How Laser Machine for Cleaning Works

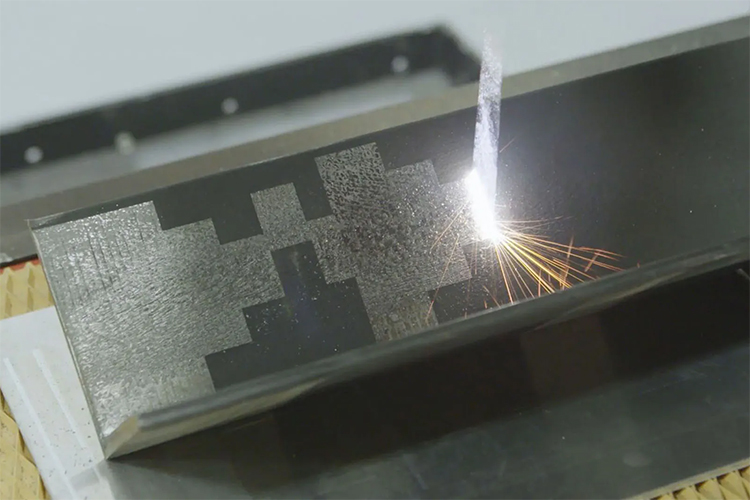

I find that laser cleaning machines are a great solution for removing things like rust, paint, oxides, and grease from surfaces. They use a focused laser beam to do the job. The method behind it is called laser ablation.

The Principle of Laser Ablation

Laser machine for cleaning works through laser ablation, where the laser beam hits the surface and the unwanted material absorbs its energy, heating up rapidly and transforming into vapor or fine dust that is then removed. By adjusting parameters such as wavelength, pulse duration, and power, the process can selectively target only the contaminants, achieving cleaning precision down to 10 microns without damaging the underlying material. Since it is a non-contact method that requires no harsh chemicals, it not only protects the surface but also offers an environmentally friendly solution.

Key Components of a Laser Cleaning System

- Laser Source: This part provides the energy. I recommend using pulsed lasers for fine, detailed cleaning. If you’re working on a large area with heavy buildup, a continuous wave laser is more suitable.

- Gain Medium & Power Source: These parts generate and amplify the laser light.

- Optical System: This system focuses the laser beam very precisely to make sure the cleaning is effective.

- Control Interface: This lets you set the cleaning parameters. I’ve noticed many new systems have AI that monitors the process in real time, which helps achieve wonderful results.

- Extraction System: This part collects the dust created during cleaning. It’s important for keeping the work area safe and clean.

Step-by-Step Laser Cleaning Process

- First, I suggest you configure the laser settings to match the type of dirt or rust you’re removing.

- Direct the focused beam onto the area you want to clean.

- The unwanted material absorbs the laser’s energy and turns into vapor or dust.

- An extraction system or vacuum removes the leftover debris.

- What’s left is a clean surface. The original material underneath remains safe.

Performance and What It Can Do

I am impressed that modern laser cleaning machines can process up to 1 square meter per minute. That’s about 15 square meters per hour. This really improves speed compared to old-school manual and chemical methods. These machines work well on different materials, including metal, stone, and plastics. I have seen them used in many fields, from manufacturing and restoration to electronics and art conservation.

Reason 1: How a Laser Machine for Cleaning Gets a Great Clean Without Damaging Surfaces

From my experience, laser cleaner offers incredible precision. By adjusting the laser’s settings, it can remove rust, paint, or grease as thin as 10 microns. This accuracy means it zaps away the grime. There’s no risk of harming the surface underneath.

Safe for Delicate Items

I recommend laser cleaning for sensitive surfaces. It’s a great choice for:

– Cultural artifacts

– Electronics

– Precision metal parts

It cleans without causing pits or warping. It also leaves no residue behind. This makes it a solid choice for jobs where you must protect the surface, such as restoration or high-tech manufacturing.

How It Compares to Older Methods

– No abrasion or physical contact like sandblasting.

– No harsh chemicals that could damage or corrode materials.

– No secondary waste or chemical residue left to manage.

My Recommended Uses

– Restoring fine art or historical items

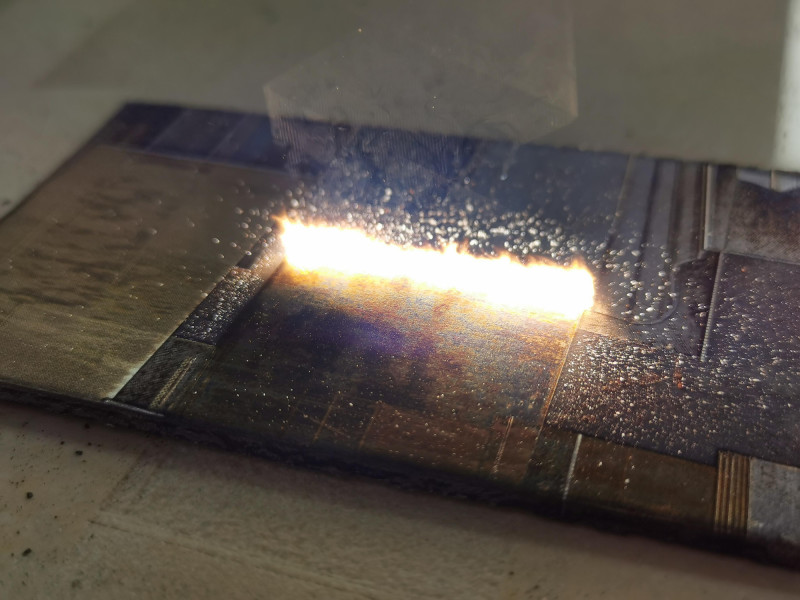

– Preparing a surface before welding or coating

– Cleaning precise machine parts or electronic components

I find that with laser cleaning, you get a spotless result. You do not have to sacrifice surface quality or safety.

Reason 2: How a Laser Machine for Cleaning Boosts Your Efficiency and Cuts Downtime

I recommend laser cleaning because it makes your work more productive. You’ll also spend less time dealing with stoppages. Based on my experience, these machines are fast. They can clean up to 15 square meters per hour. That’s much quicker than scrubbing by hand or using abrasive blasting. This helps your company finish cleaning jobs in less time, letting you move to the next production step without delay.

Easy Automation

From what I’ve seen, modern laser cleaning systems are easy to automate. You can add them into your production line. This allows cleaning to happen nonstop, so you won’t have to stop the entire line. I find this to be a huge benefit for industries like automotive and aerospace. In those fields, every minute of downtime costs money.

Lower Labor and Maintenance Costs

Because laser systems work fast and can run on their own, I’ve seen them reduce labor costs a great deal. There’s less need for people to handle or watch the machines. You’ll also have less downtime for maintenance. The process is non-contact, which causes very little wear on your equipment.

In my view, this combination of speed, automation, and low labor makes laser cleaning a smart investment. I recommend it for large operations that want to boost efficiency and avoid interruptions.

Reason 3: Why a Laser Machine for Cleaning Is a Safe and Green Choice

I believe switching to laser rust cleaning machine does more than give you better results. It also protects the environment and your team. Old methods like chemical solvents or sandblasting are messy. In my experience, laser cleaning is a much cleaner and safer technology.

Minimal Waste, No Chemicals

Laser cleaning is a dry and clean process that works without water, solvents, or harsh chemicals, leaving the surface spotless without the usual mess. It generates almost no hazardous waste, since the removed material simply turns into dust that can be easily collected. With no need for consumables like abrasive media, pads, or chemical agents, it not only simplifies maintenance but also delivers significant cost savings.

Lower Risks for Workers

Laser cleaning enhances workplace safety by reducing the need for extensive protective gear, since operators are not exposed to chemical fumes or splashes. The process produces almost no harmful vapors, keeping the workshop air cleaner and eliminating the need for expensive ventilation system upgrades.

Cost Savings and Compliance

Laser cleaning can reduce operating costs by up to 80%, since it eliminates the need for purchasing chemicals and paying for waste disposal. With minimal waste and no hazardous materials, it also makes compliance with environmental and safety regulations much easier to achieve.

I recommend laser cleaning if you want a fast cleaning method that lowers costs and risks. These machines are a green and safe choice. They are simple to operate, which is great for your team and the planet.

Reason 4: Versatility Across Applications and Materials

I find laser rust removal machines incredibly flexible. They work on many different materials and have a huge number of uses. It doesn’t matter if you’re in heavy industry, electronics, or art restoration. I’m confident these machines can adapt to what you need.

Broad Application Range

Rust Removal: I use them to get rust off tools, cars, and factory equipment.

Paint Stripping: You can strip old paint quickly. This gets surfaces ready for a new coat or an inspection.

Degreasing: They clean up greasy surfaces in workshops, on production lines, and in auto shops.

Weld Surface Preparation: You can get joints ready for welding. You can also clean finished welds without harming the metal.

Art and Heritage Conservation: I’ve seen them used for careful cleaning on sculptures, old buildings, and historic artifacts.

Compatible With Many Materials

Based on my experience, laser cleaning works on:

Metals: Steel, aluminum, copper, and more.

Stone: Marble, granite, limestone.

Plastics: It works on certain plastics that can be cleaned carefully without heat damage.

Other surfaces: You can adjust the laser’s power and wavelength. This means it can be used on even more materials.

Serving Diverse Industries

I’ve seen these machines in many fields:

– Heavy manufacturing plants for cleaning machinery and parts

– Automotive and aerospace for preparing and taking care of sensitive parts

– Electronics for cleaning circuit boards and contacts

– Art and heritage sectors for handling museum-quality surface care

Why This Matters

From my point of view, this flexibility is a huge plus. It means one investment covers many tasks in your business. I believe you don’t need several different tools for each cleaning job. This simplifies your equipment and reduces upkeep. With the right settings, you can use your laser machine on everything from factory steel to fragile old sculptures. I think this saves space, money, and training time.

Reason 5: Little Upkeep and a Long Lifespan

From my experience, laser rust removers are fantastic because they need very little maintenance and last a long time. They are different from old-school media blasters or chemical systems. Laser cleaners don’t have parts you use up like grit or filters. They also don’t have complex moving parts that you have to keep replacing. This means you’ll see fewer breakdowns and get consistent results every year.

Simple Daily Care

Laser cleaning requires only simple routine care, such as cleaning the optics and ensuring the ventilation system works properly, without the need to constantly buy or replace consumables like abrasives or chemicals. Since the process uses no harsh chemicals, there is no hazardous waste to dispose of, which reduces both maintenance demands and compliance costs.

Made to Last a Long Time

These machines are built with solid-state parts, which I think is a smart design choice because it reduces wear and tear, allowing key components to last much longer. With fewer chances of failure, downtime is kept to a minimum, so your machine stays running smoothly and your business operates without costly interruptions.

Saving Money in the Long Run

Reason 6: Enhanced Worker Safety with Laser Cleaning

From my experience, modern laser cleaner machines offer a much safer workplace for operators. They are built with strong safety measures. Traditional methods, like chemical solvents or abrasive blasting, often put workers in danger from hazardous materials and physical injuries. I’ve found that laser cleaning removes many of these risks.

Built-In Laser Safety Features

I’ve noticed most laser cleaners come with:

– Protective enclosures that keep the laser beam safely inside, preventing accidental exposure.

– Interlock systems which shut the machine down if the enclosure is opened or if a safety protocol is broken.

– Mandatory safety eyewear is needed to protect eyes from the intense laser light.

I believe these built-in safeguards are key. They ensure operators have almost no direct contact with the laser, which cuts down the chance of accidents.

Reduced Exposure to Workplace Hazards

Creating a Safer Work Environment

In my experience, these modern safety features protect employees well. They also make it easier for companies to follow health and safety rules. I find that the mix of precise control, non-contact operation, and solid protective systems makes the workplace much safer and more comfortable for the entire team.

Summary

If you’re looking for a cleaning tool that saves money, protects workers, and delivers flawless results, a laser cleaning machine is the clear winner. It’s not just a tool—it’s an investment in efficiency, safety, and long-term growth. Don’t wait until your competitors get ahead—bring the power of a laser machine for cleaning into your business today, and contact us now to get your personalized quote.