Even a tiny bit of heat in the wrong place can turn a perfectly good lithium-ion cell into a ticking time bomb. Traditional welding methods often overheat separators, damage foils, or create hidden defects that only appear months later. Laser welding flips the script—it delivers energy precisely where it’s needed, melts the joint cleanly, and keeps the surrounding battery layers cool. In this post, we’ll explore how modern laser systems protect your cells from heat damage, extend cycle life, and dramatically reduce safety risks, all while enabling fast, high-precision production.

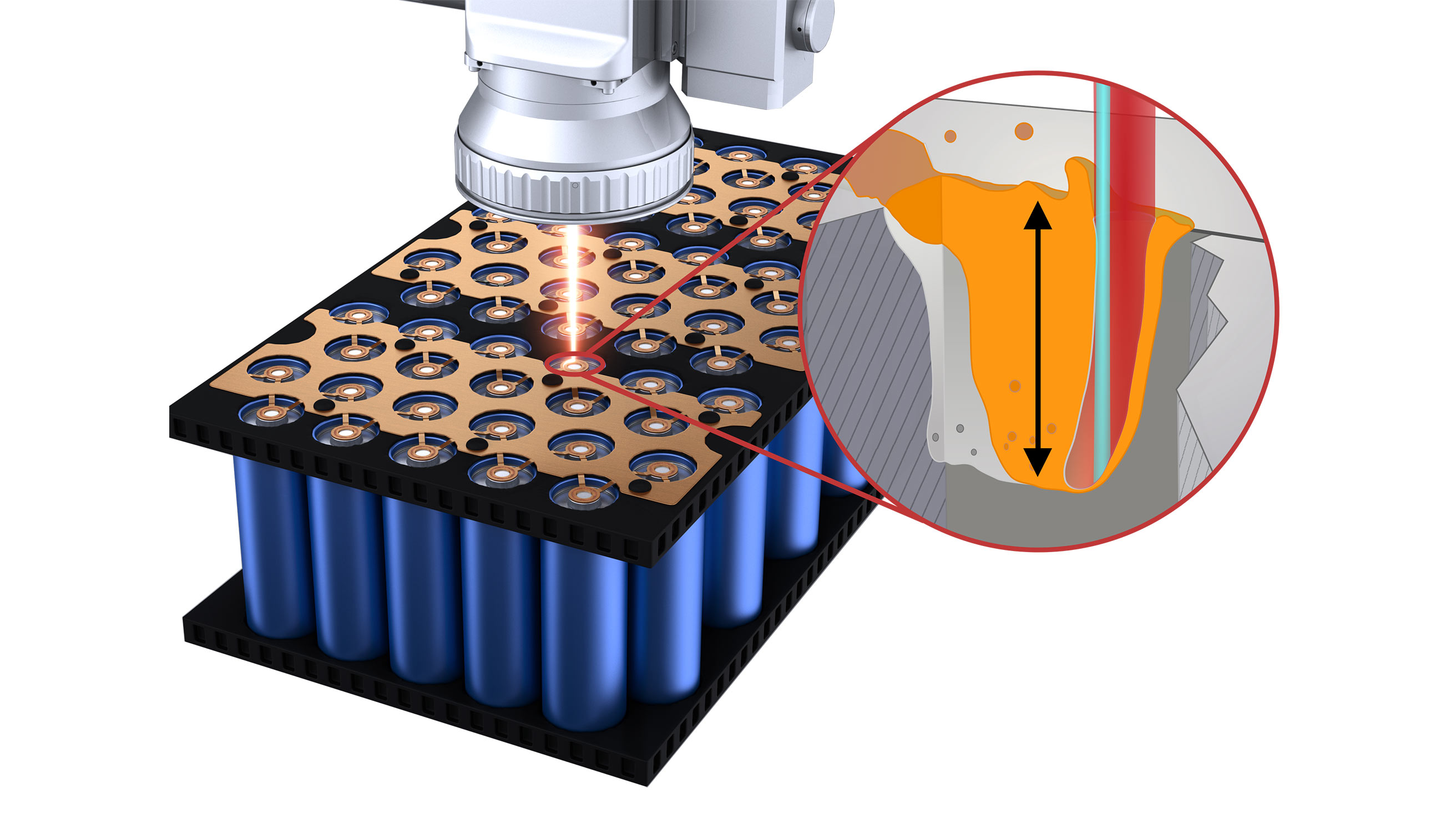

Why Laser Welding Prevents Heat Damage in Lithium-Ion Battery Tab Applications

Laser welding lithium battery tabs’ thermal advantage boils down to three things: focused energy, minimal spread, and quick exit.

Non-Contact Process With Surgical Precision

Laser welding doesn’t touch the material—just light hits the surface. No current, no electrodes, no pressure—so thin foils and battery separators stay safe. With high power density, it melts only where needed, achieving deep penetration at lower total energy while keeping surrounding areas cool. In tests, spots 10 mm away stay around 45°C, compared to 80–120°C with resistance welding. Precise, clean, and gentle.

Localized Heat-Affected Zone Control

In tab laser welding, the heat-affected zone stays tiny. Tests on Al/Cu busbars show nearby surfaces only exceed 120°C for 1.5 to 4 seconds—and just a few millimeters away, temperatures drop quickly. This steep thermal gradient protects critical parts: separators, electrolyte, and cathode coatings never reach damage points, and the temperature rise does not affect the battery. Properly tuned laser settings keep the heat in the joint, without spreading into the battery roll.

Speed Equals Thermal Protection

Higher welding speeds mean less heat damage. In industrial battery lines, continuous-wave lasers reach 50–100 mm/s, so the beam moves fast enough that heat doesn’t spread into surrounding material. The melt zone stays small, and the heat-affected zone shrinks. Tests show 100 µm foils weld perfectly with optimized settings, but 20 µm foils can peel if heat isn’t controlled. The key is short exposure and high power density—less time, less thermal damage.

Real-Time Temperature Monitoring

Advanced laser welding systems rely on in-situ temperature monitoring with IR cameras and thermocouples—this isn’t optional, it’s essential. Three probes on the busbar track temperatures in real time, adjusting power and speed instantly if readings approach limits. This closed-loop control prevents accidents, so you’re never guessing whether settings are safe. Sensors make sure sensitive parts stay cool throughout the process.

Engineered Beam Shaping Reduces Waste Heat

Modern fiber laser welding for battery pack manufacturing process use core-and-ring beam setups to precisely shape the keyhole and melt pool. Energy goes straight into forming the joint, not sideways into surrounding material. Optimized power density ensures it stops spatter formation and melt ejection, preventing hot particles from landing on nearby parts. With tuned settings and protective metal shields around tabs, the laser keeps energy exactly where it belongs—in the weld itself, not scattered across your assembly. This is minimal heat input welding at its best.

Narrow Welds, Maximum Protection

Laser welding creates very narrow joints, with weld widths of 0.2–0.8 mm and penetration depths of 0.1–0.8 mm on Al, Ni, and Cu tabs from 0.08 to 1.2 mm thick. This precision limits how much material gets hot, so surrounding parts—cell casing, nearby tabs, and internal layers—stay cooler. Using careful test designs, safe settings are established for the electrode tab connection methods, minimizing HAZ size and preventing foil detachment or thermal damage.

The result? Yield rates exceeding 95% in production sites where thermal management makes or breaks success.

Core Mechanisms: How Laser Parameters Control Heat Damage

Four laser settings decide if your battery tab laser welding protects the battery or destroys it. Power, pulse duration, spot size, and wavelength work together. Get one wrong? Thermal damage spreads through your cells.

Power Intensity: The Primary Heat Control

Laser power density determines how fast the weld heats up. Higher intensity means faster heating, but cross the threshold and you risk thermal explosion in the material. Short, intense pulses deliver energy before heat spreads, while long, low-power exposures let heat creep into surrounding areas—exactly what you want to avoid in battery tab welding. Too much power? You melt through the tab and damage the separator. Too little? The weld is weak and may fail during thermal cycling.

Exposure Time: The Thermal Buildup Factor

Thermal damage depends on irradiance × exposure time = total heat input. You can deliver energy quickly at high power or slowly at low power—but the effects differ. Short, high-power pulses create localized damage with minimal spread, keeping the heat-affected zone narrow. Long exposures let heat diffuse, enlarging the HAZ. Battery lines optimize pulse durations (0.5–5 ms) and power levels to make strong welds while preventing thermal buildup. Monitoring systems track total exposure, adjusting for overlapping pulses to avoid overheating.

Spot Size and Beam Profile: Spatial Heat Distribution

A laser beam doesn’t heat evenly—peak intensity is at the center, so damage starts there first. Battery welding uses spot diameters of 0.1–0.6 mm. Smaller spots concentrate energy for deep penetration with minimal lateral heating, while larger spots spread energy, requiring more power and risking heat diffusion. Advanced systems use core/ring beam shaping: a high-intensity core melts the joint, and a lower-intensity ring stabilizes the melt pool. This keeps energy in the weld and prevents defects.

Wavelength Selection: Absorption and Penetration Depth

Different metals absorb different wavelengths differently. 1064 nm fiber laser welding dominate battery tab welding because aluminum, copper, and nickel absorb it efficiently, turning energy into heat right at the surface. This creates a tight, controlled melt pool with minimal wasted energy. Shorter wavelengths, like blue light (447 nm), can cause unwanted photochemical effects. Using the right wavelength ensures predictable, controllable thermal welding.

Repetition Rate and Total Thermal Loading

Multiple pulses on the same spot can cause heat to accumulate, raising the baseline temperature before the next pulse. Battery welding systems manage this with pulse repetition rates of 10–100 Hz and careful spot overlap. Thermal cameras monitor in real time—if temperatures near the separator damage threshold (130–150°C), the system adjusts automatically. Optimized pulse trains create 40% less total thermal stress than continuous-wave welding at the same average power. Cooling time between pulses makes the difference between a perfect weld and a damaged cell.

Real-World Results from Production Floors

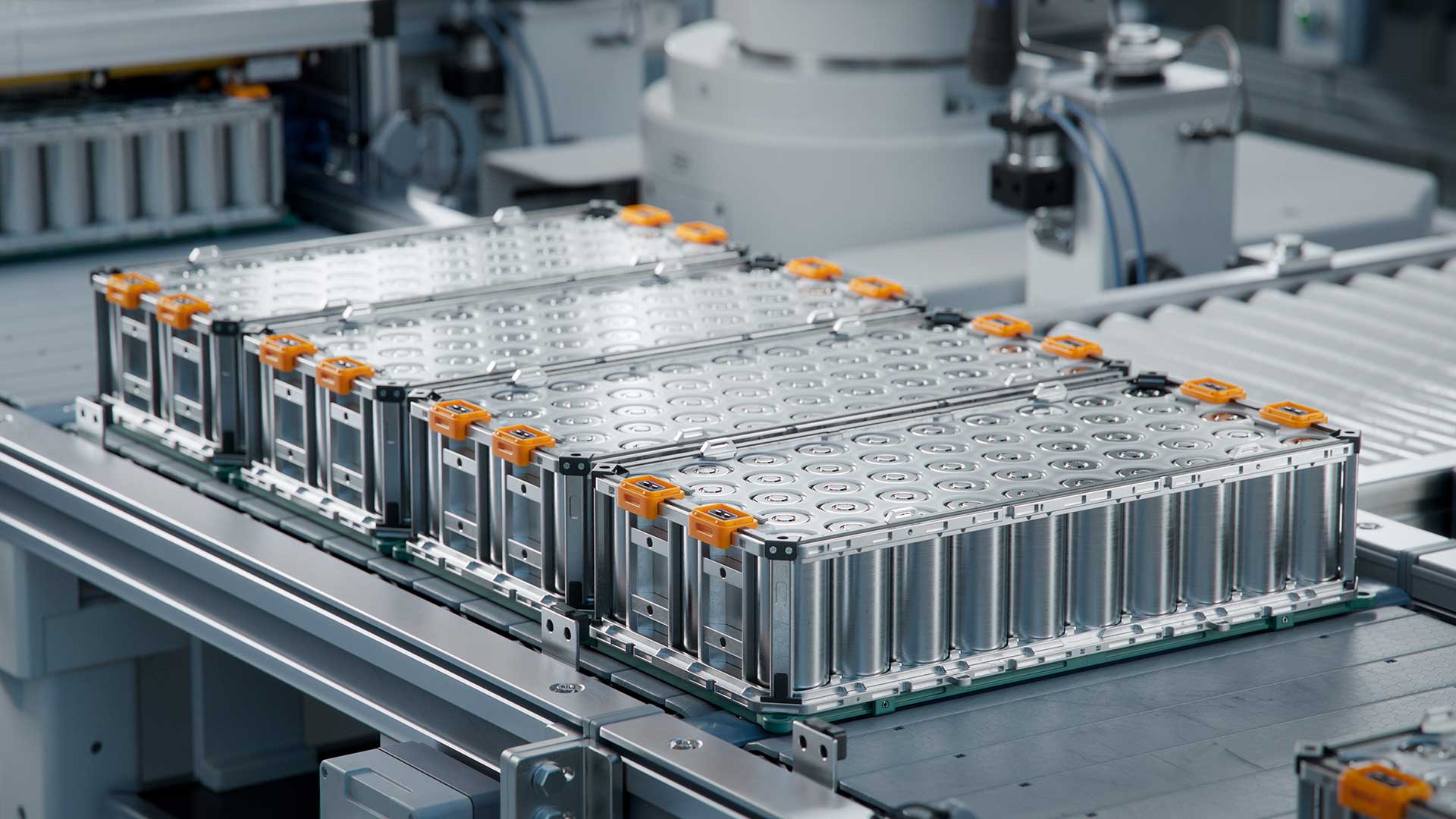

Production floors worldwide prove lithium-ion battery welding works. Hard ROI numbers show the thermal control advantage. Yield improves. Costs drop. Battery performance gets better across different factories.

Automotive Battery Assembly: Yield Rate Breakthrough

A major European EV battery maker made a switch. They moved from resistance welding to fiber laser welding for busbar-to-tab connections in their 48V battery pack manufacturing process. The thermal challenge? Connect 0.3 mm aluminum tabs to copper busbars. Don’t damage the separator layers just 2 mm below the joint.

Results after 6 months:

– Yield rate climbed from 88.3% to 96.7%

– Scrap reduction saved €1.8 million per year on a 2 million cell/year line

– Cycle life testing showed 15% improvement (1,850 cycles vs. 1,600 cycles at 80% capacity retention)

– Thermal damage defects dropped from 6.2% to 0.8% of total rejections

The plant manager reported ROI on laser equipment in 14 months—faster than their 24-month target. The key? Control heat-affected zone lithium battery damage. Resistance welding couldn’t solve this at their production speeds.

Consumer Electronics: Speed Meets Precision

A Chinese battery pack supplier for power tools deployed precision welding battery tabs tech. They used dual-head fiber laser welding systems. The challenge? 100 µm nickel tabs on cylindrical 18650 cells running at 60 units/minute line speed.

What improved:

– Production throughput increased 22% (from 60 to 73 units/min) without quality loss

– Cold welding lithium cells approach cut energy use by 35 kW per production shift

– Warranty returns for connection failures fell 68% in first-year field data

– Low heat input welding stopped separator shrinkage issues that plagued ultrasonic methods

The operations director noted: “We tried ultrasonic first. Foil detachment killed us. Laser welding’s thermal management battery welding solved what mechanical methods couldn’t touch.”

Energy Storage Systems: Large-Format Cell Challenges

A US grid-storage maker faced thermal damage problems on their prismatic LFP cells with 1.2 mm copper tabs. Old welding methods created HAZ temperatures over 160°C. That’s well above their separator’s 135°C rating.

Their fiber laser welding battery assembly solution used real-time IR monitoring. Plus adaptive power control.

Benefits after setup:

– Thermal damage dropped to zero defects in 180,000 cells produced

– Internal resistance uniformity improved 18% across welded joints

– Production line reject rate decreased from 4.7% to 1.1%

– Estimated savings per year: $2.3 million in reduced scrap and rework costs

Quality engineers confirmed the laser parameters battery welding settings worked. Pulse modulation at 85 Hz with 3.2 ms duration kept all measured points below 125°C during formation.

Medical Device Batteries: Safety-Critical Performance

A German medical battery maker produces implantable device cells. They face the strictest thermal limits in the industry. Any electrode tab connection methods that risk separator integrity threaten patient safety. Regulatory compliance is at stake.

Laser welding results:

– Achieved 99.4% first-pass yield on 0.08 mm tabs (was 91.2% with resistance welding)

– Post-weld separator inspection showed zero thermal deformation in 50,000+ units tested

– Passed IEC 62133 certification on first submission (old method required three attempts)

– Thermal damage prevention welding protocols cut validation testing time by 40%

The regulatory affairs manager said: “Laser welding didn’t just improve our numbers. It made our safety case bulletproof. Auditors saw the thermal data and stopped questioning our tab integrity.”

Small-Scale Production: Accessible Tech

A Korean startup makes custom battery packs for drones. They adopted compact fiber laser welding systems designed for battery pack manufacturing process flexibility. Production volumes stay under 5,000 units/month. They needed tech that delivered precision without huge investment.

Outcomes:

– Equipment payback achieved in 8 months through scrap reduction alone

– Enabled use of 20 µm aluminum foil tabs too delicate for other methods before

– Cycle life competitive with major makers: 1,200+ cycles at 85% DoD

– Customer return rate for connection failures: 0.09% (industry average: 0.4-0.8%)

The founder noted: “We compete with giants using cold welding lithium cells tech they pioneered. The thermal control lets us match their quality at our scale.”

These cases span industries, cell formats, and production volumes. The common thread? Measured thermal control turns into better financial performance and product reliability. The tech isn’t theory—it’s delivering real results on operating production lines right now.

Conclusion

If you’re ready to bring precision, safety, and efficiency to your battery manufacturing line, laser welding is the solution. Our advanced systems let you control heat, prevent spatter, and protect sensitive components with confidence. Don’t leave your cells to chance—contact us today to see how our laser solutions can optimize your production, reduce defects, and keep your batteries performing at their best. Get in touch now!