I wonder if my usual method for cleaning rusty metal can also help the environment. When I compare sandblasting and laser rust removal, I notice it’s about more than just how shiny the surface gets. For me, it is about the impact we have on our planet. Yes, sandblasting works quickly. But I always consider its effect on the air and soil. Laser cleaning seems like a promising alternative. From what I’ve seen, many people don’t yet understand all its actual advantages…

Are you thinking about restoring metal surfaces in a cleaner, safer way? I find this topic both important and timely. The method you choose doesn’t just affect results—it shapes the impact you leave behind. From my experience, many people focus on effectiveness but often miss one key factor: sustainability. In my view, laser rust removal offers a smarter, more eco-friendly alternative to traditional sandblasting. It’s worth asking—could your rust removal method do more than just clean metal?

What Is Laser Rust Removal

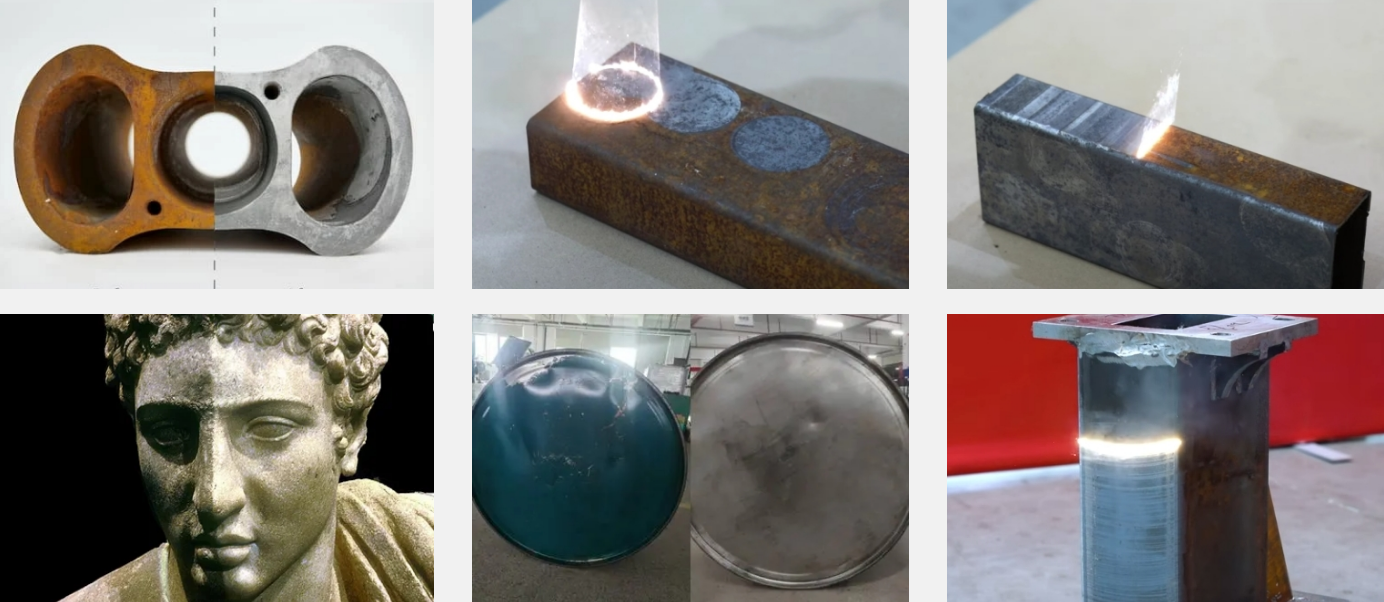

Laser rust removal is a great method because it doesn’t touch the metal directly. A strong laser beam targets the rust, which absorbs the laser energy faster than the metal. This heats the rust, turning it into gas, which is then carried away, leaving a clean, undamaged metal surface.

Key Features of Laser Rust Removal

Laser rust removal is a fast, precise, and eco-friendly way to clean metal surfaces without causing damage. It uses adjustable settings to remove rust while preserving the original shape. Handheld devices are great for small jobs, and stationary machines work well for large-scale tasks. It’s chemical-free, safe, and ideal for industries like automotive, aerospace, electronics, and medical. It’s cleaner, faster, and reduces labor and waste, with a wide range of applications.

Typical Example and Data

A portable 1000W fiber laser rust removal unit can clean several square meters of metal per hour. Its effectiveness depends on factors like rust thickness and metal type. The process preserves the metal’s original texture, size, and properties. For instance, thin surface rust on steel cleans quickly, while thicker rust on other alloys may take longer.

What Is Sandblasting

Sandblasting, or abrasive blasting, is a powerful cleaning method that uses a fast stream of rough material to remove rust, paint, scale, and other unwanted substances. It works by using compressed air or a spinning wheel to accelerate the abrasive. In my experience, it’s great for preparing surfaces for new coatings or restoring them.

How Sandblasting Works

I find that a standard sandblasting setup has two key parts: – Blast pot: This holds the abrasive stuff, like sand, glass beads, or tiny metal pieces. – Air compressor: This part forces the abrasive out of a nozzle very quickly. I’ve seen speeds from 50 to 130 PSI.

When the abrasive material hits the surface, it takes off rust, paint, and other dirt. I’ve seen this method also make rough surfaces smooth. You can even use it to create textures or get materials ready for more work.

Types of Abrasive Media

I’ve learned that choosing the right abrasive is key for each job. Here are some I’ve worked with: – Sand: Best for tough cleaning, like removing stubborn rust and paint. – Glass beads and plastic media: Gentler, great for polishing or cleaning delicate items. – Metal shot: Ideal for large jobs or strengthening metal. – Walnut shells and corncobs: Mild abrasives, perfect for gentle cleaning without damage. – Baking soda: Ideal for soft or delicate items, especially when restoring.

To sum it up, I believe sandblasting is a really versatile and quick way to clean and prepare surfaces. I’ve seen it used in many different industries. This is because you have so many abrasive types to choose from and different ways to use them.

Cost Comparison: Laser Rust Removal vs Sandblasting

If you’re comparing laser rust removal costs, I find that laser methods and sandblasting have different expenses. These differences impact both companies and individuals.

Initial Investment

In my experience, sandblasting systems have a lower purchase price at first. Many setups, even for industrial needs, cost much less upfront than a laser system.

Laser rust removal machines have a much higher starting price. I’ve seen prices range from $3,800 to $52,000. A machine’s power affects its cost. Smaller portable units are less expensive. High-power, automated systems cost much more. For smaller businesses or those with tight budgets, I think this initial investment can be a barrier.

Long-term Operational Costs

Sandblasting has ongoing operational costs. You need to keep buying consumables like sand or metal shot, and waste disposal can be expensive, especially for large or hazardous jobs. It often requires skilled labor, sometimes a two-person team, which adds to costs. Additionally, there’s a risk of rework if residue is left behind or hidden damage is uncovered.

Laser rust removal has almost no consumable costs, requiring no sand, grit, or cleaning fluids. Maintenance is minimal, and labor costs are lower, as one trained operator can handle tasks that would need a full sandblasting crew. Rework is rare since the laser precisely removes only rust, leaving the base material undamaged.

While sandblasting seems cheaper upfront, its hidden costs add up over time. Laser removal has a higher initial price but offers better long-term value for frequent or heavy use—especially when considering environmental impact and cleanup efficiency.

Efficiency Comparison: Laser Rust Removal vs Sandblasting

If you’re looking at how well laser rust removal and sandblasting clean, I think both methods have their own good points. Let’s look at them from a hands-on, working viewpoint:

Operational Automation & Labor Efficiency

Laser rust removal is ideal for automation—one trained person can operate the system, and it can run continuously with remote control or pre-set programs, reducing labor costs. In contrast, sandblasting usually requires manual operation, especially for large or complex surfaces, often needing a team and increasing daily labor expenses.

Scalability & Area Coverage

Laser cleaning works well on large or hard-to-reach surfaces and doesn’t require moving heavy equipment around, which can save a lot of time. Sandblasting is fast for removing heavy rust or coatings, especially in automotive and equipment maintenance, but covering large areas often needs more manual effort and multiple operators.

Equipment Maintenance & Longevity

Laser cleaning machines can last over five years with minimal upkeep and rarely need replacement parts, keeping maintenance costs low. In contrast, sandblasting equipment requires frequent checks, with parts like nozzles and hoses wearing out quickly—often needing replacement within two years—leading to higher supply costs and more downtime.

Application Suitability & Substrate Impact

Laser cleaning is ideal for precise work on metals or delicate surfaces like aircraft parts, offering gentle, adjustable cleaning without damaging the base material. Sandblasting is better for tough jobs like construction or car restoration but can roughen soft metals and expose hidden damage.

Performance on Different Rust Levels

Sandblasting is faster for heavy rust or thick coatings and works well on tough metals. For light rust or delicate surfaces, laser cleaning is better—it removes only the unwanted layer, preserves the original texture, creates less mess, and reduces waste.

Environmental Impact: Comparing Laser Rust Removal and Sandblasting

I find that the environmental impact is a big difference when you compare laser rust removal to sandblasting.

Environmental Risks of Sandblasting and Chemical Cleaning

Old rust removal methods like sandblasting and chemical cleaning can cause significant environmental and health issues. Chemical cleaning uses toxic substances that can pollute water and harm workers’ health, leading to strict waste disposal regulations. Sandblasting produces abrasive dust and used grit, which can contaminate soil and water. The dust also lowers air quality, posing breathing risks for workers and nearby people.

I believe these issues mean companies using these older methods face higher costs to follow rules and must deal with tougher regulations.

Environmental Benefits of Laser Rust Removal

I recommend laser rust removal technology as a better, eco-friendly solution: – It uses no harmful chemicals or abrasives, avoiding toxic runoff and gritty waste. – It generates minimal secondary waste, with lasers turning rust into dust or vapor that’s easy to capture and filter. – It helps with regulatory compliance, meeting standards from OSHA and the EPA. – It reduces energy use compared to abrasive blasting, lowering carbon footprints and saving energy. – It ensures cleaner air and workspaces, improving air quality and reducing respiratory risks for workers. This makes it a safer choice for the environment and workplace.

Global Market and Industrial Adoption

Cleaner surface cleaning is on the rise: – The laser cleaning market is growing fast—from $0.66B in 2023 to $1.15B by 2032—as industries shift to greener methods. – One naval fleet switched to lasers, boosting ship performance and lifespan while cutting environmental and waste risks.

Summary of Environmental Benefits

Based on my experience, here are the key environmental advantages: – It greatly reduces hazardous and secondary waste. – There is no risk of soil or water contamination. – It helps businesses comply with strict environmental laws. – It leads to better air quality and safer working conditions. – It fits with global goals for sustainability and reducing pollution.

In my view, for companies that are serious about meeting modern environmental standards and cutting their operational risks, laser rust removal is the superior choice when compared to sandblasting. I believe it’s not just efficient; it provides a cleaner, safer, and more responsible solution.

Summary

I’ve looked closely at both rust removal methods, and I believe laser rust removal is the way forward. It’s not just about getting the job done—it’s about doing it responsibly. While the upfront cost is higher, the long-term benefits are clear: it’s safer, more efficient, and much better for the environment. Industries are moving fast, and I think eco-friendly methods like laser cleaning will soon become the norm. Choosing cleaner technology now means we’re not just protecting metal—we’re protecting the planet too. For more details about laser rust removal cleaning machine or to get a quote, contact us today!