The direct answer is no—laser welders do not use Flux Cored Arc Welding (FCAW) wire. This is a common point of confusion when moving from traditional welding. Laser welding relies on a focused beam to melt and join materials, eliminating the need for the arc and flux inside FCAW wire. Using the correct filler material is key to achieving the clean, strong welds that define laser welding performance. Let’s clarify why FCAW wire is not suitable and what you should use instead for the best results.

Why Laser Welders Don’t Use Flux Cored Arc Welding Wire

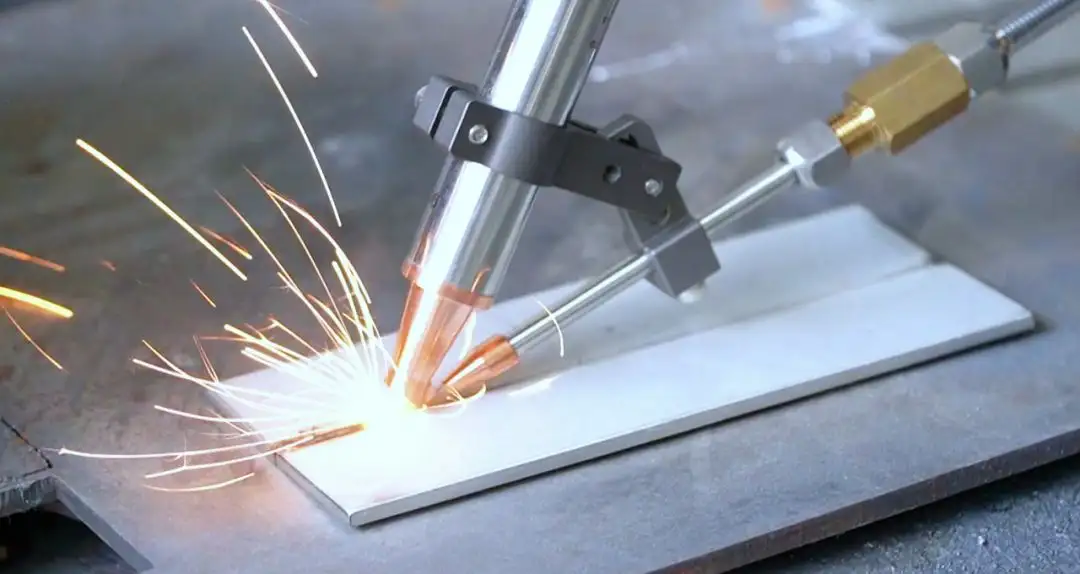

Laser welding machine and flux-cored wire are fundamentally incompatible due to their different heat sources: the laser creates a deep-penetration “keyhole” with extremely high energy density, for which flux-cored wire is not designed. Under the intense laser heat exceeding 10,000°C, the flux vaporizes and combusts instantly, generating a plume that severely interferes with the beam, scattering energy and preventing proper base metal fusion—ultimately compromising weld integrity.

Physical Damage During Wire Feeding

The laser welding wire feed system causes mechanical problems. This happens before the wire reaches the weld pool. Most laser wire feeders use steel drive rollers. These rollers push wire through the delivery system. They crush and damage the flux coating on FCAW wire during transport. You end up with inconsistent flux delivery. Sometimes too much. Sometimes too little.

This inconsistency causes burnback defects. The wire fuses to the contact tip. The damaged coating changes electrical resistance. Even the standard 3/4-inch wire stickout doesn’t prevent this failure in laser applications.

Shielding Gas Requirements Show the Mismatch

Laser beam welding needs external inert gas shielding (argon or helium). This stabilizes the plasma and prevents oxidation. This gas flow is required for keyhole stability. Flux-cored wire generates its own shielding through flux breakdown. This self-shielding works in arc welding. But it creates problems under laser conditions.

The problem gets worse outdoors. Wind disrupts flux-generated shielding gases. This causes porosity in arc welds. But in laser welding, you’re already using controlled inert gas. Adding flux vapors creates a double contamination scenario. Unstable flux gases mix with your precision gas shielding. Plus, you get particulate matter in the beam path.

Hard Data on Quality Degradation

Research on titanium alloy laser welding shows the performance gap. Flux-cored wire in laser applications produces welds with 70% or more low misorientation zones in the microstructure. This might sound good. But it damages overall weld integrity.

The fusion zone shows reduced texture strength. It drops from 30.47 (solid wire baseline) to 22.85 with flux-cored wire. This means lower directional grain alignment. Potential weakness under load follows. Extreme cooling rates in laser welding (10^4 to 10^6 K/s) make any flux contamination worse. You get brittle microstructures. Mechanical properties become unpredictable.

Voltage and Power Incompatibility

Flux-cored arc welding runs at 24-32 volts. This maintains stable arc characteristics and proper flux activation. Laser welding wire diameter and feed systems need very different electrical parameters. Trying to run FCAW wire creates inconsistent arc behavior. Excessive spatter occurs. Welds fail. This is worse on reflective materials like aluminum and copper. These already reflect over 90% of laser energy.

Clean laser welding techniques need solid wire or purpose-designed powdered fillers. The flux has no functional role in photon-based melting.

Correct Wire Selection Standards for Laser Welding Applications

To achieve strong, defect-free welds, selecting the correct filler wire for your laser welder is critical.The core principle is to match the chemistry and properties of the filler metal to the base material. To make the optimal choice for any project, focus on four decisive aspects for each material: the guiding principle for selection, the specific wire grade recommendations, diameter guidelines based on thickness, and the essential process controls to ensure weld integrity. The following guide provides clear, actionable standards for the most common workshop materials.

Carbon Steel

Core Principle: Match base metal strength and strictly control impurities to prevent weld defects.

Recommendation: Use solid wires like ER70S-6, which complies with the AWS A5.18 standard and provides a tensile strength of at least 480 MPa, matching common structural steels such as Q235 or A36.

Diameter Guidelines:

- For plates under 3mm: Use 0.8-1.0mm wire to prevent burn-through and control heat input.

- For plates 3-6mm: Use 1.0-1.2mm wire to balance penetration depth and feed stability.

- For plates above 6mm: Use 1.2-1.6mm wire to meet deposition rate requirements for multi-pass welds.

Critical Control: Ensure the wire has sulfur and phosphorus content below 0.025% to fundamentally prevent hot cracking.

Stainless Steel

Core Principle: Precise matching of alloy composition is key to maintaining corrosion resistance in the weld zone.

Recommendation: Use ER308 or ER308L wire for welding 304 or 304L stainless steel. For 316 series, select molybdenum-containing ER316 or ER316L wire.

Diameter Guidelines:

-

For thin sheets under 3mm: 0.8-1.2mm wire is recommended.

-

For thick sections over 6mm: 1.6-2.4mm wire is suggested.

Critical Control: Employ high-quality shielding gas, such as a helium-argon mixture, with excellent coverage to prevent oxidation loss of critical elements like chromium.

Aluminum & Its Alloys

Core Principle: Select matching wire based on the base alloy type and application needs (conductivity or strength), with cleanliness as the top priority.

Recommendation:

-

For pure aluminum components: Use high-purity aluminum wire like the 1070 or 1100 series for optimal conductivity.

-

For structural alloys like 6061: ER4043 wire offers superior crack resistance and fluidity, while ER5356 wire provides higher as-welded strength for load-bearing structures.

Diameter Guidelines: Due to aluminum’s high thermal conductivity, larger diameters than those used for steel are required. For plates under 3mm, 1.0-1.6mm is recommended; for thicker material, increase to 2.0-3.0mm.

Critical Control: Strict mechanical and chemical cleaning of both wire and base metal prior to welding is essential to remove oxides and contaminants. This is the only effective method to avoid porosity.

Copper, Brass & Bronze

Core Principle: Overcoming high thermal conductivity and suppressing alloy element vaporization are prerequisites for achieving sound welds.

Recommendation: Use deoxidized copper wire for pure copper. To reduce zinc vaporization when welding brass, consider using silicon bronze filler wire as an alternative. Match with corresponding bronze wire for phosphor bronze.

Diameter Guidelines: Generally use smaller diameters to control heat input.

-

For brass under 1.5mm: Use 0.8-1.0mm wire.

-

For brass 1.5-3mm: Use 1.0-1.2mm wire.

-

For brass over 3mm: Do not exceed 1.6mm.

Critical Control: A trailing gas shield must be used to provide extended protection to the hot, freshly solidified weld area, preventing rapid oxidation.

Why Your Laser Welder Matters as Much as Your Wire

Choosing the correct wire is crucial, but its full potential is only unlocked with a laser welder designed for precision delivery. A basic machine can struggle with inconsistent feeding and complex settings, turning a theoretically perfect wire choice into a disappointing result. The right equipment transforms this from a challenge into a seamless, efficient process.

The MW-HW800D’s Precision Feed System

The core of flawless wire deposition lies in synchronization. The MAXWAVE MW-HW800D features a high-precision digital wire feeder that is perfectly synchronized with the laser’s pulse. This eliminates spatter and ensures buttery-smooth, consistent wire delivery, which is critical for clean weld starts, uniform bead appearance, and overall process stability.

The Built-In Material Library

Forget complex parameter guesswork. The MW-HW800D comes with a pre-loaded “Expert Database” that stores optimized welding parameters for various material-thickness combinations, including recommended wire types. This provides you with proven settings at the touch of a button, drastically reducing setup time and minimizing the skill threshold required to produce perfect welds consistently.

Superior Energy Control

Ultimately, weld integrity depends on how energy is delivered. The MW-HW800D’s stable fiber laser source produces an exceptionally focused beam with high energy density. This allows for deeper penetration with lower overall heat input. Often, you can use a thinner diameter wire than with conventional systems, achieving strong welds while conserving material and minimizing thermal distortion.

In summary, the MAXWAVE MW-HW800D does more than just accept the right wire—it actively optimizes the entire welding ecosystem. It is engineered to turn technical decisions into simple, repeatable, and highly efficient operations, guaranteeing superior weld quality and maximizing the return on your investment in both consumables and equipment.

Conclusion

In summary, laser welding achieves its superior performance by relying on a focused beam and precise filler metals, not flux-cored wires. The clear path to success involves selecting the correct solid wire for your material and pairing it with a machine engineered for precision.Ready to experience the difference that comes with perfectly matched materials and technology? Contact us today to discover how the right laser welding machine can transform your workshop’s capabilities and results.