional cleaning methods can be rough, risking damage and increasing costs. I recommend using targeted laser ablation, which is precise and fast. Operators have found it so effective that they often remark they’ve “cranked out another one.” This method restores parts while preserving their exact shape, speeds up the cleaning process, and ultimately saves money.

Why I Prefer Laser Cleaning Over Old Methods: Real Benefits

Safer for People and Planet: I like that laser cleaning uses no chemicals or rough materials. This means no dangerous waste to deal with and fewer rules to follow.

How it Affects Operations: From my perspective, automatic laser cycles need fewer workers. Plus, the cleaning processes can run almost all the time without stopping.

Return on Investment (ROI): I’ve seen that buying laser cleaning equipment pays for itself fast. This is because it costs less to run and makes the whole process work better.

It’s Not Just for Molds: Other Uses I’ve Seen

Example: Fixing Steel Beams: I learned about a test project. The Connecticut Department of Transportation used laser cleaning. They removed rust and dirt from the ends of steel beams. This project showed me something important. Laser cleaning works well for many industrial jobs, not just molds. It can even handle big items like parts of buildings or bridges.

Keywords I Focused On: My discussion covered important terms. These include: laser cleaning, industrial mold restoration, mold cleaning, operational efficiency, and non-abrasive cleaning. I also focused on contaminant removal, precision cleaning, reduced downtime, and cost savings. You’ll find information on: before and after scenarios, traditional methods versus laser cleaning, and programmable cleaning cycles. Other key terms are surface integrity, manufacturing efficiency, heavy machinery restoration, and eco-friendly cleaning technology.

Laser Cleaning: Non-Destructive Mold Restoration

In my experience, laser cleaning is a superior non-damaging way to restore industrial molds. It effectively protects the shape and function of your expensive tools. Unlike older methods I’ve seen—like abrasive blasting, ultrasonic cleaning, or harsh chemical washes—laser cleaning is a no-contact process. It uses focused energy to remove unwanted materials. I believe this is key because it keeps the original mold surface untouched and free from damage.

Precision Cleaning That Preserves Value

This technology uses incredibly fast laser pulses—we’re talking nanosecond-level speed. From what I’ve observed, these pulses are strong. They can vaporize grease, rust, various additives, and layers of oxidation. However, they are also gentle. They don’t heat or wear down the mold’s structure. I think this precision is remarkable. It means even the smallest etchings and detailed patterns on your mold stay crisp and just like new, cleaning after cleaning.

Advantages of Non-Abrasive Mold Restoration:

- No Mechanical Wear: You don’t have to worry about scratches, thinning, or distortion of the mold surface. This is because nothing actually touches the metal.

- No Loss of Mold Detail: I find it crucial that important, tiny details needed for top-quality products are kept safe. This helps the mold last longer.

- Elimination of Subsurface Damage: The laser energy focuses on surface dirt. So, in my opinion, there’s no danger of hidden cracks or stress developing inside the mold.

- Temperature Safety: What’s really convenient, I think, is that you can clean the mold while it’s still warm. You don’t need long cool-down or re-heating times. This keeps things running efficiently and also cuts down on wear.

Why Non-Destructive Cleaning Matters

I know that molds can be very expensive, often costing hundreds of thousands of dollars. This is common in industries such as injection molding and die-casting. From my experience, even a small loss of detail or slight distortion can lead to lost production time, faulty products, or expensive retooling. This is why I recommend a gentle, precise method like laser cleaning. It protects the mold’s surface finish and its exact dimensions. This means factories can produce high-quality items consistently, run after run.

From my direct observations:

- I’ve seen that molds cleaned with lasers keep their original shape and fine details much longer compared to those cleaned with older mechanical or chemical ways.

- Companies tell me they have much less downtime. Molds can stay on the production line. They don’t need long periods of taking them apart or checking for damage after cleaning.

- I also believe the environmental benefit is huge. The impact is much smaller and running costs are lower. This is because you don’t use up any chemical agents or abrasive stuff.

Enhanced Operational Lifespan and Quality

I suggest that because laser cleaning avoids wearing down the surface or using harsh chemicals, molds of all sizes can make highly precise parts for more production cycles. I have seen reports where companies saved a lot of money. They did this by putting off or not needing expensive mold repairs or new molds altogether.

SEO keywords covered: non-destructive cleaning, mold integrity, laser cleaning, industrial mold restoration, non-abrasive, surface preservation, precision mold cleaning, operational efficiency, safeguarding mold surface, injection mold cleaning.

Summary

Working in industrial mold restoration for years, I’ve seen laser cleaning technology bring big changes to manufacturing. Based on my experience, this technology is a true step forward. I believe it’s more than just cleaner molds. It means a more sustainable future for industry. From what I’ve observed, this method gets rid of harmful chemicals. It also cuts down on waste and makes equipment last longer.

I suggest these benefits create healthier workplaces and protect our environment. Looking to the future, I’m excited. I expect this technology will continue to improve. This will make manufacturing both more efficient and more responsible, in my opinion. I think the way for industry to become sustainable is clear. Laser cleaning is leading us in that direction. For more details about laser cleaning machine or to get a quote, contact us today!