Personalizing, branding, or labeling products becomes effortless with laser technology, a true game-changer. But not all lasers are the same—laser marking and laser engraving deliver very different results, and choosing the right one can make or break your project. From delicate electronics to bold jewelry, understanding the key differences ensures your marks are precise, durable, and perfectly suited to your materials.

Laser Marking vs. Laser Engraving: Key Differences You Need to Know

I often use laser marking and laser engraving in my work. Both techniques create lasting marks on materials like metals, plastics, ceramics, leather, and glass. People often confuse the two processes. Based on my experience, their methods and results are quite different.

| Aspect | Laser Marking | Laser Engraving |

| Process | Alters surface color or creates shallow marks | Removes material to create visible grooves |

| Depth | Very shallow (usually <0.02mm) | Deeper (up to several millimeters) |

| Main Use | Barcodes, QR codes, logos, anti-counterfeiting marks | Decorative patterns, text, deep engraving |

| Speed | Generally faster | Relatively slower |

| Material Impact | Minimal, does not change structure | Removes material, more visible impact |

| Typical Applications | Electronic components, packaging, medical devices | Jewelry, wood, leather, trophies, nameplates |

When you understand these differences, you can choose the best method for your needs. This helps ensure your mark is visible, durable, and has the right look for your material.

Core Mechanism: Laser Markinh vs. Laser Engraving

Laser marking and laser engraving affect a material’s surface in different ways. Based on my experience, understanding how they work helps you choose the right one for your job.

How Laser Marking Changes a Surface

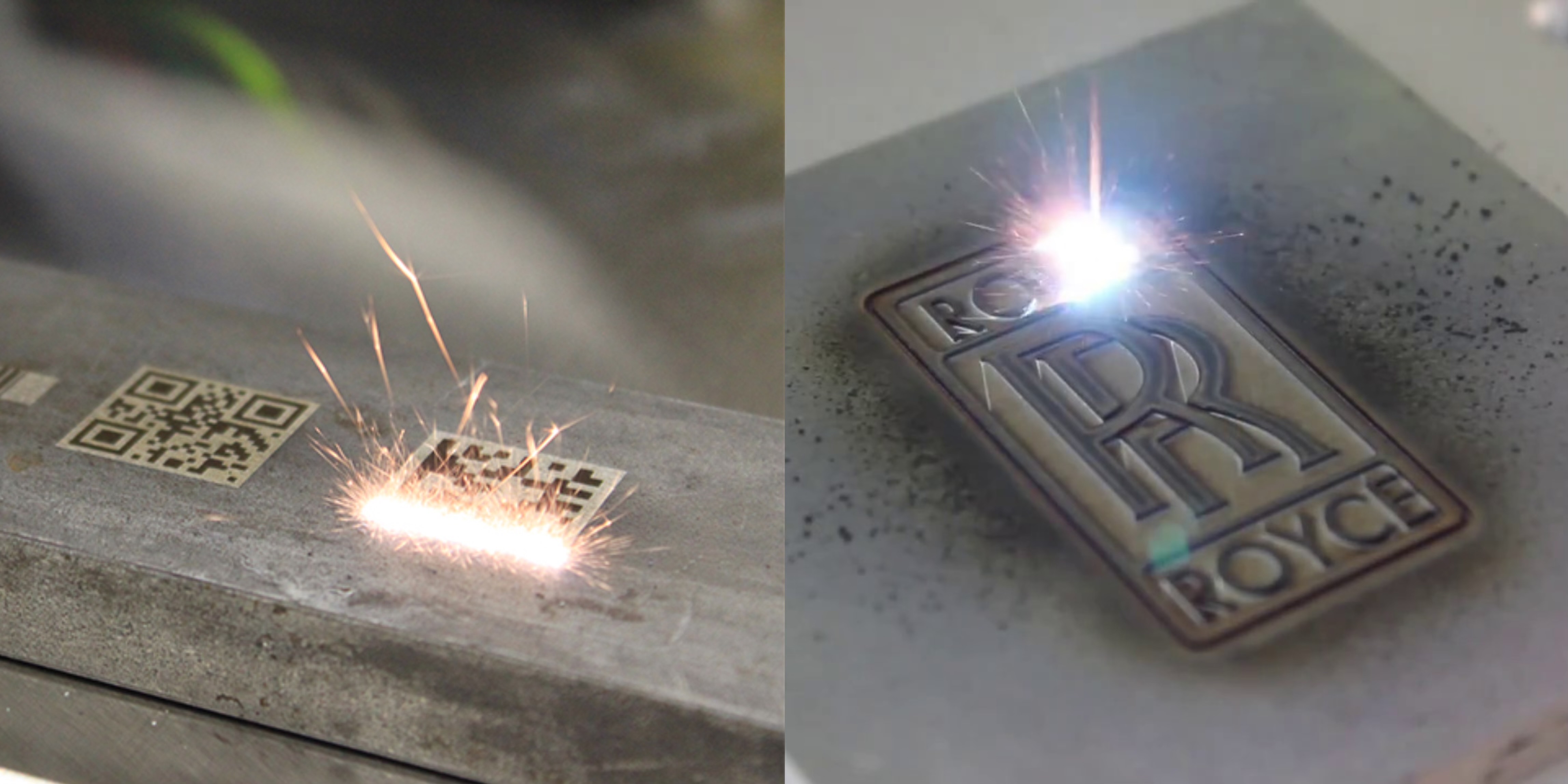

Laser marking machine changes the surface appearance without cutting into it. A controlled laser heats the top layer, causing color changes that form the mark. No material is removed, leaving the surface smooth—though some plastics may show a slight “foaming” bump. Because the part keeps its original strength, this method is ideal for electronics and medical components that must not be weakened.

My Recommended Marking Applications: I suggest it for barcodes, logos, and serial numbers. It’s a great fit for electronics and medical tools. These items must keep their original shape and strength.

How Laser Engraving Removes Material

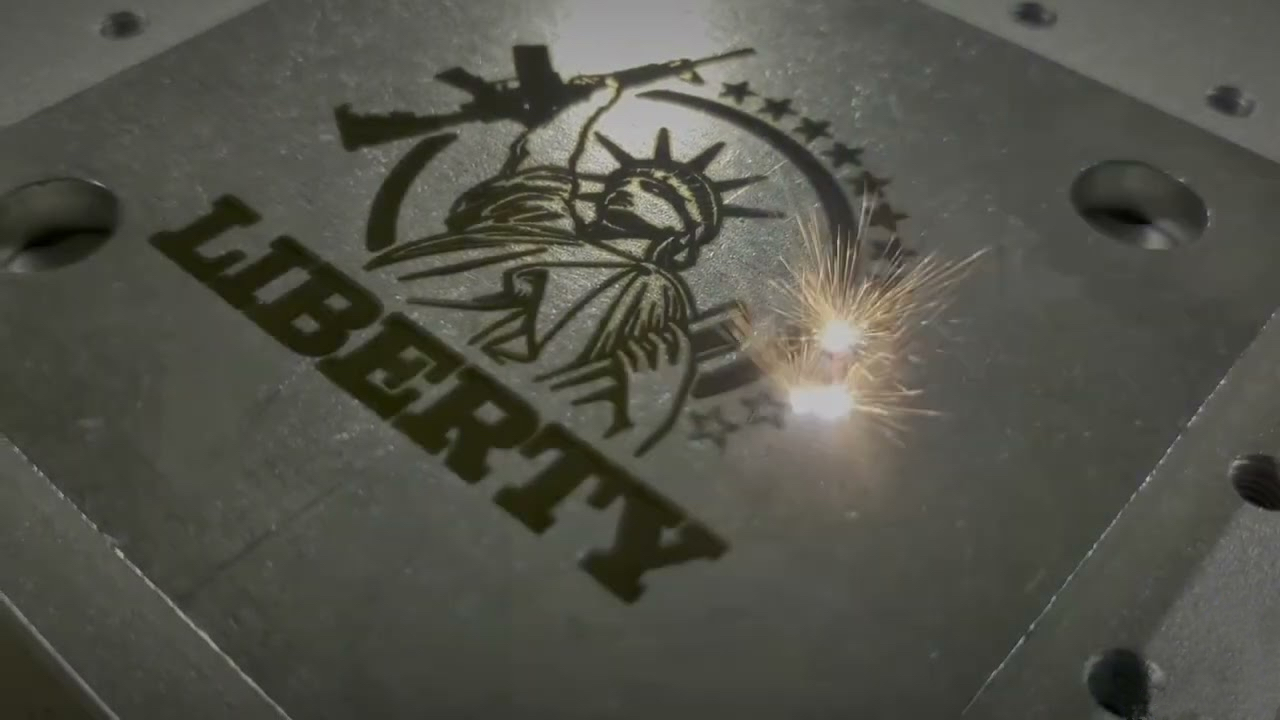

Laser engraver removes material to create visible grooves using a strong laser beam. The engraved mark is permanent and can be felt, with depth ranging from a few microns to several millimeters, depending on the material, laser power, and dwell time. On fabrics, medium power produces light patterns, while higher power can cut through the material. Because engraving alters the surface depth and thickness, the marked area may become weaker in that spot, so it requires careful consideration for structural parts.

My Recommended Engraving Applications: I suggest engraving for projects needing a deep, lasting mark you can feel. It works well for custom nameplates and trophy plaques. I also use it to personalize jewelry or add designs to glass and leather.

A Quick Comparison from My View

- Laser marking: I use this to change the surface color. It leaves a smooth or slightly raised finish. No material is lost, and the part stays strong.

- Laser engraving: I use this to carve away material. It makes deep marks you can feel and changes the texture of the spot.

I think you should ask yourself a simple question. Do you need to just change the surface color, or do you need to remove material? Your answer will help you pick the best process for your project.

Laser Marking vs. Laser Engraving: Depth of Mark

Laser marking and laser engraving produce marks with different depths. I find this depth difference changes the mark’s strength, how long it lasts, and its use in various industries.

How Deep Are Laser Marks?

Laser marker creates very shallow marks on the surface, typically less than 0.001 inches (0.025 mm) deep. This process changes the color or appearance without removing any material, making the mark mainly visual rather than tactile. You’ll often see this on barcodes or serial numbers on metals and plastics, and the surface remains smooth to the touch.

Laser engraver removes material to create deeper, visible, and tactile marks. On metals, standard engraving depth reaches up to 0.005 inches (0.127 mm), while industrial deep engraving can go as far as 0.020 inches (0.508 mm). In special cases like graphite electrodes, depth may reach 0.125 inches (3.175 mm). For materials such as wood, plastic, leather, and glass, the engraving depth depends on hardness and laser type, often using CO₂ or fiber lasers.

Depth Comparison Table

| Process | Typical Depth (inches) | Common Examples |

| Laser Marking | < 0.001 | Surface text, barcodes on steel |

| Laser Etching | 0.0001 – 0.001 | Logos or codes on aluminum |

| Laser Engraving | 0.001 – 0.020 | Metal medical tools, jewelry, plaques |

| Deep Engraving | 0.020 up to 0.125 | Graphite electrodes, security tags |

Laser Marking vs. Laser Engraving: Material Compatibility

From my experience, picking the right material is a big deal for laser marking and engraving. These two methods work in different ways with various materials and lasers. If you know the right match, you will save time and get a much better final product.

Laser Marking: Where Surface Matters

Best Materials & Uses: Laser marking works on metals, plastics, ceramics, and coated materials, changing color or contrast without removing material. Ideal for codes, branding, electronic parts, and decorative marks.

Laser Types: Fiber lasers for metals and some plastics; UV lasers for plastics and glass with fine, low-heat marking.

Laser Engraving: For Deep, Lasting Marks

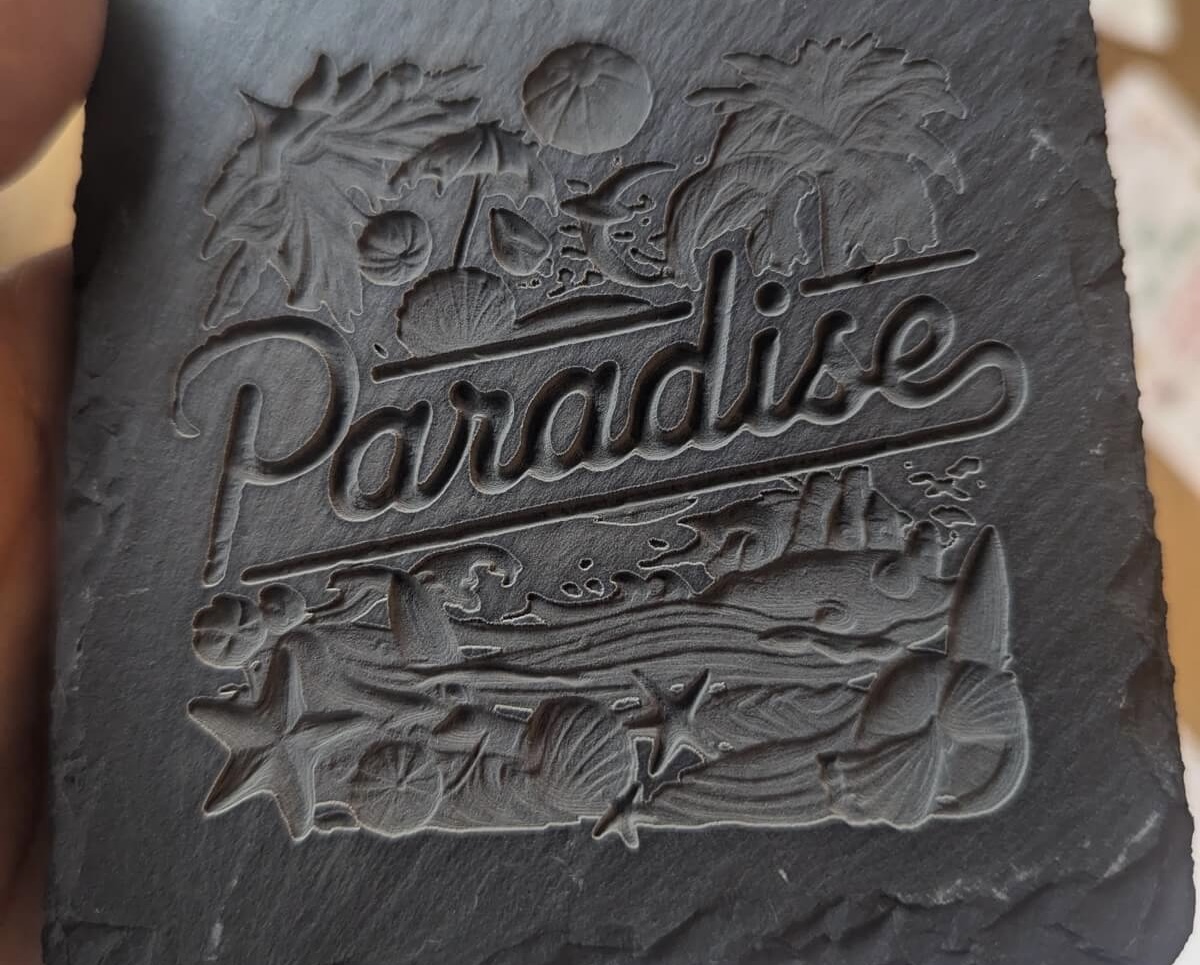

Best Materials & Uses: Laser engraving works on metals, plastics, wood, leather, glass, stone, and acrylic, creating deep, durable marks you can see and feel. Ideal for personalized gifts, logos, VINs, and artistic engravings.

Laser Types: Fiber laser marking machines for tough metals, CO₂ lasers for wood, leather, acrylic, and cardboard, UV lasers for fine, delicate work on glass and plastic.

Process & Material Matching Guide

- Fiber laser: Best for metals, select plastics, ceramics

- CO₂ laser: Best for wood, glass, acrylic, leather, some plastics

- UV laser: Best for plastics, glass, ceramics, sensitive metals

If you match the right laser process to your material, you will get the best results. I think this improves readability, strength, and looks. This way, you can pick the perfect solution for any marking or engraving job you have.

Laser Marking vs. Laser Engraving: Visual Appearance and Contrast

When you compare laser marking and engraving, the first things you’ll see are the visual appearance and contrast. In my experience, these differences affect both how the mark looks and how it works in practice.

How Laser Marking Looks: Flat but High-Contrast

Laser marking creates high-contrast marks on the surface by heating the material, causing a slight chemical change without removing any material. The marked area remains completely smooth, with no grooves or dips, while the contrast is clear and easy to read, making it ideal for serial numbers, barcodes, logos, and applications where the surface must stay strong, such as electronics or medical tools.

Industry example: Based on what I’ve seen, laser marking is great for medical tools and electronics. You get a clear mark, but you don’t risk damaging the surface.

How Laser Engraving Looks: Deep, With Visual and Tactile Impact

Laser engraving machine removes material to create deep, visible grooves, giving marks a bold, textured feel. The engraved area is permanent and easy to feel, while the depth adds shadows, enhancing visibility even in poor lighting. Typical depths reach 0.020″ on metals and up to 0.125″ on softer materials like graphite, allowing for detailed designs and fine lines, making it ideal for industrial parts, jewelry, and decorative applications.

Real-world case: In my experience, an engraved nameplate on a machine will stay readable for years. It holds up to heavy use, cleaning, and weather.

Direct Comparison: Marking vs Engraving

Here is a clear side-by-side breakdown:

| Method | Visual Appearance | Contrast | Touch | Typical Depth | Use Cases |

| Laser Marking | Flat, no grooves | High (color tone) | Smooth | Surface | Barcodes, electronics, tools |

| Laser Engraving | Deep, visible cavities | High (shadow/depth) | Tactile grooves | 0.020″–0.125″ | Nameplates, awards, machinery |

So, if you want a smooth mark with high-contrast color, my advice is to go with laser marking. If you need a deep, long-lasting mark that stands out, laser engraving is the better option. I believe its physical depth offers superior contrast, which is great for tracking industrial parts or for premium branding.

Typical Applications of Laser Marking and Laser Engraving

I find that laser marking and laser engraving have very different uses in today’s industries. Each one has unique strengths that make it suitable for specific jobs. Let me walk you through them.

Laser Marking Applications: Precision, Durability, and Compliance

From my experience, laser marking system is the best choice when you need to protect a part’s surface. It’s also excellent for creating clear, precise marks that last a very long time. Here are some common situations where I would recommend laser marking:

- Traceability & Compliance: It’s standard practice to mark barcodes, serial numbers, and other tracking codes on medical devices, semiconductor chips, and aerospace parts. These marks help track batches and meet industry rules. I like that the marks stay crisp and readable without damaging the part’s surface.

- Branding & Logos: I suggest using it to add permanent brand logos on consumer products, automotive components, and industrial equipment. The logos and symbols created this way are difficult to tamper with and resist wear.

- Regulatory and Product Information: This process is essential for adding expiry dates and certification marks in pharmaceuticals, food packaging, and on oil & gas equipment. Laser marks can handle harsh chemicals and high heat, so they stay easy to read.

- Harsh and Corrosive Environments: This method is perfect for the military, electronics, and automotive fields. Marks on corrosion-resistant metals need to survive chemicals, rubbing, and bad weather, and I’ve seen these marks last.

- Aerospace Use Cases: It is a key method for identifying parts made of metals, polymers, or ceramics. The marks do not weaken the part’s structure, and they meet strict safety codes.

Laser Engraving Applications: Depth, Permanence, and Tactile Readability

When you need deep, extremely durable marks that you can feel, I believe laser engraving is the way to go:

- Personalization & Gifts: You can engrave names or messages on jewelry, awards, trophies, and custom gifts. The deep, touchable features of the engraving stay clear for many years, even with regular handling and cleaning.

- Asset Tracking & Permanent ID: It is great for machine parts, industrial tools, and military equipment. The engraved marks help meet regulations and make identification simple. In my opinion, the best part is that the marks stay clear through scuffs, exposure, and the entire life of the part.

- Harsh Service & Safety: I see it used for marking important data on energy sector equipment like generators and batteries. The engraved marks make use and maintenance safer. They resist high-stress work and daily wear.

- Defense & Aerospace Compliance: Military standards often require deep engraving. This is used on weapons, field gear, and data plates. It ensures vital information is always readable for tracking and logistics, even in the toughest conditions.

Both of these methods work well for large-scale and automated factory operations. Based on my experience, choosing the right process is up to you. You should think about the mark depth you need and the environment it will face. Also, consider the material you are using and any specific industry rules you must follow.

Summary

Whether you need smooth, surface-level markings that preserve strength or deep, textured engravings that make a statement, the right laser can elevate your work. Investing in the proper laser tool not only improves efficiency but also delivers professional-quality results your clients will love. Explore our selection today and find the perfect laser solution for your business or creative projects. Ready to learn more? Contact us now for expert advice on laser marking machines.