I often wonder if certain cleaning methods can harm a project and the planet. When I choose between laser cleaning and sandblasting, I think about more than just the cost or how fast it is. I believe the effect on our environment is a huge factor.

Using methods that are better for the earth makes a big difference. Based on my experience, many people don’t understand the amount of waste and mess that comes from old-school sandblasting. I feel there’s a key point that people often miss, and it could change how we look at this choice.

Brief Introduction: What Are We Comparing?

Thanks for sharing this comparison between laser cleaning and sandblasting. This is great technical info that clearly shows the key differences between these two ways of preparing a surface.

From my perspective, your table shows the main distinctions well:

Key Insights I See in Your Comparison:

- Technology: Laser cleaning machine uses focused energy. Sandblasting uses physical scraping.

- Effect on Material: Laser offers precision without contact. Sandblasting can damage the surface.

- Environment: Laser creates little waste. Sandblasting produces a lot of debris.

- Best Use: Each method works for different tasks based on how sensitive the material is.

My Suggestions for Enhancing Your Content:

If you are making marketing content or a technical guide, I recommend you add:

- Cost comparison: What is the purchase price versus the daily running costs?

- Speed and efficiency: How fast does each method work on different materials?

- Safety points: What protection does an operator need? What are the environmental rules?

- Return on Investment (ROI): How long does it take for different industries to earn back the cost?

Let me know what you plan to do with this comparison. I can help you build it into the best format for your readers.

Unpacking the Pros of Laser Cleaning

From my experience, laser cleaner offers some great advantages over sandblasting. I find it’s a better choice for many modern industrial and restoration jobs.

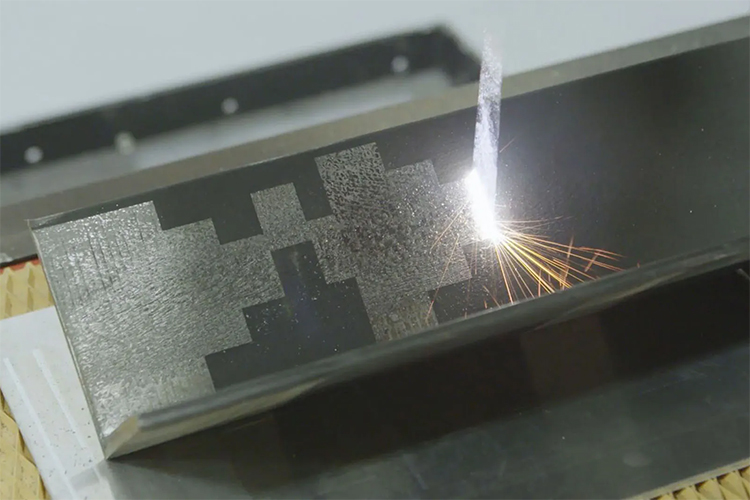

Precise and Gentle Control

I’ve seen that laser cleaning provides amazing precision. This makes it perfect for detailed or sensitive work. With adjustable settings, you can target just the unwanted material and leave the surface underneath unharmed. This tiny level of control is key for things like aerospace parts, electronics, and other delicate materials. For instance, if you’re restoring a valuable artifact or cleaning soft metals, laser cleaning keeps the surface intact. It avoids the pitting, marks, or warping that sandblasting can cause.

A Non-Abrasive Touch Protects Materials

Laser cleaning uses heat to vaporize contaminants instead of physical force, so it doesn’t scrape the surface. This means it has a very low impact on the base material. I think this is a huge benefit for fragile, oddly shaped, or high-value items. It lets you clean things without worrying about damaging the surface.

An Earth-Friendly Process with Less Waste

I appreciate that laser cleaning is better for the environment. The process creates almost no dust or extra waste because it turns contaminants into vapor instead of scattering them. You don’t need materials like sand or grit, which reduces your supply costs and makes it easier to meet environmental rules. The main byproduct is the vaporized residue, which means less waste to get rid of.

A Better, Smoother Surface Finish

Surfaces that have been laser cleaned are smoother. They are free from the rough patches or marks that sandblasting often leaves behind. I’ve found this cleaner finish means you can skip extra post-cleaning steps. This saves a lot of time and labor in fields like automotive restoration or aerospace manufacturing, where surface quality is a top priority.

Easy to Automate with Low Upkeep

You can automate modern laser cleaning systems. They integrate well with robotic arms or production lines. This lowers the need for skilled workers and allows for nonstop, predictable results. These systems are also built to last. In my experience, they can operate for over five years with little maintenance and few part replacements. Sandblasting units, on the other hand, often need new nozzles or hoses within two years, which means higher maintenance costs.

A Safer Workplace for Everyone

With laser cleaning, operators just need eye and skin protection, which reduces health risks. Sandblasting is much different. It exposes workers to airborne silica dust and flying particles. This requires full-body suits and respirators because of serious health issues like silicosis. By cutting down these risks, laser cleaning helps create a safer place to work.

What I See as the Downsides of Laser Cleaning

If you are choosing between laser cleaning and sandblasting, I want you to be aware of some drawbacks of using a laser.

High Upfront and Running Costs

From my experience, fiber laser cleaning machines have a high purchase price. Basic models begin at $4,700, while industrial systems can cost more than $11,000. Sandblasting setups are much cheaper. Equipment for small businesses or home use is affordable, with material costs ranging from $1.50 to $7 per square foot. You should also know that professional laser cleaning services charge $150–$250 per hour. This price can make large or long projects too expensive.

Slower on Large-Scale Jobs

Laser cleaning is very precise, but I find it is much slower for cleaning big or very dirty surfaces. It takes a lot more time to remove thick rust, paint, or dirt from a large area. Sandblasting clears material much faster and needs fewer passes. This makes sandblasting a better choice for large industrial jobs where speed is important.

Needs Special Skills and Operator Training

You can’t just pick up and use a laser cleaner. Unlike sandblasting, which often just needs basic instructions and safety gear, a laser system requires specific training. Operators must follow strict safety rules. Setting the correct parameters like power and speed is critical, and some jobs may require certification. I think this training requirement makes laser cleaning a poor fit for untrained workers or simple DIY use.

Pros of Sandblasting: Key Advantages

From my experience, sandblasting is a go-to choice for surface preparation in many industries. I believe its main strengths are its low cost, speed, and ability to adapt to different jobs.

Cost-Effective Surface Preparation

I’ve found that sandblasting equipment costs much less upfront than laser rust removers. For any workshop or contractor working with a budget, this is a big win. The abrasive materials, like sand, garnet, or glass beads, are cheap and easy to get. This helps keep the day-to-day running costs down. I recommend sandblasting for large-volume or repeat jobs where you need to control spending.

Fast and Efficient Large Area Cleaning

One of sandblasting’s best features is its speed. I think this method is excellent for stripping rust, old paint, oils, and other grime from big surfaces in a short amount of time. In heavy industry, like when restoring a steel bridge, a crew can clean and prep hundreds of square meters a day. This reduces project delays and helps you finish faster. Another plus is the quick setup. I’ve seen onsite sandblasting units ready to go in less than one hour.

Versatility Across Materials and Applications

I like how you can adapt sandblasting to so many materials. By picking the right abrasive and adjusting the air pressure, it works on metals, plastics, carbon fiber, and more. This flexibility means you can use it to prep auto parts, industrial machines, or even decorative items. I find that it works much better than chemical stripping or manual cleaning on hard-to-reach areas. Sandblasting performs well with both portable or fixed equipment, so I can use it for jobs of any size and in any location.

Cons of Sandblasting: Key Disadvantages

High Risk of Surface Damage and Material Loss

From my experience, one of the biggest problems with sandblasting is surface damage. The process doesn’t just strip off coatings and dirt; it also eats away at the original material. I find this is a major issue on softer surfaces, like zirconia or certain metals.

For example, using a 50 µm abrasive at high pressure for a long time will remove much more material. I’ve seen it cause far more loss than a 110 µm abrasive would under the same settings. I also know that raising the blasting pressure—say, from 0.1 MPa to 0.6 MPa—removes more material and makes the surface rougher. Blasting for too long does the same thing. On metals, I’ve seen this process create surface peaks of 100 microns or even higher. It all depends on the abrasive and method used. Sandblasting can also trigger unwanted changes within materials. In zirconia, it can alter the material’s internal structure, which I believe weakens it and reduces its durability.

Intensive Post-Process Cleanup and Debris Management

In my opinion, the cleanup is a huge chore. Sandblasting creates a large amount of dust and used abrasive. The job is messy. You get not just the leftover grit but also tiny particles from the surface you blasted. This debris spreads everywhere, and I find that cleaning it up takes a lot of work and time. If you are working in an open area or on a site with an odd layout, I think containing the dust becomes much harder and more costly.

Significant Health and Safety Risks for Operators

Sandblasting poses serious health risks, especially without proper protection. The process creates dust that may contain crystalline silica, toxic metals, and harmful chemicals — all of which can cause severe lung diseases like silicosis. I strongly recommend full-body protection, including respirators, gloves, suits, and hearing gear, as both the abrasive and removed coatings can expose workers to dangerous substances.

Environmental Impact and Waste Disposal Challenges

I also think we must consider the environmental impact. Sandblasting produces hazardous waste. This waste is made of used abrasives mixed with paint, rust, metals, or toxic materials. Dust from the job can settle in the work area and also drift away. It can contaminate nearby soil or water.

Laser Cleaning vs. Sandblasting: My Take on Choosing

If you’re picking between laser surface cleaning machine and sandblasting, I think you should match the method to your project. Consider the need for accuracy, the material’s sensitivity, your budget, and the local rules. Here is my simple, practical breakdown of the two.

What to Use and Where: Application Scenarios

Laser Cleaning

– Best for delicate or valuable jobs: Ideal for artifacts, electronics, and historic items because it removes dirt or coatings without harming the surface.

– Great for smooth finishes: Often no need for extra polishing—perfect for auto or aerospace work.

– Eco-friendly and clean: Creates little dust or mess, making it safe for indoor use and strict environments.

– Easy to automate: Works well with robots, giving consistent results and needing fewer skilled workers.

– Worth the investment: Though the starting price is around $4,700–$11,000, low maintenance and no consumables make it a cost-effective choice for high-value or regulated projects.

Sandblasting

– Best for large, tough surfaces: Ideal for bridges, ships, and heavy machinery—great at removing thick rust and paint.

– Perfect for roughening surfaces: Helps coatings stick better—commonly used on tools, equipment, and pipelines.

– Budget-friendly choice: Lower equipment and material costs (about $1.50–$7 per sq. ft.) make it good for big jobs or small businesses.

– Fast but rough: Works best when speed matters more than a smooth finish—you may need extra polishing afterward.

My Final Thoughts:

From my point of view, laser cleaning offers amazing precision and is very clean for restoration or sensitive work. I think sandblasting is the clear winner for cost and speed on big, tough jobs. Just be ready for more mess, safety measures, and some potential wear on the surface.

Summary

After looking at both methods, I believe your choice depends on your specific needs and values. Based on my experience, I recommend laser cleaning if getting the details perfect is your top priority. It is also the kinder choice for the environment and a good long-term investment, even with the higher initial cost. On the other hand, if you are working with a smaller budget and need pure speed and power, I think sandblasting is your best bet. Whatever you decide, I suggest making sure it fits your project’s goals. It should also meet safety standards and your own environmental standards. Picking the right cleaning method is a key step that shapes your final outcome. Ready to learn more? Contact us now for expert advice on laser cleaning machines.