Choosing the right laser engraving machine can feel like a high-stakes puzzle—do you go for an affordable, compact model under $5,000, or invest in a powerful industrial system over $10,000? Each option has its strengths, from fast, precise marking on small parts to large-scale, high-volume production. In this guide, I’ll break down the key differences in work area, power, speed, and versatility, so you can decide which machine is the perfect fit for your business or workshop.

Power/Wattage: A Look at Laser Engraving Machine Wattage and Price

Based on my experience, power, or wattage, is the main difference between laser engravers under $5,000 and those over $10,000. It directly affects the machine’s performance and what jobs it can handle.

Wattage Range & Typical Use

| Feature | Entry-Level (< $5,000) | Professional/Industrial (> $10,000) |

|---|---|---|

| Wattage | 20W–30W | 50W–1000W+ |

| Best For | Light metals, plastics, delicate materials | Stainless steel, hard metals, deep engraving, continuous runs |

| Marking Depth | 1–1.5 mm | >1.5 mm, several mm with higher power |

| Production Use | Small jobs, low–medium speed | Fast marking, high output, shorter cycles |

| Material Handling | Low heat risk, limited for thick/hard materials | Handles thick/tough materials; risk of heat damage on thin items |

Marking Area: How Size & Coverage Impact Laser Engraving Machine Value

When I compare laser engravers under $5,000 to those over $10,000, I see the marking area as a key difference. It affects your workflow, the size of your projects, and how much work you get done.

Typical Marking Area Sizes & Use Cases

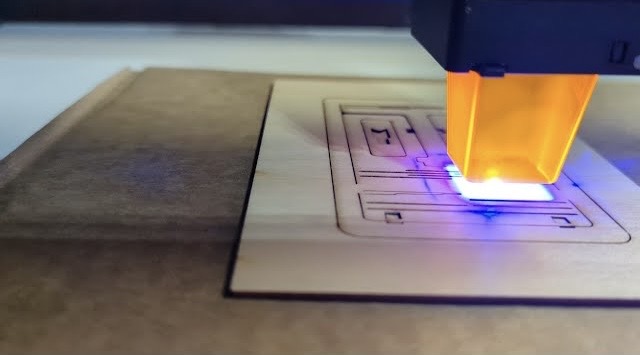

Under $5,000 Laser Engravers: Most budget laser marking machines offer a 110 × 110 mm work area (expandable to 200 × 200 mm) and are ideal for logos, serial numbers, and barcodes on small parts. A 20–30W fiber model in this range can reach 3,000 mm/s for efficient batch work. However, larger items must be moved manually, which slows down big orders.

Over $10,000 Laser Engraving Systems: High-end industrial machines offer a 400 × 400 mm to 800 × 800 mm work area, perfect for large panels, LGPs, textiles, and bulk metal parts. With 100W+ power, they handle big production runs but may see slower speeds and slightly larger laser spots. To ensure precision, they use advanced optics, high-precision galvanometers, and dedicated cooling systems.

Performance, Material, and Quality to Think About

Material Focus: Lower-priced machines with small areas focus the laser’s energy well. This creates fine details and deep marks. I recommend them for things like metal tags, electronic parts, and crafts. High-power machines with large areas are about speed and coverage. They work well on raw metals, plastics, and fabrics. You might have to accept a little less fine detail as a trade-off.

Marking Quality & Spot Size: In my experience, you get denser and finer details with smaller marking areas. When the marking area gets bigger, the laser spot size also grows. This can reduce the fine accuracy of the mark.

Quick Comparison Table

| Price Range | Marking Area | Power | Best Use Cases | Typical Mark Speed |

|---|---|---|---|---|

| Under $5,000 | 110mm–150mm square | 20W–30W | Barcodes, logos, serial numbers, small parts | Up to 3,000 mm/s |

| Over $10,000 | 400mm–800mm square | 50W–100W+ | LGPs, textiles, bulk/large-format marking | Slower for large areas |

You should choose a marking area based on your typical item size, production numbers, and quality needs. I suggest a small machine for precise, tight marking. If you need mass production or have bigger formats, a large, expensive unit is the right choice.

Software & Control: A Look at Laser Software Under $5,000 vs. Over $10,000 Laser Engraver

The software in a laser marker makes a huge difference. From my experience, I see a big gap in what you get with machines under $5,000 compared to professional systems over $10,000.

Entry-Level Laser Marking Machine Software (Under $5,000)

Most budget laser markers use free or open-source software. LaserGRBL is popular with hobbyists for vector/raster work but lacks automation. LaserWeb supports more file types and cost estimation but feels less polished. CorelLaser with CorelDRAW combines design and control, common on CO₂ lasers but basic in automation. OpenBuilds CAM & Control offers G-code editing and previews for simple jobs. These tools suit beginners and small shops for 2D logos, barcodes, and serials, but lack pro-level support—something MaxWave covers with 24/7 service and lifetime technical support.

Industrial Control Systems (Over $10,000)

High-end laser marking machines usually come with advanced software like EZCAD3, LightBurn Pro, or RDWorks, offering 3D marking, dynamic focusing, automation, and support for multiple laser types. These programs handle complex workflows, variable data, and high-volume production with excellent file compatibility, from standard formats to CAD/CAM and 3D. They also provide motion control, process monitoring, and job queuing for seamless operation. With professional training, vendor support, and regular updates, such systems are highly reliable for demanding, continuous industrial use.

Key Differences at a Glance

| Software/Control | <$5,000 Machines | >$10,000 Machines |

|---|---|---|

| Main Software | LaserGRBL, LaserWeb, CorelLaser | EZCAD3, LightBurn Pro, RDWorks, OEM interfaces |

| Main Features | 2D vector/raster, manual controls | 3D galvo, dynamic focus, layering, automation |

| Automation & Monitoring | Minimal, requires manual operation | Extensive, real-time monitoring, job queues |

| Support | DIY/community help | Professional/vendor support, training, regular updates |

| Use Scenarios | Hobby, crafts, basic marking | Industrial production, serial & deep marking |

From my perspective, if you only need simple DIY operations for light work, the entry-level software is fine. If you’re doing professional, heavy-duty, or varied marking jobs, I strongly recommend the advanced software. The benefits like automation, precision, and long-term support are absolutely worth the higher price.

Marking/Engraving Speed & Throughput: How Laser Engraver Price Affects Productivity

If you’re looking at laser engraving machines, the big difference between models under $5,000 and those over $10,000 comes down to two things. From my experience, marking speed and throughput are what really affect your business’s productivity.

Marking Speed Benchmarks

Machines Under $5,000: Most UV laser engravers in this price range give you marking speeds of 800–1000 mm/sec for 5–10W models. For example, the xTool F1 (diode laser, ~$1,700) is rated for up to 4000 mm/sec. In my tests, I’ve found the engraving quality suffers at that speed, particularly with detailed designs. I find there’s a clear trade-off with budget lasers. If you push for maximum speed, you often lose fine precision and clarity in the details.

Machines Over $10,000: Industrial machines are in a different league. For instance, the Epilog Fusion Pro 36 (~$33,500) hits 4191 mm/sec. It delivers precise, detailed results on every single pass. I think this is perfect for serious production work. Even a mid-range machine like the Thunder Laser Bolt (~$5,500) gets you 1000–2000 mm/sec with great accuracy. The top-tier fiber lasers over $10,000 go even faster while maintaining excellent detail.

Fiber, UV & CO2 Laser Performance Differences

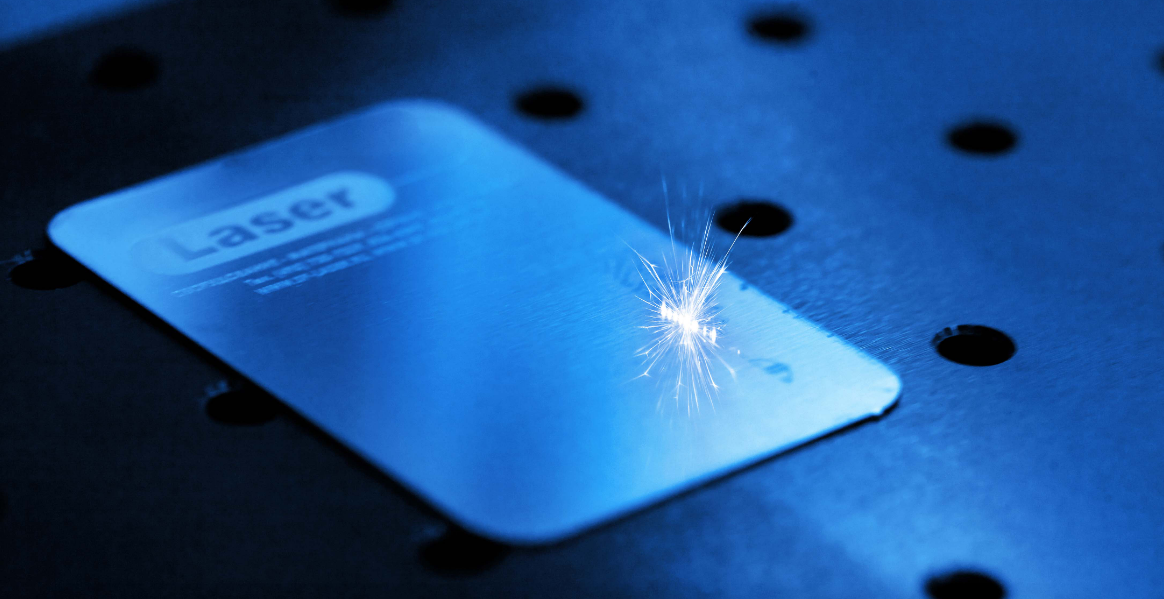

- Fiber Lasers: High-power fiber lasers (50W–100W+), which are often priced above $10,000, can mark at speeds up to 1200 mm/sec. I’ve seen them produce fast, deep marks on metals. This is essential for industries that need permanent marks on a huge scale.

- UV Lasers: I find UV models (3W–10W, under $10k) are great for certain jobs. They run at 800–1000 mm/sec and work well for delicate, low-heat marking. They don’t handle metal as well as fiber lasers.

- CO2 Lasers: CO2 lasers are typically found in more expensive machines. They give you higher speed and can work on more types of materials. This combination really boosts your overall output.

Quick Reference: Speed & Throughput Comparison

| Feature | Under $5,000 Machines | Over $10,000 Machines |

|---|---|---|

| Technology | UV/Dual-beam/Low-Watt Fiber | High-Watt Fiber, CO2, Dual-Source |

| Speed (mm/sec) | 800–1000 (UV), up to 4000* | 2000–4191+ |

| Throughput | Small to medium jobs | Industrial, continuous mass production |

| Mark/Quality Trade-off | Precision drops at top speed | Maintains high detail at high speed |

| Deep Engraving | Slow, limited | Fast, industrial strength |

| Example Models | MaxWave MW-F25CA | Epilog Fusion Pro 36 |

My take: If you need to produce a lot of items quickly and consistently, I’d suggest going with an industrial laser. Entry-level lasers are a better fit for small jobs where details matter more than raw speed.

Who Should Buy a Laser Engraving Machine: Under $5K vs Over $10K

From my experience, picking the right laser marker system starts with two questions. What will you mark? And how much will you produce? Let me show you how users and their needs change based on price.

Target Users & Industries by Price

Laser engravers Under $5,000

Main Users are small businesses, startups, hobbyists, and custom product creators, often in jewelry, promotional products, crafts, and independent workshops. They choose these machines because they’re compact, easy to learn, and perfect for small-batch or personalized marking.

Laser Markers Over $10,000

Main Users are industrial manufacturers, automotive suppliers, electronics makers, and medical device companies, operating in large-scale factories and high-volume production lines. They choose these machines for advanced automation, strict compliance tracking, 24/7 operation, and the ability to mark complex materials.

At-a-Glance Use Case Comparison Table

| Price Range | Core Users & Industries | Example Use Cases |

|---|---|---|

| Under $5,000 | Small business, hobbyists, startup manufacturers | Product labeling, custom engraving, awards, tags |

| Over $10,000 | Automotive, electronics, aerospace, contract manufacturing | Mass/inline marking, regulatory compliance, medical parts |

Laser Engraving Market Insight: The laser marking industry is big, with a value estimated at $3.91 billion by 2025. This tells me there are great options for everyone. You can find a machine that fits your needs. It doesn’t matter if you’re decorating small gifts or keeping a large production line moving smoothly.

Summary

At the end of the day, the right laser engraving machine depends on your production needs, materials, and budget. If you’re running a small workshop or crafting personalized items, a compact, under-$5,000 machine delivers speed, precision, and affordability. But for large-scale production or heavy-duty materials, investing in a high-end $10,000+ system ensures unmatched power, consistency, and versatility. By understanding the differences, you can choose a machine that boosts efficiency, enhances quality, and grows with your business—making every mark count. Ready to learn more? Contact us now for expert advice on laser engraving machines.