Thinking about buying a laser cleaning machine but overwhelmed by the price range? You’re not alone. From compact $3,000 entry-level models to robust $30,000+ industrial-grade systems, the cost differences can be staggering. But what exactly do you get at each price point? And more importantly—what do you really need for your workshop or business? In this guide, we break down the real-world differences between entry-level and industrial laser cleaning machines, so you can make a smart, cost-effective decision without sacrificing performance.

| Item | Entry-Level Laser Cleaning Machine | Industrial Laser Cleaning Machine |

| Power Range | 100W – 300W | 500W – 2000W and above |

| Price Range | $2,500 – $7,500 | $15,000 – $60,000+ |

| Cooling | Mainly air-cooled | Water-cooled or hybrid (water + air) |

| Portability | Lightweight, handheld or backpack | Usually heavy, fixed installation |

| Ease of Use | Simple, beginner-friendly | Complex, requires professional training |

| Typical Uses | Light rust removal, fine cleaning, small workshops | Large industrial lines, heavy rust removal, continuous operation |

| Maintenance Cost | Low | Higher |

What is an Entry-Level Laser Cleaning Machine?

What is an Entry-Level Laser Cleaning Machine?

Based on my experience, an entry-level laser cleaning machine is a small, easy-to-carry machine. I think it’s a great fit for small businesses, first-time buyers, or anyone with occasional cleaning tasks. These machines are simple to use, light, and don’t cost a lot. This gives you access to advanced laser cleaning without a huge investment.

Key Specifications and Features

- Laser Power Range: Most of these models have a 100W to 200W pulsed laser output. I find this provides plenty of power for daily cleaning tasks. It also keeps the surface safe from damage.

- Laser Source: They often use a Yb-doped fiber laser. In my opinion, this delivers very reliable and effective cleaning performance.

- Energy per Pulse: The output can go up to 1.5 mJ per pulse. This power level is perfect for detailed cleaning jobs and for use on delicate materials.

- Scan Patterns & Adjustability: I like that these laser cleaning machines support up to 8 scan patterns that you can customize. You can adjust the laser power from 10% to 100% on a simple touchscreen. This is very helpful for people who are new to laser tools.

- Cooling System: Air cooling is the standard. I believe this makes the machine simpler, saves space, and means less maintenance for you compared to water-cooled systems.

- Voltage Compatibility: With a wide input range of 110–240V, you can use these cleaners in most places around the world.

- Ergonomics & Portability: The tool itself is handheld, shockproof, and drop-resistant. Many are built like a backpack or suitcase, which makes them easy to carry. This is great for mobile work.

- Accessory Kit: When you buy one, it usually includes the laser head, nozzles, and safety goggles. This means you have everything you need to start right away.

Typical Applications

Removing rust from metal surfaces, like you would find in a car repair shop.

Stripping paint from small items or precision parts.

Cleaning surfaces for electronics repair, home appliances, and kitchen items.

Cleaning small spots in factories, on pipes, or in places that are hard to reach.

Advantages of Entry-Level Laser Cleaners

Surface Friendly: The cleaning process doesn’t touch the surface, which reduces damage. I suggest it for sensitive or valuable surfaces.

High Precision: It lets you aim at specific spots. This prevents damage to the surrounding area.

Eco-Friendly: You use no chemicals and create little waste. It’s safe for many different work areas.

User-Centric Design: From my perspective, these are easy to operate. Just plug it in and start. The maintenance is also very simple.

Cost-Effective: The price is much lower than industrial laser cleaners. I believe it’s a perfect choice for someone on a budget or for jobs that don’t come up every day.

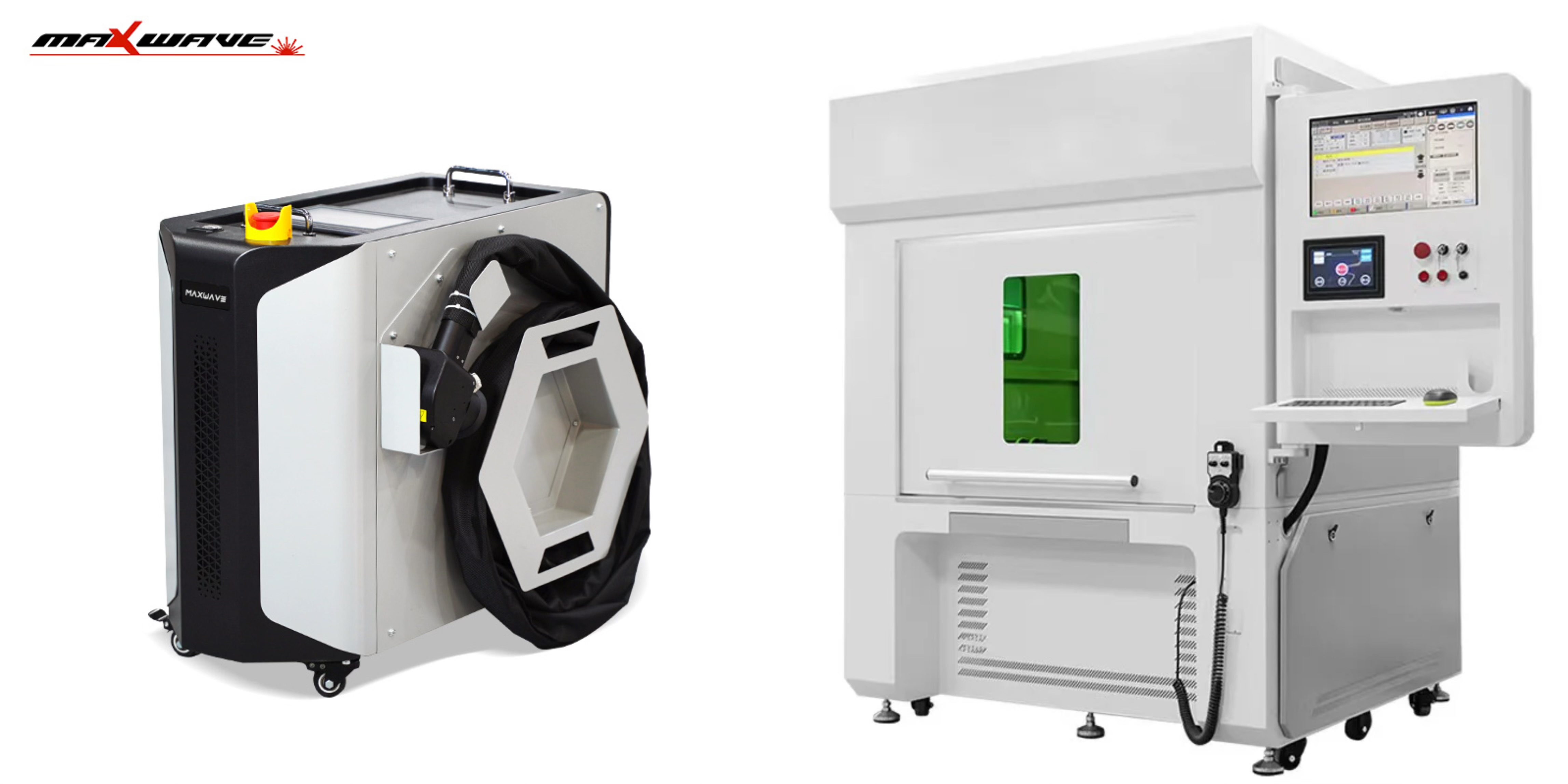

Example Models and Comparison

– UniLaser 200W: A backpack/trolley-style 200W air-cooled unit, great for car repairs, pipe cleaning, and fine surface finishing.

– STYLECNC LCP100–300: Handheld air-cooled models (100–300W) ideal for rust, paint removal, and use in electronics or aviation.

– iGCL: Entry-level handheld laser cleaning machine with air cooling, perfect for spot rust removal and precision surface tasks.

Typical Price Range

Entry-level laser cleaning machines typically cost between $2,500 and $7,500, depending on power and features. They are ideal for light rust removal and small cleaning tasks, offering good value for startups and small workshops.

Who Should Choose an Entry-Level Laser Cleaner?

So who should buy one? I recommend them for maintenance workshops, mobile repair crews, and individual tradespeople. They are also great for businesses that want a flexible, effective, and affordable cleaning tool without needing a large facility.

What is an Industrial Laser Cleaning Machine?

From my perspective, an industrial laser cleaner machine is a powerful, no-touch cleaning tool. It’s built for tough jobs in places like factories, shipyards, and car plants. These systems use strong laser beams to clean surfaces. They can remove rust, paint, grease, and even hazardous materials from metal.

Key Specifications and Powerful Features

- Power Output: I see that industrial laser cleaning machines start at 100W and can go up to several kilowatts. This high power is great for quickly stripping thick layers from large areas.

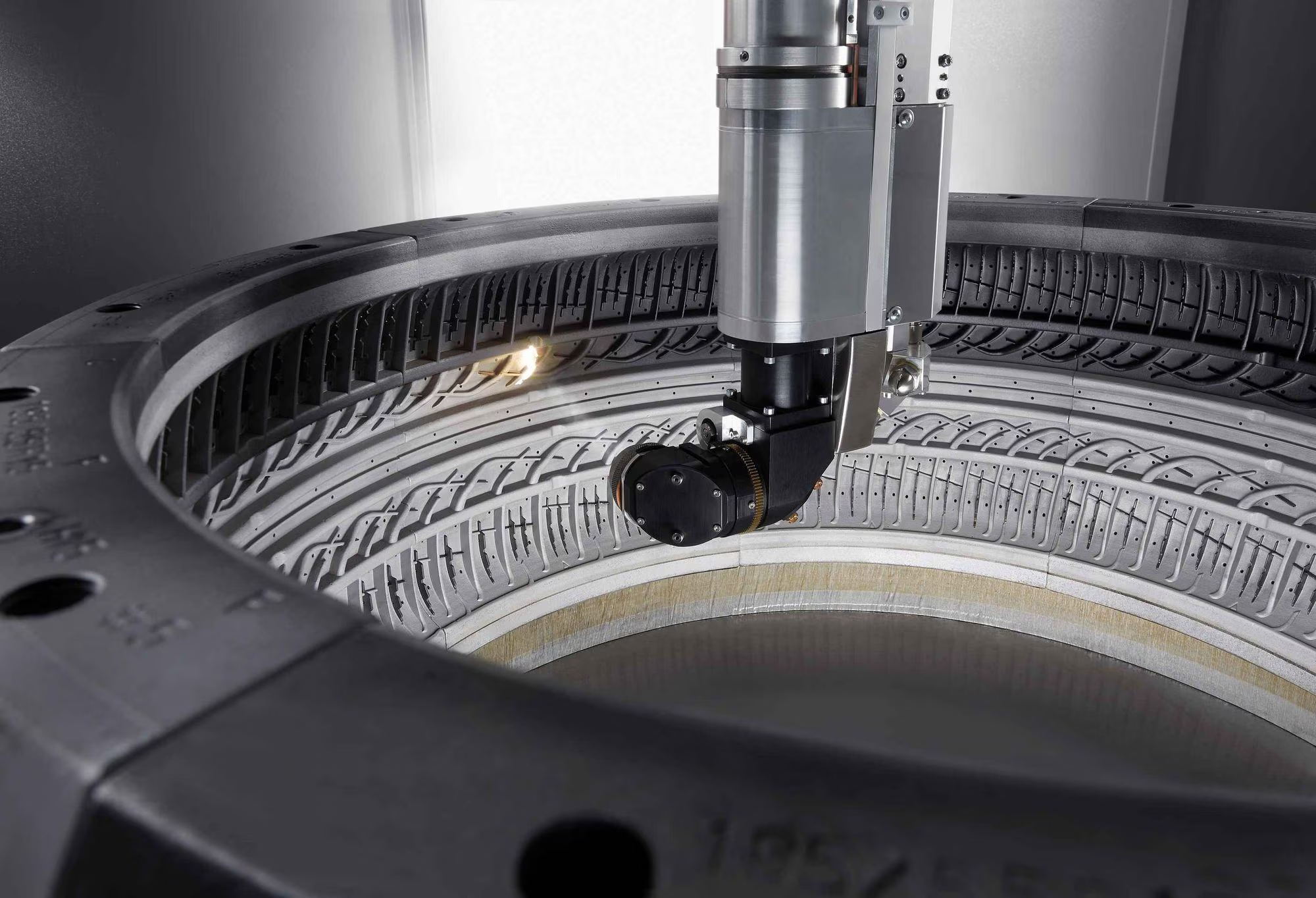

- Coverage: These systems use special scanning optics. You can also automate them with robots. They clean wide areas effectively, which I find perfect for things like ship hulls or big machinery.

- Control Systems: I recommend you look for features like touch-screen controls and real-time adjustments. Many also offer data logging and remote monitoring, which helps them fit into modern factories.

- Durability & Safety: These laser cleaning machines are built for heavy use. They have overheat protection, strong casings, and meet Class IV laser safety rules. Most also have safety interlocks and professional fume extractors.

- Operation Modes: You can get both pulsed and continuous wave models. I find that pulsed lasers give you pinpoint control. Continuous wave models clean thick surfaces even faster.

- High-Speed Performance: Some models have pulse rates over 200,000 per second. Their scan speeds can reach up to 10 meters per second. This provides very fast cleaning for large items like airplane wings.

Where Industrial Laser Cleaners Excel

Heavy machinery maintenance: They are great for quickly stripping rust or paint from equipment.

Aerospace: You can use them for de-coating and preparing aircraft parts.

Automotive: They are useful for cleaning surfaces before welding and for mold upkeep.

Nuclear industry: They handle radioactive surface cleanup.

Marine and Shipbuilding: I find them ideal for removing paint and corrosion from large vessels.

Oil & Gas, Rail, and Power Generation: These tools work well for pipe cleaning, valve repair, and maintaining turbines and rails.

Advanced Capabilities

Industry 4.0 Integration: Many industrial laser rust removal machine support data logging and remote diagnostics. This allows them to connect to smart factory systems.

Safety: To keep operators safe, they include features like overheat protection and interlocks. They also use advanced fume extraction to maintain air quality.

Example Models and Main Applications

– CleanTech IR-3040: Suitable for corrosion, coating, and paint removal, offering handheld, dual-axis, and mobile connectivity.

– TRUMPF Industrial Systems: With power capabilities up to several kilowatts, it’s suitable for weld preparation and oxide removal, and can be integrated with robots for high-precision work.

– High-Power Adapt Laser: With power ranging from 500W to over 2000W, it can handle industrial rust and hazardous coatings, and features a touchscreen and real-time control.

Typical Price Range

Industrial laser rust removers typically range in price from $15,000 to over $60,000, depending on power and features. They are designed for large-scale industrial production and continuous operation, offering powerful performance to handle heavy rust removal and surface treatment tasks.

Who Should Choose an Industrial Laser Cleaner?

So who is it for? I recommend industrial laser cleaning machines for factories, shipyards, aerospace companies, and manufacturers with high-volume cleaning needs. These machines are ideal for businesses requiring powerful, continuous performance for heavy rust, paint, or coating removal on large surfaces. If your operation demands efficiency, precision, and long-term durability, an industrial-grade laser cleaner is the smart investment.

Summary

Based on my experience, picking the right laser cleaning machine means knowing your specific job. You might need a small machine to start, or you could need an industrial one for heavy-duty work. I think these machines are a big step for cleaner, more exact production.

I see this as the future for preparing surfaces. It’s a method that is both efficient and good for the environment. I recommend you stop asking if laser cleaning will change your operation. Instead, you should decide how soon you’ll adopt this technology. Reach out now to request a laser cleaning machine quote and get all the details you need.